The front and rear suspension of Vesta differs significantly from the one that AVTOVAZ used on Grant, Priora, Kalina, etc. All the reviews tell us that the new chassis design is better than before. However, during the first months of operation, the owners began to notice extraneous noises (knocks, creaks, rattles, crunches) in the front and rear suspensions of Vesta, which occur when driving over speed bumps or other road irregularities...

Rattle in the front suspension on Lada Vesta

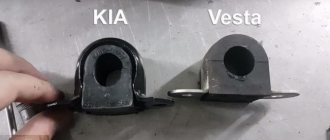

The most common cause of squeaking is the stabilizer bushing

The increasing grinding noise of the front suspension of the Lada Vesta is especially worrisome, because the main load , the steering and braking systems are located, the condition of which must always correspond to the norm.

A front-wheel drive car, as in our case, is prone to problems with the nose.

Creaks in the suspension are Vesta's disease!

Even new Vestas begin to creak after a short period of operation.

Inspection of the front suspension.

The very first cause of the malaise is considered to be an unfinished design of polyurethane stabilizer bushings , which almost immediately begin to make groaning sounds when driving through plump speed bumps. In wet weather he begins to moan constantly, which is very exhausting.

This problem can be corrected in several ways, radical and not so radical:

- Replacement of pillows with analogues from Chevrolet Niva or other suitable foreign cars.

- Regular application of mastic to places where polyurethane rubs against metal.

- Wait until AvtoVAZ corrects the defect, inviting everyone to the service station for a replacement.

Self-diagnosis of problems

If there is a knocking sound in the steering wheel or the Vesta suspension rattles, you should immediately contact the dealership.

If this is not possible, you can diagnose and identify problems yourself. To do this, just hang up the Lada wheels and do the following work:

- Let's rock the wheels in different planes; if play is felt when the brake pedal is released, this indicates that the hub bearing has failed;

- If there is a problem with the suspension, play is felt regardless of whether the brake pedal is pressed or released;

- If the ball joint is defective or the strut is poorly secured, play is felt in the vertical plane;

- Failed tie rod ends are accompanied by play in the horizontal plane.

Thus, it becomes clear why the front suspension of the Lada Vesta creaks. It is not recommended to drive with such defects; if they are detected, you must contact a service station. And at the dealership they will conduct a full diagnostic of the chassis and not only give recommendations on how to eliminate the crunching sound in the front suspension, but will also carry out the repair work in a qualified manner.

Problem with stabilizer links

The problem with squeaks in the front suspension can be solved by replacing the stabilizer bushings with polyurethane.

If after performing one of the operations the grinding does not stop, then you can go further down the list.

What else could be wrong with stabilizers? The design has a strut that is attached to the shock absorber body and the cross member of the stabilizer itself. It has two fingers as fastening. Without diagnostics at a service station, it will not be easy to figure out whether there is a breakdown in this unit, but you can try.

Official opinion of AvtoVAZ

Dealers replace stabilizer links free of charge. But sometimes you have to butt heads!

The problem with the struts is not far-fetched , since in April 2021, official representatives of AvtoVAZ reported that they knew that after just a few thousand kilometers Vesta was already detecting knocking and creaking noises from this particular unit. This important element experiences special stress and wears out prematurely.

There was no word on whether the fault was a manufacturing defect.

Replacement of struts on Lada Vesta for free

Replacement of squeaking elements at the dealer should be free of charge. All questions can be resolved by calling the hotline!

However, all car owners who complain about the performance of the struts during the warranty period will have them completely replaced at the dealership free of charge .

It is noteworthy that we are not talking about installing a repair kit, but a complete replacement of the unit.

So, if the warranty has expired, you will have to try to solve the problem yourself. The replacement process is simple. After inspecting the removed parts, you can decide whether to replace the entire mechanism or limit yourself to a repair kit.

Forward Auto

That's what I did: I called Forward Auto. They immediately surprised me with the first phrase after the greeting: they said that by not hanging up the phone, I agree to the processing of personal data and agree to the use of my phone number and the content of the conversation - no application!!

Well, okay, they offered to come to them tomorrow with a warranty card and order bushings of a new type that the plant produced, but they said, I quote: “within a MONTH (!!) MAYBE (!!!) they will come!” A limited number of them have arrived and they are calling clients who contacted us back in February (how poor they have been driving for one and a half to two months with a creaking suspension!), who also confirmed that “they used to lubricate, but the lubricant does not help.”

He asked: should I drive a creaking car for a month?

They answered: it turns out like this...

Do you have to drive for a month (maybe(!), or maybe more!!) with a creaking suspension?

Other causes of squeaks in the front suspension

Lada Vesta does not have any other serious problems other than those listed above.

The front suspension is designed reliably, similar to foreign brands, taking into account long-term use.

Quite often, extraneous squeaks are caused by brake calipers.

There are isolated cases where the following types of breakdowns have occurred over time:

- The silent blocks of the steering gear levers require , which are extremely inconvenient to remove.

- Brake calipers may gradually begin to click , replacing the pins may solve this problem.

- A small play appears in the place where the strut cups are attached to the body , associated with wear on the threads of the mounting bolts.

Loose wheel bolts

The situation when the fastening bolts of one or several wheels have become loose is typical not only for Lada Vesta, but occurs frequently. There can be many reasons - from inattention during tire fitting to an unsuccessful attempt to steal a wheel.

If a knocking sound occurs while driving, the first step is to perform the most accessible action - stop the car and check the tightness of the wheel bolts, since a tire that falls off while turning can cause the car to roll over with unpredictable consequences. In this case, diagnostics is inseparable from troubleshooting.

After tightening the bolts or making sure that the reason for the knocking is not their tightening, you can continue driving. If the problem is not solved, you should not put off diagnosis for a long time. In order not to aggravate the situation when one malfunction causes another, it is strongly recommended to contact an authorized dealer as soon as possible for qualified diagnosis and elimination of the causes of knocking or other abnormal suspension noises performed on a car raised by a lift.

conclusions

In addition to these factors, time plays a decisive role.

If the service life of some units has come to an end, then they need to be replaced urgently, since one breakdown can lead to others, and the entire mechanism will go into disarray.

If we return a little to squeaks, then with significant fatigue of the ball joints, steering tip and rack, failure of the shock absorber, or its broken supports, unnatural irritating sounds may appear. Then it is best to go for a diagnosis and then treat the problem.

What creaks and knocks in the cabin

At the back, the rear shelf creaked where it touched the glass.

The plastic trim of the triangular window also creaked - I simply sealed all the fastening points. When I bought the Lada Vesta in 2021, I read a bunch of reviews about the first series of cars. There have been complaints about the seat belt retractors rattling in the rear and front. The owners removed the rear shelf, the plastic trim on the front, tightened it, and inserted additional washers.

I avoided this flaw, but it cannot be ruled out even on new machines. Handles and door cards may creak in front. There may also be squeaks behind the instrument panel. There may also be noise behind the multimedia system. Also, the glove compartment lid sometimes knocks, or the light switch limit switch is not pressed all the way.

There was an adhesive seal there, but it came off. The glove compartment body creaked, I glued it. The sun visors may rattle on uneven surfaces. The passenger one has not yet been replaced under warranty due to knocking on the trim. The central pad on the steering wheel also creaked. It was glued by the personal manager himself on his initiative. Now the steering wheel is new, replaced under warranty due to wear on the lower insert. There are no extraneous noises now.

First maintenance of Lada Vesta

What kind of work does the first maintenance for the Lada Vesta sedan consist of? This includes replacing the oil, air and cabin filters, changing the engine oil, checking the condition of the brake pads, as well as diagnosing the engine control unit using a special scanner. At the official service station of the Lada brand in Kazakhstan, German synthetic oil Rowe 5W40 was poured into the Lada Vesta of automotive journalists. It was chosen because it is officially supplied to the car showrooms of this dealer network in Kazakhstan. The Lada Vesta engine control unit was checked for errors using a special scanner, which had an interface similar to the Windows 8 operating system. This equipment is certified for the Lada Vesta model car. According to specialists from the official Lada service station in Kazakhstan, this device costs about 300,000 rubles. Fortunately, this device did not show errors in the Lada Vesta engine control unit.

This is what the error scanner looks like for the Lada Vesta engine control unit.

When lifting the Lada Vesta car onto a lift, it was immediately discovered that the winter tires of the Nokian Nordman 5 model had lost quite a lot of studs in the conditions of winter Russian roads.

Problems with noise and squeaking from the rear of the car

Creaking from the rear of the car Malfunctions can also manifest themselves as a knocking sound in the rear suspension when driving over uneven surfaces or a creaking noise from the rear. All these sounds signal a problem that needs to be solved. In order to remove it, as recommended by the factory, it is necessary to cut out the gasket and install it on the upper shock absorber support. This will eliminate knocking in the Lada Vesta suspension.

Poorly spun wheels can crunch and squeak. This often occurs on other car models and is caused by the car owner’s carelessness when changing wheels. It is urgent to stop and tighten the wheels.

Poorly packed items in the trunk of a car can make knocking and crunching noises. Before trying to eliminate suspension squeaks, you should empty the trunk of all unnecessary things and drive the car.

If there are no extraneous sounds, then the issue is resolved. Sources of extraneous noise from behind can also be minor problems, but to eliminate them you need to know them:

- The handbrake cable is not secured, just tighten the tie;

- The trunk lid dampers may make different sounds; they should be lubricated with silicone grease;

- With increased play, the trunk lid begins to rattle; lubricate and eliminate the play;

- The locks of the rear seat back may squeak, just lubricate and wrap a little electrical tape;

- Things are poorly packed in the trunk.

The engine is the holy of holies of any car, and therefore, when extraneous sounds begin to be heard from under the hood, car owners immediately sound the alarm and try to figure it out.

Support bearing knock

Often, car enthusiasts perceive the shock of the shock absorber rod as the knock of the wheel bearing.

This can be explained by the design of the rack: two cylinders and a metal rod. During systematic use, the bypass valves wear out and the strut does not dampen vibrations. With a sharp push, a blow occurs, which is perceived as a knock of the support bearing.

To guarantee that the latter is faulty, it is necessary to conduct a comprehensive diagnosis. It’s not difficult to do this yourself; in the transport position of the car, it’s enough to bleed the strut with a few presses on the car’s fender. After sharp pressure, the car must stabilize on its own, otherwise the shock absorber strut is faulty.

If there are no complaints about the shock absorber, then you are guaranteed to replace the support joint. The process is quite complex and requires minimal knowledge in servicing equipment. Unprofessional intervention does not guarantee full functionality of the mechanisms.

In order to carry out comprehensive diagnostics and replace worn-out equipment, contact a certified service station for help.