An air lock in the engine cooling system is one of the main reasons for the engine taking a long time to warm up to operating temperature. Therefore, every driver should be interested in removing air lock from the cooling system of his car.

How to properly remove an air lock from the cooling system?

According to the law of physics, air accumulates in the highest place. In a car, the highest link in the coolant chain is the throttle body. That is why the air must be removed from there. There are several ways to get rid of an air lock. Here's the first one from the bottom:

If you have a 1.6 liter engine, then the first step is to remove the plastic cover on the engine - unscrew the cover on the engine to fill the oil, and then pull out the entire cover. It is seated on rubber seals. After removing this plastic screen, screw the oil cap back on to prevent dirt from getting into the crankcase.

- We find the heating pipes for the throttle assembly (there are 2 of them), see the figure. Pick up any phone

- Next, unscrew the cap of the expansion tank (coolant reservoir) and cover the neck of the tank with a clean rag.

- We begin to blow into the tank with liquid. We blow until all the air comes out of the hose and antifreeze flows out.

- We quickly put the tube back on and tighten it with a clamp so that no air gets in.

(It is worth noting that depending on the tube that you removed, antifreeze may leak from both the tube and the fitting from which the tube was removed)

The second method of removing air from the cooling system is less perverted. There is no need to blow anything here:

- Warm up the engine to operating temperature

- Warm up, turn off the engine

- The expansion tank cap does NOT need to be unscrewed.

- As in the first method, unscrew the clamp of the coolant pipe on the throttle assembly.

- Having removed the heating pipe of the throttle assembly, release the air, and after the antifreeze begins to flow out, immediately put it back on the fitting and secure it well with a clamp.

But be careful and careful! Don't forget that the coolant temperature is approximately 90 degrees.

There is also a simpler, but less effective way to eliminate an air lock:

1) We drive up a steep hill so that the radiator cap becomes the highest point of the cooling system.

2) Unscrew the cap of the expansion tank and the radiator cap.

3) Let the car warm up to operating temperature

4) Then we accelerate several times and at the same time add coolant into the barrel.

Do this until bubbles stop appearing.

How to remove an air lock on a VAZ with electronic (e-gas)?

Since there is no throttle valve cooling system, you need to bypass this unit. Here you can also set the car up.

I hope that these three methods will help you solve the problem, and that you have found all the answers to your questions on the topic “How to get rid of an airlock?”

An air lock in a car's cooling system can cause problems in the operation of the engine, electronic sensors, thermostat and other mechanisms. Next, we’ll figure out how to solve the problem yourself.

FEATURES OF ENGINE COOLING VAZ 2114

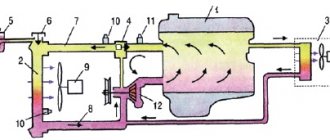

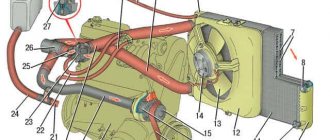

This car, like the VAZ 2113 and VAZ 2115, uses a VAZ closed liquid cooling system, the coolant in which is antifreeze or antifreeze. The coolant circulates through special channels in a running engine. Its circulation is ensured by a pump, which is driven by the engine crankshaft using a drive belt.

It regulates the flow of coolant, its direction, by a device called a thermostat. It is designed in such a way that before the coolant warms up to operating temperature, it circulates in a small circle, bypassing the radiator. When the liquid reaches a temperature of 87 0 C, it opens and the liquid flow is directed to the radiator for cooling.

The radiator is blown by a flow of oncoming air, and when there is not enough air, an electric fan turns on. For these purposes, a sensor is installed in the radiator, which produces a signal to turn it on. Also, hot liquid flows through the heater radiator and heats the interior of the car in cold weather. Excess antifreeze from thermal expansion is collected in an additional tank, which is called an expansion tank.

How to remove air from the engine cooling system?

The process of removing an air lock on cars is almost the same, be it Kalina, Priora, Granta, Hray, Vesta, VAZ 211(0-5), 2101-2107, Opel, Daewoo Matiz, Nexia, Nissan Almera, Gazelle Business, Audi 80-100 , BMW E39, Peugeot, Chevrolet Cruze, Skoda, Mazda, Mitsubishi Lancer, Suzuki Grand Vitara, Niva, UAZ, Volkswagen, Ford, Renault Duster, on Chinese Lifan and even on premium class cars.

There are several options for removing an air lock from the cooling system:

Option #1:

- Remove the plastic casing from the internal combustion engine. Why do you need to unscrew the filler cap to fill the oil? Remove the trim. After removing the casing, you need to close the neck to avoid the ingress of various kinds of objects.

- Find the pipes that provide heating for the throttle assembly.

- Remove any one pipe.

- Unscrew the cap of the expansion tank.

- Cover the neck with a clean piece of rag or tightly connect the hose and blow into it.

Thanks to this method, air and the general system are bleed. You need to blow until liquid flows out of the disconnected pipe. Then, immediately put the hose back in place.

Option #2:

- Start the engine and let it run for about 15 minutes.

- Turn off the engine.

- Disconnect any pipe on the throttle assembly.

- We do not touch the tank lid; it must be closed.

- Wait until the coolant starts to flow out.

- Place the pipe in place and tighten it tightly with a clamp.

To use this option, it is advisable to wear thick rubber gloves and overalls, because the temperature of the liquid is about 90 degrees.

Option #3:

- Place the car on a steep incline with the front end facing up (the steeper the better).

- Set the handbrake.

- Place wheel chocks (chocks) under the wheels.

- Unscrew the plugs from the expansion tank and the cooling radiator.

- The car should run for about 15 minutes with this setting.

- The antifreeze will gradually descend into the system, and the air will escape.

- Add antifreeze and gas.

- When the bubbles end, all the air has escaped.

PRESENCE OF AIR IN THE SYSTEM

Air in the engine cooling system is an unacceptable phenomenon. Heat exchange processes in the motor are disrupted, which can cause it to overheat, thereby creating the preconditions for failure. In cold weather, there will be no heating of the car interior or body glazing. Sensors installed in injection engines begin to provide distorted information to the electronic control unit, which disrupts the engine’s operating cycle.

WHY DO AIR LOCKES OCCUR?

In order for an air lock to occur in the cooling system, one of several possible reasons for its occurrence is sufficient. These may be such violations in the operation of the system:

You may also be interested

Why does antifreeze “leave” from the expansion tank?

The situation when the antifreeze has left the tank, and the reasons for this are unclear, occurs even too often - and it sometimes takes a long time to determine why this happened. However, there is a list of typical faults for which the car should be checked first.

How does antifreeze get into the engine?

Among the malfunctions that can happen to a car, one of the most common is antifreeze getting into the internal combustion engine. If oil gets into the antifreeze, you should also immediately diagnose and eliminate the cause of the breakdown. This will avoid major repairs to the machine and minimize damage.

Plug, sensors and expansion tank

And a little about the little things that, as it may seem, do not greatly affect the operation of the engine. But still, if the functioning of the plug is disrupted, the engine will begin to boil. And the reason is that it has two valves that, working together, maintain a pressure of just over one atmosphere. Consequently, if the valves become clogged, the pressure in the cooling system increases sharply (the liquid expands, but the air that was in the tank has nowhere to go).

Personally, on my VAZ 2109 the tank once swelled, a little more and it would have burst! Now I’m writing and I’m surprised how things didn’t come to this. When I stopped and opened the hood, I was simply stunned - the tank was round, like a ball, seething, steam was pouring out from everywhere. Therefore, the condition of the plug is extremely important for the normal functioning of the system.

The same is true with sensors - one, which is installed near the thermostat (if the power system has an injector, such a circuit is used), serves not only to generate a signal for sending to the indicator, but also to turn on the electric fan. The signal from the sensor goes to the electronic control unit, which is responsible for promptly turning on/off the electric fan.

VAZ 2114 no antifreeze circulation

Eh, I’ve suffered a lot over the last month, it’s -10...-20 outside, the same in the cabin, but the fan still works, and the antifreeze continues to flow out... here I’ll write down point by point everything that was changed and modified during the troubleshooting process

in the summer I started going somewhere

Shariot engine

semi-synthetic VAZ 2105 at minus 30

Eh, I’ve suffered a lot over the last month, it’s -10...-20 outside, the same in the cabin, but the fan still works, and the antifreeze continues to flow out... here I’ll write down point by point everything that was changed and modified during the troubleshooting process

Even in the summer, antifreeze began to leak somewhere, I added it more and more often... and one October morning I found a puddle on the driver’s mat and that’s where it all started

1) replaced the heater radiator, found a leak. To do this we had to remove the entire panel, but the most difficult thing was to return all the wires, terminals, connections, bolts to their places 2) replaced the heater valve 3) tightened all the damper cables 4) taped all the joints of the air ducts with splen 5) plugged the air ducts to the feet of the rear passengers with foam rubber

but the antifreeze continued to leak and after a couple of months I went to the service center again to look for the cause

5) found a leak in the cooling radiator, replaced it 6) changed the pipes going to the radiator

the next day the epic began, the engine stayed at 100 degrees, the fan ran intermittently for a minute, the stove blew cold, antifreeze splashed out through the top

7) tried to remove the plug from the system, it didn’t help

went to the service

8) they changed the thermostat, nothing changed, and the new one was delayed from the stated 87 to 96

I discovered that even with the fan running, there is no circulation of antifreeze from the upper pipe into the expansion tank, the conclusion is that the pump impeller was probably cut off... I went once again to another service

9) they replaced the pump, it turned out to be in vain, a new 7-blade pump with a plastic impeller, the old blades were already metal, and the reason for the release of antifreeze from the expansion tank turned out to be trivial - in the previous service they mixed up the upper and lower radiators) and it’s annoying and offensive, liters of antifreeze were wasted 10 through the top, pump, belt, replacement cost...

The problem with the emission was solved, but the problem with overheating and cold in the cabin was not... back to the service...

10) since the thermostat was lagging, we changed it again, already at the factory temperature of 85 degrees, checked, it was also lagging (... up to 91-95 11) we flushed the cooling system with a hi-gear flush 12) to avoid a plug, drained all the liquid and poured it back on engine new antifreeze 13) changed the metal tube coming from the pump... sometimes it gets clogged or microcracks appear. 14) replaced the remaining pipes with new ones and stretched everything

... nothing helped... and during all this time, only one service center offered to change the cylinder head gasket, and then out of despair and without any visible signs. Although I asked everywhere and reminded about this option...

...and then one day, when I went to the service center, the car began to shake, thick blue smoke was coming out of the chimney and the condensation was sweet...they finally recognized the cylinder head gasket as the cause. ...I went to the services, found somewhere cheaper, made an appointment for the evening...I left in the evening, the smoke was incredible, I couldn’t see anything from behind, the temperature was 130, the car was shaking, all the antifreeze had gone through the exhaust and, as luck would have it, the hood wouldn’t open (something with the cable happened) and wild traffic jams while driving, I turned off the engine 70 times, leaving only the ignition on so that only the fan worked... in the end I got to the service station on a cable... otherwise it was already scary! I was afraid for the engine!

changed the gasket, oil, antifreeze went into the first cylinder... Now it’s -20 outside, in the car more or less, at idle the air is no longer cold... A LITTLE WARM, YOU GIVE THE GAS WARMER... AND HOW DOES YOUR OVEN BLOW IN THE FREEZE?

PS Thanks to everyone who helped with advice and who read this post to the end =) Maybe my post and personal experience will help someone with a similar problem!

Is it possible to start from a pusher with flooded spark plugs?

what is better to buy bmw e36 bkb

Astra sedan 1 8 dynamics

Similar articles:

Useful tips → Winter driving rules

Useful tips → Secret letters in your car

Helpful tips → How to properly drive over a speed bump

Useful tips → How to get out of a skid correctly

Useful tips → How to protect your car and property from theft?

Signs of an air lock in the cooling system

You can determine the presence of air in the engine refrigeration system by conducting independent diagnostics and eliminating the causes. We carry out diagnostics based on the above criteria.

Signs:

- Checking the system for leaks. Over time, clamps weaken, oxidize, or break completely. The hose also has shock absorption; over time, it bursts and cracks; either heat or cold gradually destroy the rubber.

- Problems with the thermostat. If the engine heats up very quickly after starting, that is, the cooling fan has already turned on, and the temperature sensor shows that it is about to push the needle into the red scale, then this indicates a non-working thermostat or the presence of air in the pump discharge pipe. In this case, the thermostat valve will be in the closed position, the coolant will move in a small circle. The opposite may also happen. The engine takes a very long time to warm up after starting. This means that the thermostat valve is fully open or there is an air lock in the thermostat. In all cases, you will have to remove air from the engine cooling system.

It’s easy to check the thermostat yourself; you need to do the following:

- start the engine;

- after a couple of minutes, touch the radiator pipes (the top one should be warm first, then cold, the bottom one should be cold);

- when the engine temperature reaches operating temperature, 80-90 degrees, the thermostat should open and the lower pipe should heat up.

It's also easy to check functionality. It is determined by the noise level (it is not worth using a noise sensor and determining the level in decibels (dB)), by the sound you can already feel how the pump is working. The vibration of the pump is also checked. The pump bearing may have fallen off.

The main clue is that air has appeared in the engine cooling system in the heater. If the engine is hot and the heater is blowing cold air, then there is an air lock.

Now you know what to do if air gets into the cooling system, and also how to prevent such a situation. We wish you success!

Air removal methods

If you observe on the dashboard that the operating temperature of the engine is constantly exceeded (100 degrees or more), follow a number of steps to identify the problem:

- examine the joints of the pipes, the water pump and the expansion tank for leaks;

- check the fluid level in the tank;

- make sure that the cabin heater is functioning properly;

- If the temperature sensor is installed outside the cylinder head, check the operation of the electric fan by closing the contacts.

Before bleeding the cooling system, it is necessary to eliminate all leaks, if any are found. A water pump seal that has lost its seal should be replaced (as a rule, together with the pump), hose clamps should be tightened, and so on. There is no point in removing an air lock from a leaking cooling system.

Checking the heater and fan sensor will help you more accurately determine the location of the air bubble. When the engine temperature reaches a critical threshold and the heater does not heat up, it means that the plug is in a small circulation circuit - in the stove itself or in the supply pipes. If the sensor does not turn on forced airflow in time, then it has entered an area where the movement of antifreeze has stopped - the bubble is in a large circuit.

Advice. Often, due to an air lock, the thermostat refuses to open the passage of antifreeze in a large circle because it does not “see” the temperature increase. Don't make a common mistake and don't rush to change the thermostat - first try to bleed the cooling system.

Method one - blowing

This simplest method requires caution from the car enthusiast, since it is performed on a fully warmed-up engine. The order of operations is as follows:

- If necessary, add fluid to the minimum level and warm up the power unit to operating temperature. Carefully unscrew the cap of the expansion tank.

- Wear gloves and disconnect the thin coolant pipe at the highest point. For an engine with an injector, this is the throttle valve heating unit; on a carburetor engine, it is the intake manifold or the lower part of the carburetor itself.

- Wipe the reservoir neck thoroughly. Place a wide bowl under the removed hose and blow into the expansion tank. When clean antifreeze flows from the pipe, put it on the fitting and secure it with a clamp.

Attention! On a warm engine, unscrew the expansion tank cap slowly, allowing air to escape. If you remove it abruptly, hot antifreeze will splash out of the neck and burn your hands.

If your vehicle has a thermostatic main radiator cap, try removing the air lock through it. Open both plugs and blow into the neck of the expansion tank.

Method two - complete replacement

This option is suitable for all cases when it is not possible to detect and push a bubble out of pipelines. The point is to completely empty the system and fill it back with antifreeze, following all the rules. The disadvantage of the method is the difficulty of implementation in road conditions.

We recommend: Why do the spark plugs on the injector flood and how to deal with it?

The procedure is performed in the following order:

- Drain the antifreeze into a wide basin, placing it alternately under the plug on the cylinder block and the main radiator.

- Replace all caps and tighten them.

- Loosen the clamp and remove the throttle body or carburetor heater pipe (the highest point of the system).

- Insert a funnel into the neck of the expansion tank and slowly pour coolant in a thin stream. Air will be removed through the removed hose.

- Monitor the moment when antifreeze runs out of the pipe and immediately put it on the fitting.

Before emptying, be sure to fully open the cabin heater tap.

When the throttle (or carburetor) heating hose is put on and secured with a clamp, add fluid to the container to the required level. Next, check the functionality of the cooling by completely warming up the engine until the thermostat opens and the electric fan turns on.

Method three - road

When faced with overheating of the power unit on the road, try to remove the airlock using this method:

- Having secured the car with the handbrake, lift the front part with a jack to a height of 0.3–0.4 m.

- Slowly unscrew the expansion tank cap, start the engine and turn on the cabin heater to maximum mode.

- Pour antifreeze into the tank in a thin stream until its level reaches the upper limit. Increase the crankshaft speed to 3000 rpm and wait until it warms up completely.

- Squeeze the lower hose leading to the radiator with your hand. The air should escape through the expansion tank. Use gloves or thick cloth to avoid getting burned.

The procedure ends when air stops coming out of the tank. Feel the remaining pipes - they should warm up. Make sure the stove produces a hot stream.

To avoid having to fuss with removing air pockets, always fill in antifreeze according to the instructions described in the previous section. This is the best way to force air out of the system. Fix leaks in a timely manner, do not drive with endless additions of coolant.