To prevent camshaft wear and valve burnout, attention should be paid to the prevention of the gas distribution mechanism. Engines with a simpler timing system require periodic tuning. Adjusting the valves of the VAZ 2110 8 valves with your own hands is a common task for many motorists. We will try to describe in detail the entire work process.

For reference! The valves on the VAZ 2110 with an injection 16-valve engine cannot be adjusted. These engines have a gas distribution mechanism with hydraulic compensators, which should be changed periodically.

Symptoms

To understand that the valves on the VAZ 2110 engine need adjustment, it is enough to know the behavior of the engine.

After prolonged use, the car owner may notice that the engine has begun to work somehow differently. This fact should alert you, because the consequences can be serious. The main symptoms of a faulty valve mechanism adjustment on a VAZ 2110 look like this:

- the engine is noisy when starting up after a long period of parking (clacks);

- compression in the cylinders disappears (the engine loses its former power);

- Valve cover gasket leaks oil;

- “shots” appeared in the carburetor or muffler;

- fuel consumption has increased.

The listed signs can be diagnosed independently, without resorting to the services of a car service. Before you put the VAZ 2110 in for repairs and begin adjusting the valves, you should prepare a mechanic’s tool: a micrometer, a rack for pressing the pushers and a multi-part feeler gauge. The last thing to measure is the thermal gap between the camshaft cam and the adjusting washer. Instead of a rack, it is possible to use two powerful slotted screwdrivers. An installation kit (clamp and probe) is sold in most Auto Parts stores. Its cost varies from 200 to 500 rubles. Correct installation of valves on a VAZ 2110 8 valve injector or carburetor is the key to success.

Preparing and disassembling the mechanism

Adjusting the clearances in the valve drive

To carry out the work, you will have to purchase a special device for pressing the pushers and a set of adjusting washers of various thicknesses - you will not be able to do without them. If you constantly plan to make adjustments yourself, then this purchase will help you save money on car service costs. With a one-time promotion, purchasing devices is impractical; it is better to immediately contact the specialists.

To disassemble and adjust the clearances under the cams, you will need the following tools:

- a pair of flat probes with a thickness of 0.2 and 0.35 mm;

- a regular plumbing kit with screwdrivers and pliers;

- tweezers;

- sets of ring and open-end wrenches;

- spark plug wrench.

Since during the adjustment process you will have to repeatedly turn the crankshaft, to facilitate rotation it is recommended to unscrew all the spark plugs, having first removed and put the high-voltage wires aside. Further disassembly includes:

- Disconnecting from the valve cover all pipes that interfere with its removal.

- Unscrewing the valve cover and removing it. You need to make sure that the rubber bushings do not get lost from the holes.

- Removing the gasket.

- Removing the plastic timing belt cover.

After wiping off any oil stains on the cylinder head flange where the gasket was located with a rag, you can begin tuning.

Reasons for replacement

As mentioned above, the reason for replacing the valves may be a broken timing belt, but this is not always the only reason. Often the valves need to be replaced due to the motor chain jumping. When this happens, the valves simply turn out and it is clear that their further operation becomes impossible. After this, the valves look like this:

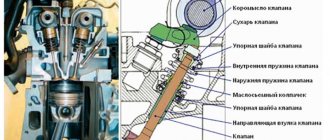

Replacing valve guides for VAZ 2110

In addition, the valves themselves may wear out. More precisely, it is the valve stem, which has a certain size, that is subject to wear. The leg is specially measured with a micrometer to check compliance with the standards. So, if the valve stem has a size that is less than 7.97 mm, then this is wear and tear and such a valve should be sent to the trash bin. Finally, a burnout or crack in the plate itself may cause the valves to be replaced.

Replacing valve guides on a VAZ 2110

Tool for work

In addition to the everyday set of sockets and spanners, which the owner of a VAZ 10 should already have, a few more tools will be required:

- A device that presses out pushers for removing adjusting washers from them. You can get by with a couple of powerful screwdrivers, but the price issue here is not so great that you pay for the savings with less convenience. You can completely remove the camshaft - but then you will have to remove the timing belt as well, again there is no gain in time.

- A set of feeler gauges - we will use them to measure the gaps.

- Micrometer - This is not necessary, but is very useful. When adjusting, the thickness of the new washer is calculated based on the thickness of the old one and the measured gap, but what to do if the thickness marking on the washer is erased (and no one has canceled the wear?). You can borrow a 0-25 mm micrometer, fortunately you can trust it by simple mixing without calibers.

Something else useful for you:

Valve adjustment frequency

After using the car for a long time, its owner may notice that the engine is no longer performing as well as it was before. In principle, all changes in engine operation should always alert the driver, since this is often fraught with quite serious consequences. In most cases, adjustment of the VAZ-2110 valves (8 valves) is required if the following symptoms are present:

- excessive noise when starting the engine after the car has been idle for a long time;

- lack of compression in the cylinders (a noticeable decrease in engine power);

- oil leaks through the cover gasket;

- regular “shots” in the muffler or carburetor;

- increased fuel consumption.

It is not necessary to go to a specialized car service in order to diagnose the above problems.

Device

In order to understand why there is a need to adjust the valves, you need to understand a little about the operation of the VAZ 2110. So, when the engine is cold, there is a gap between the cam and the pusher.

It is needed for the so-called compensation of thermal expansion. Simply put, we all know that when heated, all objects tend to expand.

So that there is room for expansion, and the component parts do not break or bend, there are gaps. However, they must be of a strictly defined size, otherwise instead of benefit we will get harm.

Engine device

Preparatory stage

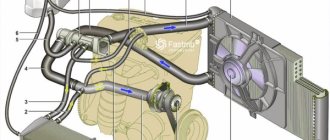

It starts with turning off the on-board power supply to the car, for which the terminals are removed from the battery and it is necessary to drain the old engine oil into a prepared container through a service plug and coolant from the engine crankcase, this is done by disconnecting the lowest radiator pipe from the cylinder block, the only precaution is Carrying out the procedure on a cooled engine, otherwise you can get your hands burned!

Spare parts and tools for work

Before starting work on replacing valves on a VAZ 2110, high-quality new parts are purchased, the names and original articles of which are as follows:

- Set of gaskets: valve cover (art. 2108-1003270/77) and cylinder head (art. 21083-1003020), intake and exhaust manifolds (set art. 21083-1008081), exhaust gas intake pipe (art. 2103-1203020-04) , as well as an oil seal (art. 2108-1005034) and oil flinger rings (art. 2108-1007026-86) (the so-called cylinder head repair kit)

- New valves for the fuel mixture intake system 4 pcs. (art. 21083-1007010)

- New exhaust system valves 4 pcs. (art. 2108-1007012)

- Valve guides 8 pcs. (art. 2108-1007032-87)

- Engine coolant

- New bolts securing the cylinder head to the cylinder block (art. 2108-1003271Н/О)

- Timing belt (art. 2108-1006040-86) and generator drive belt (art. 1000012562)

- Engine oil and oil filter

Repairs to replace worn-out parts are carried out using a standard set of tools, which are usually sold as a set, namely:

- a set of open-end wrenches marked from 8 to 21 mm;

- set of internal hex keys;

- a set of sockets with a diameter from 8 to 24 mm;

- valve desiccant;

- screw valve guide puller;

- torque wrench (needed for proper tightening of the camshaft, cylinder head and camshaft gear bolts);

- Screwdriver Set;

- electric drill;

- specialized lapping paste of two types (for rough lapping of valves to their working surface of the combustion chamber and for finishing grinding);

- gloves to protect hands from possible damage.

This is interesting: How to remove the heater and its pipes with your own hands: replacing the heater radiator on Audi 80 and 100?

The presence of tools, parts and a covered room will allow you to carry out troubleshooting work yourself, since the price of replacing 8 valves on a VAZ 2110 in non-certified services in the fall of 2021 varies from 30 to 45 thousand rubles. At a certified service station of official dealers, such work will cost more than 50 thousand, which will greatly affect the financial situation of the car owner.

Characteristics of VAZ 2110

The VAZ 2110, or Lada 110, is a four-door sedan equipped with front-wheel drive and distinguished by a design that is different from other models. AvtoVAZ began production of the Lada 110 in 1996 and ended in 2007, but the Ukrainian LuAZ plant is still producing the car under the Bogdan brand.

Simultaneously with the Lada 110, several modifications were produced: engines with 8 and 16 valves. The maximum speed of the car increased to 170 and 180 km/h on 8-valve and 16-valve engines, respectively. The VAZ 2110 has excellent technical characteristics that allow the car to be used in almost any conditions.

The VAZ 2110 is the upper price segment in the AvtoVAZ car line, so it has a number of new and useful features: an immobilizer, an on-board control system with a diagnostic unit, a gasoline vapor detection system, electric lifts and power steering.

Characteristics of VAZ 2110

| Engine | 1.6 l, 8kl (Euro-2) | 1.6 l, 16cl (Euro-2) | 1.6 l, 16cl (Euro-3) |

| Length, mm | 4265 | 4265 | 4265 |

| Width, mm | 1680 | 1680 | 1680 |

| Height, mm | 1420 | 1420 | 1420 |

| Base, mm | 2492 | 2492 | 2492 |

| Front wheel track, mm | 1410 | 1410 | 1410 |

| Rear wheel track | 1380 | 1380 | 1380 |

| Load capacity, kg | 475 | 475 | 475 |

| Luggage compartment volume, dm3 | 450 | 450 | 450 |

| Permissible total weight of a towed trailer with brakes, kg | 1000 | 1000 | 1000 |

| Permissible total weight of a towed trailer without brakes, kg | 500 | 500 | 500 |

| Wheel formula / drive wheels | 4x2 / front | ||

| Car layout diagram | Front-wheel drive, front engine, transverse | ||

| Body type / number of doors | Sedan/4 | ||

| engine's type | injection gasoline, four-stroke | ||

| Engine displacement, cm3 | 1596 | 1596 | 1596 |

| Supply system | distributed injection with electronic control | ||

| Number and arrangement of cylinders | 4, in-line | ||

| Maximum power, kW (hp) / rev. min. | 59 (80) / 5200 | 65,5 (89) / 5000 | 65,5 (89) / 5000 |

| Maximum torque, Nm at rpm | 120 / 2700 | 131 / 3700 | 131 / 3700 |

| Maximum speed, km/h | 170 | 180 | 180 |

| Fuel consumption by driving cycle, l/100 km | 7,2 | 7,2 | 7,2 |

| Fuel | AI-92 (min) | AI-92 (min) | AI-92 (min) |

| Transmission | mechanical | ||

| Number of gears | 5 forward, 1 reverse | ||

| Main gear ratio | 3,7 | 3,7 | 3,7 |

| Acceleration to 100 km/h, s | 13,5 | 12 | 12 |

| Steering | with hydraulic booster, rack and pinion steering mechanism | ||

| Tires | 175/65 R13 | 175/65 R13 | 175/65 R14 185/60 R14 |

| Fuel tank capacity, l | 43 | 43 | 43 |

Modifications of VAZ 2110

- VAZ-21100 (8-valve petrol carburetor engine with a working volume of 1.5 liters was produced from 1996 to 2000);

- VAZ-21101 (8-valve gasoline injection engine with a working volume of 1.6 liters, produced since 2004);

- VAZ-21102 (8-valve gasoline injection engine with a working volume of 1.5 liters);

- VAZ-21103 (16-valve gasoline injection engine with a working volume of 1.5 liters, produced since 2001);

- VAZ-21103M (16-valve gasoline injection engine with a working volume of 1.5 liters, produced since 2001);

- VAZ-21104 (16-valve petrol injection engine with a working volume of 1.6 liters, produced since 2004);

- VAZ-21104M (16-valve gasoline injection engine with a working volume of 1.6 liters, produced since 2004);

- VAZ-21106 GTI 2.0 16V (16-valve Opel C20XE petrol engine with a displacement of 2.0 liters);

- VAZ-21106 Coupe (variation of a car in a coupe body);

- VAZ-21107 (Sports modification of the VAZ-21106 car);

- VAZ 21108 “Premier” (extended by 17.5 cm, has additional handles on the rear doors, enhanced sound insulation);

- VAZ 21109 “Consul” (limousine with five doors, a glass roof and an interior made of wood; non-serial production);

- VAZ 2110 RPD (Sports variation of the VAZ-2110 car with a rotary piston engine).

In 2002, MAI specialists developed the VAZ 2110 with a continuously variable transmission (VT1 variator).

From 2005 to 2007, only modifications 21101 and 21104 were produced.