A VAZ 2107 car with a gasoline engine is equipped mainly with an Ozone carburetor; it controls idle speed using an electric pneumatic valve. This valve shuts off the fuel supply when the ignition is turned off.

Cars of this model were not equipped with engines that use a more modern 16-valve timing system. The pneumatic valve of a car with a carburetor is highly reliable in comparison with other models. This device allows you to avoid glow ignition in the cylinders after stopping the engine, and also save fuel. The principle of operation of the electro-pneumatic valve is that it shuts off the fuel supply through the idle channel. This design is much simpler than previously used EPPCs. After minor improvements, this valve began to be used in power supply systems for engines equipped with a 16-valve gas distribution mechanism. They were used on them until the installation of distributed and mono injection.

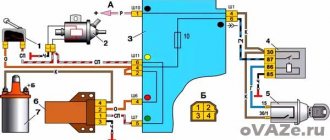

↑ Diagram of the carburetor electro-pneumatic valve control system

1 - microswitch in the carburetor;

2 - pneumatic valve; 3 — mounting block; 4 - ignition relay; 5 — ignition switch; 6 — pneumatic valve control unit; 7 - ignition coil; A - to terminal “30” of the generator; B - order of conditional numbering of plugs in the control unit. A working control unit 25.3761 should turn off pneumatic valve 2 when the engine crankshaft speed exceeds 1600 min-1 and turn it on again when the speed drops to 1200 min-1.

Before checking the operation of the unit, you must make sure that the vehicle wiring harness is connected correctly to the control unit (see view “B” of the control unit connector).

The functionality of the control unit is checked using a tachometer and a voltmeter (with a measurement range of 0–15 V) in the following order:

- disconnect the wires from the microswitch installed on the carburetor;

- connect 1 voltmeter to the control unit using a special adapter connector 2;

- start the engine and, gradually increasing the speed, monitor the voltmeter readings: after starting the engine, the voltmeter should show a voltage of at least 10 V, and at the moment the pneumatic valve is turned off, an abrupt decrease in voltage to a value of no more than 1.5 V;

- after turning off the pneumatic valve, gradually reduce the rotation speed until the pneumatic valve turns on: the voltmeter should show a sudden increase in voltage to at least 10 V.

Possible problems with EPHH

The solenoid valve is a quite good car component in terms of operation. It doesn’t experience particularly frequent breakdowns, but it can’t be called an “uninterrupted worker” either. Due to the fact that in the post-Soviet space, electromagnetic valves of Solex carburetors and DAAZ carburetors are most often used, let’s look at typical EPHH problems using their example. In general, the list of frequently encountered unit failures is as follows:

The valve jet is clogged. This problem usually occurs in conjunction with a general malfunction of the carburetor in all engine speed modes. This malfunction is eliminated by disassembling the carburetor into individual components, purging it and otherwise cleaning it.

In this case, special attention should be paid to the EPHH jet, as well as the carburetor channels that interact with it;

The valve stem (needle) is stuck in one position or other components of the device have failed (spring, core, etc.). A malfunction of this kind manifests itself in the form of a lack of signs of “life” in the economizer. In such a case, a faulty EPHH is often beyond repair. However, in some situations, removing the valve from the carburetor, purging it and then connecting it to an alternative power source helps. If the node again shows no signs of “life,” then replacement is inevitable;

The connection wire has broken. The problem is typical, often occurring due to the poor quality of production of the EPHH and its wires. This “sore” is diagnosed by connecting the valve to a power source outside the vehicle system and checking its operation when the connection wire moves in different directions. As a rule, it cannot be treated, however, as a rescue measure, you can try to simply replace the wire, cutting it as close as possible to the economizer body, or otherwise eliminate the hole in the circuit;

The EPHH control unit is faulty. In this situation, the valve itself works properly when connected to an alternative power source, but while in the carburetor it does not function at all. This problem is solved by replacing the control unit connected to the EPH, not otherwise;

The solenoid valve has a manufacturing defect. This, by the way, happens quite often. Surprisingly, there were cases when out of 10-20 EPHHs lying on the store counter, only 1-2 copies worked. If you become a victim of such a case, then simply replace the valve with a new one and not worry.

All of the above breakdowns have one pronounced symptom, or rather, a complete or partial lack of stability in the idle speed of the car. If such problems happen to you, then, first of all, you should check the solenoid valve and its control unit, and only then the main idle jets and other components of the carburetor.

↑ Checking the functionality of the control unit

The operation of the control unit is checked using an adapter connector with a voltmeter in the following order:

- disconnect the wire from the carburetor limit switch and connect the tip of this wire to ground;

- connect a voltmeter to the control unit using an adapter connector;

- start the engine and, gradually increasing the speed, monitor the voltmeter readings: after starting the engine, the voltmeter should show a voltage of at least 10 V, and at the moment the valve is turned off, an abrupt decrease in voltage to a value of no more than 0.5 V;

- after turning off the valve, gradually reduce the rotation speed until the valve turns on: the voltmeter should show a sudden increase in voltage to at least 10 V;

- set the crankshaft speed within 2200–2300 min-1, disconnect the tip of the wire going to the carburetor limit switch from ground, and then reconnect it to ground. When the wire is disconnected from ground, the valve should turn on, and when connected to ground, it should turn off.

It is possible to check the unit without a voltmeter by the characteristic knock of the valve when turning it off and on.

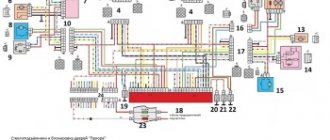

| Terminal | Address |

| 1 | To terminal "K" of the ignition coil |

| 2 | Weight |

| 3 | — |

| 4 | +12 V from fuse “10” |

| 5 | Carburetor limit switch |

| 6 | Carburetor solenoid valve |

| 7 | — |

Restoring stable idle

Restoring a stable idle shouldn't be too difficult. Troubleshooting procedure;

- Using a key set to “17”, unscrew the pneumatic valve from the carburetor.

- The valve is disassembled, washed well with kerosene or pure gasoline and blown out with compressed air.

- We screw it into place and check its functionality.

If, however, the cause of the unstable idle speed has not been eliminated, you need to check the power supply control circuit. If the power supply circuit is broken, the carburetor pneumatic valve is constantly in the closed position. This results in the engine not idling. Repairing the open circuit will solve this problem without much effort.

Malfunctions associated with the electro-pneumatic valve are extremely rare, but if this happens, it should be replaced.

Troubleshooting the unit

Upon completion of diagnostic operations on the VAZ 2107 engine, other breakdowns that may have similar manifestations should be excluded. The econometer works by changing the pressure in the carburetor channels; damage to its tube can lead to air leaks. A modern injector electronic control system eliminates electro-pneumatic devices that are less reliable.

An accurate determination of the cause of the EPHH malfunction is only possible if the unit is dismantled and completely disassembled. The economizer is removed from the carburetor in the following order:

- Using a “10” wrench, unscrew the 3 nuts holding the filter cover and lift it up along the studs.

- Unscrew two Phillips-head screws that secure the pneumatic block with the membrane and valve. The control tube is removed from the fitting of the device.

- The device is removed from the socket and carefully inspected for damage and carbon deposits on the valve or its seat.

The operation scheme of the carburetor, which was replaced by an injector, assumes a reaction to changes in pressure in the chamber with a decrease or increase in fuel supply. The economizer implements this feedback through a flexible membrane rigidly connected to the stem and valve

When checking this block, special attention should be paid to this node

There are repair kits for sale for Solex carburetors that were previously installed on the VAZ 2107. The forced idle unit, if it does not work, can be repaired using parts from such a kit. Installation of the unit in its intended place must be accompanied by a leak test. The last thing to connect before installing the air filter is the econometer located on the control panel. The position of the arrow in the green sector indicates acceptable fuel consumption.

A VAZ 2107 car with a gasoline engine is equipped mainly with an Ozone carburetor; it controls idle speed using an electric pneumatic valve. This valve shuts off the fuel supply when the ignition is turned off.

Cars of this model were not equipped with engines that use a more modern 16-valve timing system. The pneumatic valve of a car with a carburetor is highly reliable in comparison with other models. This device allows you to avoid glow ignition in the cylinders after stopping the engine, and also save fuel. The principle of operation of the electro-pneumatic valve is that it shuts off the fuel supply through the idle channel. This design is much simpler than previously used EPPCs. After minor improvements, this valve began to be used in power supply systems for engines equipped with a 16-valve gas distribution mechanism. They were used on them until the installation of distributed and mono injection.

Main characteristics

The principle of operation of electromagnetic valves resembles conventional locking mechanisms, but the flow is closed not manually, but with the help of a solenoid. This allows you to automatically regulate this process without human intervention.

The main structural elements of such a product are:

- frame;

- electromagnet;

- a special device used to regulate the flow (piston or disk).

This product can work in various environments, which allows it to be used not only with liquid substances, but also with gases. There are several types of such devices, which differ in technical parameters, such as the ability to regulate flow and throughput.

Valve inspection and repair

Checking valves is a mandatory process when diagnosing a car. It will help to weed out some of the possible causes of the malfunction.

It often happens that the needle valve of the VAZ 2109 carburetor can sometimes simply “stick”. And this causes problems. If the fuel supply needle valve is faulty, it should be cleaned or replaced.

It happens that the valve stops working in very hot weather. This can be expressed in the fact that the car starts, but after ten to twenty seconds the engine stalls. Externally determining the cause can be very problematic.

Sometimes in such cases, tapping on the carburetor cover helps, and then a few strokes are made on the manual drive of the fuel pump.

When the needle valve stops working in the closed state, nothing happens externally and you will not hear any sounds. An open valve produces the sound of gasoline filling the float chamber.