in our VKontakte group

DIAGNOSE YOUR CAR YOURSELF!

Code P0102 is entered if the following conditions exist:

engine speed above 560 rpm air consumption below 2.5 kg/h. The CHECK ENGINE lamp comes on 8 seconds after a permanent fault occurs.

1. Check the presence of supply voltage and the reliability of the connection to ground.

2. The resistance between pin 5 of the harness block and ground is determined, which should be within 4.6 kOhm.

An intermittent malfunction can be caused by poor contact, incorrect route of the harness, damage to the insulation or wire core, or an unreliable connection of the sensor to ground, or the connection of additional powerful consumers to the harness. You must ensure that there are no following faults:

Unreliable connection between pins 7 and 12 of the injection system harness and controller. Inspect the harness block and the controller connector for completeness and correct alignment, damage to the locks, the presence of damaged contacts, and the quality of connection of the contacts to the wire.

Wrong harness route. Make sure that the sensor wiring harness is not routed near high voltage wires.

Damage to the tourniquet. Check the harness for damage. If the harness appears to be normal, move the appropriate pad and harness while observing the scan tool.

Clogged air filter in the air intake system. If necessary, replace the filter element.

Start the engine. Select "Errors" from the menu. If the DTC is not currently active, refer to Diagnostic Information. Code P0102 is not permanent. If there are no other codes, analyze the conditions under which the code occurred.

1. Turn off the ignition. Disconnect the harness connector from the sensor. Turn on the ignition, the engine does not run.

Using a multimeter, measure the voltage between the terminals of the harness block. The multimeter should show the following voltage values:

between contacts “2” and “3” – more than 10 V; between contacts “3” and “4” – 5 V. between contact “3” and ground – 0 V. For other voltage values, eliminate breaks or short-circuits to ground in the corresponding circuits.

2. Turn off the ignition. Using a multimeter, measure the resistance between contact “5” of the harness block and ground.

If the resistance is within 4..6 kOhm, the mass air flow sensor or its connection is faulty.

If the resistance is about 0 Ohm, there is a short to ground in wire 4 F, or the controller is faulty.

If the resistance is more than 100 kOhm, wire 4 G is broken, or the controller is faulty.

After repair, start the engine, reset the codes and make sure there is no signal from the “CHECK ENGINE” lamp.

Modern cars are stuffed with all kinds of electronics. On the one hand, this is convenient, since most faults can be determined using the on-board computer, but on the other hand, frightening messages often appear with fault codes in engine operation. Error P0102 is a frequent culprit of failures in VAZ family cars. What this code means and how to eliminate it, we will tell you in the article.

How and how to clean the mass air flow sensor (MAF)

Therefore, you can destroy the sensor with an aggressive liquid in no time. It costs a lot. For example, a mass air flow sensor for a Chevrolet Aveo will cost from 2400 to 3500 hryvnia (85-100 dollars), and the same sensor for a Ford Focus or Mazda6, MPV, CX, VAG cars from 80 to 120 dollars.

And yet, if the sensor has already been repaired or cleaned several times, it is useless to play with it. Most likely, the active sensitive elements have done their job.

To clean the sensor, under no circumstances should you use brushes, ear sticks, matches, pins or other nonsense. This is guaranteed to ruin the sensors. As well as liquids containing acetone and other solvents.

Interesting on the topic: Crankshaft position sensor: check, principle of operation and replacement

At your own risk, you can try the available cleaners:

- Alcohols (ethyl, methyl, isopropyl). Apply to the sensor carefully, spraying through a medical syringe with a needle.

- Formic alcohol . Best used on non-sensitive surfaces.

- Aqueous solutions of glycerin (detergents, liquid powders, soaps). A questionable method, but if there is nothing else, you can try. Careful drying after washing is required.

There are a bunch of different compositions for cleaning mass air flow sensors on sale. There are also fakes among them. It's clear where the original is. The danger is that most cheap e-liquids contain acetone. Which destroys the sensitive element of the sensor.

What does error P0102 mean?

The operation of the engine is completely subordinate to commands coming from the vehicle's ECU. By collecting information from different sensors, the controller selects the correct modes for all machine systems. Error code P0102 indicates that the signal coming from the mass air flow sensor (mass air flow sensor) has a low voltage. This malfunction can be caused by several reasons:

- Excessively clogged air filter. The amount of air entering the engine is not enough for the sensor to operate correctly - this is one of the most common reasons.

- Proximity of high-voltage ignition wires to the mass air flow sensor. High voltage in nearby wires can create self-inductive currents in the sensor and lead to the generation of incorrect signals.

- DMRV contamination.

What is the MAF for?

An internal combustion engine runs on a combination of fuel and air. For effective operation, a mixture is required that will burn out almost completely in the cylinders, and for this you need to choose the right ratio.

The mass air flow sensor, otherwise known as the MAF sensor, transmits readings to a computer, which selects the exact proportion of air and gasoline corresponding to certain crankshaft speeds.

Symptoms of the error

Undoubtedly, with error P0102, the car can continue to drive, but the operation of its engine will be unstable.

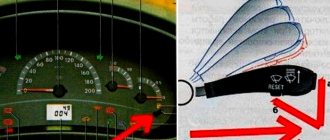

First, the Check Engine sign lights up on the instrument panel, indicating a problem. In this case, the car may have difficulty starting. Instead of stable speed, a cold engine will work intermittently, you will have to rev up the gas so that the engine does not stall.

The error signal may disappear for some time, but later the situation only gets worse: failures can occur not only at idle, but also while the engine is running under load. For example, during overtaking, when you need to squeeze out maximum power, the car may begin to jerk without gaining speed. The car may stall while driving as soon as your foot is removed from the gas pedal. All this can lead to an emergency on the road.

Symptoms of a problem

The mass air flow sensor is located in the air duct near the air filter. It is designed to determine the amount of incoming air. Depending on its readings, the control unit will show how much fuel is needed to form a high-quality fuel mixture. The normal ratio is 1:14. Therefore, the quality of the fuel-air mixture depends on the correct readings of the flow meter.

The high-quality operation of the mass air flow sensor depends largely on the cleanliness of the air filter. Therefore, if symptoms of a malfunction of the mass air flow sensor appear, you should first check the air filter before making repairs. The flow meter is usually beyond repair. If it is faulty, it is replaced with a new device. But its cost is quite high, so you should first make sure that the causes of the problems are in the sensor and not in other malfunctions of the machine.

The signal for diagnosis is the following symptoms of a malfunction of the mass air flow sensor:

- Check Engine appears on the instrument panel;

- an error is displayed indicating a low level of the mass air flow sensor signal;

- the engine is bad, accelerates very slowly, stalls, its power drops;

- high level of fuel consumption;

- the engine is unstable at idle;

- the engine stalls when changing gears;

- The rpms are either high or low.

There are other symptoms of a “dying” sensor. For example, it may have cracks in the corrugated hose that connects the throttle body to the sensor. If the engine stalls, there may be a power problem or damaged wiring. This is a signal to check the electrical wiring. If malfunctions are detected, the machine's electrical system must be repaired.

In addition to the above possible signs of failure of the mass air flow sensor, you should diagnose the sensor signal level.

A low signal level may mean the following:

- Mass air flow sensor is not connected;

Disconnected sensor connector

- open circuit in the sensor connection circuit;

- the mass in the chain breaks, oxidation appears;

- signal wires are broken or incorrectly connected;

- Engine control unit malfunction.

You should not draw conclusions about a malfunction of the mass air flow sensor, relying only on the symptoms listed above. A complete diagnosis of the engine and machine should be carried out, since signs of a flow meter failure may appear if other devices malfunction (for example, due to a clogged air filter). Then you need to repair these devices to restore the car's functionality.

DMRV error code

The following errors may indicate a malfunction in the operation of the mass air flow sensor:

- P0100 - damage to the electrical circuit connecting the sensor. To eliminate the breakdown, you need to check the wiring for integrity, since accidental disconnection of the connector or damage to the electrical contacts is possible.

- P0102 - the vehicle control unit began to receive a low signal, which was recorded at the input of the mass air flow sensor power line. To eliminate the cause of the breakdown, it is necessary to check the electrical wiring and the insulating layer of the cable; oxidation of the contacts of the wiring connector (the so-called chips) is possible.

- P0103 - critically high signal detected at the input of the mass air flow sensor power line. If the cause of the malfunction is not the wiring, then a visual inspection and cleaning of the flow meter will be required or it will have to be replaced with a new one.

How to check the sensor

Before buying a new MAF sensor, you need to make sure that the old one is faulty. First you need to clean the air flow sensor with a special spray for sensors. Then look at the condition of the air filter. Replace if necessary. In more than half of the cases the malfunction will be fixed.

In order to diagnose the cause of error P0102, you need to do the following:

- Erase the error code from the ECU.

- Connect a scanner or on-board computer to the OBD-II connector and make a test drive.

- If the error comes on again, check all the potential culprits: filter, connector, wiring harness.

In addition, you need to check the electrical circuit using a multitester and measure the voltage between the contacts of the block.

When the ignition is turned off, the connector from the sensor is disconnected. Then the ignition is turned on and the voltage is checked between contacts 2 - 3, 3 - ground, 3 - 4. Between contacts 2 and 3 the voltmeter should show 10 volts, between 3 and 4 - 5 volts, and between 3 and ground there should be no voltage.

After checking, you need to install resistance between pin 5 and ground. In normal condition it will be 4 – 6 kOhm. If the measurement data does not correspond to the nominal value, then there is either a break or a short circuit in the wiring. Resistance diagnostics are performed with the ignition off.

Only after the previous check can a conclusion be made that the MAF sensor is faulty.

Checking and repairing at home

There are eight ways to independently check amplitude and frequency mass flow sensors.

Method No. 1 - disabling the air flow meter

The method consists of disconnecting the sensor from the fuel system of the car and checking the functionality of the system without it. To do this, you need to disconnect the device from the connector and start the engine. Without a mass air flow sensor, the controller receives a signal to switch to emergency operation mode. It prepares the air-fuel mixture only based on the throttle position. If the car moves faster and does not stall, it means that the device is faulty and requires repair or replacement.

Method No. 2 - flashing the electronic control unit

If the standard firmware has been changed, then it is unknown what reaction of the controller is programmed in it in case of an emergency. In this case, you should try to insert a 1mm thick plate under the throttle stop. The turnover should increase. Now you need to pull out the chip from the air flow meter. If the power unit continues to work, then the cause of the malfunction is the firmware.

Method No. 3 - installing a working sensor

Install a known good part and start the engine. If after replacement it begins to work better, the motor does not stall, then replacement or repair of the device is required.

Method No. 4 - visual inspection

To do this, use a Phillips screwdriver to unscrew the clamp holding the air collector corrugation. Then you need to disconnect the corrugation and inspect the internal surfaces of the air collector corrugation and the sensor.

Inspection of duct corrugation

There should be no traces of oil or condensation on them, the surfaces should be dry and clean. If you do not take care of the air filter and change it rarely, then dirt can get on the sensitive element of the sensor and cause it to break. This is the most common malfunction. Traces of oil may appear in the flow meter if the oil level in the crankcase is high, or if the oil sump of the crankcase ventilation system is clogged. If necessary, you need to clean the surfaces using special cleaning products.

Method No. 5 - checking the mass air flow sensor with a multimeter

To do this, you need to turn on the tester in a mode in which constant voltage is checked. The limit value for measurements should be set to 2V.

DMRV operation diagram

- The yellow wire is located closer to the windshield. It serves as an input for a signal from the flow meter.

- The white-gray wire is the sensor voltage output.

- The black and pink wire leads to the main relay.

- The green wire is used to ground the sensors, that is, it goes to ground.

The wires may have different colors, but their location is unchanged. To check, you need to turn on the ignition, but do not start the car. The red probe from the multimeter must be connected to the yellow wire, and the black one must be connected to ground, that is, to the green wire. We measure the voltage between these two outputs. Multimeter probes make it possible to connect without disturbing the insulation of the wires.

On the new device, the output voltage ranges from 0.996 to 1.01 V.

During operation, this voltage gradually increases and by its value one can judge the wear of the flow meter:

Indications of the ADC of the flow meter

Diagnostics of the mass air flow sensor "Tseshkoy" is not complicated and can be done with your own hands.

If there is dirt on the removed sensor, you can clean it yourself. You can use WD-40 to wash it. To clean the mass air flow sensor, you must first remove the pipe from it, and then dismantle the device itself. Inside the device there is a mesh and several wires - sensors.

They need to be sprayed with cleaning agent and washed. Then let the liquid dry. If dirt remains, the procedure should be repeated. You need to clean the pipe with the same product. It must be free of dirt and oil stains. After replacing the air filter, all parts must be returned to their place. After the cleaning procedure, the functionality of the device can be restored to 80%, the error about the reduced sensor signal level disappears (the author of the video is “24 hours”).

Flushing the sensor will help avoid costly repairs.

Method number 6 - checking with a scanner

- Install a diagnostic program on your phone (smartphone), tablet or laptop computer (for example, Torque Pro, Opendiag, BMWhat, OBD Auto Doctor).

- Connect your mobile device or laptop to the diagnostic connector located on the vehicle's electronic control unit using a special cable, Bluetooth channel.

- Launch the diagnostic utility on your phone (smartphone) or computer.

- Wait until the program finishes scanning all vehicle components. As a result, the utility will check the serviceability of each vehicle unit.

- Decipher the error codes that the program will show after the diagnostics are completed.

How to replace it yourself

The air flow sensor is located between the air filter and the massive air pipe connected to the intake manifold.

Once you have established that the VAZ error P0102 pops up due to the mass air flow sensor, you can safely go to the store for a new part. A new sensor costs more than 3,000 rubles and is sold complete with the pipe in which it is installed.

Replacement work takes place with the ignition off. First you need to disconnect the block with wires from the sensor. To do this, press the bottom of the chip on the latch and carefully remove the connector. In this case, you need to pull not by the wires, but by the block.

Replacing the air flow sensor

To replace the sensor with your own hands, you need to prepare a shaped screwdriver and a “10” key.

The replacement procedure consists of the following steps:

- First you need to turn off the ignition and open the hood.

- Then you need to disconnect the negative terminal on the battery.

- At the next stage, you need to loosen the clamp with which the corrugation is attached to the mass air flow sensor.

- Next, remove the corrugation from the pipe.

- Then you need to bend the comb and disconnect the sensor connector.

Disconnecting the sensor connector

Thus, if the car stalls and has all the signs of a breakdown of the mass air flow sensor, then before you start repairing it, you should check the level of its signal, it should not be low, perform a full diagnosis of the car and repair all faulty components and parts.

It is important to undergo regular vehicle inspections and perform timely maintenance, then the parts and components will last longer.

DESCRIPTION

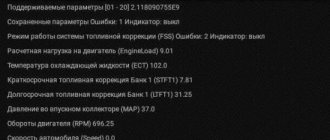

The MAF sensor (mass air flow sensor) measures the volume of air passing through the throttle body. The ECM uses this information to determine the duration of fuel injection and generate the appropriate air-fuel ratio. Inside the MAF sensor there is a heated platinum wire that is exposed to the incoming air flow. By passing a specified amount of current through the wire, the ECM heats it to the desired temperature. The flow of incoming air cools the wire and the internal thermistor, changing their resistance. To keep the current constant, the ECM varies the voltage applied to specified devices in the MAF sensor. The voltage level appears to be proportional to the air flow rate passing through the sensor, and the ECM uses this level to calculate the intake air volume. This circuit is designed in such a way that the heated platinum wire and the temperature sensor form a bridge circuit, and the power transistor is controlled so that the potentials of A and B remain unchanged, thereby maintaining the set temperature.

| DTC No. | DTC Detection Condition | Faulty area |

| P0100 | MAF sensor voltage less than 0.2 V or more than 4.9 V for 3 seconds (1 trip detection logic) |

|

| P0102 | MAF sensor voltage less than 0.2 V for 3 seconds (1 trip detection logic) |

|

| P0103 | MAF sensor voltage greater than 4.9 V for 3 seconds (1 trip detection logic) |

|

HINT: If one of these DTCs is set, check the air flow by accessing the following menus on the handheld scan tool: Powertrain / Engine and ECT / Data List / MAF.

| Air mass flow (g/s) | Malfunction |

| Approximately 0.0 |

|

| Not less than 271.0 |

|

Video “Checking the mass air flow sensor using a multimeter”

This video from the “Simple Opinion” channel demonstrates how to check the mass air flow sensor with a multimeter.

Possible error of the mass air flow sensor on VAZ cars - P0103 (VAZ 2112, VAZ 2110, VAZ 2114). The error may be displayed constantly, or it may appear periodically. Error 0103 occurs because the ECU receives a signal from the mass air flow sensor with a very high voltage signal.

The error is recorded in the memory (error log) of the ECU under these conditions:

- Air consumption is above a threshold depending on the crankshaft speed and the degree of throttle opening

- Two drive cycles have passed since the malfunction occurred.

If this error appears periodically, then you must first check the reliability of the connection of the sensor itself to ground (with the sensor block disconnected, measure the resistance between the battery negative and terminal “3” of the block, it should be less than 1 Ohm), whether the IAC is jammed. You should also check the wiring for damage.

Diagnose the problem with a tester by measuring the voltage supplied to the sensor.

Pull out the connector and use a tester to check the voltage between the contacts:

- between contacts “2” and “3” - more than 10 V;

- between contacts “3” and “4” - 5 V.

- between contact “3” and ground - 0 V.

Most often, a high signal level usually means a break or short to ground.

Another possible reason is interference from the high-voltage part, as well as from the starter (it is located not far away).

DTC P0100 Mass or Volume Air Flow Sensor Circuit

DTC P0102 Mass or Volume Air Flow Sensor Circuit Input Low

DTC P0103 Mass or Volume Air Flow Sensor Circuit Input High

TEST SEQUENCE

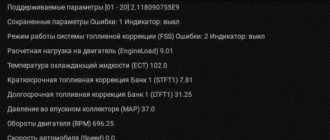

HINT: Use a handheld diagnostic tool to read the fixed parameters. These parameters reflect the state of the engine at the time the malfunction was detected. When troubleshooting, fixed parameters allow you to determine whether the car was moving at the time of the malfunction or not, whether the engine was warmed up, what the air-fuel mixture was (lean or rich), etc.

| 1.TAKE HAND-HELD TEST READINGS (MASS AIRFLOW) |

Connect the handheld diagnostic tool to the DLC3.

Start the engine and turn on the handheld scan tool.

Select the following menu items: Powertrain / Engine and ECT / Data List / MAF.

Read the values displayed on the scan tool.

Result:

| Air mass flow (g/s) | Next step |

| 0,0 | A |

| Not less than 271.0 | B |

| Between 1.0 and 270.0 (*1) | C |