Even at the stages of car development, it was known that the Vesta platform would be truly new, and not just another modernization of the VAZ 2108 suspension. Now that serial production of the sedan has already started, and the first samples have already been on test drives in various car magazines, more detailed details are being clarified about the chassis of the Lada Vesta.

The last adjustments to the suspension characteristics took place in winter in Spain, at the IDIADA training ground. Then a balance was found between comfort and car controllability. What happened?

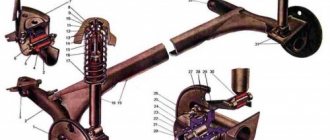

Lada Vesta front suspension design

The supporting structure is based on a subframe, which is an innovation for the domestic automobile industry. Also, for the first time, the L-shaped levers were used.

The subframe performs the additional function of strengthening the body, giving it strength, and preventing deformation on uneven surfaces. As a result, the overall safety score was increased by five points.

In general, the suspension design is quite simple and in many ways similar to Renault Logan and Renault Duster of the second generation. Carrying out preventive maintenance does not require additional costs. The steering gear is now secured to the bottom of the engine compartment.

Independent suspension

From a physical point of view, the “low” position of the rack provides maximum connection with the steering knuckle. An electric amplifier is pre-installed on the rail, which was not previously in the design of VAZs. The shape of the transverse stabilizer has been redesigned to improve the “feel” when turning the steering wheel. The castor (tilt) angle is 5°, independent suspension, MacPherson struts, which together make the car smoother.

Stabilizer bushings and struts

To check these elements of the chassis, you can rock the body in the transverse direction together with an assistant, grasping the roof on both sides. If knocking noises appear during such a build-up, this may indicate a malfunction.

Sounds that arise when rocking slightly behind may indicate a loose exhaust system of the car.

By performing these simple steps, you can check the basic elements of the suspension of a modern car. Regular do-it-yourself diagnostics of a car's chassis is available to most car enthusiasts.

This does not require you to have any special skills or abilities. In this case, you do not need to use special tools, a jack, an inspection hole or a lift. The condition of the suspension can be determined almost with bare hands.

According to car repair experts, a large number of cars are operated with faults of varying degrees. Despite the fact that the car rolls heavily in corners and sways after driving over road irregularities, motorists often continue to use it without taking radical measures to eliminate the sources of the problem; drivers adapt to the deterioration in the functioning of the car's chassis. Under such circumstances, serious problems may arise suddenly and cause an emergency.

Rear suspension device

The food is borrowed from the French brand Renault Logan of the second generation. The design is typical - a transverse metal beam with springs spaced on the sides.

The brake system is of a drum type, which was expected, since disc mechanisms would increase the cost of the model by 3 - 4%. In general, the “drums” do an excellent job of the task at low and medium speeds.

Design (diagram):

- Levers.

- Gaskets for springs.

- Upper support.

- Compression buffer.

- Gas shock absorber.

- Hub axis.

- Brake drum.

- The wheelbase is extended to 1510 mm.

Dismantling the casing with bells and whistles

If the car is equipped with automatic windows, there are speakers on the door, and a large diffuser on the side, removing the trim is easier in most cases, but requires preliminary removal of the external trims. That is, before removing the casing itself, you need to:

The glass goes all the way down; The speaker (or rather, its grille) is carefully moved towards the door hinges and removed from the grooves (at the same time, when it is removed, you can clean it); A screwdriver or clip is placed in the center of the size diffuser, carefully hooked and removed; The protective cover of the power windows and mirrors control unit is removed from the handle; The fastening plug is rotated at a right angle and the entire panel is dismantled; Now you can remove the trim: pull out the three clips at the bottom of the door and pull the trim down. There are no self-tapping screws or hidden clips in this design. As you can see, there is nothing complicated or requiring special skills in the process

You just need to know how to remove the door trim, based on its design

As you can see, there is nothing complicated or requiring special skills in the process. You just need to know how to remove the door trim based on its design.

What's new: about built-in technologies and stabilization system

In addition to the above innovations, we additionally note the presence of systems:

- ABS;

- ESP;

- EBD;

- electric power steering wheel from the Japanese concern Nissan;

- braking system from French Renault.

The stabilization system controls the vehicle's traction, which makes it easy to overcome various drifts and obstacles while driving.

You can significantly improve the vehicle's maneuverability by simulating a differential lock. In Lada Vesta such a system is configured very effectively. Now the car is not “afraid” of dirt, bumps, or wet roadsides. When the mode is activated, the electronics enter the “all-terrain” phase. It is not recommended to use this mode on an ongoing basis.

Conclusion

After studying the numerous innovations that were used in the manufacture of the suspension, we can conclude that AvtoVAZ took the creation of the Lada Vesta very seriously. It's clear that close attention has been paid to more than just the engine and design. Creating a high-quality design and giving the car excellent driving characteristics indicates that the company cares about its reputation and thinks about its customers. The new stabilization system allows Vesta’s suspension to be considered revolutionary in the Russian automobile industry.

What are the advantages of the new Lada Vesta suspension?

- The suspension concept has been radically changed. The supporting structure is based on a subframe at the bottom of the engine compartment;

- increased rigidity;

- compliance of body geometry with standards;

- improvement of vibro-acoustic properties;

- steering rods are directly connected to the hubs;

- castor (tilt) angle is 5°;

- MacPherson struts;

- upgraded anti-roll bar;

- maximum adaptation for domestic roads.

Conclusion

The average resource of the front and rear suspension of a car is designed for 90,000 km and above. If you follow the manufacturer's recommendations, take care of the equipment, and moderate speed conditions, the replacement interval for parts can be increased to 120 - 130 thousand km.

Carry out preventive work at certified service stations, where they provide a guarantee. If you have experience, practice repairs yourself, but this should not conflict with the requirements of the warranty. Buy spare parts mainly from domestic manufacturers. The quality of the components is not inferior to foreign analogues, and the price is 25–30% cheaper.

Honest dealer - Bright Park

Bright Park began by deceiving me even at the stage of the telephone call: I listened to the phrase “...in a few seconds they will answer you...” I listened for more than two minutes, but when they answered me, it turned out that they knew about the problem, they offered to come in two weeks, since the repair zone is supposedly “fully occupied until this date.”

To my reasonable question, how can I drive for two weeks on a creaking suspension, what if something serious is there and something falls off, they haven’t even seen the car, they immediately stated that absolutely ALL cars have this situation (!!!) and nothing will happen (are they psychics there, can they make diagnoses over the phone?).

At the same time, when I called the second time, they were ready to make an appointment for tomorrow (that is, when for money, their repair area is empty, and when under warranty, the repair area is suddenly completely occupied for two weeks? Well, well..).

At the end of the conversation, I was even offered to contact another dealer (this is customer-centricity - to lose a client by sending him to another dealer??).

Reviews

| № | Positive |

| 1. | Dmitry Vasilyevich , 43 years old (otzovik.com): the suspension is mounted on a subframe, a new form of levers, steering knuckles. Road obstacles are overcome without impact. |

| 2. | Arkady Semenovich , 39 years old (www.zr.ru): there are no complaints about the suspension at speeds up to 120 – 130 km/h, it works quickly and softly. At higher modes, there is a decrease in control efficiency, the car rolls when entering turns. |

| 3. | Kirill , 22 years old (autobann.su): control is sharp due to the fact that the rack is pre-installed on the subframe and has an indirect connection with the steering knuckles. |

| 4. | Matvey , 33 years old (lada-vesta.net): on previous modifications of the Lada, the chassis, suspension, and steering mechanism were worse. I can compare, since before the Lada Vesta there was a Priora and a Granta. |

| 5. | Vasily Petrovich , 43 years old (otzovik.com): my positive review of the chassis and suspension of the Lada Vesta. I've been using the car for three years now, no complaints. |

| 6. | Pyotr Semenovich , 45 years old (www.zr.ru): for me, as a resident of a rural area, you can’t find a better car. I'm happy with the purchase, no complaints. I fix minor breakdowns on my own without going to a service station. |

| 7. | Sergey , 20 years old (autobann.su): rear springs and shock absorbers have become softer compared to the Lada Granta. Minor unevenness is silently absorbed. For our imperfect roads, this is what we need. |

| 8. | Saveliy Petrovich , 43 years old (lada-vesta.net): the vehicle’s ground clearance allows it to overcome many obstacles without reducing speed, detours, or maneuvers. This is very good for city roads when the car follows the flow. |

| 9. | Dmitry , 30 years old (otzovik.com): my positive review of the Lada Vesta, there are no critical comments, and I fix minor breakdowns on my own. |

| 10. | Nikolai Petrovich , 43 years old (www.zr.ru): there are no comments on the components, I systematically carry out technical inspections, diagnostics, and treat equipment with care. The car is three years old, the condition of a new car. |

| 11. | Alexey , 35 years old (autobann.su): replaced the bushings in two years, checked the wheel alignment. I'm pleased with the build quality, my recommendations to motorists. |

| Negative | |

| 12. | Vitaly Nikolaevich , 43 years old (www.zr.ru): in the first year of service, replaced the chassis bushings. The shock absorbers began to leak and the springs began to creak. |

| 13. | Leonid , 27 years old (otzovik.com): after 35,000 km, replaced the standard stabilizer seals with polyurethane ones. The manufacturer saves on materials and installs the cheapest ones. |

| 14. | Arsen Mikhailovich , 45 years old (autobann.su): the model needs to be improved and defects eliminated. It’s better to wait a while or buy a second generation Renault Logan. |

Self-diagnosis of problems

If you don't like the way your vehicle drives over obstacles after a while, or turns into turns less smoothly. First, carry out diagnostics to eliminate other “suspects” and come to the technical center with a clear task for specialists:

- Release the brake pedal. Take the wheel with both hands by the opposite parts and rock it. If a pronounced play is noticeable, this may mean that the problem is in the hub bearing - it must guide the wheel correctly, strictly in one plane; if it is neglected, it can “go figure eight”.

- If the wheel play does not occur due to the hub, then the fault is in the chassis. In this case, play appears even when the brake pedal is pressed.

- If the car “wobbles” in a vertical plane, the stabilizer link is poorly secured or the ball joint is worn out.

- If the car wobbles “horizontally” (push it into the front fender, after tightening the handbrake), it may be that the rod ends have worn out and become unusable.

The design of the front suspension of a front-wheel drive vehicle assumes that all its parts should “age” evenly, almost equally, that is, even if they have different wear patterns, they need to be replaced with new ones in pairs. New components will work evenly, “erasing” from scratch.

The upper “bar” of front-wheel drive VAZs

In this paragraph, we will briefly consider those technological innovations that were implemented along with the release of the first front-wheel drive cars. Further, it becomes incomprehensible to the Russian consumer why the design solution regarding the design of the car suspension has not changed for decades, as if remaining an insurmountable bar.

Were the ideas too successful? Or VAZ did not risk increasing the cost of a car that was already losing its position. But the fact remains: the suspension design of the VAZ 2108 - VAZ 2170 is practically no different.

To fully appreciate the efforts of AvtoVAZ designers, let’s look at some of the “sores” that the concern faced in 2015. The suspension cannot be called unsuccessful, since the entire line from the “Eight” to the “Priora” will have its fans.

But on the threshold of the 21st century, it was necessary to solve some problems that were turning our cars into Soviet-era cars. While the French or, for example, the Germans made full use of the technology of damper flywheels and pulleys, and also transferred a significant part of the load from the body to the subframe, domestic cars continued to actively respond to the slightest irregularities on the road.

The MacPherson suspension may have provided the required level of reliability, but without significant modifications it was extremely stiff, flimsy, and showed disgusting stability results on the highway.

What saved the strut from longitudinal displacement was a trivial stretcher, which in the front part of the car, at best, rested against the beam using a silent block. In the worst case, we remember the tears of car owners replacing broken aluminum “crabs”. Certain shortcomings were also identified in the design of the upper support. Along with low reliability, we inherited constant bearing knocking, which became an incurable “disease”.

AvtoVAZ's response

To the credit of the Russian manufacturer, it is worth noting that AvtoVAZ recognized the flaw and made recommendations for eliminating it. They consist of installing a suitable size washer under the upper supports of the rear struts. The method has the right to life, but it has certain disadvantages.

The main problem is that the washer does not cover the entire support area, but only part of it. As a result, after installation there remains a gap into which dust, sand and dirt accumulate. Some seal the specified opening with sealant, but this does not really help.