On the Lada Vesta, the design of the front suspension is not much different from previous VAZ models. Main components:

- Stabilizer's pole;

- Oil shock absorbers;

- Springs;

- Silent blocks;

- Suspension arms;

- Stretcher;

- Rubber boots, bushings.

During the operation of the machine, parts wear out, become deformed, and break into pieces. The simplicity of the suspension design allows you to carry out repairs yourself. We contact the service station in case of major repairs of the unit.

Originals, analogues, article number, price of stabilizer struts for Lada Vesta

Technical data: length 275 x width 30 mm x diameter 10 mm.

Stand structure: tip, metal base, rubber boot, retaining ring. The nuts are supplied complete with the original stands.

| vendor code | Cost, rub.) | vendor code | Cost, rub.) |

| Original front | |||

| LADA Vesta AvtoVAZ front left/right 8450006750 from 550 - 600 | |||

| Front analogues | |||

| CTR CLT50 | From 400 / unit | PATRON PS4035 | From 400 / unit |

| Kroner K303118 | —/— | JP Group 1140401100 | —/— |

| TRW JTS393 | —/— | Ruville 917814 | —/— |

| LEMFORDER 5459874 | —/— | SWAG365565 | —/— |

| VAG 6R0411315 | —/— | Renault 82006-69065 (new model) | —/— |

| SASIC 4005146 | —/— | LEMFORDER 2833401 | —/— |

| SIDEM 5666 | —/— | LEMFORDER 2600401 | —/— |

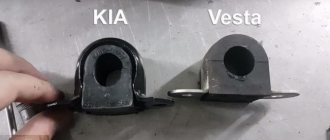

To the surprise of most Lada Vesta car owners, the model can be equipped with stabilizer bars from RAV 4 (TOYOTA RAV4), article number 48820-42020. The diameter is identical, completely matches. The same cannot be said about the length of the rod - 285 mm. In fact, 10.0 mm longer than standard size. However, this does not prevent the front suspension from working properly.

Before purchasing spare parts, do not forget to check the catalog number against the data in the operating instructions. Manufacturer's warranty is 80,000 km.

Replacement resource. Consequences of untimely prevention

Lada Vesta stabilizer struts are replaced under warranty after 50,000 km. In practice, the interval is shorter by 5–10 thousand km. If the machine is actively used on rough terrain, the “update” interval is reduced by a third.

The duration of use largely depends on:

- quality of road surface;

- driving style and manners;

- speed and temperature conditions.

When the first knocks appear in the front-wheel drive area, you need to visit a service station and order diagnostics using digital equipment.

Ignoring the vehicle’s “signals” contributes to a decrease in control efficiency. When cornering, the car rolls on its side, making it difficult to control the vehicle at speeds over 90 km/h. At higher speeds, emergency situations cannot be ruled out.

Lada Vesta suspension diagnostics

Before starting repairs, be sure to carry out diagnostics. This is necessary to assess the condition of the machine, identify breakdowns, and correctly calculate spare parts and consumables.

The process is not at all complicated, you can do it on your own. If you encounter any difficulties with installation, please read the instructions and watch video tutorials on the Internet.

- We drive the car into the inspection hole, fix the rear row of wheels with boots to avoid any arbitrary rollback;

- Jack up the side and remove the wheel;

- From under the bottom we press on the stabilizer bar, check for play, deformation, cracks;

- Additionally, we inspect the condition of adjacent parts, levers, and mechanisms.

To check the tightness of the fit, we use a metal pry bar. We summarize, analyze the received data, and calculate the number of necessary spare parts.

Finally, we check the brake pads, disc, and cylinder. If the actual thickness of the pads is less than 17.0 mm, they must be replaced with new ones. Subsequent operation of the vehicle is unsafe.

Principle of operation

The stabilizer is a metal pipe that is attached to the front wheels using rubber cylinders, each of which is called a stabilizer bushing. It provides the ability to rotate the stabilizing unit itself relative to the vehicle. The suspension of the Lada Vesta car was taken by the developers from the famous Renault, which has proven itself quite well on our roads. Therefore, the Vesta suspension design does not represent some new and unknown mechanism.

After some time during the operation of a new car, the owner may hear extra noise from below the bottom. The fastening elements of the car's suspension began to gradually fail. This occurs either due to the quality of the material from which they are made, or due to constant lubrication of the suspension bushings with sand, water and dirt. This contact is detrimental to this node. The driver begins to hear the bushings creaking; they have simply gradually become unusable. It is very rare for the stabilizer itself to fail, but you need to try hard. The repair comes down to replacing worn bushings on the Lada Vesta. This type of repair is very important for the safe operation of the vehicle.

Causes of wear on Lada Vesta suspension

- Saving on maintenance of technical equipment;

- Purchase and installation of low-quality parts;

- Violation of the rules for operating the vehicle by the driver;

- Manufacturing defect;

- Natural wear and tear of components due to prolonged use without intermediate preventive maintenance;

- Rupture of the boot, water entering the metal structure;

- Excessive wear of subframe silent blocks.

Review of prices of original manufacturers

| Catalog item | Price in rubles |

| LADA Vesta front left / right (8450006750), stabilizer link length 275 mm | From 700 |

| RENAULT Logan suspension mounting bolt (30768) | From 130 |

| Nut RENAULT 7703034221 | From 300 |

| Cushion bracket 8450006747 | From 350 |

| Rod cushion 8450006748 | From 450 |

*prices are current as of 03/06/2019.

Replacing stabilizer struts on Lada Vesta

We replace suspension elements in pairs; it is unsafe to leave worn parts in their original places. Repeated repairs will be required soon.

- We drive the Lada Vesta into the inspection channel and ensure safety measures during the work;

- Jack up the side, unscrew the bolts, remove the wheel;

- Alternately unscrew the upper and lower mounts of the stabilizer bar;

- We carry out troubleshooting of the mounting socket, if there are no defects, we install a new stand and screw the nuts.

If the silent blocks need to be replaced, additionally unscrew the fastening of the ball joint and remove the suspension arm. We fix it in a stationary vice and press out the worn silent blocks. We troubleshoot the lugs, clean the surface of rubber residues, and press in new polyurethane bushings. We assemble the structure in reverse order.

Motorists claim that polyurethane bushings are interchangeable with Lada Kalina. It is not yet known what they are suitable for.

Sometimes the source of the knock is worn out cross member bushings. To replace consumables, additionally unscrew the beam mount, remove the rubber bushings, and install new ones. We screw the mechanisms back on.

Why do you still need to replace?

Let's return to the principle of operation of the car's lateral stability unit. When the outer wheel turns, the force of inertia pulls the outer wheel in the direction opposite to the turn, and the inner one tries to break away from the road. Thus, the suspension of the outer wheel is compressed, which forces the stabilizer to rotate upward. This means that the part of the stabilizer closest to the turn attracts the wheel to the road, which, thanks to the force of inertia, tries to break away from the road. The stabilizer lever rotates inside the bushings. There is no point in explaining further why timely repair of failed elements of the stabilization system with high-quality new ones is necessary.

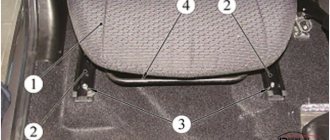

What you need to know about the rear suspension elements of the Lada Vesta

In the rear part, the suspension function is performed by a torsion beam, shock absorbers, springs, silent blocks pressed into the beam.

As the machine is used, parts wear out, backlash is formed, and free play increases. To eliminate the defect, it is necessary to replace the rear suspension elements.

- After removing the wheel, unscrew the upper and lower fastenings of the shock absorber strut assembly with the spring. Next, we unscrew the beam fastening, press out the silent blocks, inspect the mounting socket, and press in new bushings.

- Sometimes sagging rear springs make a metallic knock. Inexperienced motorists mistake this for a knocking sound from the stabilizer bar. To replace the spring, first remove the rear shock absorber and spring assembly.

- Using a crab-shaped puller, we compress several turns of the spring and disassemble the module. We install a new spring and assemble the structure.

- At the same time, we carry out troubleshooting of the brake circuit, pads, disc, and working cylinder. If the actual thickness of the pads is less than 19.0 mm, replace them with new ones. Subsequent operation of the machine is unsafe.

Dismantling sequence

The first step is to remove the wheel: unscrew the mounting bolts. If the nut does not budge (soured), VD-40 is used.

Rust is cleaned off and dirt is removed from the fingers of the stabilizing mechanism. The work is carried out using a metal brush.

The upper fastening nut is dismantled. You will need a ring wrench No. 16. To secure the hinge pin from turning, use a wrench No. 5.

Work with the lower fastening is similar in the sequence of removing the upper arm.

Tips for caring for Lada Vesta suspension

- We adhere to the manufacturer’s recommendations regarding the interval of scheduled technical inspection - every 15,000 km;

- The average service life of the suspension is 60 – 65 thousand km. Mandatory preventive maintenance after 15,000 km;

- Purchase components from official points, representative offices, dealers;

- Order paid car repair services only from those service stations that provide a quality guarantee for the work performed;

- Always check the compatibility of parts according to the catalog numbers specified in the operating instructions;

- After carrying out repair work at the service center, check that the technicians have entered maintenance data into the service book.

Driver, remember that a moderate driving style and original parts increase the service life of Lada Vesta parts by 7 - 10%.

Which stabilizer struts are best to install? Obviously, new ones and with factory catalog numbers. Installing parts from other models is a temporary solution to the problem, not always effective or correct.

Reviews

| № | Positive |

| 1. | Kirill , 33 years old (drive2.ru) Sverdlovsk: the car is three years old, there are no capital investments, except for the costs of scheduled technical inspections. The front end does not make noise, does not knock, I drive carefully, at medium speed. The car “sleeps” in the garage, and I systematically carry out diagnostics. |

| 2. | Anatolyevich , 43 years old (prom.ua), Krasnodar: I have no complaints about the suspension of the Lada Vesta, I use the car actively, every day. In two years, I checked the camber-toe angle once. |

| 3. | Gennady , 36 years old (autotoday.com), Omsk: I didn’t expect such good quality from a domestic manufacturer. Lada Vesta was a great success, I like it, good build. I have no complaints, I’ve been riding for a year and a half with pleasure. |

| 4. | Kirill Ivanovich , 46 years old (rozetka.ua), Rostov-on-Don: the car is three years old, like new condition. I look after the equipment, drive carefully, and regularly visit service stations for diagnostics. |

| 5. | Dmitry Vyacheslavovich , 42 years old, Kursk (avtoflit.com): my positive review of the Lada Vesta car. There is something to compare with, the previous model was Lada Granta, the quality is “weaker”. Well built, it turned out to be a solid car. Finally, a domestic manufacturer has pleased car enthusiasts. |

| 6. | Valentin , 34 years old, Voronezh (autotoday.com): I buy only original consumables; I don’t trust analogues, even high-quality ones. The car is in its fourth year, there are no comments on the suspension or chassis. I consider this a good indicator that I am on the right path. |

| 7. | Fedorovich , 45 years old, Ufa (drive2.ru): I saved on consumables once, but later regretted it. It was hardly 40,000 km, so I replaced it with original ones. The racks are still in service, no complaints. |

| 8. | Mikhalych , 39 years old, Bashkortostan (drive2.ru): during the three years of active operation of the car there were no critical breakdowns, all mechanisms operate as normal. There are no complaints about the suspension, I hope it will last for more than a dozen kilometers. |

| Negative | |

| 9. | Vasilyevich , 48 years old (prom.ua), Saratov: I’m not satisfied with the quality of manufacturing of the factory seeds; they served for 45,000 km, after which they replaced them with foreign analogues. The last ones were already 60,000 and without a hint of repair. |

| 10. | Davidich , 45 years old, Moscow (avtoflit.com): after the second winter, the suspension made itself felt. I drove onto the overpass, checked the hinges and racks - they needed to be replaced with new ones, there was some play. |

| 11. | Ivanych , 33 years old, Voronezh (drive2.ru): the car is in its third year, the front creaked, most likely the bones were worn out. For such a short mileage the resource is small. Comrades advised to buy foreign analogues, the price is 20 - 30% cheaper than the originals. I'll try it and post the results. |

| 12. | Vladimir , 36 years old, Pskov (autotoday.com): after buying a car off the showroom floor, at the second maintenance, I replaced a number of spare parts with foreign analogues. Their quality is an order of magnitude higher than domestic ones, and their service life is longer. Stabilizer struts from Renault Logan and Kia are suitable for Lada Vesta. |