- Preparing for work

- Bearing replacement

- What are the best bearings to install on Priora?

While driving, an unpleasant cracking noise may be heard in the area of the front or rear wheel. It usually disappears when turning. This behavior of the chassis indicates that the wheel bearing requires replacement. A malfunction occurs in almost every car that has already experienced a lot of mileage. The condition of the front or rear wheel bearing is also affected by driving style. The replacement is quite simple, but the driver will have to remove the strut and then take the Priora to a wheel alignment.

Don't want extra costs? Then read how to replace a wheel bearing without dismantling the strut and subsequent “camber” .

Replacement

The work must be carried out using the necessary tools. There are two options for replacing the wheel bearing - with subsequent wheel geometry and without its need. The replacement is similar for all VAZ cars (front-wheel drive).

Tool you will need:

- Ratchet with head "7", "10", "13", "17", "19" or E30;

- A key for unscrewing the CV joint or a head at “30”;

- Powerful flat head screwdriver;

- Gas torch or wheel bearing puller;

- Hammer;

- Steering wheel end puller (may not be needed);

Replacement with subsequent wheel geometry

- You need to start by unscrewing the CV joint nut; the car should be installed on a horizontal plane with the steering wheel turned slightly to the side. Using a wrench, unscrew the grenade nut counterclockwise.

CV joint is a Constant Velocity Joint (not to be confused with lubrication). Colloquially it is called a "grenade". It got its name because of the presence of a large number of balls inside and its appearance similar to a combat grenade. There is also CV joint grease -3 and 4, used to lubricate this joint.

- We jack up the car and secure it so that it does not roll or fall off the jack. Remove the wheel;

- Separate the brake pads using a flat screwdriver;

- We unscrew the caliper from the steering knuckle and hang it by the wire (under no circumstances hang the caliper by the brake hose).

- We dismantle the brake disc by unscrewing the guides.

- Unscrew the two bolts securing the strut to the steering knuckle.

- Unscrew the bolts securing the ball joint.

- We remove the steering knuckle from the car.

- We take out the retaining rings on both sides of the fist.

- Next we need to knock out the old bearing; for this you can use a punch of the required diameter or use a puller.

- Then, once the bearing is removed, a new one must be installed. Pre-install one retaining ring and press in a new one on the opposite side.

- If you have a puller, then carefully press in the new bearing, avoiding distortion.

- If you don’t have a puller, you first need to put the new bearing in the freezer for a couple of hours.

According to the laws of physics from the school curriculum, cold bodies contract, and hot bodies expand. Therefore, a cold bearing will have a smaller diameter than a hot one, making installation easier.

- Next, use a torch to heat the steering knuckle and carefully lower the bearing into it, tapping a little. IMPORTANT, avoid distortion; the bearing should run smoothly without snagging.

You can use an old bearing as a mandrel.

- After the bearing is pressed in, install the second retaining ring and assemble everything in the reverse order.

Replacement without wheel geometry

In order to carry out a replacement without the need for wheel geometry, it is necessary to completely dismantle the steering knuckle assembly with the strut.

- Without removing the wheels from the car, we need to loosen the CV joint nut (grenade) to “30”. To do this, unscrew the grenade nut counterclockwise with a wrench.

- We tuck the car, which is fixed, so that it does not roll or fall off the jack. We remove the wheel.

- Separate the brake pads using a flat-head screwdriver.

- We unscrew the caliper from the steering knuckle and hang it by the wire (do not hang the caliper by the brake hose).

- Remove the brake disc by unscrewing the two guide wheels.

- We unscrew the steering tip mount and remove it from the strut bipod using a puller.

- Unscrew the two ball mounting bolts.

- Unscrew the three bolts securing the strut support to the side member.

- We remove the strut along with the steering knuckle from the car.

The next step is to remove the bearing from the knuckle and install a new one.

- We remove the retaining rings on both sides from the steering knuckle.

- Next, you need to knock out the old bearing; for this you can use a punch with a diameter smaller than the diameter of the bearing or use a puller.

- After the old bearing is removed, a new one must be installed. Pre-install one retaining ring and press in a new bearing on the opposite side. To do this, if you have a puller, carefully press the bearing into place, avoiding distortion. If you don’t have a puller, then you first need to put the new bearing in the freezer for a couple of hours (so that its diameter decreases slightly).

- Next, use a torch to heat the steering knuckle and carefully lower the bearing into it, tapping a little. IMPORTANT: avoid distortion; the bearing must run smoothly without snagging.

An old unnecessary bearing can be used as a mandrel for installing a new one.

- After the bearing is pressed in, install the second retaining ring and assemble everything in the reverse order.

The wheel bearing replacement process is complete.

Advice from a practical master

I would like to give you some practical tips that will help you replace the part without any problems.

The tips are:

— use WD40 fluid when dismantling. It will give you the opportunity to more easily separate parts from each other;

- if you have replaced the wheel bearing on one side, replace it on the other. The parts wear out at the same time. Will soon fall into disrepair

and a second bearing;

— having dismantled the entire assembly, pay attention to the condition of the parts around it. They may also need replacement;

- not every garage has a press. Perform one operation to remove the bearing and press it in at a service station. You need to resort to this if you do not have both a puller and a vice;

— for easy pressing of the bearing, heat the fist. The metal will expand when heated and the part will easily fit into it;

— do not forget to lock the hub nut upon completion of installation;

- treat all threaded parts and fasteners with graphite lubricant;

- If you don’t have a torque wrench, do this. Tighten the bolts and nuts until they stop. Next, loosen them by turning the key in the opposite direction by 20 degrees.

After studying this article, I think you will easily cope with the repair. However, if you have any questions or problems while working, please contact me.

I am always happy to help with practical advice.

Wheel bearing replacement video

The front wheel bearing on the Priora VAZ 2170, as on other VAZ cars, often fails, especially when the mileage exceeds 80,000 km. First there is noise from the wheel, which can increase during acceleration.

Vibration also often occurs, wheel play increases, and in some cases the noise turns into a grinding sound - all these signs mean that the front wheel bearing of the Lada Priora requires immediate replacement. If you delay repairs, the consequences can lead to wheel jamming, which leads to unsafe situations on the road.

This article will tell in detail about the principles of replacing wheel ball bearings (hereinafter referred to as SP) on cars of the VAZ family, in particular on the Lada Priora. The instructions are accompanied by many photos and videos. The material also provides information on how to choose a front wheel bearing for a Priora by number, size, price, and manufacturer.

After reading the article, you will understand that replacing the front wheel bearing is done with your own hands without special skills, experience, or special tools, and the price for repair work of this type in a car repair shop is very high.

Tips, tricks and repair videos from specialists

1. The parts of the front wheels wear out evenly, so when replacing one side, be sure to check or change the other.2. If you do not have a puller, as well as a vice (press), it is recommended to take the assembly to a car workshop for pressing / pressing.3. It is recommended to press-fit using non-impact methods.4. Life hack: heat the steering knuckle before inserting p/w.5. Be sure to lock the hub nut after tightening.6. When assembling, treat threaded connections with graphite lubricant.7. Before installation, check the amount of lubricant inside the unit by carefully opening the rubber seal.8. Buy spare parts from certified stores, ask for documents for original products.9. This video collection presents a detailed replacement process.

The Prior release bearing is an integral element of the clutch system, which is involved in the gear shifting process. The part is involved in the process of pressing the clutch pedal and changing gear, and is responsible for disconnecting the clutch discs.

If we talk about the service life of the bearing, in most cases it is quite long and amounts to at least 100 thousand kilometers of the vehicle. However, during operation in difficult conditions (off-road, constant switching in traffic jams, lack of lubrication), faults are diagnosed even after 15 thousand mileage.

How to diagnose the front wheel bearing on a Priora and the causes of failure

At the beginning of the article, signs of a malfunction were already mentioned, if they occur in the VAZ 2170, it is necessary to check the hub assembly. To diagnose a breakdown, it is enough to do several operations:

- Raise the car with a jack;

- Check the play of the suspended wheel with your hands;

- Rotate the wheel and listen for noise;

- Watch several videos on the principle of diagnosing the front wheel bearing of a Priora.

Faulty wheel bearing:

An example of the operation of a failed wheel bearing:

How to check the ball bearing of a wheel hub:

Wheel bearing diagnostics:

vazoved

I drive a LADA VESTA CROSS, Moscow

Then there will simply be no one to pay the fines! This is a Korean tablet video recorder 15 in 1 for Android..

I forgot about fines and Yandex Navigator.

There is FULL HD shooting, radar detector and GPS with 32 satellites. I got it at a reasonable price for such great functionality: HERE

Why does the front wheel bearing of a VAZ 2170 (Priora) fail:

- Expiration of service life;

- Incorrect operation of the suspension, aggressive driving style, road quality;

- Poor quality ball bearing (defect, counterfeit, manufacturing defect);

- Depressurization (dust, moisture, dirt);

- Malfunction of adjacent components (brake disc imbalance, etc.);

- Road accidents, collisions with deep potholes in the asphalt or holes.

. — , , .

| 256707 1118/2170/2190 CS818 | 12:02, 15 |

| 256707 1118/2170/2190 CS818 Trialli CS818 | 22:05, 24 |

| 256707 1118/2170/2190 CS818 | 07:44, 14 Autopolka |

| 1118, 2170 (256707) Trialli, | 20:26, |

| 1118, 2170 (256707) 3020-118, | 20:26, |

| 1118, 2170 (35680037) Torque, | 20:26, |

| 2108-15, 2170 (256706) Kraft KT100506 | 20:26, |

| 1118, 2170 (6-256707EK14) -, | 20:26, |

| LADA 2108-2115/ 1117 -19 / 2170 Priora NB722 HOLA HOLA | 05:31, 15 (… |

| 1118 , (256707) -4 | 14:10, 15 … |

| 2108-2112, 1117-1119, 2170, 2190, 2192, 2194 Pilenga. PWP1307 | 01:53, —… |

| 1118, 2170 finwhale hb411 Finwhale. HB411 | 06:08, —… |

| lada, /40/ Finwhale. HB411 | 04:26, —… |

| 1117-19 (), 2192, 2194 (2), 2170-72 (), 2190 (Espra. ES6707 | 04:00, —… |

| 1118, 2170 priora, 2190 granta LADA. 11180310302004 | 03:53, —… |

| 1118, 2170. (trialli) (10) Trialli. CS818 | 01:43, —… |

| 256707 1118/2170/2190 cs818 Trialli. CS818 | 00:21, —… |

| 256707 1118/2170/2190 cs818 Trialli. CS818 | 22:43, —… |

| 1117-19,2170 256707 . 11180310302018, | 05:44, —… |

| , . 113343 | 04:42, —… |

| Lada 2170 Iberis. IB4242 | 04:02, —… |

| 1118,2108-2115,2170,2190 LADA .21080310402000 | 03:40, —… |

| -2108-15, 1117-19(), 2192, 2194 ( 2), 2170-72( Espra . ES132567 | 01:48, —… |

| LADA Priora Kalina K151118 | 03:33, 16 -PN1 — … |

| 1117-19,2170 256707 11180310302018, | 00:06, 16 -PN1 — … |

| , 113343 | 00:05, 16 -PN1 — … |

| 1118, 2170 Priora,2190 Granta 11180310302004 | 23:33, 15 -PN1 — … |

| 1118, 2170 Herzog HL3 3020 HL33020 | 23:26, 15 -PN1 — … |

| 1118, 2170 Finwhale HB411 HB411 | 23:20, 15 -PN1 — … |

| 1117-19,2170 256707 11180-3103020-18, | 01:10, 13 -PN1 — … |

| , 113343 | 01:09, 13 -PN1 — … |

| 1118, 2170 Priora,2190 Granta 11180-3103020-04 | 00:43, 13 -PN1 — … |

| 1118, 2170 Finwhale HB411 HB411 | 00:29, 13 -PN1 — … |

| 1118, 2170. (AT) (42) | 15:01, 10 Autoclub02 |

| 1118, 2170. (Gallant) | 15:01, 10 Autoclub02 |

| 1118, 2170. (Hofer) (48) | 15:01, 10 Autoclub02 |

| 1118, 2170. (Trialli) (10) | 15:01, 10 Autoclub02 |

| 256707 1118/2170/2190 CS818 | 14:06, 10 Autoclub02 |

| 1118 -2170 VPZ. Vaz Priora 2170 Vaz 80235-vaz | 14:42, 12 .. … |

| . . . Coram 2170 | 01:47, KubanZap-… |

| . . . B-RING 1118, 2170., | 01:37, KubanZap-… |

| . . . ASP 1118-2170, | 01:00, KubanZap-… |

| . . . 23 1118 2170 , | 00:35, KubanZap-… |

| . . . LGR 1118, 2190, 2170, | 09:44, KubanZap-… |

| . . . Kroner 1118-2170, | 09:37, KubanZap-… |

| . . . Herzog 2170, 1118, | 09:10, KubanZap-… |

| . . . Finwhale/, | 08:49, KubanZap-… |

| . . . B-RING 1118, 2170. B-RING BLS0118F, | 01:47, |

| . . . ASP 1118-2170 ASP BCR002, | 01:07, |

| 256707 23 1118 2170 256707 23() 256707 | 00:48, |

Design and operation Wheel bearing. What are bearings for?

What front wheel bearing is in Priora: dimensions, number, prices, characteristics

Before you begin the repair, you need to know which front wheel bearing is on the Priora, as well as which one is better in terms of price, reviews, quality, and manufacturer. The designers at the manufacturing plant included in the design an angular contact double-row sealed ball bearing with lubricant inside (LITOL-24).

According to reviews and statements from VAZ owners, the best option would be original products from VBF or foreign manufacturers: SKF, SNR, SWAG, FAG.

The dimensions of the front wheel bearing, as well as the catalog numbers of recommended manufacturers, are presented in the tables in a similar article on replacing the wheel bearing in a Lada Granta car; look for detailed information there.

practical guide

To complete the work you will need:

— two- or three-jaw puller;

— puller of internal retaining rings;

Removal

1. We prepare the car for work.

2. Loosen the rear wheel hub nut in the same way as shown on the front wheel.

3. Place the car on a stand, remove the wheel and brake drum.

On vehicles equipped with ABS, the wheel speed sensor disc must also be removed.

4. Unscrew the nut and remove the thrust washer of the hub nut.

Replacing the front wheel hub bearing

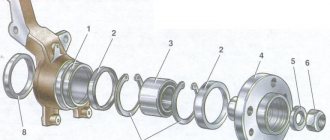

There are two ways to replace a bearing. The first is by removing the steering knuckle assembly, the second is without removing it from the car. The work is shown on the right wheel bearing. The left wheel hub bearing is replaced in the same way. We remove the wheel.

Using a screwdriver, remove the protective cap from the hub. We install the wheel and tighten the two bolts that secure it. We lower the car onto its wheels.

Use a bevel to straighten the dented collar of the hub bearing nut in two places. Apply the parking brake, engage first gear and place shoes under the wheels.

Use a 30mm socket to loosen the hub bearing nut. The nut is tightened with a large torque, so the head and driver must be strong enough to transmit the necessary force. We hang up the front part of the car (namely both front wheels, because otherwise the anti-roll bar interferes with dismantling, pushing the suspension elements up). We remove the wheel. Unscrew the hub bearing nut completely...

...and remove the puck. Remove the front wheel brake disc (see “Removing the front wheel brake disc”). Disconnect the right wheel drive from the hub (see “Removing the front wheel drives”). In order not to disturb the wheel alignment angles, you can replace the bearing without removing the steering knuckle. To do this, connect the ball joint to the knuckle...

...and compress the hub by striking it through a soft metal drift. You can also compress the hub using the front wheel brake disc.

We pass M12 × 1.25 mm bolts about 130 mm long through two diametrically opposite holes in the disk and screw them into the holes of the hub to a depth equal to its thickness. By sharply hitting the bolt heads with a disk, we compress the hub. Then use a cup puller to press the bearing out of the knuckle, as shown below. If it was not possible to remove the hub in this way, remove the steering knuckle. To do this, unscrew the nuts of the bolts securing the shock absorber strut to the steering knuckle, remove the bolts (see “Removing the shock absorber strut and disassembling it”) and remove the steering knuckle.

We install the steering knuckle on the jaws of the vice and press the hub out of the knuckle through a mandrel or head of a suitable diameter, applying force to the end of the hub.

We remove the hub from the fist. In this case, the outer part of the inner ring of the bearing remains on the hub.

Remove the mud ring from the hub.

We insert a blunt chisel between the ends of the inner ring of the bearing and the hub and, striking the chisel with a hammer, move the inner ring.

Use a puller to compress the inner ring of the bearing.

Using circlip pliers, remove the circlip.

Use a cup puller to press the bearing out of the steering knuckle...

...and take it out with the puller.

Remove the bearing from the puller. Clean and lubricate the inner surface of the steering knuckle. Using a needle file, we clean out the nicks from the chisel on the hub. We press the new bearing into the steering knuckle, applying force to the outer ring of the bearing. We install a retaining ring in the groove of the steering knuckle socket. When pressing the hub, we use the puller washer to rest on the inner ring of the bearing. We carry out further assembly in the reverse order, tighten the bearing nut to the prescribed torque (see “Appendices”) and be sure to lock it by jamming the collar. If the bearing was replaced with the steering knuckle removed, then it is necessary to check and adjust the wheel alignment angles at a service station.

The front wheel bearing on the Priora VAZ 2170, as on other VAZ cars, often fails, especially when the mileage exceeds 80,000 km. First there is noise from the wheel, which can increase during acceleration.

Vibration also often occurs, wheel play increases, and in some cases the noise turns into a grinding sound - all these signs mean that the front wheel bearing of the Lada Priora requires immediate replacement. If you delay repairs, the consequences can lead to wheel jamming, which leads to unsafe situations on the road.

This article will tell in detail about the principles of replacing wheel ball bearings (hereinafter referred to as SP) on cars of the VAZ family, in particular on the Lada Priora. The instructions are accompanied by many photos and videos. The material also provides information on how to choose a front wheel bearing for a Priora by number, size, price, and manufacturer.

After reading the article, you will understand that replacing the front wheel bearing is done with your own hands without special skills, experience, or special tools, and the price for repair work of this type in a car repair shop is very high.

Preparing for work

This process is best carried out in the light if we are talking about the street. A bearing is a miniature component. It will be ideal if you drive Priora into the inspection hole. We will disassemble the front hub part, since this is more difficult than carrying out the same operation with the rear hub, especially without removing the strut. And now to the tools:

- Spanners for 17, 19.

- A bearing puller is the main tool, so without it you will have to dismantle the strut and perform a wheel alignment.

- The head is 30, it is desirable that it be equipped with a reliable wrench.

- The frame is usually a homemade tool, which is a cut of a pipe of a certain size. With its help we will knock out the hub.

- WD-40 lubricant.

Lada Priora, like other passenger models of this brand, is a front-wheel drive vehicle. There are many more parts in the front, hence the more complex process of removing the bearing. The rear support component of the hub is removed in the same way; you will need less time to do it, so the instructions describe the rear support bearing.

How to diagnose the front wheel bearing on a Priora and the causes of failure

At the beginning of the article, signs of a malfunction were already mentioned, if they occur in the VAZ 2170, it is necessary to check the hub assembly. To diagnose a breakdown, it is enough to do several operations:

- Raise the car with a jack;

- Check the play of the suspended wheel with your hands;

- Rotate the wheel and listen for noise;

- Watch several videos on the principle of diagnosing the front wheel bearing of a Priora.

Faulty wheel bearing:

An example of the operation of a failed wheel bearing:

How to check the ball bearing of a wheel hub:

Wheel bearing diagnostics:

vazoved

I drive a LADA VESTA CROSS, Moscow

Then there will simply be no one to pay the fines! This is a Korean tablet video recorder 15 in 1 for Android..

I forgot about fines and Yandex Navigator.

There is FULL HD shooting, radar detector and GPS with 32 satellites. I got it at a reasonable price for such great functionality: HERE

Why does the front wheel bearing of a VAZ 2170 (Priora) fail:

- Expiration of service life;

- Incorrect operation of the suspension, aggressive driving style, road quality;

- Poor quality ball bearing (defect, counterfeit, manufacturing defect);

- Depressurization (dust, moisture, dirt);

- Malfunction of adjacent components (brake disc imbalance, etc.);

- Road accidents, collisions with deep potholes in the asphalt or holes.

Packaging companies

These companies do not produce the parts themselves, but pack them in branded boxes, and often the parts are of low quality.

- Ruville is a packager that interacts with product leaders and small firms;

- Optimal is a company from Poland that packages parts from Eastern Europe and China, often of poor quality;

- Corteco, QH, NK, Coparts - pack the cheapest parts, even fakes;

- CX is a packer of Chinese parts with low quality.

It is better not to buy products offered by these companies, even if they are much cheaper. The quality will be low, the parts will not last long.

What front wheel bearing is in Priora: dimensions, number, prices, characteristics

Before you begin the repair, you need to know which front wheel bearing is on the Priora, as well as which one is better in terms of price, reviews, quality, and manufacturer. The designers at the manufacturing plant included in the design an angular contact double-row sealed ball bearing with lubricant inside (LITOL-24).

According to reviews and statements from VAZ owners, the best option would be original products from VBF or foreign manufacturers: SKF, SNR, SWAG, FAG.

The dimensions of the front wheel bearing, as well as the catalog numbers of recommended manufacturers, are presented in the tables in a similar article on replacing the wheel bearing in a Lada Granta car; look for detailed information there.

Is it worth buying the original?

It is often advised to buy original bearings. An original is a part selected by a car manufacturer for sale on markets. These are the parts that are delivered to conveyors. When buying an original bearing, you will be absolutely sure that it will suit you. But there are several questions that need to be addressed here.

The original or a fake?

The original bearings are all the same and if you examine it carefully you will find the engraving. It is located on the edge of the upper or lower part. It should contain several information:

- manufacturer (logo);

- Country of Origin;

- designation digital or alphanumeric details, sizes;

- Additional information is possible;

- The kit must include a hub nut (usually disposable), there may be pins or bolts, seals.

- SKF brand

- Full bearing designation

- Manufacturer country

- Production date code

- Deviation of the average outer diameter ∆Dm [µm] and the position of the maximum eccentricity of the outer ring

- Deviation of the average bore diameter ∆dm [µm] and position of the maximum eccentricity of the inner ring

- Marking of thrust end, stamping

- Serial number (for bearing sets only)

- "V" marking (matched bearing sets only)

If the country of origin is not indicated, it is not an original, but a fake.

Is it worth paying extra for the original?

As a rule, you will find completely similar bearings from different companies on the market. So is it worth paying more for the original if other companies produce the same parts? If you decide to pay attention to any company, then choose well-known, popular manufacturers that supply parts to conveyors. Some people prefer Japanese companies, others prefer European products, for example, they trust only German quality. Our rating of the best manufacturers will help you determine which wheel bearing company is better and who to give preference to. Even if these companies offer products made in China, they will be high-quality products that meet all the requirements. Pay attention not to the country of origin, but rather to the supplier’s brand.