What models are installed on VAZ 2106/2107 cars

All types of carburetor mechanisms equipped with the VAZ 2106/2107 are aimed at reducing fuel consumption and giving the car maximum dynamism. In addition, an important role is played by such an indicator as environmental friendliness. For a decade, AvtoVAZ engineers gave preference to the most environmentally friendly types of carburetors.

Carburetors of three different models were installed on modern VAZ 2106/2107, as well as on cars produced in previous years:

- Manufacturer: Dimitrovgrad Automobile Assembly Plant (or DAAZ). It should be noted that the company produced carburetors under license from Weber. Structurally, these devices were as simple as possible both in operation and in further maintenance. In addition, their main advantage was to provide excellent speed performance for cars of the sixth and seventh VAZ models. At the same time, DAAZ carburetors consume a very large amount of gasoline - from 10 to 14 liters per 100 kilometers.

- Manufacturer: DAAZ, modification “Ozone”. This is a more advanced version of the first type of DAAZ, which has high environmental performance. The device provides good acceleration characteristics and consumes less than 10 liters of fuel per 100 kilometers. However, the disadvantage of this model is that it comes with a second camera. In its operation, a pneumatic valve plays an important role, which, in case of contamination or poor-quality adjustment, can stop the carburetor from working.

- Manufacturer: DAAZ, modification 21053, which is produced under license from Solex. One of the most modern types of carburetors for equipping the VAZ 2106/2107. Maximum environmentally friendly and productive. It has a more complex design; the first in the DAAZ line is equipped with a reverse fuel supply system, which makes it as economical as possible. However, Solexes are demanding on the quality of gasoline - otherwise the fuel nozzles become clogged very quickly.

Modern VAZ 2107 models are equipped with this unit.

Common features in the design of carburetors for the VAZ Six and VAZ Seven

The carburetor mechanisms that are equipped with all VAZ 2106/2107 models throughout the entire production period of the car are two-chamber, that is, they have two internal combustion chambers . Structurally, all carburetors have three indivisible parts:

- at the top there is a cover of the device, which protects the mechanism from dirt, and fuel fittings;

- the middle part is a housing, inside which the chambers and diffusers themselves are located, transfers the air-fuel mixture to the engine;

- The float compartment and throttle valves are located in the lower part.

In the operation of DAAZ carburetors, small parts are of great importance - gaskets, jets, float, economizer or dampers. All elements of the system are interconnected and failures in one part will inevitably lead to failure of the entire device.

The DAAZ carburetor on the VAZ 2106/2107 works according to the following principle:

- Gasoline enters the float chamber through the inlet valve.

- The required fuel level is regulated by the needle of the forced idle economizer or power stroke economizer - in any case, fuel enters the chamber in a strictly defined proportion.

- Next, the fuel is sent to emulsion chamber No. 1 through nozzles.

- In the chamber (or VBC), gasoline is crushed into small parts and mixed with air.

- When the torque increases during acceleration, internal combustion chamber No. 2 may also be activated.

- After the formation of the air-fuel mixture, the pump directs it to the diffusers, and through them to the engine.

That is, the main task of the carburetor is to form the air-fuel mixture in a strictly adjusted proportion to ensure smooth operation of the engine.

The presence of many small elements ensures reliable operation

How to adjust the idle speed on a VAZ 2101-VAZ 2107?

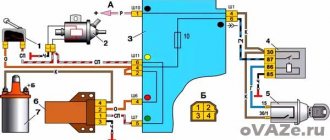

Before proceeding with the adjustments, check out the photo below:

Note! Let's start with the fact that the photo above shows the screws through which the idle speed is adjusted. As you can see, the screws are located deep in the carburetor throttle body, so the screw under the number “1” is not visible in the photo. On some cars, bushings are pressed onto both of these screws, thanks to which the screws can only be turned half a turn. If these bushings make it impossible to turn the idle speed adjustment screw properly, then remove the screws and, as a result, break the bushing heads. When the screws are removed, brush off the remaining broken bushings and then screw the screws back into place!

We recommend: Why a car accelerates poorly: possible causes and their elimination

Adjusting the idle speed using a gas analyzer:

Note! So that you understand in more detail, when tightening the screw, the crankshaft speed will gradually decrease, and with the opposite effect, that is, when it is loosened, the speed will gradually increase!

2) Now smoothly proceed to adjusting the “CO” content in the exhaust gases, to do this, rotate the screw indicated under the number “1” in the photo above. When tightening the screw number “1”, the “CO” content in the exhaust gases will gradually decrease, and when unscrewing it will correspondingly increase.

Note! It is necessary to regulate the CO content in exhaust gases in accordance with GOST for today. There is no need to lower the “CO” content below the norm, because in connection with this the content of unburned hydrocarbons “CH” may sharply increase. By the way, when adjusting screw “1”, it can change the crankshaft speed!

3) Finally, turn the screw under the number “2”, thereby bringing the crankshaft speed back to normal. After this, it is also recommended to use a device to check the “CO” content in the exhaust gases. If it becomes necessary to re-adjust both screws, adjust them until engine performance and CO emissions reach normal levels.

Note! After all the adjustments, sit in the car and sharply press and then release the gas pedal. Make sure that when you press the pedal, the engine runs smoothly, and when you release it, the car’s engine should not stall. If the engine stalls after releasing the gas pedal, then increase the crankshaft speed to “800 rpm”. The crankshaft rotation speed is adjusted with the screw number “2”!

Adjusting the idle speed without a gas analyzer:

1) To begin, slowly begin to rotate the mixture composition screw, which is indicated under the number “1”. Rotate it until the crankshaft speed is at its maximum. (The crankshaft rotation speed can be very easily determined by the tachometer readings)

Note! When this screw rotates, the release of harmful substances into the atmosphere is regulated. When turning this screw, the amount of CO emitted into the atmosphere will decrease, and when turning it away, on the contrary, it will increase!

2) Then use the screw under the number “2” to set the crankshaft speed to “1100 rpm”.

Note! The screw under the number “2” regulates the crankshaft rotation speed, therefore, when tightening this screw, the rotation speed will gradually decrease, and accordingly, when unscrewing it, it will gradually increase!

3) And finally, tightening the mixture screw (Number 1), ensure that the crankshaft rotation speed is “800 rpm”.

Question? How do you adjust the idle speed on your car? (Write your answer in the comments)

Additional video: Another way to adjust the idle speed, which you can see in the video below:

Note! Even if you watch the video, we advise you to still read the article because it goes into more detail!

How to repair a carburetor yourself

Repair work on the VAZ 2106/2107 carburetor involves removing and disassembling the mechanism. In this case, the repair includes all two stages:

- Washing (cleaning, blowing) elements from carbon deposits and adhering dirt.

- Replacement of worn or failed parts.

Before carrying out any actions with the unit, you must firmly make sure that the carburetor is faulty. Often, incorrect operation of other systems can affect the performance of the carburetor mechanism.

For the smooth operation of an internal combustion engine, high-quality cooling is necessary. One of the elements of this system is a water pump, which circulates the antifreeze. You can read more about repairing your pump yourself here:

The carburetor is located under the hood, above the engine.

Troubleshooting

DAAZ carburetors of any modification are designed to operate stably regardless of operating modes. However, it is precisely the change of modes (for example, starting “cold” or accelerating when overtaking) that can show the first problems in the operation of the device. The carburetor is clearly faulty if:

- at idle there are failures in engine operation;

- while driving, a time interval is noticed between pressing the gas pedal and accelerating the car;

- jerks in engine operation at high speeds;

- a series of jerks when overtaking;

- Gasoline consumption has increased significantly;

- Difficulty starting the engine after long periods of parking.

Each of these signs, as well as their combination, indicates that there is a problem with the carburetor and repairs or adjustments are necessary.

Overflows

One of the most common problems with carburetor engines is the so-called overflow. An excessive amount of fuel is supplied inside the device, and for some reason the check valve is not able to drain excess gasoline back into the tank. Therefore, under the carburetor and on it itself, the driver may notice drops of fuel.

In this case, it is recommended to clean all the fuel supply and exhaust channels, as well as the jets - most likely, the holes are clogged with debris. Diagnostics of the accelerator pump will not be superfluous.

Shoots

This concept is inextricably linked with transfusion. If the carburetor begins to shoot (or sneeze) - that is, jerk sharply while driving and even ignite - there is a fuel leak. The mechanism needs to be flushed.

Gasoline is not supplied

The problem may lie either in the carburetor itself (the jets are seriously clogged or the pump is broken) or in the supply hoses. It is recommended to blow out the fuel supply pipe and test the operation of the fuel pump. If they function normally, you will have to remove the carburetor and wash it.

The secondary internal combustion chamber does not work

Failure to operate PIC No. 2 will immediately affect the vehicle’s dynamism: it loses almost 50% of its original speed characteristics. The problem is that the throttle valve is sticking, which regulates the flow of fuel into the chamber cavity. You will have to disassemble the mechanism and replace the damper with a new one.

Video: how to repair a carburetor on a VAZ 2106

The principle of operation of the VAZ 2107 carburetor

The fuel pump supplies gasoline from the tank to the float chamber. Before entering it, gasoline passes through a mesh filter, which prevents clogging of the valve and jets.

The fuel dosage is regulated by a needle valve driven by a float, which, when the chamber is filled, floats up and forces the valve to close.

We recommend: Replacing the handbrake cable on a VAZ 2107

From the float chamber, fuel is directed through the jets of the VAZ 2107 carburetor into two mixing chambers, which also receive air from the air filter. Then the air is mixed with gasoline in the emulsion wells of the carburetor, forming a fuel-air mixture of the required concentration. Before entering the atomizer, the mixture passes through an econostat, which enriches it at high speeds and at high engine loads.

The final preparation of the mixture occurs as it passes through the diffusers - the fuel droplets are “broken” and the flow is directed to the center of the mixing chamber and further into the intake manifold and cylinders.

The amount of fuel mixture entering the cylinders is regulated using throttle valves actuated by the gas pedal.

To further enrich the mixture when you press the gas pedal sharply, an accelerator pump is provided.

The amount of mixture entering the cylinders at idle (with the gas pedal released) is regulated by the idle jet.

Engine power and efficiency depend on the correct ratio of gasoline and air contained in the fuel mixture entering the cylinders. For correct dosage, clean jets and working surfaces of the carburetor, smooth movement and absence of play in rods, drives and dampers are required. The advantage of a carburetor in comparison with modern injection systems is its unpretentiousness. A carburetor engine can even operate on low-quality fuel, which can damage the injection system.

This principle of operation, like the design of the VAZ 2107 carburetor , is relevant for all VAZ models with a carburetor engine.

How to remove the unit

Indeed, this question may take an inexperienced owner of a “six” or “seven” by surprise. But the dismantling procedure itself is not considered difficult. The main thing is to remember or write down the connection points of different hoses, since the reverse installation may cause difficulties during the first experience.

It is recommended to dismantle the DAAZ carburetor on a cold engine, since the device is located directly on the intake manifold.

It is important to disconnect the fuel lines and wires in sequence

The preparatory stage includes removing the air filter box, since the filter will prevent free access to the carburetor . Further work takes no more than 10 minutes:

- First, two thin wires are disconnected from the carburetor body - the first ensures the operation of the air damper, and the second is connected to the throttle.

- The return spring and its retainer are immediately disconnected.

- The next step is to disconnect the forced idle economizer wire.

- Loosen the clamp connection on the wide gasoline supply pipe and remove the hose itself. After this, you can remove the fuel return hose.

- The ventilation and vacuum hoses can be disconnected from the fittings at the top of the housing.

- Next, it is possible to dismantle the carburetor block itself. To do this, you need to unscrew the four fastening nuts and carefully remove the carburetor along with the gasket from the studs.

- During work, it is recommended to close the open hole in the manifold with soft cloths or a special plug, which can be purchased at a car dealership. This will ensure the cleanliness of the engine and prevent dirt from getting inside the power unit.

Washing DAAZ without disassembling

Flushing DAAZ carburetors is recommended by the manufacturer in cases where there are clearly any problems with its operation: increased gasoline consumption, jerks and jolts when driving, unstable idle speed, problems with starting.

The traditional method of washing carburetors is to completely disassemble them into individual components, which is not always possible for an inexperienced VAZ owner to do. To simplify the procedure, a technique was created for washing and cleaning the carburetor without disassembling it into components. This technique is based on the use of special aerosols in cans. The most affordable carburetor cleaners are considered to be aerosols produced by ABRO and Mannol - they can be bought at any auto store for 100–150 rubles.

The cans are equipped with a thin tube for access to all parts of the carburetor

These cleaners do an excellent job of cleaning carburetor mechanisms, and they are also very easy to use. To flush the carburetor, it is recommended to turn off the engine, let it cool and begin the procedure:

- Remove the air filter box from the car and place it to the side.

- Unscrew the solenoid valve from the carburetor body.

- Place a special narrow nozzle on the aerosol can and treat the nozzle channels, first and second chambers, dampers and all visible elements of the carburetor assembly with liquid.

- After this, spray the aerosol on the external parts of the mechanism.

- Wait 5–8 minutes (depending on the aerosol manufacturer’s recommendations). During this time, the liquid will be able to corrode accumulations of soot and dirt.

- Next, you can start the engine so that it removes all remaining dirt.

- If during one procedure the carburetor did not have time to be properly cleaned, then you can treat it again with the same aerosol.

After such cleaning, the VAZ 2108/2109 will significantly increase its dynamic characteristics, since the accumulation of dirt will not interfere with the normal operation of all parts of the carburetor.

Repairing a VAZ-2107 carburetor with your own hands: step-by-step video instructions

Old VAZ models often had a carburetor of brands such as Solex, Weber and Ozone installed. Just like many years ago, today they are no less in demand. However, regular use may cause the device to fail over time. In order not to waste your time and money, let's get acquainted with the manual for repairing, adjusting and servicing the carburetor on the VAZ-2107. Every car owner should understand at least a little about the insides of his iron horse, because constantly contacting technical service is inconvenient and costly.

VAZ-2107 carburetor repair: what a car owner needs to know

Carburetor repair is necessary if the mechanism does not work correctly. The main problems with the DAAZ 2107 carburetor are:

- The engine stalls at idle.

- The car accelerates with dips.

- At speeds over 100 km/h the engine begins to jerk.

- A cold engine will not start.

- The engine does not start or does not start well in hot weather.

To solve the first problem, you need to make sure that the fuel nozzle is not dirty. Also check the serviceability of the EPHH valve and the EPHH control system. The problem may be that the fuel valve is leaking. In addition, there is a problem with the resistor, which does not produce a stable spark.

How to change the gasket

Over the years, gaskets made from a wide variety of materials were installed on DAAZ: heat-resistant cardboard, paronite, metal. The main function of the gasket is to create the most reliable and tight connection between the carburetor body and the surface of the engine intake manifold. This is the only way to ensure normal operation of the power unit.

After dismantling the carburetor, it is necessary to inspect the gasket for deformations, tears or severe dents. The manufacturer recommends changing the seal after each carburetor removal.

On the left - new, in the center - when dismantling the carburetor for the first time, on the right - after 3 years of operation of the car

The gasket is selected according to the type of the old one. You cannot install a gasket made of a different material or with a change in shape - it will not be able to provide an adequate joint between the parts of the mechanisms.

The gasket replacement procedure is not difficult:

- A new gasket is placed on the carburetor mounting studs.

- Before this, you need to clean the planting site from soot and dirt.

- It is necessary to install the gasket in the same position as the old one.

- Then install the carburetor on it and tighten the fixing nuts until they stop.

DIY adjustment

Each car owner of a “six” or “seven” has the ability to adjust the carburetor independently. Adjustment work can enhance the dynamic qualities of the car, as well as reduce gasoline consumption. Undoubtedly, these are important indicators for any car owner, so you should be responsible when adjusting the carburetor.

Preparatory stage

Before you start work, you need to prepare thoroughly. This stage is necessary to ensure that nothing distracts the driver during setup and configuration.

First, it is recommended to prepare your work area. The carburetor must be installed on a flat and hard surface; it is better to stock up on rags in advance, as gasoline leaks are possible. In addition, it is necessary to ensure that the room in which the adjustment is planned is well ventilated and has high-quality lighting.

The second point of preparation is the set of necessary tools. You will need to prepare in advance a set of wrenches and two screwdrivers - a Phillips and a flathead with a narrow blade.

Next, find the service book for your car. It is there that the operating parameters are indicated, which will need to be checked during adjustment.

Attention! Adjustment work is carried out only after the carburetor has been washed, worn elements have been replaced and the device has been installed on the engine.

How to enrich or lean the mixture

Enriching or depleting the air-fuel mixture must be done at engine idle speed:

- Start the engine and wait until it warms up to its operating temperature.

- Tighten the fuel quality and quantity screws until they stop.

- Next, unscrew each screw 3 turns back.

- Referring to the idle speed data given in the VAZ service book, set the required number of revolutions by adjusting the screws in one direction or another.

- That is, the principle of adjusting the mixture is to set the idle speed recommended by the manufacturer by reducing or increasing the enrichment of the mixture (quality screw) and reducing/increasing the amount of mixture (quantity screw).

At the bottom of the tube there is a quality screw, and a little to the right in a tube of smaller diameter there is a quantity screw

How to reduce gasoline consumption

The main element in a carburetor is the float. After you have adjusted the enrichment/leanness of the mixture, the float will invariably return to its axis. However, it may be slightly higher than normal - in this case, fuel consumption will increase. In addition, adjusting the float is also necessary in order to reduce the toxicity of gas emissions, since due to poor-quality sealing of VAZ cars, some gases can enter the cabin.

Adjustment of the float mechanism is carried out on a completely cooled motor. In order to get to it, you will need to remove the air filter box and unscrew the carburetor cap:

- The float tongue needs to be adjusted.

- The float stroke should correspond to the recommended value of 8 mm. If on a VAZ 2106/2107 this value is greater, fuel consumption increases; if it is lower, losses in dynamics appear.

- Adjusting the clamps and axle fastenings allows you to set the desired stroke.

- Then you need to install the cover on the carburetor and screw the filter box into place.

The following article will help you adjust the carburetor on a NIVA car:

Adjustment of the float tongue is ensured by screws and clamps

DIY repair

If your carburetor suddenly becomes unusable, do not throw it away. Repairing this important “organ” of the car involves replacing faulty parts as quickly as possible. In order to determine which parts need to be replaced, you should disassemble, clean the carburetor and carefully inspect the component mechanisms.

How to remove a carburetor

The carburetor is removed if a malfunction is detected in it, but there is no way to do this by partial disassembly. The carburetor is also removed to replace, adjust and clean it.

It is removed as follows:

- To begin with, all kinds of hinged parts and damper drive cables are removed.

- The air filter housing is removed from the studs. To do this, you need to unscrew all the nuts that secure it to the carburetor. The clamping nut is pulled back and the choke cable sheath is pulled out from the mounting bracket.

- The outer surface of the parts is cleaned of dirt.

- The choke drive cable is loosened and the fuel supply and crankcase gas exhaust hoses are removed.

- The hose between the economizer and the pneumatic valve and the hose of the vacuum ignition distributor are disconnected.

- Then the nuts that secure the carburetor to the intake manifold are unscrewed.

- The carburetor body is removed and the intake manifold hole is plugged with a clean rag to avoid clogging.

Don't forget to check the integrity of the sealing gasket, which is located between the carburetor and the intake manifold. Replace it if necessary.

Photo gallery: removing the carburetor from a VAZ

Unscrew the nuts and remove the air filter housing, then disconnect the hoses and pipes. Disconnect the pads and loosen the throttle valve. Turn the carburetor mounting nuts, remove it and close the intake manifold.

How to clean a carburetor

Before you start cleaning the carburetor, you need to carefully prepare: buy a special aerosol cleaner at a car shop, arm yourself with smooth, dry cloths, a tire inflator, remove the carburetor and disassemble it.

Cleaning the jets

Jets—fuel and gas supply channels—are cleaned with compressed air or a liquid cleaner under pressure. Mechanical cleaning with any fleecy or metal objects is prohibited.

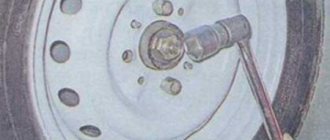

When cleaning the jets with compressed air (you can use a tire pump for this), the body of the idle jets, the main metering system (air and fuel), then the valves and channels of the pump sprayer are blown out.

In case of severe contamination, the jets are placed in acetone so that the deposits soften or completely dissolve. Then they should be blown out.

Table: jet calibration values

| Hole diameter, mm | First camera | Second camera |

| Main fuel jet | 1,35 | 1,25 |

| Air jet | 1,70 | 1,90 |

| Idle fuel jet | 0,45 | 0,60 |

| Idle air jet | 1,80 | 0,70 |

| Accelerator pump nozzle | 0,50 | — |

| Accelerator pump bypass jet | 0,40 | — |

| Fuel nozzle of enrichment device | — | 1,50 |

| Emulsion nozzle of the enrichment device | — | 1,70 |

| Air jet of enrichment device | 0,70 | — |

We recommend: Do-it-yourself removal of scratches on a bumper - methods and technology

Flushing the float system

To get to the carburetor float system, you must:

- Remove the air filter and fuel hose clamps.

- Disconnect the cable that controls the starting device.

- Remove the electrical connector on the solenoid valve.

- Then unscrew the fastening bolts and, without turning over, remove the carburetor cover.

It is best to clean the float compartment with a rubber bulb, carefully drawing out any remaining fuel from the chamber. You should not use fluffy rags - they can accidentally clog the jets.

To complete the cleaning, you can wipe the bottom of the float chamber with a stiff brush.

To check how well you have cleaned the float chamber, you need to unscrew the air jets and blow out the emulsion wells. If dirt appears in them, washing should be repeated and checked in the same way.

It is best to clean the float system compartment with a rubber bulb

Flushing the throttle valve

It is produced using a cleaner, which can be purchased at a specialized auto store.

- The throttle valve itself is washed, as well as all accessible elements, channels, valves, etc. Particular attention should be paid to the forced crankcase ventilation channel, since it becomes clogged more often and more severely than other parts.

- After this, the idle speed sensor is unscrewed and the internal elements are washed.

- The procedure is repeated again.

Video: how to clean the throttle valve on a VAZ

Replacing the gasket

The gasket is located between the carburetor body and its cover. If during disassembly you find any damage to the gasket, it should be replaced.

This is not so difficult to do - you just need to dismantle the float and put a new one in place of the old unsuitable gasket. Then install the float and put the carburetor cap back.

After washing the internal elements of the carburetor, it should be blown out. An air or car compressor is perfect for this.