What is a rear stabilizer

The rear stabilizer for the VAZ 2107 is a curved C-shaped rod installed next to the rear axle of the “seven”. The stabilizer is attached at four points. Two of them are located on the rear suspension arms, two more on the rear side members of the “seven”. These fasteners are ordinary eyes with dense rubber bushings inside (these bushings are the weak point of the entire structure).

The rear anti-roll bar for the VAZ 2107 is a conventional curved rod with fasteners

Today you can purchase a rear stabilizer and fasteners for it at any spare parts store. Some drivers prefer to make this device themselves, but this is a very labor-intensive process that requires certain skills that a novice car enthusiast simply does not have. That is why the replacement of bushings on a finished stabilizer will be discussed below.

Purpose of the rear stabilizer

The anti-roll bar on the “seven” performs two important functions at once:

- this device gives the driver the opportunity to control the tilt of the car’s chassis, while the force acting on the camber of the rear wheels practically does not increase;

- After installing the stabilizer, the tilt of the suspension between the axles of the car changes significantly. As a result, the driver is able to better control the car;

- The improvement in car control is especially noticeable on sharp turns. After installing the stabilizer, not only does the lateral roll of the car during such turns decrease, but you can also take them at a higher speed.

About the disadvantages of the rear stabilizer

Speaking about the advantages that the stabilizer provides, one cannot fail to mention the disadvantages that also exist. In general, the installation of a stabilizer still remains the subject of fierce debate among car enthusiasts. Opponents of installing stabilizers usually justify their position with the following points:

- Yes, after installing the rear stabilizer, lateral stability increases significantly. But this is a double-edged sword, since it is the high lateral stability that makes it much easier for the car to skid. This circumstance is good for those who engage in so-called drifting, but for an ordinary driver who finds himself on a slippery road, this is completely useless;

- If a car enthusiast decides to install a rear stabilizer on his “seven”, then he is strongly recommended to install a front one, and not a regular one, but a double one. This measure will help prevent excessive loosening of the car body;

- The cross-country ability of a car with stabilizers is reduced. On sharp turns, such a car often begins to cling to the soil or snow with its stabilizers.

It is easy to notice that the ground clearance of a VAZ 2107 with a stabilizer decreases, which affects cross-country ability

Thus, a driver who is thinking about installing stabilizers should weigh all the pros and cons as carefully as possible, and only after that make a final decision.

Replacing stabilizer bushings

There is no need to remove the sway bar to replace the outer bushings. It is enough to remove the mounting brackets. Bracket connections are exposed to water and dirt. Therefore, in addition to a set of keys and a mount, you will need a tool that makes it easier to work with rusted threads. For example, WD-40.

The procedure for replacing the outer bushings is as follows:

- Treat the threads of the studs holding the brackets with an anti-rust agent.

- Unscrew the nuts and remove the brackets, remembering their location.

- Press the stabilizer up, inserting a pry bar between it and the lower arm.

- Remove old bushings.

- Inspect the stabilizer at the bushing attachment points. If significant wear is noticeable, replace it with a new one.

- Put on new bushings.

- Install the brackets and tighten the nuts. It is better to tighten smoothly, in three stages, gradually increasing the force.

To replace the inner bushings, the anti-roll bar must be removed. To do this, you will have to unscrew the brackets at all four mounting points.

Signs of a broken rear stabilizer

It’s not difficult to guess that something is wrong with the rear stabilizer of the VAZ 2107. Here's what's observed:

- a characteristic grinding or creaking noise, which is especially clearly heard when entering a sharp turn at high speed;

- a significant increase in vehicle roll when cornering and a decrease in controllability when cornering;

- the appearance of play on the stabilizer. Play can be easily detected by placing the car in an inspection hole and simply shaking the stabilizer bar up and down;

- destruction of bushings. The play mentioned above is almost always accompanied by the destruction of rubber bushings. They are squeezed out of their eyes, crack and completely cease to perform their functions.

On the right is a worn stabilizer bushing, the hole in which is much larger than in the new bushing on the left

All of the above things indicate only one thing: it’s time to repair the stabilizer. In the vast majority of cases, repairing the rear stabilizer comes down to replacing damaged bushings, since the fasteners and rod rarely need repairs. Such a need may arise only in the event of serious mechanical damage, when the driver caught a large stone or curb with the stabilizer, for example.

How should the stabilizer be positioned?

A properly installed stabilizer should be able to twist under the influence of forces on the wheels, and it should do this even when the forces applied to the right and left wheels are directed at completely different angles.

On the "seven" rear stabilizers are installed only with rubber bushings

That is, stabilizers on passenger cars should never be directly welded to the frame; between the frame and the wheel mount there must always be some kind of intermediate link responsible for compensating for multidirectional forces. In the case of the VAZ 2107, such a link is dense rubber bushings, without which it is strictly not recommended to operate the stabilizer.

The stabilizer on the VAZ 2107 is usually attached at four key points

Why does the stabilizer bushing squeeze out?

As mentioned above, the bushings on the stabilizer serve to compensate for the forces on the wheels. These efforts can reach enormous values, especially when the car enters a sharp turn. Rubber, even of very high quality, systematically subjected to enormous alternating loads, inevitably becomes unusable. Severe frosts and reagents that are used to sprinkle roads in our country during icy conditions also contribute to the destruction of bushings.

The rear stabilizer bushing is worn out, torn lengthwise and comes out of the clamp

It usually starts with cracking of the bushing surface. If the driver does not notice the problem in time, the cracks become deeper and the bushing gradually loses its rigidity. At the next sharp turn, this cracked bushing is squeezed out of the eye and does not return back to it, since the elasticity of the part is completely lost. After this, play appears on the stabilizer bar, the driver hears a creaking and grinding sound when entering a turn, and the car’s controllability decreases sharply.

About double stabilizers

Double stabilizers are installed only on the front wheels of the VAZ 2107. As the name suggests, there are already two bars in this device. They have the same C-shape and are located approximately four centimeters from each other. The mounting lugs in the double stabilizers are also paired. Otherwise, this design does not have any fundamental differences from the rear stabilizer.

Front stabilizers on the VAZ 2107 are usually made of two paired c-shaped rods

Why use two bars instead of one? The answer is obvious: to increase the overall stiffness of the suspension. The double front stabilizer copes with this task perfectly. But one cannot fail to note the problems that arise after its installation. The fact is that the front suspension on the classic “seven” is initially independent, that is, the position of one wheel does not in any way affect the position of the second. After installing a double stabilizer, this situation will change and the suspension will turn from independent to semi-independent: its working stroke will be significantly reduced, and in general the control of the car will become tougher.

Of course, the roll when entering turns with a double stabilizer will be reduced. But the driver should think: is he really ready to sacrifice personal comfort and cross-country ability of the car for the sake of its stability? And only after answering this question can you start working.

Purpose and design of the VAZ 2107 stabilizer

The design of the front suspension of cars of the VAZ 2101-07 family uses a front stabilizer, the task of which is to distribute the load as efficiently as possible. This is the load that the suspension of a domestic car experiences when turning and performing maneuvers on the road. Due to the presence of a stabilizer, the occurrence of a roll is eliminated, and the car is kept in a horizontal position. If you remove the front stabilizer, the driver will immediately feel how much the car will shift to one side during sharp turns or maneuvers. Moreover, the rolls are so large that the vehicle can tip over.

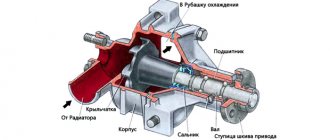

Structurally, the part of the suspension of the VAZ 2107 car under consideration consists of a long rod, which has the shape of the letter U. The rod is made of special steel, which has increased elasticity.

This is interesting! Springs for cars are made from similar steel, which have high strength, memory, and resistance to deformation.

The part in question is fixed using a bracket with a rubber bushing. The ends of the bar are secured to the lower control arms, and the middle area is secured to the front of the body. During operation, depending on the mileage and driving habits of the car, wear occurs on the rubber bushings or stabilizer pads. When they wear out, they need to be replaced. However, first let’s look at the design of the unit in question:

- The rod is made of steel with increased elasticity. The diameter of the part is 18 mm. It has a U-shape.

- Brackets for securing the rod in the structure of the machine chassis. Their quantity is 6 pieces.

- Rubber bushings of the same sizes and diameters in the amount of 4 pieces.

Read more: Where are Volkswagen Polos made in Russia?

Bushings made of rubber material are needed to soften the connection of steel parts. The stabilizer is attached in 4 places, but there are 6 brackets for fixation in its design.

The bar is activated only when the body shifts when turning or maneuvering. When driving in a straight line, the device is practically inactive. When maneuvering, one end of the device bends upward and the other downward, which leads to balancing stability. The harsher the driving style, the faster the rubber bushings of the front stabilizer on the VAZ 2107 will wear out.

Stub maintenance

The part in question rarely fails, however, as soon as the vehicle becomes unstable on the road, it is time to make repairs. When operating a classic, several types of malfunctions of the VAZ-2107 anti-roll bar bar occur. Some of these malfunctions include:

- The rubber bushings, which act as a damper between the rod and the car body, wear out.

- The pins that secure the device to the levers break off.

- The U-shaped fastening comes off. Four such brackets attach the middle part of the stub to the body of the seven.

Servicing the SPU is a simple process that includes replacing the rubber bushings. To change them, you will need to dismantle the part, remove the worn rubber bands, and replace them.

It is important! It is recommended to change all rubber seals of the stabilizer so that you do not have to replace it again after a short period of time.

Most often, rubber seals have to be replaced, and cases of stud breakage rarely occur. Usually the result of a breakage is extreme driving, so in order to prolong the life of the studs, it is advisable to drive moderately. Identifying a device malfunction is quite simple. If a roll occurs on sharp turns, accompanied by the formation of loud sounds, this means that the end of the rod has become free and is now in contact with the metal of the lever.

Changing classic stabilizer bushings

We recommend inspecting the bushings every 30–50 thousand km. However, parts can last 100 thousand or more if you drive moderately and do not overload the suspension. You can detect wear visually, but to do this you should look under the front end. The presence of cracks in the rubber bands, as well as visible gaps between them and the bar, indicate that the bushings need to be replaced. The more wear the rubber bands have, the higher the chance of hearing unpleasant knocks in the suspension and experiencing a deterioration in the car's handling. To restore the original controllability and control confidence, you will need to replace the VAZ 2107 stabilizer bushings.

Read more: Which picture shows a crossroads

To replace the rubber bands, you will need to completely remove the bar from the suspension. It is recommended to carry out work on replacing the device directly from the inspection hole or by placing the car on an overpass. The algorithm for replacing stabilizer bushings is as follows:

- dismantling begins with the need to jack up the front of the car, hanging both wheels. This will relieve the rod, which will simplify its removal;

- using a ratchet wrench with a 13 mm head, unscrew the nuts that secure the clamps of the device to the suspension;

- using a pry bar, you need to remove the brackets from the studs;

- dismantle the structure and mark the location of the old bushings;

- dismantling old rubber bands is very simple, since they already sit loosely on the stub and can simply be cut off or pulled together by hand;

- We recommend cleaning the inside of the device mounting clamps from rust. You can use a round file for this;

- treat the holes of the rubber seals with a soap solution, then put them on the rod to the place where the old ones are installed;

- install the stabilizer in place;

- When installing, the most important thing is not to mix up the ends of the stabilizer, otherwise the device will not function correctly. That is why before dismantling, appropriate marks should be made;

- screw the fastening clamps into place.

At this point, the replacement process is considered complete, and all that remains is to lower the front part and test the unit in action.