Upper support of the front strut for viburnum - features of choice

As practice shows in most cases, the upper support assembly is replaced.

There are three models of “supports” on sale, which you should pay attention to when purchasing. The photo below shows original sets of supports from three companies: SEVI. SS20 (SS20), ASOMI (ASOMI). The cost of products varies from 2000 rubles. up to 4000 rub. depending on the configuration. Watch the spare parts review video:

If you do change the support bearing individually by installing it in the old support, then you should buy from trusted manufacturers, a summary table of which and photographs are presented below. Catalog number (article) - 1118-2902840.

How to check a support bearing - the third way

- Choose a section of the road where there are no cars.

- Do a little test: stop completely, then move away, turn the steering wheel, and brake sharply.

- If the support bearing is faulty, you will hear a crunching or non-metallic squeaking or grinding sound in the area of the front wheels. When this creaking noise appears, you will feel the steering wheel gradually move to the side, depending on which of the “supports” is faulty.

It should be understood that the support bearing should be checked not only if it is suspected of being faulty; it is recommended to check the support bearing at least once every 15-20 thousand. km. mileage This can be done either independently or at a service station on a special diagnostic stand.

“>

Video 2

In order to replace at least one of the elements that is part of the Kalina front strut, you need to remove the entire assembly from its seat.

To do this, open the hood and use a 22 wrench to rip off the upper support nut, while holding the shock absorber rod with a 9 wrench. There is no need to unscrew the nut completely yet.

We also use a wheel wrench to remove the wheel nuts and only then lift the car with a jack. Immediately you need to place a stop for belaying.

Now you can safely unscrew the wheel nuts and remove the wheel. The brake hose is attached to the strut, so it needs to be released from the mount so that it does not interfere when we remove the strut. Now we will need WD-40; we need to treat all the bolts and nuts that will have to be unscrewed. The main thing is to spray on the lower nuts and bolts of the shock absorber that secure the assembly to the steering knuckle.

We remove the steering tip nut and hit the eyelet into which the ball pin of the tip is inserted with strong blows, while inserting a pry bar between the steering tip and its mount on the rack.

If you have a special puller, you can press out the finger using it. Unscrew the two self-locking nuts securing the shock absorber to the swing arm. To do this, we use keys 17 and 19.

It is better to use similar heads and knobs.

After removing the nuts, it happens that the bolts do not come out. They have to be knocked out. You must first knock them out through a wooden block so as not to spoil the thread, and then, using a punch with a smaller diameter, knock out the bolt when it is already sunk into the steering knuckle.

Replacing the support bearing on Grant

Video 2

In order to replace at least one of the elements that is part of the Kalina front strut, you need to remove the entire assembly from its seat.

To do this, open the hood and use a 22 wrench to rip off the upper support nut, while holding the shock absorber rod with a 9 wrench. There is no need to unscrew the nut completely yet.

We also use a wheel wrench to remove the wheel nuts and only then lift the car with a jack. Immediately you need to place a stop for belaying.

Now you can safely unscrew the wheel nuts and remove the wheel. The brake hose is attached to the strut, so it needs to be released from the mount so that it does not interfere when we remove the strut. Now we will need WD-40; we need to treat all the bolts and nuts that will have to be unscrewed. The main thing is to spray on the lower nuts and bolts of the shock absorber that secure the assembly to the steering knuckle.

Replacing the support bearing for a viburnum (VAZ 1118, 1119, 1117)

Replacing and installing support bearings on Kalina begins with checking the condition of the remaining elements of the module: lower cup, power buffer, bump stop, corrugation, shock absorber springs. They will need to be replaced if necessary. How to correctly install the support bearing on Kalina and change it is described in order below.

- Before assembling the front jay, make sure that the ends of the shock absorber spring rest against the special tabs at the lower and upper cups.

- We place a rubber gasket on the top cup, with a new “support” on top of it, and orient the product upwards with the markings.

- On top of the p/sh we install the upper part of the support (cover).

- Now we attach the shock absorber rod nut, which we tighten until it stops.

- Unclench the shock absorber spring ties. We tighten the rod nut with a torque wrench to the torque indicated in the table at the end of the article.

- We install the assembled module back, first attach it to the body glass. We carry out the assembly in the reverse order: we screw the steering tip to the lever, fasten the stand with two bolts to the steering knuckle, and mount the wheel at the end. This completes the replacement.

Replacing support bearings on Priora

The support bearing serves to absorb and distribute shock loads coming from the wheel through the shock absorber strut to the car body.

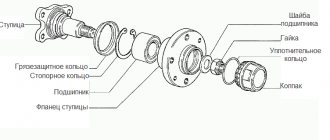

It is the main working element of the upper support of the front shock absorber, designed to connect the body and the strut. The design of the “support” is a bearing consisting of a rubber cage with metal balls placed in it, and two thick rubber gaskets that protect it from above and below.

In Lada Priora cars, support bearings are installed in the “cups” of the front shock absorbers, located in the engine compartment above each of the wheels.

How to change a support bearing without a camber on a Lada Kalina

Replacing the support bearing on Kalina without removing the strut is impossible, or will not be correct, but replacing the part without further camber is still possible. In this case, the technology for removing the rack will change:

- After removing the wheel, unscrew the hub lock nut.

- Disconnect the steering knuckle from the ball joint and steering rods.

- Then we remove the steering knuckle from the CV joint with the strut and shock absorber spring, this way you will not break the camber bolts.

How to check a support bearing

The easiest way to check the performance of a support bearing is with the help of an assistant. You need to remove the plastic cover from the strut cup, there you will see the bearing mounting nut. You need to put your hand on the support and ask an assistant to rock the car. As soon as the car starts to rock, you will immediately feel the bearing working.

If you hear a knocking or squeaking sound in the support, it is most likely faulty and needs to be replaced.

New Lada: Tires and wheels for Lada Granta

Diagnostics

To diagnose the current condition of the support element, you need to perform a couple of simple steps.

- Open the hood and place your palm on the element, that is, the bearing. In this case, your assistant should rock the car. If a knocking sound is heard, then it should be changed immediately.

- Disassemble the structure to clearly see that the element is faulty and needs to be replaced. It is important to note that the approximate service life of the support bearing on a VAZ 2114 is 40 thousand kilometers. This is the recommended mileage after which the element must be replaced, regardless of its current condition.

A faulty support can lead to quite tragic consequences, such as wheel alignment disorder, increased risk when driving at high speeds, and increased wear of shock absorber struts.

If you do not pay attention in time and do not take appropriate action to eliminate the breakdown, you risk completely destroying the suspension of your car. It is not uncommon for a hole to form in the hood from the pillar. As you understand, such problems entail significant financial losses.

How to remove the support bearing on a viburnum - step by step guide

Replacing the Kalina front strut supports begins preparing the car. Place the car on a flat surface, if there is a lift or pit available. Engage first gear and release the parking brake. Dismantling sequence in order:

- We unscrew the wheel bolts, then raise the car with a jack or a lift as in our case.

- We gain access to the brake disc, but you don’t need to remove it, nor do you need to unscrew the hub locknut.

- Let's move on to the swing arm and tie rod. First, remove the cotter pin from the fastener. Next, unscrew the nut itself.

- After this, use a tip remover to press it out of the hole in the lever or, as a last resort, use a hammer. We install the device, tighten the thread and remove the tip.

- Now disconnect the brake hose and speed sensor wire from the front strut.

- Next, we find two bolts securing the strut to the steering knuckle and lubricate them with penetrating lubricant.

- To unscrew the nuts, we use a 17 socket wrench, as well as a head with a ratchet.

- The bolts will have to be knocked out; use a wooden guide to avoid damaging the threads.

- The lower part of the module is freed, let's move on to the upper part. Unscrew the three fastenings of the front pillar to the body glass.

- When unscrewing the last nut, hold the stand, or place a support under it, for example, a removed wheel. After this, remove the module with the support and shock absorber assembly.

- We install two ties on the springs of the removed suspension module. As shown in the photo, we compress the shock absorber spring evenly on both sides.

Note:

In garages and car repair shops, special machines are used to compress shock absorber springs; when using them, the replacement process is faster.

- We continue to compress the shock absorber until the upper support is freed from the spring tension, and only then unscrew the rod nut. We use the key at 19.

Attention:

The photo on the right shows the SS20 shock absorber mounts, the design is different from the standard mounts, as in the photo on the left. The essence of replacing and repairing the Kalina support bearing of different designs does not differ.

- Now we remove the upper part of the support (cup), under which the “support” is located. We remove the old part and proceed to replacement.

Replacing the support bearing on Grant

The Grant support bearing is an element of the front strut system. The purpose of the product is to provide rigidity to the entire mechanism, absorb axial loads, and ensure unhindered rotation of the front pillar. It is worth noting that the element is not used in all cars, but only in those where the strut moves simultaneously with the steering knuckle. In terms of location, the support is located just above the front spring where the shock absorber is attached to the car body. There are several types of parts: - with an inner or outer ring; — with a detachable ring element.

- Occurrence of problems and their causes

- Signs indicating a faulty support bearing

- How to change the support bearing on a Grant

Occurrence of problems and their causes

I would like to note that many problems that arise with bearings installed in Lada Granta cars are a common “disease” of this brand. Most malfunctions occur already in the early stages of operation. The most common causes of failure:

- low quality of the unit;

- ingress of debris into the element structure as a result of low security and isolation from contamination;

- natural wear and tear.

Signs indicating a faulty support bearing

Wear or contamination of the assembly elements inevitably leads to the appearance of extraneous noise (crunching, knocking) during rotation of the steering wheel. In addition, the characteristics associated with vehicle handling are noticeably reduced. Therefore, it is extremely important, even if minor signs described above appear, to carry out a thorough diagnosis. If a breakdown is confirmed, the support bearing of the Granta fret is immediately replaced. Many car owners know that in order to change the problematic element, they will need to dismantle the struts and springs, which is a rather labor-intensive and specific process. However, do not rush to get upset, there is a method that allows you to replace the problem unit without removing the shock absorber struts. We will dwell on this in more detail.

How to change the support bearing on a Grant

To complete the work you will need the following equipment and tools: - any two reliable jacks; — a hexagon made of durable metal (to fix the rod and prevent it from turning); — specialized ties for springs; — keys of various sizes (for “13, 14, 17, 22”); - hammer; - chisel; - center punch; — composition for fighting rust (WD-40); — a “30” key with a long lever; — new bearing assemblies or a separate bearing.

Below are 10 stages of work:

- Place the car on a level surface. Provide comfortable lighting conditions. To avoid troubles during work, place chocks under the rear wheels.

- Before jacking up the vehicle, loosen the four wheel mounting bolts.

- Using a jack, we lift and fix the area of the car body where the work is planned.

- Unscrew the bolts and remove the front wheel.

- We unscrew the bolt that secures the stabilizer link (so that it does not interfere with further work).

- We move to the engine compartment. We take the hexagon in one hand, insert it and hold it in the rod, and with the other hand, using a “22” wrench, loosen the nut securing the shock absorber rod itself.

- We prepare, place a second jack under the ball. We raise the rack to its possible limit.

- In order for the bearing to be freely removed, it is necessary to loosen the shock absorber spring. To do this, we take the previously prepared ties, hook them onto the spring and tighten them until the stand drops lower and thereby releases the support device.

- Unscrew the rod completely (if you haven’t unscrewed it previously). Through the resulting space, remove the support mechanism.

- Reinstallation is similar to the removal process. We hope that if any problems arise in the future, you will no longer have questions regarding how to remove the support bearing on the grant.

Signs of front strut malfunction

- The appearance of knocking noises when driving over uneven surfaces in the area of the pillar. This happens when the thrust bearing has become disintegrated and is not performing its function properly. This also happens if the coil spring bursts.

- When hitting an obstacle, the car sways for some time due to the fact that the shock absorber itself does not dampen the vibrations.

- During a visual inspection, if you see that the strut is wet on a dry road, this means that the front shock absorber has lost its tightness.

Oil leaks out of it.

New Lada: Description of the VAZ-21116 engine design for Lada Granta

Table of bearing sizes 8112n and technical characteristics

Characteristics Unit of measurement Value according to GOST (TU)

| Inner diameter of the tight ring, d | mm | 60 |

| Outer diameter of the tight ring, d1 | mm | 85 |

| Free ring inner diameter, D1 | mm | 62 |

| External diameter of free ring, D | mm | 80 |

| Installation height | mm | 17 |

| Dynamic load capacity | kH | 41,5 |

| Static load capacity | kH | 95,0 |

| Nominal speed | rpm | 3600 |

| Axial clearance | mm | — |

| Steel type | — | SHH-15 |

| Hardness of steel and rollers | H.R.C. | 61-65 |

| Contact angle | hail | — |

| Torque | kN*M | 220 |

| Ring roughness | Ra | 0.32 |

| Number of balls | PC. | 24 |

| Ball diameter | mm | 8,731 |

| Mounting chamfer radius, r | mm | 1,5 |

| Weight | G. | 295 |

Table of recommended manufacturers

No. Manufacturer Manufacturer's article Price 2021, rubles Equipment Features Retaining rings Protective cap

| 1 | VBF Russia Analogue | 1118-2902840-01 | 700 | — Clip made of hardened steel; — Manufactured according to GOST; — Increased service life; — High-quality lubricant. | — | — |

| 2 | NPP "System Technologies" Russia Analogue | SS10113/11180-2902840-00 | 900 | — Silence; — Vibration damping; — Work at low temperatures; — Protection from dirt and dust. | — | — |

| 3 | AvtoVAZ Russia Original | 1118-2902840 | 750 | — Original product; — 1 year warranty; - Durability. | — | — |

Advice:

When installing ss20 support bearings on a viburnum, it is recommended to install new “Vibration and Noise Insulators” for springs made of synthetic rubber; they soften the load on the suspension and shock absorbers so that a crack does not appear on the Kalina strut support, and this also prevents other malfunctions.

It is important to know:

Inside the plastic housing of the support bearing from VBF there is a single-row thrust ball bearing, marked according to GOST - 8112Н, according to ISO (51112).