Lada K alina 2 . CHECKING AND REPLACING THE VOLTAGE REGULATOR ON THE CAR

You will need: a flat-blade screwdriver, 8", 12" wrenches, 7", "8", "24" socket wrenches, a hammer, a DC voltmeter, a megger.

The operation of the voltage regulator is to continuously automatically change the generator excitation current so that the generator voltage is maintained within specified limits when the rotation speed and load current change.

If necessary, you can check and replace the voltage regulator without removing the generator from the car.

Shown is working on a car without air conditioning. On a car with air conditioning, a generator of a different model is installed, and to remove the relay-regulator, the generator must be removed from the car. 1. Move the rubber boot aside and connect the “plus” wire and the “minus” wire to the generator housing.

2. Start the engine and turn on the headlights.

3. After 15 minutes of engine operation at medium speed, measure the voltage; it should be 14.4-15.1 V. If undercharging or overcharging is observed (the voltage does not fall within the specified limits), replace the voltage regulator.

4. The serviceability of the capacitor can be checked with a megger or tester (on a scale of 1-10 MOhm). Connect the tester probes to the capacitor contacts. Before connecting, the device shows infinity. At the moment of connection, the resistance decreases, and then again tends to infinity. In this case, the capacitor is OK.

The faulty capacitor is replaced together with the rectifier unit as follows.

1. Disconnect the wire from the negative terminal of the battery. 2. Disconnect the wiring harness block from the generator terminals.

12. Check the serviceability of the voltage regulator. Connect a 12V test lamp to the brushes. Apply a voltage of 12 V “plus” to the terminal, and “minus” to the “ground” of the brush holder. In this case, the control lamp should light up.

13. Set the voltage to 15-16 V - the lamp should go out. If the lamp is on or off in both cases, then the regulator with brush holder is faulty and needs to be replaced.

14. Install the voltage regulator in the reverse order of removal.

On Kalina cars, the generator is three-phase and produces alternating current. There is no need to go into too much theory; an ordinary motorist only needs to know how to independently diagnose and repair the installation. This means installing the generator and voltage regulator directly. The fact is that at the output of the power windings the voltage jumps in the range of 10-30 V, and to power the entire on-board network you need 12 V. The first step is to rectify the voltage and then stabilize it.

Generator operating principle

To visually visualize the operation of the installation, use the generator connection diagram. The second component of the installation is a voltage regulator, which is included in the power circuit of the rotor winding. The instrument panel contains a charge control lamp that:

- Lights up when the ignition is turned on and there is a breakdown in the generator set.

- Does not light up in normal mode and when there is a proper charge level.

A relay with normally closed contacts is used to power this lamp. Therefore, when the ignition is turned on, it lights up. Further, as soon as you start the engine, the generator begins to generate voltage. The relay winding is connected to the rotor power circuit; when voltage appears, the contacts switch - they open and the lamp goes out.

The generator must always be in good working order

Any modern car is equipped with electrical equipment that is absolutely necessary for the vehicle:

- without a starter it is impossible to start the engine;

- a car cannot be driven without lighting at night;

- The heater motor creates heat in the cabin;

- The wiper motor clears the windshield of rain and snow;

- FM radio makes it possible for the driver not to get bored on the road.

But all these devices cannot work without electricity, so the car must have a power source.

The current from which all consumers in the car are powered is produced by the generator, and the performance of the entire electrical circuit of the vehicle depends on its condition.

Therefore, the generator must always be in good working order, and if any breakdowns occur with it, they must be eliminated in a short time.

Main Generator Components

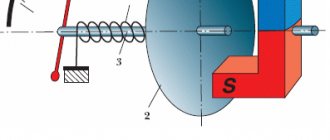

In general, a generator is a converter that creates electrical energy from mechanical energy. On all cars, the design and operating principle of these devices are similar. The design consists of the following components:

- The stator winding, a thick copper wire is used for it, since it is with its help that voltage is generated.

- The rotor winding is excitation. Without it, it is impossible for current to appear in the stator winding. In order for any potential difference to appear in the frame, the presence of two components is necessary - rotation and a magnetic field. Thanks to the generator belt on the Kalina, the rotor rotates. It is its winding that fulfills these two conditions - a magnetic field is created around it, and it rotates around its axis.

- The rotor is equipped with slip rings, to which voltage is supplied using a brush assembly.

- A pulley mounted on the rotor allows rotation to be transmitted from the crankshaft via the generator belt on the Kalina.

- A mechanical or electronic voltage regulator changes the voltage on the rotor winding. Due to this, the generator produces a stable voltage.

- The block of semiconductors (valves) mentioned earlier is necessary to convert three-phase alternating voltage into unipolar direct voltage.

- Covers with bearings are designed for rotor alignment and normal operation of the unit.

- The capacitor allows you to get rid of residual alternating current after rectification.

Video about the reasons why the battery on the Lada Kalina does not charge

Welcome! Voltage regulator - it is installed on the generator and is directly connected to it, thanks to it, the entire current that the generator gives out changes and flows more evenly, for example, the more you turn the engine of a car (increase the speed, that is), the generator will work stronger and much more give out current, all this happens because the generator is connected to the engine (namely, it is connected to the crankshaft), but the voltage in the on-board network will also change from this (The more current the generator gives, the stronger this current increases in the entire on-board network car), therefore, when the speed increases, the light will constantly burn stronger, and when it decreases, it will dim because the current strength will decrease, so no matter what happened, a voltage regulator was invented, thanks to which the current strength in the on-board network always remains the same, but it changes when you turn on additional devices that need more current, that is, for example, you turn on the high beam headlights of a car and the current supply increases through the regulator so that there is enough power for these headlights, in addition, the current supply flowing through The regulator is constant and does not jump higher or lower, so the headlights work in the same mode and do not shine either stronger or weaker.

Note! In order to change or check the voltage regulator, you will need: Two different types of screwdrivers, as well as two wrenches that will be “12” in size, and you will also need a DC voltmeter thanks to which you can clearly determine what voltage you have in your on-board network and whether it is jumping, and among electrical appliances, a megohm meter is also useful, thanks to which you can check the regulator’s capacitor for serviceability, thanks to which the current strength remains constant when supplied to the on-board network!

Summary:

Where is the voltage regulator located? It is located on the generator itself, as was already said a little earlier, a plus wire and a wire block are also suitable for it, so that the regulator does not become dirty; for this purpose it is also closed with a plastic cover, in more detail the pin that comes out of the regulator you can look at photo which is located below, in this photo you can just see the same plastic cover that closes the regulator, and in the other photo (Small) you can see that the cover has already been removed and only one pin sticks out, which comes from the regulator (This pin is on both indicated by a red arrow in the pictures).

Read more: Rear view camera with dynamic markings

When should you change the voltage regulator? It needs to be changed when it begins to pass alternating current into the on-board network (Alternating current is the current that rises or falls under the condition that the circuit leaves its direction unchanged), in other words, if the current strength fluctuates (And this should not happen), then the regulator must be replaced, if the current fluctuates, for example, the headlights may burn either worse or more intensely (Depending on the engine speed, at high speeds the headlights will burn stronger), and the regulator must also be replaced if it begins to produce either less current than necessary (In this case, you will have an undercharge of the battery), or more (With a stronger current, you may burn out the main part of the wiring in the car that will not withstand the heavy load, or if you have fuses, then at best they will have time to open the circuit and nothing bad will happen to the wiring).

Signs of generator failure

To diagnose the generator set, it is not necessary to remove it. Here are some typical symptoms of breakdowns:

- The presence of a hum and whistle from the generator indicates that the bearings are damaged. If you start it, the rotor may jam and the belt may break.

- Whistling, short-term ignition of the charging control lamp - the alternator belt on the Lada Kalina is worn out, or it has low tension. If the lamp is constantly on, there may be a break.

- If the charging lamp is on, this means that there is no voltage at the generator output. The reason may lie in the windings, voltage regulator, slip rings, diodes, wiring.

Malfunctions

All generator malfunctions can be divided into two categories:

- lack of charging (or undercharging);

- increased noise.

A whistling or grinding noise may be caused by bearings or tension belts.

The reason for poor charging or its complete absence may be:

- break or short circuit in the rotor or stator winding;

- wear of the brushes (they are located in the same housing with the relay regulator);

- charging relay malfunction;

- breakdown of the diode bridge;

- loose belt.

Actions when charging disappears

The generator on a Kalina with air conditioning has more power than on cars without an air conditioning system. The design and faults are the same. What to do if charging is lost? Don't panic and check immediately:

- Voltage regulator. The easiest and most expensive way is to replace it with a known good one. But you can also apply voltage of 12 V and 15 V to check operation. Regardless of whether the regulator is mechanical or electrical, it will behave the same. In the first case, voltage will be supplied to the excitation winding, but in the second - not.

- Alternator slip rings and brushes. You can use a simple lamp probe to check the contacts. The length of the brushes must be more than 5 mm, otherwise they should be replaced.

- The integrity of the field winding can be checked with a tester. Moreover, there is no need to remove the generator, just crawl up to the slip rings and check the resistance between them. Please note that they should not short to ground.

- The condition of the stator winding and diode bridge can be assessed only after dismantling the generator.

How to replace the voltage regulator and check its serviceability on a VAZ 1117-VAZ 1119?

Checking the voltage regulator for serviceability:

1) At the beginning of the operation, you will need to find where the generator itself is located and after you find it, move your hand to the side with the rubber cover indicated by the red arrow, this cover covers the “B+” terminal; in simpler words, this is the positive terminal and it comes from the generator to this terminal (By the way, it is also indicated by a blue arrow) you will need to connect the positive wire of the voltmeter and after connecting it, throw another wire (Minus wire) coming from the same voltmeter to ground (The places where you need to connect the wire , indicated by a green arrow), after the operation has been completed, a DC voltmeter will show you the voltage in the vehicle’s on-board network.

2) After everything is connected, start the engine of the car and turn on the headlights, when the engine is started, let it run for a while (About 15 minutes) and after this time has passed, at medium speed engine, measure the voltage in the on-board network, which you should have in the range of 14.4-15.1 V.

Note! If this voltage is either more or less, then replace the voltage regulator with a new one!

3) Now, as for the capacitor, to check whether it works or not, you just need to use a megohmmeter to connect the leads that go from it to the contact of the capacitor; when connecting, your resistance should initially decrease and then become infinite (What kind of infinity do you have on the device? it’s very easy to understand, for this, without connecting anything, first look at the numbers that the megohmmeter shows, for example, if it shows 0, then this will be infinity), if this is what happened, then in this case the capacitor is fully operational and does not require replacement, otherwise, replace the capacitor with a new one.

How to dismantle the generator

Now we need to tell you how to remove the generator. To do this, proceed according to the following principle:

- Disconnect the battery.

- Disconnect all wires going to the generator.

- Pre-treat threaded connections with penetrating lubricant such as WD-40.

- Unscrew the nut from the top mounting of the generator. The bracket can also be removed.

- Unscrew the nut from the lower mounting bolt. Hold the bolt head from turning.

- Remove the Kalina generator belt from the roller. There is no need to perform any manipulations with the air conditioner and power steering.

- Remove the generator from its seat.

Replacing the roller and brushes

If you hear a rustling noise coming from the tension roller of the Lada Kalina generator belt, then you need to check its serviceability and replace it.

To perform this procedure, you need to use a set of wrenches and a flat-blade screwdriver. Replacing the roller is a very simple procedure. To perform this, you must first loosen the belt tension by unscrewing the rod. Then use a flat-head screwdriver to pry off the protective cap of the roller and unscrew the bolt securing the bearing to the bracket.

The bushing and washer are removed from the old roller, then they are installed on the new roller. The entire assembly assembly is placed in place of the old roller and secured with a bolt. Next, the belt is properly tensioned and the car engine is started to check how the new roller works. After replacing the roller, no extraneous noise should be heard from the Lada generator.

One of the reasons that the battery does not charge well is wear on the generator brushes. To eliminate this malfunction, it is not necessary to replace the entire generator; it is enough to change only the brushes. To check their condition, the brushes must be removed and inspected. This can be done both with the generator installed and with it removed.

To avoid a short circuit when performing this procedure, it is necessary to remove the negative terminal of the battery. After this, remove the protective cover of the device and remove the power plug using a flat-head screwdriver. In this case, you need to make sure that the solder does not come off from the voltage regulator.

At the final stage, the bolts are unscrewed and the voltage regulator with the brushes attached to it is removed. To find out if the brushes are working properly, you need to measure their height. It must be at least 5 mm. If this value is lower, then the generator brushes complete with the voltage regulator must be replaced.

Disassembling the device

To disassemble the generator, you need to perform several simple manipulations:

- Remove the drive pulley. Try not to lose the key.

- Unscrew the nuts from the back cover that secure all parts of the structure.

- Remove the voltage regulator. At the same time, evaluate the condition of the brush assembly.

- Disconnect all parts of the generator.

After this, you can begin to carry out repairs.

Bearings often fail, especially the one located in the front cover. The reason for this is excessive belt tension. To make a replacement, you need to unscrew four screws and press the bearing out of its seat. Instead, install a new bearing. To increase reliability, change both rollers at once.

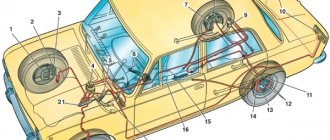

Device

The Lada Kalina generator consists of the following parts:

- housing (front and back cover);

- pulley;

- stator windings;

- armatures (rotor);

- voltage regulator relay (charging relay);

- diode bridge (rectifier unit);

- two armature bearings;

- rear plastic casing.

Inside the generator housing, along its walls there is a stator with a winding, and a rotor is located in the center.

At the back of the case there is a diode bridge and a voltage regulator relay; the diode bridge is covered with a plastic casing to prevent dirt and dust from entering.

There is a pulley in front of the housing; it is put on the rotor shaft and secured with a nut.

The generator is driven by a drive belt placed on a pulley.

Installation and repair features

Installation occurs in reverse order. If necessary, the generator is replaced or repaired. In some cases, repair will be impractical, since there are many unusable components, including stator and rotor windings. Restoration will be expensive; it will be much easier to completely replace the generator on Kalina. The cost of a new generator in stores is 4-5 thousand rubles. At "showdown" you can buy it 2-3 times cheaper.

As already mentioned in previous articles, the main malfunctions of the generator are failure of the diode bridge, brushes with a voltage regulator, or even an open circuit in the winding of the device. Below I will give some of the types of diagnostics using a multimeter that anyone can perform independently if they have this device.

When is it time to change?

On Lada Kalina cars, the manufacturer does not regulate the replacement of this part. However, its failure is a common problem. In particular, we are talking about Lada Kalina cars. This applies to both 16-cl and 8-cl engines.

This is what a deformed element of a Kalina generator with an 8-cyl internal combustion engine looks like

Therefore, let’s look at the signs that indicate that the belt may fail in the near future:

- Whistle when moving. As a rule, this whistle appears when the electrical appliances of the vehicle begin to load. For example, if you start the car, and when you press the gas, a loud whistle is heard from the engine compartment, this indicates that the belt is loose. In this case, it must be tightened using a tensioner or replaced.

- Cracks on the strap. If you open the hood, look at the belt and see cracks on it, then you know that it’s time to change the element. Neither tensioning nor adjusting the rollers will help here. The component can be tightened, but this will not be enough for a long time. The only option left is replacement.

- Deformation. As in the previous case, neither tightening the tensioner nor adjusting the rollers will give much effect. You just need to change the element.

- Noise when the engine is running. If the element has already served its service life, this can be understood by the noise that appears when the motor is running. For example, some Lad Kalin car owners report loud knocking and even impacts when the engine is running.

The assembly is disassembled: this is what the strap looks like on the shafts

If the vehicle is equipped with a generator sensor that determines its performance, then it will be easier to identify the malfunction. For example, if you heard a whistle from under the hood, and at this time the indicator on the sensor came on, then you need to pay attention to the strap. This indicates that the belt needs to be tightened, since it may be in a weak state or that its service life has been exhausted.

One way or another, if the slipping and whistling of the strap cannot be eliminated by adjusting the belt or rollers, it needs to be changed.

Checking the rectifier unit (diode bridge)

To perform this diagnostic, it is necessary to remove the diode bridge from the Kalina generator; this was described in more detail in previous articles in this section.

Then we connect the tester with the black wire to the negative plate of the block, and the red one in turn to the three contact terminals of the diodes. This way we check all the rectifiers in the block. The values on the device should be in the range from 400 to 800 Ohms. Personally, on my Kalina, during this test, all diodes showed a resistance within 535 Ohms. But the repair instructions from the Third Rome publishing house talk about numbers of 580-620 Ohms. I will say right away that when I rang two serviceable generators, the values specified in the manual were not achieved, although there were no problems with charging, so I personally doubt the accuracy of the data in this instruction.

Then we carry out the same operation, only swapping the contact wires of the multimeter. In this case, the device, with working diodes, will show infinity, that is, its readings will not change:

Vehicle voltage

For normal operation of all consumers in the car, the generator must maintain a certain voltage; for the Lada Kalina on-board network, with a working generator, it must be in the range from 13 to 14.8 volts.

Within specified limits, the voltage is provided by a relay regulator, and with any deviation from the specified norm, various problems arise:

- At high voltage, the electrolyte in the battery banks boils, and the battery quickly fails;

- If there is insufficient charging, there is not enough current for consumers, as a result the battery quickly discharges.

The voltage generated by the current source is measured in the following way:

- On a digital multimeter (voltmeter), set the limit to 20 volts;

- We connect the probes of the measuring device to the battery and start the internal combustion engine, the voltmeter should show a voltage of about 14 volts;

- Without turning off the engine, we turn on the load - headlights (high beam), heater motor at maximum speed, windshield wipers, radio, etc. If the generator is in good condition, when the engine is idling, the voltage should not fall below 13.2V, optimal The voltage is considered to be 13.7-13.9 V.

Checking the serviceability of the voltage regulator with brushes

To do this, you need to connect a 12 Volt light bulb to the two ends of the brushes, and apply 12 Volt voltage to the regulator contacts. If this device is working properly, the light should light up. When the voltage supplied to the regulator increases to 15-16 V, the light should go out.

In case of detected malfunctions in various devices, we replace them. More details about this are written in previous articles from the “Generator” section.