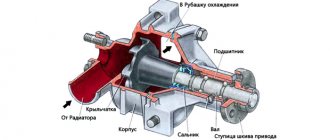

Malfunctions of the pump are manifested in significant play in its shaft, violation of the tightness of the seal, wear (corrosion or breakage) of the impeller. All of these defects lead to the fact that the car’s water pump does not work properly, which is why the required pressure is not maintained in the engine cooling system, which, in turn, leads to an increase in the temperature of the coolant until it boils. You have to buy a new pump and install it in place of the old one.

How to check the pump without removing it from the engine? Read about the ways

Quite a lot of car owners are wondering how to check the pump without removing it from the engine.

After all, it is highly not recommended to mess around with the cooling system, so it’s worth learning how to check it directly on the car. Please note that this will minimize repair time and also make it possible to avoid unnecessary costs for unnecessary components. Even a completely inexperienced driver can carry out such diagnostics, which will make his task easier, especially if the engine suddenly heats up. Do not delay carrying out diagnostic work; remember that overheating of the power plant leads to its rapid failure. How to check the pump without removing it from the engine is actually a fairly simple question. There shouldn't be any problems with this. But, you need to know how this system works. Careful study of the work process will greatly simplify the diagnostic process. Another point that should not be forgotten is the ability to carry out such diagnostics at any convenient time. Even if you are on the road in a deserted area, you can conduct a check and decide on further movement.

Technical features

First, let's look at the main technical characteristics and features of the water pump; this will allow us not only to make a correct diagnosis, but also to understand why the breakdown occurred.

Antifreeze is pumped using an impeller, which is mounted on a shaft. The drive is carried out from the crankshaft of the motor; a belt drive is used for this. Here it is worth clarifying that in practice there are 2 drive methods used for the pump:

- Directly from the crankshaft

. This method is used on engines with a timing chain. Usually one belt drives the generator and pump, sometimes the power steering and air conditioning pump are also connected here; - Another option is timing belt drive.

There is one serious drawback here. When the bearing jams in the pump, the belt breaks, which leads to breakdown of the gas distribution system, and under certain conditions, to a complete overhaul of the engine. In this case, you should carefully monitor the condition of the pump.

The pump housing is usually located at the front of the motor. This allows for the most optimal pumping of coolant through the system. It is also precisely this approach that makes it possible to use the crankshaft pulley as a moving element. In addition, placing the part at the front makes it easier to access for repairs.

The main malfunctions of the pump are directly related to its technical features; accordingly, this must be taken into account when carrying out diagnostic actions. As a rule, all signs of a malfunction are completely related to the characteristics of the various elements that ensure the operation of your car's cooling system.

Possibility of installing an additional water pump on the Lada-Priora

One of the disadvantages of the heater on the Lada Priora car is its low efficiency when the engine operates at low speeds in the cold season, due to insufficient coolant circulation. Therefore, the car interior warms up slowly and insufficiently, which causes some discomfort for the driver and passengers.

There are some requirements that must be met to obtain a high-quality result after installing an additional electric pump.

These include the following points:

- the installed product should not create excess pressure in the heater radiator during operation in order to avoid damage to the pipes or the formation of cracks;

- It makes sense to replace the thermostat and install this component with an increased opening temperature (90–95 degrees Celsius) due to the fact that as the speed in the coolant circulation increases, the engine parts will warm up more slowly, increasing wear on the power unit.

To solve this problem, you can install an additional water pump in the cooling system of the power unit, which will qualitatively improve the heating of the car interior even when the engine is idling. This technology is not new. Engineers have been using it for a long time. Examples include German cars BMW or Mercedes Benz.

Device selection

As a rule, devices from various manufacturers are suitable as an additional water pump for the Lada-Priora car.

These, for example, could be brands from:

Video: positive effect of installing an additional electric pump on the Lada Priora

However, most often the Lada Priora is equipped with an electric water pump, which is installed on Gazelle cars. This may be an old or new design, but the principle of operation is the same for both: due to the vacuum at the inlet during operation of the product, a pumping force arises, which drives the coolant through the system. In fact, the pump from the Gazelle car is a classic centrifugal pump.

The design of the new pump version is much more successful and causes fewer complaints from car enthusiasts. And it is also less noisy during operation. The main problem that motorists encounter when using such an electric pump is its leakage.

Installation and connection of an additional electric pump

To equip a car with an additional electric water pump, you will also need a regular relay that has normally open contacts (this can be an ignition or starter relay from a VAZ 2105, VAZ 2108). It is necessary to close contacts No. o86 and No. o30. And you will also need a reinforced hose and clamps for clamping the pipes.

An additional pump can be installed in any of the gaps in the supply or outlet pipes of the car’s heating stove.

Installation of an additional electric pump is quite simple, and the efficiency of the heater increases significantly

The pump is fixed in the Lada Priora in the following places:

- stud for fastening the washer reservoir;

- studs located next to the battery;

- on the engine shield.

The device can be connected to a wide variety of systems.

- recirculation button;

- SAUO stove block;

- heated mirrors;

- other convenient places.

How to check?

An important point is to check the pump. Many car enthusiasts believe that in order to diagnose it, it is necessary to dismantle the part, but in most cases you can do without this. There are a number of signs by which you can understand that the problem is in the pump. To begin with, it is worth noting that most manufacturers recommend replacing the water pump after 60-80 thousand kilometers

. In some cases, regulations indicate the need to replace simultaneously with the timing belt. Therefore, if the pump on your car has gone through such a mileage, then it makes sense to replace it at the first opportunity.

Please note that using low-quality antifreeze or mixing incompatible types of coolant can lead to increased wear on the pump. Therefore, always pay attention to the composition of the liquid you use for cooling.

Diagnostics is carried out in the following order

:

- Start the engine and warm it up to operating temperature;

- Next, pinch the pipe

that goes from the radiator to the pump with your hand. When the pump is fully operational, you will feel the pressure it creates. Usually, this is felt in the form of fairly strong tremors. If they are, then there are no problems with the water pump; - If the shocks are weak or completely absent, then you need to move on to a more thorough inspection of the pump. Turn off the engine; on some models you will need to remove the timing case. Pay attention to the presence of leaks near the pump mounting location; antifreeze may also leak through the pulley seal. If there are such signs, then it is definitely necessary to remove the pump and troubleshoot it.

Replacing the pump on a Lada Kalina (8 valves)

On an 8-valve Kalina, you can change the water pump yourself. However, if the car owner does not have minimal experience in car maintenance, many questions may arise. For example, which pump to buy, how to choose the right tool, and is it worth draining the antifreeze from the system completely?

Which pump to choose

When the time comes to change the water pump, car owners begin to look at car dealerships for a worthy replacement. But which pump to choose so that it lasts as long as possible and does not cause problems for the owner?

It is important to choose original factory products. This is immediately evident from the packaging - an uncreased box, a warranty card, the date of manufacture and service life are indicated. Original pumps are necessarily packaged in protective film and have holographic stickers.

In contrast, it will not last long - after 10 thousand kilometers the pump will need to be changed again.

At AVTOVAZ, designers install a TZA water pump on the Kalina. It has a long service life; drivers often change the pump only after 100 thousand kilometers. As an alternative, you can install more expensive German-made Bosch pumps - they are also famous for their quality and durability.

Where is the water pump located on Kalina?

Due to the fact that the pump is driven by the timing belt, it is part of the gas distribution mechanism. That is, you need to look for the water pump on the Lada Kalina from the side of the engine itself. Visually, before removing the belt, you can only see the pump pulley, which is involved in the gas distribution system.

The pump on the VAZ is located in the timing device

Preparing tools

It is recommended to prepare a standard set of tools for removing bolts and unscrewing nuts. You will also need a 6-point hex key. To drain the antifreeze without contamination and inconvenience, it is better to immediately find a container for draining and a rag to blot up any drops that have fallen on the engine elements. To ensure reliable installation of the pump, you can use a sealant with good thermal conductivity properties.

How much coolant to drain/fill when replacing the pump

In any case, before dismantling the old pump, you will need to drain the antifreeze from the system. This is necessary in order to reduce the pressure in the hoses and not be injured during sudden releases of liquid.

If the water pump has not been changed for a long time, then it is advisable to immediately drain the entire volume of antifreeze from the system and replace it with a new one. If the car owner has recently filled in new coolant, then there is no point in completely draining it: just disconnect the hoses from the expansion tank and wait until the antifreeze comes out.

To make it easier to fill a large volume of coolant, drivers usually use funnels

Operating procedure

First of all, you will need to install the machine on a flat surface. You can drive the Kalina into the inspection hole, you can simply lift the front right part on a jack. It is recommended to make sure that the car is securely secured; it is better to place additional supports under the body beam.

When dismantling the pump, you will need to remove the timing belts.

The work of replacing the pump on the Lada Kalina is carried out according to the following instructions:

- Remove the engine splash guard.

- Disconnect the negative terminal from the battery.

- Unscrew the cap from the expansion tank and immediately remove the plug located on the cylinder block. Wait until the coolant drains out.

- If all the antifreeze is drained, then unscrew the cap from the radiator and place a container under the drainage area.

- After the antifreeze has been drained, screw all the plugs back on.

- Remove the protective cover from the timing belt.

- Loosen the belt by slightly tightening the timing pulley.

- Remove the drive belt.

- Remove the four bolts that secure the pump pulley to the cylinder block.

- After removing the pulley, unscrew the last screws securing the pump.

- Pull the water pump out of its socket along with the gasket.

- Clean the planting site from adhering dirt and antifreeze drips.

- Apply heat-resistant sealant to the edges of the hole and install a new gasket on it.

- Place a new pump on the gasket and then proceed in the reverse order of removal.

Video: how to replace the pump yourself

When working with timing rollers and pulleys, it is recommended to immediately fix the working position, since the installation process can be very drawn out due to the length of time it takes to set all the marks.

Possible faults

Now let's look at the main malfunctions of the pump; all problems have their own signs, knowledge of them will allow us to make more competent diagnostics. So, most often drivers face the following reasons:

- Depressurization of a part

. In this case, the coolant leaves through the shaft seal or through the gasket. Here there is a decrease in the efficiency of the pump; part of the pressure is lost due to a leak. With such a malfunction, antifreeze drips are often observed, and it also quickly leaves the system; - Bearing wear

. The shaft on which the impeller is mounted has a bearing, which wears out over time and may fail. Bearing jamming, as already mentioned, on some engines can lead to a number of serious breakdowns. It is worth considering that this problem can manifest itself in different ways. Most often, the bearing begins to howl, this is due to the depletion of lubricant, as well as a high level of wear of the race. But sometimes a breakdown manifests itself as a knock. This happens when the bearing is completely or partially destroyed. Another possible malfunction is a jammed bearing, in which case the pump cannot be turned; - Impeller destruction

. This is a rare malfunction, but it does happen. The reason is the poor quality of the part. With such a breakdown, a strong roar is observed immediately after starting the engine, and the car quickly overheats.

Signs of trouble

I would like to immediately note that in order to determine faults in the water pump, you will need to remove the unit and disassemble it. Only this method provides a real opportunity to see the resulting traces of corrosion, signs of cavitation and contamination.

Practice clearly shows that this happens on a wide variety of machines:

- VAZ 2107;

- Volkswagen Passat;

- FF2, that is, Ford Focus 2nd generation;

- Lada Granta;

- Kia Spectra;

- Chevrolet Aveo;

- Audi A5;

- Nissan Qashqai;

- Mitsubishi Outlander;

- Toyota Camry;

- Skoda Octavia, etc.

Moreover, the situation is approximately the same everywhere. That is, it is impossible to determine whether there are problems without disassembling and looking inside the cooling system water pump.

Therefore, the main emphasis is on indirect signs. With their help, the driver gets the opportunity to diagnose the problem in advance and prevent serious consequences.

The following indirect signs are distinguished:

- A thin whistle appears without interruption during engine operation. Moreover, it comes from the area of the camshaft pulley of the internal combustion engine. A whistle indicates that a higher bearing is failing;

- Coolant leaks. Traces of antifreeze can be seen directly on the power unit, or under the bottom of the car, that is, on the asphalt;

- Pump play. To check for its presence, simply grab the pump pulley with your hand and try to swing the device up and down.

Do not forget about the possible airing of the system, due to which the antifreeze does not fully perform its functions, the engine overheats and a number of resulting breakdowns occur. Here it would be correct to remind you about removing the air lock from the cooling system. Also, be sure to read the material about checking the cap of the expansion tank, which is directly related to the engine cooling system.

I won't talk about how the pump changes. Usually replacement is carried out according to the owner's manual from the car manufacturer. The point is to drain the cooling liquid, disconnect the pipes, first turn off the power to the car, and dismantle the problem unit.

The design and location of all pumps are different, therefore there is no universal instruction. You can find a video online, or simply take the car to a car service center.

We recommend: How to replace the heater radiator on a VAZ 2107

How to fix the problem?

If a malfunction is identified, it should be eliminated as soon as possible. Here it is worth understanding that the pump is still a consumable, and in most cases it is easier to completely replace it.

If there is a leak through the gasket, simply remove the pump and replace the gasket. Please note that normal tightness is required here. Therefore, be sure to carefully tighten the fastening nuts. Many drivers lubricate the gasket with sealant; such a precaution will not be superfluous. This will significantly reduce the risk of leakage. After some time, you should check the tightness of the nuts; they may loosen due to engine vibration.

If the cause is the bearing or impeller, then the best solution is to replace the water pump. Repair in this case is complicated, but its effectiveness is low, so it is better to buy a new part and install it. Don’t forget to bleed the cooling system after replacing the pump; this will remove all air pockets, which will increase its efficiency.

conclusions

. The cooling system must operate at maximum efficiency, otherwise engine problems will occur. Therefore, it is simply necessary to know how to check the pump without removing it from the engine. This will avoid costly repairs to the power unit and save you a lot of money.

Checking the pump without removing it

In some cases, you can check it without removing it: there are a number of faults that can be seen. To do this, discover the pump and then check each point:

- Backlash. If all the parts shake (or at least the pulley), then it’s time to change the part.

- Antifreeze leak. Inspect the device for signs of leaks. If they are not there, they must be elsewhere in the cooling system.

- Failure is also determined when the bearing whistles. This whistle is difficult to confuse with something: it either becomes louder or “fades away.” But keep in mind that a similar whistle can be caused by a broken generator.

How to replace the pump on a Lada Priora 16 valve car is shown in detail in this video:

Required Tools

Before replacing the Lada Priora pump, prepare a number of tools:

- Keys for 10;

- Hexagon "5";

- Flat screwdriver;

- Torx T-30 (belt removal);

- Head wrench “17” (belt removal);

- Socket or cap wrench “15” (belt removal).

Diagnostics of the LADA Kalina engine cooling system

When operating a vehicle, the technical condition of the cooling system can be assessed by looking at the coolant temperature gauge and the fluid level in the expansion tank. A decrease in coolant level is usually caused by a leak in the system. Some cars have a coolant level sensor installed. When the level drops to the MIN mark, the corresponding indicator lamp in the display unit of the on-board monitoring system lights up.

| 1. Checking the coolant level in the expansion tank . The liquid level should be 25 - 30 mm above the MIN mark on the expansion tank body. If the fluid level is at the MIN mark or below, add coolant to the reservoir |

Warning!

| The coolant level should be checked on a cold engine. A slight increase or decrease in the coolant level during heating and cooling of the engine is not a malfunction. This is due to the thermal change in the volume of the liquid. |

If you have to regularly add coolant, you should check the tightness of the cooling system.

2. Check the tightness of hoses and connections of the cooling system . Inspect the engine compartment and pay attention to the condition and tightness:

- Expansion tank hoses;

- Radiator drain holes and hoses;

- Heater radiator hoses;

- Engine cylinder block;

- Places for installing temperature sensors;

- Thermostat hoses.

3. Checking the integrity of engine cooling system elements.

- Expansion tank housing;

- Engine radiator;

- Heater radiator;

- Connections between the coolant pump (pump) and the cylinder block. We also check that there is no leakage of liquid from the drainage hole of the pump (located at the bottom of the pump), indicating wear of its seal.

There should be no coolant leaks anywhere.

| 4. Checking the thermostat . We control the coolant temperature using the indicator on the instrument panel, and the circulation of the liquid in small and large circles by touch, by changes in the temperature of the hoses and pipes of the cooling system (in the photo the air filter is removed for clarity). |

Comment

| If the engine cooling system is working properly, then when the coolant temperature is less than 90 ° C, the main thermostat valve should be closed and the coolant should circulate in a small circle. As a result, the lower radiator hose and the radiator itself will be noticeably cooler than the thermostat housing, through which hot coolant circulates. When the coolant temperature reaches about 90 °C, the main thermostat valve will open and a gradually increasing flow of hot liquid will begin to flow into the radiator. In this case, first the radiator and then its lower hose will begin to heat up. |

Once the temperature reaches 102 °C, the main thermostat valve will fully open and all fluid flow will circulate through the radiator. In this case, the radiator will become hot in the upper zone and slightly cooler in the lower zone.

We leave the engine running until the engine radiator fan operates. When the coolant temperature rises to the point where the temperature gauge needle approaches the red zone, the electric fan should turn on, and when the temperature drops, it should automatically turn off.

Pump malfunctions

Malfunctions of the pump are manifested in significant play in its shaft, violation of the tightness of the seal, wear (corrosion or breakage) of the impeller. All of these defects lead to the fact that the car’s water pump does not work properly, which is why the required pressure is not maintained in the engine cooling system, which, in turn, leads to an increase in the temperature of the coolant until it boils. You have to buy a new pump and install it in place of the old one.

Diagnostics of the engine pump without dismantling: 3 main malfunctions of the device

The pump is a key component of the cooling system. In terms of design, this is a rather primitive pump that drives coolant around the circuit. As soon as the transportation of the refrigerant stops, the motor overheats and critical wear of the components occurs. The motorist should know how to check the pump without removing it from the engine in order to avoid lengthy handicraft diagnostics followed by dismantling the components. The ability to navigate the fault markers will help minimize the number of necessary diagnostic procedures.

Checking the VAZ 2109 water pump: algorithm and video

Problems that arise with the water pump can lead to big problems, including overheating of the engine and its complete failure.

If the water pump stops moving antifreeze or other coolant through the cooling system, the engine will definitely overheat. Next we will talk about checking the VAZ 2109 pump for functionality.

How to monitor the functional condition of the pump?

This is the key difficulty of the issue under consideration: the “symptomatic range” for the imminent failure of the cooler is extremely meager. For most drivers, a pump breakdown becomes an unpleasant surprise, as car owners do not know how to identify signs that can help determine the imminent “death” of the unit. Let us immediately note that the pump cannot be repaired. The only way to restore the functional state of the cooling system is to install a new unit.

According to automakers, the pump should run smoothly for 180 - 200 thousand km. However, they change it earlier - during routine or major maintenance of the timing belt (usually they do this: replacing the timing belt is accompanied by replacing the cooling blower). When approaching the specified mileage interval, we recommend paying attention to extraneous sounds in the engine compartment. A worn-out pump makes cyclic clicking sounds, sometimes grinding. The driver can independently change the service interval: most “experienced” drivers are convinced that the pump needs to be changed at 80 thousand km in order to minimize timing belt wear.

Causes of malfunction

The following reasons are identified that affect the deterioration of the mechanism:

- Damage to the rotating components of the impeller : during intensive operation, small wings of the rotating part break off. This is especially true for plastic impellers. When the wings break off, the pump can no longer pump antifreeze at the required intensity - the engine constantly overheats.

- Drain hole clogged . This problem leads to the fact that antifreeze cannot fully circulate through the circuit. Clogged drainage can be easily tracked without removing the pump. If you suspect that the drain holes are clogged, simply turn on the cabin heater.

- De-synchronization of element and timing pulleys . In this case, the seals and bearings work in extreme conditions and wear out extremely quickly. The reason for such a breakdown is a manufacturing defect: either low-quality materials were used during assembly, or an unreliable assembler was used.

We need to speak in more detail about the third reason. No car owner is insured against manufacturing defects. But in this case, everything is serious with the prefix “hyper”. If you install a pump with potential out of sync, then the use of such a defective unit will lead to a sharp increase in timing wear. In the best case, the driver may encounter a broken belt, in the worst case, the valves “knock”.

Another marker of wear (which, however, can only be seen after disassembling the mechanism) is play in the rotating parts. Backlash indicates imminent failure of the pulleys, displacement of the central axis and damage to the seals.

The last life hack for motorists who do not want to remove the pump, but want reliable information about its functional condition. Carefully inspect the junction of the cooler and the internal combustion engine. If there are significant antifreeze leaks, then the water pump does not have long to live.

Main reasons

Before talking about the signs of a dying pump that needs replacement or repair, you need to say a few words regarding the reasons for the failure of this device.

In total, there are several main factors that cause this to happen:

- Using low quality antifreeze. About 90% of pumps break down precisely because of this. Such a cooling liquid contributes to the appearance of tarry deposits, which makes the impeller difficult to rotate;

- Corrosion. Again due to low-grade antifreeze;

- Cavitation, that is, the formation of vacuum bubbles that can literally tear out pump particles and destroy the mechanism;

- The result of normal wear and tear. Each device has a limited resource. The best samples last about 200 thousand kilometers;

- Broken fastening. It's simple. The fasteners became loose, the pump became loose and fell apart.

In most cases, it is the car owner himself who is to blame. Drivers are required to monitor the condition of the cooling system, periodically check the pump, and change the coolant on time.

We cannot exclude the problem of manufacturing defects, as well as simply low-quality and cheap pumps that are installed on budget cars or as part of repairs, thereby deceiving the client.

It is not surprising that the timing belt may then fail, the tension roller may rupture, the cylinder head gasket may break through, and other troubles that can cost a lot of money during repairs.

We recommend: The windshield washer does not work: we look for the cause and eliminate it

Problems with the water pump can occur on various cars:

- on Kalina;

- VAZ 2110;

- Lada Priora 16 valves;

- VAZ 2114;

- Lada Priora 8 valves;

- VAZ 2115;

- Daewoo Lanos;

- Niva Chevrolet;

- Daewoo Nexia;

- Lada Granta;

- Renault Logan;

- Chevrolet Aveo, etc.

Don’t think that this is a problem exclusively with cheap and budget cars, as well as simple engines like ZMZ 406.

The pump can also be used on more expensive cars. It all depends on how the owner monitors and maintains the car with his own hands, or in a car service center.