The principle of operation of a car axle shaft

An axle shaft is a part of the car's chassis, which is designed to transmit torque from the differential to the drive wheel of the car. The number of axle shafts is determined by the number of driving wheels of the vehicle. So, for example, if a car has two drive wheels, then there will be only two axle shafts. SUVs, on the other hand, have axle shafts on all drive wheels of the vehicle.

The operating principle of the axle shaft is as follows. The torque from the gearbox goes to the driveshaft, which transmits it to the vehicle's axle gearbox. The gearbox, in turn, distributes this moment along the axle shafts of the car. These elements are secured in the wheel hubs using special locking nuts.

It's even easier in a front-wheel drive car. The axle shaft of such a car is called the drive shaft, which is connected to the gearbox and transmits torque to the angular velocity joints.

Replacement of the rear axle shaft, bearing and oil seal of VAZ 2107

The "seven" axle shafts are used to drive the rear wheels of the car. In general, these parts of various rear-wheel drive cars are similar and the replacement procedure will not be much different. In addition, along with replacing the axle shaft, its bearing and oil seal are usually replaced, so this procedure will be described for three parts at the same time.

Replacement of this element may be required in the following cases:

- The part is too deformed or bent. In this case, it cannot be repaired, since the alignment is already damaged and it is impossible to restore it.

- The axle flange was seriously damaged. This can be expressed in its deformation or broken threads. This happens when driving on unbalanced wheels or when the wheel bolts are tightened too tightly.

- The special bushing, or as it is also called, the locking bushing, no longer copes with its locking duties. The entire axle shaft must be replaced.

- The splines of the part have undergone severe wear. If they are very worn, then the axle shaft must be replaced.

- The last thing to be diagnosed is the axle bearing itself. If it is too worn out, then replacing it can be limited, however, if its seat has been worn out, then the entire axle shaft is replaced.

In what cases may it be necessary to replace a VAZ axle bearing?

- The bearing has suffered severe mechanical damage and is no longer suitable for use in the chassis.

- There was a need to replace the rear axle axle shaft. Along with it, the bearing must also be replaced.

The signal for repair is usually the appearance of noise when driving in the rear of the car. As the speed increases, the noise level also increases.

The frequency of replacement is not clearly regulated, since the axle shaft is a part with a fairly long service life, which depends on the operating conditions of the vehicle. That is why the part needs to be replaced at the first sign of a malfunction.

Oil seals VAZ 2107 (dimensions)

| Designation | Dimensions (mm) | Name | ||

| D | d | H | ||

| 2101-3401026 | 37 | 19,3 | 10 | Steering shaft oil seal |

| 2101-1701043 | 47 | 28 | 8 | Gearbox seal VAZ 2107 (primary shaft) |

| 2101-1701210 | 56 | 32 | 10 | Secondary shaft oil seal VAZ 2107 |

| 2101-1005034 | 56 | 40 | 7 | Crankshaft oil seal (front) VAZ 2107 |

| 2101-1005160 | 90 | 70 | 10 | Rear crankshaft oil seal |

| 2101-2402052-01 | 68 | 35,8 | 12 | Rear axle oil seal VAZ 2107 (gearbox) |

| 2101-3401023 | 43 | 28,6 | 10 | Steering bipod shaft oil seal |

| 2101-2401034 | 45 | 29 | 8 | Axle shaft seal VAZ 2107 |

| 2101-1307013 | 36,6 | 15,5 | 20,3 | Oil pump VAZ 2107 (water pump) |

| 2101-1007026 | 10,5 | 8 | 10,2 | Oil cap (oil scraper) |

| 2101-3103038 | 57,15 | 40 | 10 | Hub seal |

You can order a crankshaft oil seal and other parts of the VAZ 2107, find out the exact price and other useful information in our office or by phone.

When is replacement needed?

The rubber reinforced cuff cannot be restored or repaired. Therefore, it is necessary to replace the crankshaft oil seal or other part on a VAZ 2107 as soon as the seal begins to leak or “take” working fluid.

Most often, replacing the axle shaft seal, gearbox, and gearbox on a VAZ 2107 is necessary under the following circumstances:

- wear due to long use;

- various damages;

- deformation;

- purchasing and installing an oil seal of the wrong size;

- low quality of the product;

- non-compliance of the product with AvtoVAZ requirements.

The oil seal of a VAZ 2107 gearbox or other car mechanism has a certain service life. But a rubber product may become unusable before the warranty period.

For example, the crankshaft oil seal on a VAZ 2107 may suffer after:

- untimely replacement of oil and filter;

- engine overheating;

- poor quality repairs.

And here it is important to remove the old cuff in time and replace it with a new one. Otherwise, oil leakage cannot be avoided.

The importance of choosing a reliable manufacturer

It’s very easy to find a VAZ 2107 crankshaft oil seal on the Internet at a low price. But most of the offers are seals from China, which are well disguised as well-known brands. As a result, the car owner soon notices puddles of oil again and is forced to spend money on a new oil seal again.

MP "CREDO" guarantees compliance of rubber reinforced cuffs with GOST 8752-79, subject to compliance with the rules of delivery, installation, operation and storage.

Our company produces two types of oil seals:

- single-edge;

- single-edge with dust collector.

Modern technologies and reliable equipment allow our company to produce axle seals for the VAZ 2107 and other reinforced cuffs for this car model that meet international standards and AvtoVAZ requirements.

The VAZ 2107 axle seal and other reinforced cuffs are tested for:

- strength;

- hardness;

- cyclicality;

- permanent deformation;

- relative extension;

- rigidity.

The role of rubber

The quality of a rubber reinforced cuff, for example, a VAZ 2107 rear axle gearbox seal, will largely depend on the performance of the raw materials. Our company uses exclusively high-quality rubber. All our mixtures are characterized by a high degree of homogenization, a wide range of operating temperatures and good resistance to all aggressive environments.

But all these characteristics suffer if the replacement is carried out incorrectly. Therefore, we advise clients who lack the experience and necessary knowledge to entrust the replacement of the axle shaft seal, gearbox, and crankshaft on a VAZ 2107 to professionals.

Advice! When buying a VAZ 2107 rear gearbox oil seal or another type of reinforced cuff, you need to check the quality. To do this, just hold the product in your hands, bending the working edge. Its surface should be smooth, elastic and sharp. It is the sharpness that largely determines the service life of this type of rubber product.

It is also extremely important for the normal and uninterrupted operation of the machine to buy the spare part that is suitable for your model.

The procedure for removing and installing the oil seal and rear axle bearing

- The car is placed on a flat surface and immobilized. To do this, use wheel chocks or other methods to stop the wheels from involuntary rotation. Remove the wheel bolts and lift the wheel using a jack.

- Remove the wheel and unscrew the guides mounted on the brake drum. After this, remove the drum itself. To do this, you can use guides that are screwed into the other two holes until the part comes out completely, or simply knock down the drum using a soft impact tool. Another option involves accelerating the drum in first gear and stopping abruptly - this will help the stuck element to easily move out of its place.

- Insert the long head through the special holes in the flange and unscrew the fastening bolts. Unscrewing and tightening is done only crosswise. Now pull out the axle shaft by hand and remove it. If this causes any difficulties, you can screw the wheel back onto two bolts and, swinging, pull the axle shaft out of the bridge.

- The new bearing and oil seal are mounted on the new axle shaft. The bearing is installed using a special puller. If you don't have one, you can use a soft frame and slowly press the bearing onto the new axle shaft with hammer blows. Try to do this very carefully so as not to disturb the alignment, and if possible, it is best to contact a car service center that has specialized equipment.

- Install the new axle shaft in the reverse order of disassembly. Similar actions are performed for the other side of the car.

Replacing the axle shaft

Let's look at the process of replacing the axle shaft, its bearing and oil seal in detail. Tools you will need:

- wheel wrench;

- a jack and a safety stand (in extreme cases, a stump or a few bricks);

- wheel stops;

- reverse hammer;

- wrenches 8 mm, 17 mm;

- slotted screwdriver;

- Bulgarian;

- round nose pliers;

- hammer;

- chisel;

- workbench with a vice;

- blowtorch or gas torch;

- spacer made of wood or soft metal;

- a piece of steel pipe with a wall diameter of 33–35 mm;

- Litol type lubricant;

- dry clean rag.

Removing the axle shaft

To dismantle the axle shaft, you should:

- Place the car on a flat surface and place chocks under the front wheels.

- Use a wheel wrench to unscrew the wheel bolts.

- Raise the car body with a jack.

- Unscrew the wheel bolts and remove the wheel.

- Using a size 8 wrench, unscrew the drum guide pins.

- Remove the drum. If it does not come off the blocks, carefully knock it down using a spacer and a hammer.

How to remove a broken axle shaft

If the axle shaft is broken, it will not be possible to dismantle it in the usual way. But there are other methods. If the shaft breaks directly in front of the flange and its broken end sticks out of the bridge casing, you can weld a piece of reinforcement to it, and then use it to pull out the rest of the axle shaft.

If the axle shaft breaks inside the casing, you can try to knock it out with a piece of reinforcement inserted from the back side of the bridge, after first removing the opposite axle shaft. In extreme cases, to remove a piece of shaft, you will have to disassemble the gearbox.

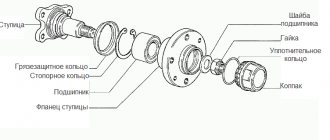

Removing and installing the bearing on the axle shaft

When replacing the axle shaft with a new one, it is recommended to replace the bearing, but if the old one is still fully functional, you can install it too. But to remove it you will need to remove the retaining ring. To do this you need:

- Securely fix the axle shaft in a vice.

- Using a grinder, saw through the outer part of the ring.

Installing the oil seal

To install a new oil seal:

- Wipe the seat with a clean, dry cloth.

- Lubricate the socket surfaces with grease.

- Lubricate the oil seal itself with grease.

- Install the part into the mounting socket.

Installing the axle shaft

Once the bearing and seal are installed, you can install the axle shaft. Installation is carried out in the following order:

- We install the sealing gasket.

- Insert the axle shaft into the housing until it stops. Check how the splines engage with the gear teeth by turning the axle shaft in different directions.

- Apply a few gentle blows with a hammer to the axle shaft flange to make sure it is seated correctly.

- Install spring washers onto the axle shaft studs. Install and tighten the nuts securing the axle shaft with a 17 mm socket wrench.

- Place the drum on the shoes and secure it with guide pins.

- Mount the wheel.

- Check to see if there is any play in the axle shaft or bearing by trying to shake the wheel along the vertical and horizontal axes.

- Lower the body and remove the chocks from under the front wheels.

- Tighten the wheel bolts.

- Check whether the signs of axle shaft malfunction have disappeared by driving on a flat section of the road.

How to change the front axle shaft of a UAZ

In principle, there is nothing complicated here either. In the same way, you need to lift the car and remove the wheel. Unlike the rear wheels, there is no brake drum here, but there is a special caliper that will in every possible way prevent the axle shaft from coming out. There is no need to disconnect the hose from it. You just need to hang it on other suspension parts and continue working. Then the brake disc mounts are unscrewed and it is removed.

After this, the flange mount is unscrewed and a special lock washer is straightened. It is removed and the nut under it is unscrewed, under which there is also such a washer. It is also removed and the last nut is unscrewed. Lastly, pull out the spacer and release the axle shaft from being fixed by the hub.

Unscrew further 4 nuts, then lightly tap on the special steering rod arm. However, it is not necessary to remove the traction. The last large cylindrical nut remains, which can be unscrewed using a special wrench. After the last nut, take out the special king pin. Then the oil seal on the ball is unscrewed and the special steering knuckle is removed.

The old ball axle shaft is pulled out, and a new part is inserted in its place, after which assembly is also carried out in the reverse order.

This completes the replacement of the axle shaft. As you can see, this is not a complicated procedure and can be done independently if you have a garage and a good set of tools.

Main technical characteristics of VAZ 2107 axle shafts and their elements

Axle shafts for the “seven” in Russia are produced under catalog number 21030–2403069–00. The right and left parts, unlike some other rear-wheel drive cars, are absolutely identical in the VAZ 2107. They have a diameter of 30 mm (for the bearing) and 22 slots. On sale you can also find so-called reinforced axle shafts with 24 splines, but to install them you will need to change the design of the gearbox.

Axle bearing

The bearing is the element that bears most of the loads. And although its declared resource is about 150 thousand kilometers, it can become unusable much earlier. It all depends on the operating conditions of the car, the serviceability of other transmission parts, as well as the quality of its manufacture. The most reliable today are considered to be bearings from the Vologda Bearing Plant, produced under article numbers 2101–2403080 and 180306. Imported analogues have catalog number 6306 2RS.

Table: dimensions and technical characteristics of bearing 2101–2403080

| Position | Index |

| Type | Ball |

| Number of rows | 1 |

| Direction of loads | Two-way |

| Outer/inner diameter, mm | 72/30 |

| Width, mm | 19 |

| Load capacity dynamic/static, N | 28100/14600 |

| Weight, g | 350 |

Stuffing box

The axle shaft cuff has a much shorter lifespan than the bearing, since its main working material is rubber. It needs to be changed every 50 thousand kilometers. Axle shaft seals are available under catalog numbers 2101–2401034.

Table: dimensions and technical characteristics of the VAZ 2107 axle shaft seal

| Position | Index |

| Frame type | Rubberized |

| Type of rubber according to GOST | 8752–79 |

| Internal diameter, mm | 30 |

| Outer diameter, mm | 45 |

| Height, mm | 8 |

| Temperature range, 0 C | -45 – +100 |