The main stages of replacing stabilizer bushings:

- We place the car within the perimeter of the repair area and raise it with a hydraulic lift.

- Remove the front wheels.

- Unscrew the upper and lower fastenings of the stabilizer strut (bone).

- Unscrew the bolts and remove the left seal.

- We unscrew the five bolts (at “10”), slide the protective cover of the steering rack, and remove the right one.

- We install new rubber (polyurethane) bushings.

- We assemble the structure in reverse order.

Resource for replacing rubber seals of the front stabilizer

It is difficult to answer unequivocally how much seals cost in each specific case.

The manufacturer indicates an average replacement interval of 60 - 80 thousand km.

The interval varies depending on a number of factors:

- quality of the road surface;

- speed limits;

- driving style;

- quality of spare parts;

- temperature conditions.

Life expectancy of bushings

The wear of bushings is not regulated by manufacturers - there are recommendations for mileage, after which it is advisable to change the bushings. But the duration of operation of these units is influenced by several factors that cannot be foreseen or calculated in advance.

Let's say there are two cars released at the same time. One of them spends 90% of the mileage on rural, dirt roads, and the second - the same mileage, but on asphalt. It is clear that the bushings of a city car will “live” longer. In addition to road conditions, the performance of rubber bands is affected by driving style and driving speed. At high speeds, there are more opportunities to “yawn” a pothole or sharply turn a corner, which will cause the stabilizer to actively work.

The average service life of bushings is 70 thousand kilometers. There were cases when the bushings “nurtured” 100 thousand, and there were cases where they did not reach 35 thousand.

Replacing stabilizer bushings on Lada Vesta

Necessary tools, materials:

- Torx wrench with set of sockets;

- ring, ring wrenches;

- knob, heads;

- Silicone based lubricant.

Sequencing:

- We hang the car with a lifting mechanism.

- We turn on the first gear to lock the front wheel drive.

- Unscrew the bolts and remove the wheels and tires one by one.

- We unscrew the nuts of the upper and lower fastening of the stabilizer (bones), use the head at “17”.

- Using a key set to “17”, release the two bolts securing the metal bracket on the torsion bar on the left side. Access to the rubber bushing is unobstructed.

- To replace the bushing, first remove the steering rack protection on the right side. Fixation of the structure with five bolts, size “10”.

- Unscrew the right bushing.

- We unscrew the two rear bolts securing the metal bracket.

- We clean the surface of the torsion bar from dirt and deposits, and lubricate it with silicone grease.

- We put on new rubber seals.

- We assemble the structure in the reverse order with a tightening torque of 1.8-2.4 kgf.m.

Self-replacement of bushings on Lada Vesta is completed.

Note to the driver! It is not necessary to make a longitudinal cut when installing seals. The presence of an incision contributes to:

- penetration of sand, dirt, moisture into the gum;

- backlash formation;

- deformation of the seal.

Can I replace it myself?

The task is not difficult, so the owners of Lada Vesta, if there are conditions to carry out the work, can safely begin to implement it. You won’t need any special skills, but you will have to acquire a few things.

These are the tools and devices:

- lifting device or repair pit;

- socket heads in a set;

- knob;

- a set of keys, both open-end and spanner;

- "TORX" - nozzles;

- a lubricant that does not have a destructive effect on plastic and rubber.

Due to the fact that the manufacturer retains the right to make certain types of changes to the design of the car, it makes no sense to specifically indicate the size of the keys. It will not be difficult to find your way around the place.

Review of Manufacturer Prices

| Name / Catalog number / Dimensions / Diameter | Price in rubles |

| Original stabilizer bushing | |

| 17012680 (inner diameter 21.5 mm) | From 400 |

| 8450006748 | From 400 |

| High-quality analogues of stabilizer bushings | |

| Polyurethane from Chevrolet Niva 2123 (17012680) | From 350 |

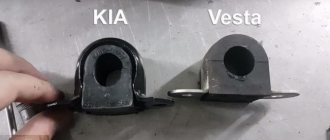

| Polyurethane stabilizer bushings for Lada Vesta from Kia Rio (548132K100, 548141G000) | From 550 |

| 54813-2K100 (diameter 21.5mm) | From 550 – 600 |

| KSBSOULF (diameter 21.5mm) – new sample | From 550 – 600 |

*prices are as of 03/03/2019.

Let's sum it up

We made sure that replacing bushings with your own hands is not considered a complex job. If the entire list of manipulations is carried out correctly, then the products are guaranteed to withstand the declared service life or even exceed its value if driven carefully. When operating the Lada Vesta, it is important to periodically inspect the products and clean them of any dirt that has fallen on the rubber surface. Rubber and polyurethane bushings tend to be particularly sensitive to the effects of engine oil or transmission lubricant. If there is a leak factor in the units, then its elimination is guaranteed to protect the bushings from premature wear and destruction. It is also important to pay attention to the squeak.

Recommendations for selection

Service center technicians recommend purchasing spare parts and components from certified points of sale and official representative offices in order to reduce the likelihood of purchasing counterfeits.

Carefully check the catalog numbers with the dimensions specified in the operating instructions. If you have any doubts about the quality or origin, refuse to purchase.

Conclusion

Replacing the front stabilizer bushings and rods requires careful attention on the part of the repairman. Violation of the technological process will lead to deformation of the structure.

What type of sealing sleeve to purchase is up to the owner to decide on his own, but motorists recommend polyurethane ones. Their service life is 4 times longer than rubber ones. Polyurethane bushings retain their shape better and remain elastic regardless of the ambient temperature, which ensures a high level of controllability of the technical device.

↑ Signs of wear

Over time, an extraneous characteristic noise begins to be heard: it is the stabilizer bushings on the Lada Vesta creaking. This can happen almost immediately after purchase, or the owner will be able to drive 1000-1500 kilometers before having to deal with the causes of the unpleasant squeak. According to inexorable statistics, about 60% of all Vesta copies inevitably suffer from such a defect. According to experts, the root of the problem lies in low-quality components or a violation of their production technology. The further course of events involves the use of several options:

- independent elimination of deficiencies;

- contacting the official representative office of the manufacturer.

Important. The essence of the phenomenon is that the noise occurs in episodes and not constantly, which makes it difficult to localize. Most often, it periodically disappears, only to repeat again.

Calling for service often changes little, since the technicians do not plan to replace the worn bushings of the Lada Vesta stabilizer, but only lubricate them. Therefore, we will have to look for other solutions.

Reviews

| № | Positive |

| 1. | Petrovich , 35 years old (drive2.ru) Sverdlovsk: the car is a year old, I drive on the original bushings, no knocks, no rattles. I hope that they will last another 40 - 50 thousand km. |

| 2. | Vasily , 43 years old (prom.ua), Krasnodar: drove Vesta for two winters, original parts. There are no comments, the right side knocks a little, I blame the weak tightening of the rack. |

| 3. | Gennady , 38 years old (autotoday.com), Omsk: I won’t say that the quality of the original seals is super, but I’ve been driving for the third season and there’s no knocking. The manufacturer gives a guarantee of 60,000 km, let's see how long it lasts. |

| 4. | Vasily Gavrilovich , 48 years old (rozetka.ua), Rostov-on-Don: drove 45,000 km, a knock appeared on the right side. I went to the service station for diagnostics, the master said that the stabilizer bushings needed to be changed. |

| 5. | Dmitry Petrovich , 43 years old, Kursk (avtoflit.com): I bought the car second-hand, got it in good condition, well-kept. The speedometer shows 50,000 km, diagnostics showed good results. |

| 6. | Alexander Petrovich , 33 years old, Voronezh (autotoday.com): I’ve heard a lot of negativity about the quality of the seals, I can’t confirm it, since I’ve already driven 65,000 km on the factory ones. |

| Negative | |

| 7. | Vladimir , 38 years old (prom.ua), Uralsk: the speedometer already has 45,000 km, and the rubber bands on the stabilizers already need to be changed. Worn out very quickly, poor quality. It's better to buy from Kia, Toyota. |

| 8. | Mikhailovich , 44 years old, Moscow (avtoflit.com): I drove the originals for two winters, but it didn’t last longer. I heard that spare parts from Kia and Toyota are compatible. You need to get advice and install it at a service station. |

| 9. | Vladlen , 34 years old, Voronezh (drive2.ru): dissatisfied with the quality of production of the original bushings, they have already flown 45,000 km. I will buy foreign analogues, since the quality there is much better. |

| 10. | Mikhail Petrovich , 35 years old, Pskov (autotoday.com): on my first car Lada Granta, the spare parts took longer to take care of, why this is the case with the Lada Vesta, I don’t know. I think the reason is the quality of domestic components. |

↑ Installation of new

Essentially, this is the reverse process of removing the old stabilizer bushings. But in reality, everything turns out to be a little more complicated: the analogues do not always match in size with the “native” parts of the Lada Vesta, it is quite possible that to adapt them you will have to use the widely known “method of modification with a file” among the people.

To do this, you need to have confidence in your own abilities, or you will have to contact specialists at the nearest service center. Searching by article number for the stabilizer bushing on the Lada Vesta will help if you have an understanding of what the part looks like in real life. There are several different options, for example, higher inserts from Chevrolet or from Kia, with a pressed-in clamp. “Nivovsky” parts are ground down to reduce their height, then a special slot is made in them.

Korean ones most often coincide in dimensions with Western ones, but may differ in the method of fastening. To avoid future problems and questions about which stabilizer bushings are suitable for the Lada Vesta, it is best to select a replacement with the removed part in hand - the method is old, reliable and time-tested. The new rubber band must fully match the dimensions of the old one, including fasteners.

Therefore, you should check with the seller in advance (especially if we are talking about expensive Korean analogues) how to secure the bushing. This smart approach will eliminate the need for repeated visits to the store, ordering additional items or exchanging purchases.

Important. Compatible spare parts can exist in 2 versions: with pressed-in eyes for installation and mounted on a clamp. Both options should be worked out in advance by talking with the salesperson at the auto parts store.

As a rule, the success or failure of the operation will quickly manifest itself: if after 1-1.5 thousand kilometers the noise does not recur, it means that the installation of new components was justified. Otherwise, you will have to start the quest again to select high-quality shock-absorbing liners.

This is why the process of initially determining compatibility (and originality) is so important: you will not need to re-purchase elastic bands and go through the hassle of installing them.

How to correctly change the Lada Vesta SPU airbags?

The technology for performing repair work on changing the rubber pads of the stabilizer bar is simple and accessible to the vast majority of motorists. Of course, if the car is under warranty, then this should be done by the mechanics of the dealer's car service center.

Preparatory activities

To carry out repair procedures, you do not even need to remove the engine protective apron. However, no one has canceled the availability of a small set of tools; for work you will need:

- Torx key T40.

- Ring wrench “16”.

- Socket wrench “13”.

- Driver, extension and 10mm socket.

- Silicone Grease.

For a comfortable and high-quality replacement of faulty stabilizer bushings on a Lada Vesta car, you need at least an inspection hole or overpass, and in the best case, a lift. Before putting the car in for repairs, it is worth washing it thoroughly, especially in the area where the work is being carried out.

Causes of squeaking and ways to eliminate it

Drivers consider the appearance of a squeak to be a harbinger of an imminent breakdown of the noisy unit. If the vehicle's chassis is configured correctly, the moving joints should not make any sounds. However, worn friction pairs may creak when moving relative to each other. This phenomenon often occurs in cars with high mileage, but components of a new vehicle can also become noisy. The source of a squeak when the car is stationary cannot always be determined. To find it, car mechanics alternately wet the hinges with penetrating lubricant or water. The disappearance of noise indicates a faulty part.

For your information!

In wet weather, after overcoming deep puddles, the squeak may disappear and appear again after the suspension parts have dried.

Ball joints and ends

Checking the front suspension arms, steering rods, stabilizer struts will allow you to identify a damaged joint. The design of the latter is a steel pin with a sphere at the end, which is clamped in plastic inserts. When the lubricant in the ball joint stops reducing the friction force (it has dried out or been washed out with water), a squeaking noise may appear when the parts move together. Hinge diagnostics:

- Inspect the anther. There should be no traces of grease, rust, or damage on it.

- Unscrew the hinge and remove the protective cap.

- By rotating the pin, inspect the condition of the sphere; the presence of corrosion products, chips, or scuffs on it is not allowed.

- Check the play. To do this, vigorously move the finger from side to side. Ease of movement is a sign of excessive wear and the part should be replaced.

After inspecting the hinges, the unsuitable ones are replaced with new ones, and the serviceable ones are filled with fresh lubricant before being installed in place. Assembly procedure for the old one:

- The hinge is washed in gasoline or kerosene, thoroughly wiped and dried.

- Fill the cavity with new lubricant.

- Install the boot on top. If the old one is damaged, you need to install a new one.

- Place the hinge in place.

Shock absorbers

In conditions of poor quality road surface, the racks quickly fail. Oil drips near the neck indirectly indicate damage to the shock absorber. The creaking of the latter occurs when the rod rubs against the sealing elements, or at the points of attachment to the suspension units. A little penetrating lubricant applied to the mating surfaces and subsequent movement of the vehicle will help determine the source of the noise. For accurate diagnosis, problem areas are moistened one by one.

Oil shock absorbers are subject to restoration. Other types of racks must be replaced. Repair sequence:

- Dismantle the shock absorber.

- Disassemble the sealing unit and wash all parts with gasoline.

- Inspect the rod, piston and cylinder. Dimensional deviations should not exceed acceptable standards (they are different for each model). If the difference is greater, the working surfaces are bored to the repair size, followed by honing.

- Fill the oil to the indicated mark and reassemble everything in the reverse order.

- Install a new sealing unit. The latter, if the rod and cylinder are bored, must be of repair size.

- Put the shock absorber in place.

Anti-roll bars

Stabilizers are attached to the car body through rubber or polyurethane bushings. The latter allow the parts to rotate around their axis. When materials are abraded, a small gap is formed at the contact point. As a result, the stabilizer creaks and moves freely. To determine the source of the sound, you must use an inspection hole. Positioned near the stabilizer, rock the car. The amplitude of movement is enough to find a noisy place. Worn bushings definitely need to be replaced.

For your information!

If you plan to postpone the repair, you can place a piece of a car or bicycle inner tube under the rubber inserts. This will delay replacing the bushings for a short time.

Silent blocks

This design combines metal clips and rubber bushings. Most often, creaking occurs when they move mutually. The phenomenon is absolutely normal even for new cars. It is not necessary to change the silent blocks; it is enough to inject graphite lubricant into the friction zone using a medical syringe with a needle. The procedure is performed without removing the parts.

A car's suspension is directly related to the safety of the driver and other road users. If a squeak occurs in the suspension area, you should diagnose the chassis elements. Only in this case is it possible to assess the condition of all component nodes.

How to solve the problem yourself

This issue has already been discussed quite a lot on the Internet in car forums about the Lada Vesta and quite a lot of solution options have been proposed. Let's talk about the most popular methods.

- Bushing lubrication. Here you can follow the path of dealers, but only use higher quality lubricating fluids for lubrication. The choice here is limited only by your imagination. From banal lithol to Japanese expensive lubricants. The disadvantage of this method lies in its fragility. Be prepared for the problem to return to you after the first good rain.

- Replacing bushings. If the problem needs to be solved once and for all, then we suggest taking the path of replacing the rubber bushings. Today, automakers from different countries are trying to follow the path of unification, so car owners are very lucky in that a low-quality part can be replaced with an analogue from another car brand. The same can be applied to the rubber bushings of the anti-roll bar on the Lada Vesta car.

AvtoVAZ official opinion

To answer thousands of questions from car owners about stabilization problems, AvtoVAZ has the following opinion; These are design features of the model caused by the long working strokes of the struts when driving on uneven roads.

- bushing lubrication;

- installation of rubber-metal hinges, .

Point one is reminiscent of servicing the Volga GAZ-21. It recommended lubricating ten lubrication points under the car body, after rain and once a week. True, no one suggested doing interesting things like lubrication of bushings. The most unclear thing is how to smear them. Whether it is worth disassembling the stabilization unit or not is still unknown. Although old cars can still be found on the roads and nothing creaks or breaks for years.

Regarding the short operation of the stabilizer struts: They promise to bring them to normal condition. Now the problem is caused by the liner, which creates play inside the ball joint. Replacement of stabilization struts can be done free of charge at the dealer, it does not cause problems, they know about the problem with the stabilization unit and are ready to make repairs. But in this case, it’s much more profitable to learn how to change yourself. The reason for this is quite obvious. Replacing standard spare parts at a dealer does not imply the installation of spare parts or consumables from other brands of cars.

How to change the stabilizer struts yourself in 5 simple steps Replacing the stabilization struts on a Lada Vesta car comes down to a simple algorithm, but there is also preparatory work: It is necessary to hang the front wheels of the car. Firstly, this is required by safety measures. Secondly, it’s much more convenient to work this way. Let's get started:

- The stabilizer link pin nuts are cleaned;

- The nut is turned out from the top of the part, keeping the ball joint pin from turning;

- The nut is turned out from the bottom using a similar tool;

- The anti-roll bar is removed, the ball joint pin is removed from the front suspension strut and from the anti-roll bar;

- To check the anti-roll bar link, you need to pull out the top pin of the ball joint, grab it firmly with your hand and swing it up and down. The presence of a knock indicates a faulty part. Installation of the node rack is performed in the reverse order. When starting a repair, you can watch the entire process in the video.

Something happened that many car enthusiasts in our country were waiting for - AvtoVAZ created a high-quality Lada Vesta car. To expect that he will be devoid of shortcomings is, if not stupid, then naive. But I wanted them to be insignificant and not disturb too often.

It’s been 3 years since the serial production of the car and it’s safe to say that the domestic auto industry has made a big step forward. The car turned out to be not only beautiful, comfortable and affordable, but also reliable.

Among the few shortcomings of the car are poor-quality stabilizer struts, which are not able to withstand the high load of driving on damaged roads. As a rule, this part fails first.

As AvtoVAZ representatives assured, the car’s suspension is reliable and can easily withstand the load of bad roads. But this turned out to be untrue, since many owners complain about the appearance of minor noise when driving on rough roads after 5-10 thousand kilometers.

In most cases, noises and knocks are associated with a malfunction of the stabilizer struts. If you contact an official dealership and have a warranty, the problem will be resolved quickly. But, as practice shows, many experienced car enthusiasts prefer to repair the suspension themselves.

Knocks in the rear suspension

Judging by the reviews of car owners, Renault left Vesta a legacy of fairly rapid wear and tear of the silent blocks of the rear beam. They begin to bother you already at the third ten thousand kilometers. Another reason for knocking noises can be the destruction of the shock absorber support.

Diagnostics

Diagnosing a problem with a car's rear suspension is not easy, despite its simple design. The difficulty lies in the massiveness of the parts, so full diagnostics can only be carried out on a special lift.

Repair

To the delight of car enthusiasts, the rear suspension of the Lada Vesta has one advantage: it is easy to repair. You can even replace shock absorber mounts at home. But changing the silent blocks of a beam without a lift is very difficult. It is advisable to contact a car service center with such a problem.

The article does not reveal a step-by-step repair algorithm, but it answers the question of how you can diagnose the malfunction yourself. If you know the list of works, then the likelihood that the car service center will try to impose unnecessary work is reduced to zero, and this is a direct cost savings.

Even during the release of the first batches of Vesta from the assembly line, buyers rightly noticed shortcomings in its work, which were corrected in subsequent batches. The sounds that the rear or front suspension can make are very varied - the design is very complex, consisting of many parts that can fail. However, the most common breakdowns among Lada Vesta owners stand out and are worth disassembling.

Creaking, crunching, knocking from the rear suspension of the Lada Vesta

Rear crunching is a fairly old problem for West. The knock of the rear chassis is corrected according to a special instruction from AvtoVAZ, according to which the design will have to be slightly supplemented. Between the upper support and the rear shock absorber strut you need to place a washer with a length of 130 mm, a distance between the holes of 100 mm (hole radii - 5 mm), a base radius of 34 mm, and finally a radius of the main hole of 25 mm.

The crunch will disappear, but only if the washer matches the dimensions, otherwise a gap will appear between the body and the support, into which dirt gets trapped. The cause of concern due to crunching or knocking may also be:

- worn trunk lid damper;

- stretched handbrake cable (it can be pulled from the passenger compartment);

- trunk lock;

- rear sofa backrest fasteners.

And just in case, check the contents of the trunk itself - there may just be tools rattling around there.

Bumping knocks and noises in the front suspension of Lada Vesta

- The first, most popular reason for calling for service is the thumping (knocking) sound of the front suspension of the Lada Vesta, which comes from the stabilizer. Typically occurs when driving over artificial bumps. Stabilizer bushings, unfortunately, are not suitable for long-term use; even lubricant will not help - the only way to treat them is by replacing them. To solve the problem, you can install polyurethane bushings from Niva Chevrolet, its number is 17-012-680.

- The second reason for knocking can be called play of the ball joint, when a large gap is created between the parts. Problems can be solved by changing the design with levers. A grinding noise can be heard due to wear on the stabilizer struts and can mean that the car is gradually “losing” confidence when cornering.

- The creaking of the front suspension is caused by the hinges of the stabilizer struts. While driving, a knocking noise may occur due to insufficient tightening of the wheel bolts. When such a sound is heard, it is better to contact a service station as quickly as possible to prevent parts from breaking.

- The reason why the suspension on the Lada Vesta rattles and creaks can be heard may be that one of the parts has worn down to a sufficient level and is now knocking against another. To notice damage in time, it is enough to periodically inspect your car. If something is rattling, the part can be identified by shaking the car.

- If crunching or knocking noises in the front suspension are heard infrequently, the cause most likely may be a torn steering rod oil seal. This oil seal is in very close contact with the subframe of the vehicle (the distance between them at rest is 1 cm), and they collide at every bump. The oil seal breaks, and the connection of the rod to the rack hits the subframe.