Sooner or later, any car owner will be faced with a problem related to the failure of the front wheel bearing on a Grant. It is good if the product is replaced on time, when the first signs are detected. It is worse if the driver ignores signs indicating a faulty element, which can lead to a serious traffic accident.

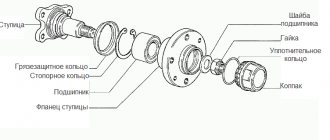

The main purpose of wheel bearings is to maintain and ensure proper rotation of the wheels. From a structural point of view, the product consists of two metal rings, between which there are rollers or balls, an insulating material that prevents debris from entering and lubricant from leaking out of the product.

Symptoms of a problem

Problems associated with the front hub are identified by the following symptoms:

- extraneous, unnatural noise from the wheel during rotation;

- wheel beating, vibrations of varying degrees of intensity;

- sounds of scraping metal;

- front wheel play appears.

Causes of breakdowns

The service life of the product is quite long and amounts to about one hundred thousand kilometers, subject to gentle operation. However, in real “combat” conditions, the element fails much earlier than its allotted time. Here are 3 important factors that significantly reduce the service life of a bearing:

- Unsatisfactory condition of roads. The fact is that when driving on an uneven surface, wheel bearings take on increased load, sudden impacts, and exposure to high and low temperatures. Over time, the metal components of the product become brittle and begin to break down.

- Aggressive environments. Due to the fact that the element is located in the center of the wheel, it is constantly in contact with moisture, water, dust, and dirt. In winter it is exposed to cold temperatures and in summer to hot temperatures.

- High operating temperatures. The rotation process is accompanied by the natural release of heat; constant heating and cooling occurs (especially in winter conditions), which has a detrimental effect on strength and wear resistance.

Diagnosis of wheel bearing failure Grants

The front wheel bearing on the Grant is not the most vulnerable part in the suspension, but its failure is possible after a mileage of 80,000 km or due to external and internal factors.

A front hub malfunction is determined by the following symptoms:

- Noise from the wheel while driving (damaged ball bearing parts: rolling elements, raceways or cage);

- Vibration, wheel beating, grinding noise (typical of a broken ball bearing);

- Front wheel play (the ball bearing has failed or the wheel nut is not tightened with sufficient torque).

The same signs of malfunction are characteristic of the rear wheel bearing on the Grant.

Watch the video with the characteristic noise when a hub unit breaks:

Bad bearing humming

Diagnostics of the front hub bearings proceeds as follows:

- The front of the car is raised with a jack;

- Spin the wheel by hand and check for noise;

- Check the axial play (clearance) according to the instructions.

- If you hear a noise or notice other signs, then replacing the front wheel bearing on Granta is inevitable.

- Be sure to watch the diagnostic video.

Diagnostics of the VAZ front wheel bearing

Replacing the front wheel bearing on a Grant

Work related to removal and installation will require special tools, namely: - a special hub puller; - chisel; - hammer; — a long lever or a specialized wrench to loosen the hub nut; - set of heads; - center punch; — a knob or key set to “30”; - a flat-head screwdriver; — retaining ring remover (or pliers with round ends); - jack or ditch lift; — wheel stands (2 pieces).

Conventionally, all work can be divided into 18 stages:

- Place the vehicle on a level surface, provide acceptable lighting conditions, and place chocks under the rear wheels.

- We loosen, but do not unscrew the bolts securing the wheel where replacement is planned.

- We loosen the tightening torque for the hub nut (it is most convenient to use a long lever).

- Using a jack, we lift the required side of the car. We dismantle the wheel.

- Using a screwdriver, pry and disconnect the protective plastic cap of the hub.

- Using a hammer and a center punch, straighten the shoulder of the bearing nut.

- Unscrew the hub nut. Please note that the tightening torque is quite high, so it is necessary to use a special wrench or tool with a long lever. Remove the nut and washer. Remove the brake disc.

- Disconnect the wheel drive.

- Unscrew the two bolts of the strut and ball joint.

- Unscrew the steering knuckle fasteners and remove it from the CV joint.

- We install the unit in a vice and, using a head of the required diameter, press in the wheel bearing.

- Remove the special protective ring.

- We place the chisel between the ends of the inner ring and, applying small blows with a hammer to the chisel, tear the ring to the side. Using a special puller we dismantle it.

- Using pliers or round-nose pliers, remove the retaining ring and remove the bearing.

- Using a brush with metal bristles, clean the inside of the steering knuckle from dirt. Then apply lubricant to the cleaned surface.

- Install the new product back into the steering knuckle.

- Further assembly is carried out in reverse order.

Now you know how to change the front wheel bearing on a Grant at home, without resorting to the help of car services.

Preparatory stage before replacing the hub mechanism

Required materials and tools:

- hydraulic (mechanical) jack;

- wooden stand;

- wheel wrench;

- screwdriver with a flat, cross-shaped bit;

- hammer;

- knob, nozzles;

- spanners;

- stationary vice;

- chisel;

- two-jaw and cup pullers. The exact dimensions of the pullers are indicated in the operating instructions;

- forceps;

- metal brush;

- lubricant type “CV joint - 4”;

- rags;

- caliper for measuring diameter;

- new wheel bearings;

- additional lighting provided that the work is carried out in the dark.

Causes of malfunctions

The resource of this part is very impressive and can reach 100 thousand km, subject to gentle operation. Modern realities show that the front hub bearing can become unusable much earlier than the specified regulatory period.

Next, we will identify three significant factors that can cause premature wear of a part such as the front wheel bearing in a Lada Granta car.

- The state of domestic roads, the quality of which is far from ideal. When driving over bumps, the front wheel bearing experiences enormous stress. Also, critical temperatures and dynamic impacts (shocks) can have a negative impact on their condition. All this leads to the structure of the material from which the front hub bearing is made losing its strength properties, which provokes destructive processes.

- Exposure to aggressive environments. Due to the structural location of the bearing, it is doomed to constant contact with moisture, dirt and other negative atmospheric factors. The influence of heat and cold is also detrimental to his condition.

- Increased operating temperature. During the rotation process, natural heat generation occurs. Temperature changes, especially in winter, also have a detrimental effect on the strength parameters of the product.

Operations for replacing the wheel bearing of Lada Kalina

The work of replacing the wheel bearing of a Lada Kalina can be carried out on a level platform, but it is more convenient to do so on an inspection ditch or a lift. A malfunction of the wheel bearing of the front fret of the viburnum manifests itself in a constant, additional sound while driving (noise, howling, buzzing). Remove the hub cap. Using a narrow chisel, we straighten the dented collar of the hub bearing nut in two places. You can replace the front bearing by replacing the Lada Kalina heater radiator. Replacing the wheel bearing - viburnum (VAZ 1118, 1119). Apply the handbrake, engage first gear and place boots under the wheels.

Use a 30mm socket to loosen the hub bearing

. The nut is tightened with a large torque, so the head and knob must be strong enough to transmit the necessary force. Loosen the wheel mounting bolts. We hang up the front part of the car (namely both front wheels, because otherwise the anti-roll bar interferes with dismantling, pushing the suspension elements up). How to replace the wheel bearing on a Lada Kalina. replacing the front one. We remove the wheel, the brake pad guide together with the caliper and tie the brake disc with the caliper so that they do not hang on the brake hose.

Unscrew the hub bearing nut completely and remove the washer. Replacing the front wheel bearing of Lada Kalina. To determine the destruction of the bearing, you need to jack up the car from the side being tested until the wheel comes off. We pass bolts about one hundred thirty mm long with an M12x1.25 mm thread through two diametrically opposite holes in the brake disc.

Original bearing

The original catalog number of the front wheel bearing is 1118-3103020. The average cost of a product is about one thousand five hundred rubles. Its kit includes: bearing, tension nut and retaining ring. Manufactured by AvtoVAZ.

Replacing the Front Wheel Bearing Kalina

Chassis Lada Kalina

Review of manufacturer prices for front and rear hinges

How to choose and buy quality parts

Service center specialists strongly recommend purchasing consumables and components exclusively from specialized stores, representative offices, and official dealers.

To a lesser extent, you need to use the services of unverified suppliers who sell spare parts at an unusually low cost.

When purchasing, check the catalog numbers with the actual data specified in the operating instructions for the technical device. If such a brochure is not available, consult a specialist.

Reviews

| № | Positive |

| 1. | Gennady: I’ve been actively using the car for two years, there are no comments on the chassis or suspension. Once I replaced the rubber boot on the left CV joint. |

| 2. | Kirill: I have driven the car over 80,000 km, I can say that the CV joint still has service life, but it is necessary to prepare for repairs. In general, the parts are maintained within the period specified by the manufacturer. |

| 3. | Vyacheslav: the car is a year and a half old, I bought it at a dealership, no complaints. I systematically carry out technical inspections, buy original consumables, and do not skimp on preventative maintenance. |

| 4. | Dmitry: replaced the “grenades” only at 90,000 km. The service station master said that the mileage is good, not every car gets that much mileage. I believe that careful driving contributed to extending the life of the vehicle's chassis. |

| 5. | Leonid: I’m pleased with the build quality of the car, there are no complaints. Breakdowns happen, but they are insignificant, I fix them myself. |

| 6. | Vasily: if you don’t take into account minor flaws, then the car is good, better than previous generations. |

| 7. | Victor: I drove Grant for a year and a half, didn’t do any repairs, visited a service station only for diagnostics. |

| Negative | |

| 1. | Ivan: I replaced the right CV joint for the first time at 45,000 km, after which the left one needed repairs. In general, the workmanship is low, I am dissatisfied with the machine. |

| 2. | Alexander: standard CV joints are weak and poorly made. After purchasing a car, experts recommend installing foreign analogues. True, the cost is 15% more expensive than domestic ones. |

| 3. | Vladlen: after two years of active driving, I can’t say anything bad. Minor defects are present, but they can be easily fixed. |

Conclusion

Provided that the equipment is used moderately on uneven road surfaces, the average service life of CV joints is 85,000 km.

The better the quality of the road surface, the longer the hubs take care of. Original components will only increase the service life of the car. However, not all owners adhere to the recommendations of specialists and systematically save on consumables.

One day, the owner of a Lada Grant will experience an unpleasant failure of the bearing on the front hub. It is necessary to take timely measures, and at the same time the front wheel bearing is replaced, and if this is not done, then you can get away with significantly lower costs. And when the owner neglects the timeliness factor and postpones repairs, he automatically falls into the cohort of “provocateurs” of an accident, because the failure of this unit while driving can have dire consequences.