In this article we will talk in detail about replacing spark plugs on a Lada Largus car with an 8 and 16 cl engine. The manufacturer recommends replacing spark plugs every 30 thousand km. This is exactly what the life of the candles and their performance are designed for.

Lada Largus cars are equipped with engines from Renault, so the spark plugs are suitable specifically for engines of this brand.

Which spark plugs are suitable for a 16 cl K4M engine?

If you have a Lada Largus with a 16 valve engine, the original Renault spark plugs 7700500155 will suit you. The official analogues of these spark plugs are Motrio 224018651R. If you can’t buy such candles from us, you can get by with analogues from other manufacturers:

- BOSCH FR 7 LDC+ 0242235668 price from 600 rubles per set

- DENSO K20TT K20TT#4 price per set from 550 rub.

- CHAMPION RC87YCL

- SAGEM RFN58LZ

The above spark plugs are suitable for a 1.6 16 cl engine. K4M 102 (105) hp To replace the spark plugs, we need a spark plug wrench with a size of 16 and a socket with a size of 8 in order to unscrew the ignition coils.

The difference between replacing spark plugs on 16-cl and 8-cl engines is that on 16-valve engines each spark plug has a separate ignition coil, and on 8-valve engines there is only one coil. Also, spark plugs have different potassium numbers, plug types, diameters and gaps.

Purpose of candles

The only functional purpose of these consumables is to generate a spark. It occurs due to the discharge between the electrodes of the product. By means of the generated spark, the mixture present at a certain moment in the combustion chamber in a compressed state is ignited. This is the basis for the principle of movement of a car equipped with an internal combustion engine Lada Largus.

Over time, the ignition elements wear out the electrodes, which causes interruptions in spark formation. Also, due to incorrect mixture formation, the working elements become overgrown with carbon deposits, which leads to a deterioration in the quality of the spark. A power unit suffering from oil leakage through the oil reflective caps can provoke the formation of plaque on the insulators, which is a harmful factor for these products.

The most common signs of failure include:

- difficult cold start of the Lada Largus engine, especially in winter;

- interruptions at idle, as well as misfires in all modes of crankshaft rotation;

- uncertain acceleration dynamics;

- increased fuel consumption.

Such significant symptoms force Lada Largus owners to regularly check the condition of these consumables and clean them.

Renault Duster rear view camera

Kia Sportage or Renault Duster, which is better?

Renault Sandero cabin filter replacement

Instructions for replacing spark plugs on a 16 valve engine

To avoid getting burned, it is best to carry out the replacement when the engine has cooled down. The first thing we need to do is remove the pads from each ignition coil.

To do this, carefully press the latch and disconnect each coil.

Using an extension and a 8mm socket, unscrew the bolt securing the coil to the body.

Now carefully pull the coil out of the well and put it aside.

Using a 16 mm wrench, unscrew the spark plug, then install a new spark plug, screw it in, put on the ignition coil and screw it in, generally reassemble in the reverse order. We change the spark plugs on the remaining cylinders in the same way.

Tighten the spark plugs with a force of 25–30 Nm.

After replacing all the spark plugs, no action is required to configure and adapt the motor.

How to remove ignition coils on K4M and K7M engines

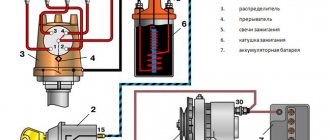

The ignition system of the K4M engine consists of individual ignition coils and spark plugs for each cylinder. There are no high-voltage wires in the ignition system - the tip of the coil is placed directly on the spark plug.

The ignition system of the K7M engine consists of an ignition coil, high-voltage wires and spark plugs. The K7M engine has an ignition module, which is a block of two coils.

The tips of high-voltage wires are connected to the terminals of the secondary windings of the coils. The current in the primary windings of the ignition coils is controlled by the ECU depending on the engine operating mode.

The coils are powered sequentially in pairs. Thus, a spark simultaneously jumps in two cylinders (1-4 or 2-3) - in one at the end of the compression stroke (working spark), in the other at the end of the exhaust stroke (idle).

Removing and installing ignition coils

We prepare the car for the job. Using a 10 key, disconnect the negative terminal of the battery.

On the K4M engine, disconnect the wiring harness blocks from coils 1.

Rice. 1

Using a 8mm socket, unscrew the 2nd bolts securing the ignition coils and remove them.

Before installing the ignition coils, you need to replace the bolts 2, the coil fastenings and, if necessary, replace the coil sealing rings.

Before installing the coils, you need to apply FLUOSTAR 2L with a thickness of 2 mm along the inner circumference of the ignition coil cap on the side of the spark plug and ignition coil.

Install ignition coils 1 onto the spark plugs, screw in and tighten the ignition coil mounting bolts. Bolt tightening torque 14 N.m (1.4 kgf.m) (replaceable head 8, extension, wrench, torque wrench).

Connect the wiring harness connectors to the ignition coils.

Connect the earth wire terminal to the battery (spanner 10).

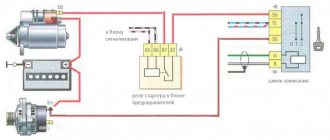

Removing and installing the ignition module

Disconnect connector 1, wiring harness from ignition module 2.

Rice. 2

Disconnect the ends of the 3 high-voltage wires from the module.

Rice. 3

Using a TorxT30 screwdriver, unscrew bolts 1 securing the ignition module and remove module 2 (Figure 3).

Installation:

- Install ignition module 2, Figure 3, screw in and tighten bolts 1 securing the ignition coils. Bolt tightening torque 15 N.m (1.5 kgf.m) (Torx T30 screwdriver, replaceable Torx T30 attachment, extension, torque wrench).

- Attach tips 3, Figure 2, of high-voltage wires to the ignition module.

- Connect block 1 of the wiring harness to the ignition module.

- Connect the negative terminal to the battery (spanner 10).

Typical unit malfunctions

The short circuit is a reliable unit with a long service life, but it can fail.

Signs of a short circuit fault:

- engine power decreases;

- failures at certain speeds;

- misfires;

- high fuel consumption;

- work with jerks at idle;

- coil overheating due to internal short circuit;

- The Check Engine light comes on.

Based on these signs, it is impossible to say for sure that the short circuit is faulty. Therefore, its diagnosis is necessary.

Instructions for replacing spark plugs on an 8 valve K7M engine

So, remove the tip from the candle and before we begin to remove it, use a pump or a rag to clean the area around the candle. This is necessary to ensure that no dirt or grains of dust get into the well.

Using a 16mm spark plug wrench or a similar head, unscrew the spark plug and screw in a new one.

Then we put on the tip and replace it on the remaining cylinders.

The tightening torque of the spark plugs is 25–30 Nm.

If you remove all the tips from the candles at once, then remember how they stood, or carefully look at the order in which they were installed. Each wire is installed on a specific cylinder; the number can be found on the module (ignition coil).

Recommendations for replacement intervals

Officially, replacement of original spark plugs on Lada Largus is required every 30 thousand km. When used in domestic conditions, the service life of consumables barely exceeds 15 thousand km. The reason for this is the low quality of the fuel sold.

During operation, unscheduled replacement of spark plugs may be required. The main reasons for carrying it out are:

it is impossible to adjust the gap; the spark plug has one of the damages shown in the image below.

Video

Sources

- https://logan-50.ru/otechestvennyj-avtoprom/svechi-zazhiganiya-na-lada-largus-podbor-zamena-rekomendacii-po-ekspluatacii-8-i-16kl-motor.html

- https://olade.ru/zamena-svechej-zazhiganiya-na-lada-largus

- https://cleanerauto.ru/svechi-zazhiganiya-na-lada-largus-podbor-zamena-rekomendacii-po-ekspluatacii-8-i-16kl-motor.html

- https://bakstrer.ru/smotrim-kakie-rodnye-svechi-na-Larguse.html

- https://avtomechanic.ru/lada-largus/elektrika-largus/zamena-katushek-zazhiganiya-avtomobilya-lada-largus

- https://avtozam.com/vaz/diagnostika-i-zamena-uzlov-sistemy-zazhiganiya/

Spark plug table for Lada Largus (articles) from 2012 to present

| Engine | Number of valves | Spark plug used | Gap | Analogue | Key size | |

| Denso | NGK | |||||

| 21129 | 16 | 21120-3707010-86 | 0.8 mm | Q20PR-U | BKR5E-11 | 16 mm |

| 11189 | 8 | 21110-3707010-86 | 1.1 mm | W20EPR-U11 | BPR6ES-11 | 21 mm |

| K4M | 16 | 224018651R | 0.8 mm | K20PR-U | BKR6E | 16 mm |

| K7M | 8 | 7700500252 | 0.8 mm | K20PR-U | BKR6E | 16 mm |

Contact? I have contact

Let's start with the most common single-pin spark plugs.

The manufacturer of the K7M power unit with 8 valves provides for the installation of Renault spark plugs - a simple and reliable ignition source. It is manufactured mainly in France or in other countries under the strict control of the developer. Among high-quality analogues, it is recommended to use candles from manufacturers such as Bosh, Denso, NGK.

Among the best developments are the German Bosch FR7DC+ with iridium coating, the Japanese Denso K20PRU11 and NGK 4856 BKR6E. These models are distinguished by proven quality and long service life. All of them are equally successfully installed on the K7M 710 or the K4M 690, which has 16 valves.

When replacement is required

The spark plugs should be replaced in accordance with the vehicle maintenance regulations, that is, every 15 thousand km. These are the requirements when it comes to standard spare parts supplied by the manufacturer. There are many innovative types of these platinum plated or iridium plated parts available in the aftermarket today. In such cases, their service life is much longer.

Spark plugs must be replaced not only as planned or for preventive purposes, but also due to malfunctions. This could be contamination of the skirt with carbon deposits or oil when driving on a cold engine, or coking of the thermal cone caused by increased oil consumption. If replacement is not done in a timely manner, the electrodes may burn out, resulting in an increase in the gap and an insulation breakdown. One of the causes of problems may be a manufacturing defect, leading to the passage of gases through the insulator and housing. If these faults are present, the car does not start well or the engine begins to stall. This is unacceptable for further operation of the car - you need to find the damaged spark plug and replace it.