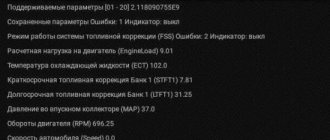

It's no secret that vibration during braking indicates crooked brake discs. The axial runout of the brake disc is allowed to be 5 hundred parts or 0.05 mm. This is partly true in 80% of cases. It is not possible to see this beat by eye; it can be seen using a dial indicator with a scale resolution of 0.01 mm. There was also a slight vibration when braking, armed with the ICH-10, I went to look for the truth. The front brake discs Brembo MAX 09.5870.75 have already served their purpose and for 45 thousand they have worn down to a minimum value of 18 mm and are getting ready to go to rest. I started by measuring the axial runout without removing the disk, putting the front right wheel on the disk and after turning it around I was shocked, the runout was 1.8 mm

with a disc runout tolerance of 0.5 mm. There are more options: either a crooked disk or a crooked hub. Let's remove the wheel and measure the runout of the brake disc 15 hundred parts or 0.15 mm, also three times more than the tolerance. There were two options left: a crooked hub or a crooked brake disc. Having removed the brake disc, I measured the hub runout of only 2 hundred parts, which couldn’t help but rejoice.

And the reason for such a huge runout of 15 hundred parts of the brake disc and 1.8 mm runout of the wheel turned out to be bonal rust

and the wheel disk itself. Harmless rust between the hub and the brake disc gave a runout of 15 acres. After cleaning the hub and the brake disc itself, its runout was 7 acres. 5 mm spacers between the brake disc and the wheel disc with a touch of rust made their own adjustments which resulted in the wheel disc running out. Having removed all traces of corrosion on the spacers, the wheel disc runout was 1.0 mm, which is 0.8 mm less. Here the runout is caused by the wheel disc, although it was forged by VSMPO, but 100 thousand km over our potholes, 5 cut tires made their own adjustments.

I drove for a couple of days, the vibration when braking disappeared and what’s most interesting is that the pads also stopped squeaking

I will accept a rear hub from a VAZ as a gift, bolt pattern 4*98, I want to set up a stand to check disk runout

Good afternoon My car has overcome me)) The problem is this: when braking from 100 and above, there is a strong vibration and hum from the rear and the brake pedal hits (it doesn’t give anything to the steering wheel). I understand that the problem is with the rear brakes. Two sets of cast iron drums were replaced (I thought it was the problem with them), brake pads, one brake cylinder, one bearing (humming), the wheels were balanced. I don’t know what to change anymore, the problem started before changing the above mentioned parts. I ask for help with advice. Thanks in advance!

Vibrations in the steering wheel/brake pedal

Cause: worn or deformed brake discs.

The brake rotor (disc) is part of the braking system; it rotates together with the wheel. Let us remind you that the wheel is fixed directly to the disk. By pressing the brake pedal, you force the brake pads to press against the brake disc, as a result, the rotation of the discs (and wheels) slows down and the car stops. As you understand, the brake disc is very important for the operation of the car.

Let's try to look at how brake discs work. Almost always discs are made of metal. They are made to a special width, which depends on the manufacturer and model of the machine. When you press the pedal, the pads, on which the abrasive material is applied, rub against the disc, creating serious pressure - the disc ultimately experiences a strong increase in temperature. This, in turn, leads to minor, but still changes in the metal (density changes) - the disk must be cooled over the entire area.

In practice, such cooling does not always occur (and sometimes abruptly), as a result of which a change in density leads to deformation changes only in some places, and the nature of the deformation itself is visible as a wavy surface. Next, this is what happens - if at high speed the pads are pressed against such a deformed disc, then the entire brake caliper begins to tremble, transmitting this vibration to the wheel, which, in turn, sends a beating either to the steering wheel or to the body of the entire car.

A sharp drop in brake disc temperature after pressing the brake pedal for a long time can be caused, for example, by snow or running into a puddle.

The common people often hear the phrase “disc led” - it just means the deformed surface of the brake disc. An additional sign, coupled with vibration, indicating deformation of the disk surface is a bluish tint of the metal on the disk, which is also a consequence of overheating.

It is very easy to diagnose a disk for deformation. You will need to jack up the wheel. In this case, the handbrake must be removed, the gear must be put in neutral (make sure that the car does not roll away). Then, in this state, spin the wheel - rotation should be easy and without jamming. An abnormally fast stop of the wheel or “heavy” rotation at a certain point most likely indicates damage to the brake disc.

If a car uses discs not only at the front, but also at the rear, the latter can be diagnosed by using the parking brake while braking. If you also feel a beating when you move the handle towards you, then the culprit is most likely the rear disc.

If it is the disc in front that has a deformed surface, you will feel a beating that radiates directly to the steering wheel. If the rear disc is to blame, then vibrations, in principle, may not be felt (except for severe deformation of the disc; in this case, at high speeds, shaking during braking is still felt). The vibration felt in the brake pedal does not clearly indicate whether the disc is warped at the front or rear.

If you drove down a hill for a long time using the brake pedal, and then drove into a puddle on the road, then the disc, instantly cooling, may well be the cause of the deformation. But deformation is not always caused by sudden cooling. On the contrary, excessive overheating of the disk can also cause deformation. In this case, the brake pads continuously rub against the disc, preventing it from rotating and causing a strong increase in temperature. As a result, the brake caliper jams. To eliminate this effect, you will need to remove the cause of the heating.

A deformed disk can be replaced with a new one, although its cost can cost a pretty penny: from 2 thousand to 10-15 thousand rubles. (this is affected by the make and model of the car). If this seems too expensive, the brake disc can be, as they say, bored out - this is a simple operation, performed in auto repair shops, and the disc does not even need to be removed. Its essence is to remove the surface of the damaged metal on the disk until it is even and smooth.

If the car is equipped with brake drums, then deformation on them is rare.

Diagnostics

“Why does the steering wheel shake when braking?” – this question should first be asked to a car service mechanic. According to the traffic rules, it is prohibited to drive onto public roads with a faulty steering brake system. Of course, you can examine your car yourself or entrust this to a “specialist” in a garage cooperative. But after that, it’s still worth sending it to a professional for diagnostics. The most reliable option is a warranty workshop. This is especially important if the car was purchased recently. If the car is used, then at the local auto forum the regulars will suggest a mechanic you can trust. But be careful, you can end up with expensive repairs if you encounter a scammer.

Remember, the sooner you diagnose the problem and go for repairs, the cheaper it will cost you.

Before diagnostics, you should drive on a deserted highway at different speed ranges - slow, medium, fast. Determine whether the steering wheel shakes when braking or accelerating. At what speeds does the beat appear, at which it becomes greater, at which it disappears. Does the vibration depend on smooth acceleration and braking or only on sharp ones?

Vibrations sent into the steering wheel after changing the disc, hub or bearing

If you notice that vibrations reverberating through the steering wheel or body of the car were detected after work was carried out in a car repair shop, then you need to look for the cause of this misfortune there. Such shaking could be caused by a previous change of the brake disc (as well as the hub bearing or the entire hub), which from time to time causes the steering wheel to shake. Usually this happens due to low-quality replacement elements, although coupled with this is an irresponsible attitude towards the procedure for replacing parts. The disk could have been tightened with the wrong force, or the disk could have been installed crosswise without tightening. The torque that should be applied to tighten is often indicated directly on the disc.

If runout on the steering wheel or body of the car was detected after operations on the chassis of the car, try to involve the same specialist who performed these operations on the chassis.

Main types

The dual-link system is considered by experts to be the most advanced system in use today, and this is not at all surprising, since it provides excellent lateral stability and wheel control, as well as optimal tire wear. This design provides for the perception of any unevenness in the surface by each individual wheel, independently of the others, so knocking in the suspension when driving over uneven surfaces occurs extremely rarely.

It also uses a system with more levers, which is a bit similar to the previous design. It includes the use of several levers, ball joints and silent blocks, and this design ensures a smooth ride, as well as minimal noise from wheel movement. It has a small mass of unsprung parts, the possibility of transverse and longitudinal adjustments, as well as complete independence of all wheels.

The adaptive type system uses hydropneumatic suspension as its basis, which makes it quite different from other types. Initially, it was distinguished by a rather complex design and heavy weight, which sometimes caused a knock in the suspension when driving over uneven surfaces, but due to its modernization, many shortcomings were eliminated, although it still has a rather complex design.

Vibrations in the steering wheel

Reason: destruction of the drum (disc).

Thanks for subscribing!

The most undesirable cause of beating is a cracked drum (disc). This usually occurs due to severe heat or intense physical activity. The problem is inherent in heavily worn brake discs (heavily worn down) or drums with significant corrosion.

Out of balance

Pay special attention when driving, does the steering wheel shake when braking or also when driving and accelerating?

Perhaps the problem is an imbalance. Far from ideal roads lead to a shift in the center of gravity, which causes the wheels to spin imperfectly and the point of contact with the surface is disrupted. This leads to beating and premature wear of the rubber.

The purpose of balancing is to distribute the mass evenly across the wheel. This happens with the help of special weights that help solve the problem. In addition, the suspension and wheel bearing wear out. Often, the frequency of service visits also depends on the car. If the steering wheel shakes when braking, the VAZ has to be balanced quite often. On modern foreign cars, balancing is usually done somewhat less frequently.

When rotating the wheel on a test bench, pay attention to whether it rotates evenly and whether it “falls out” in different directions. Either the disk itself or the tire can be deformed. An experienced installation technician should point out this flaw to you.

If the problem is in the iron disk, it is worth repairing it at the same technical station. Perhaps it should just be leveled with a sledgehammer. Or “take it for a ride.”

Pads as the reason for the steering wheel beating

Although the market is saturated with counterfeit and low-quality pads, they, along with high-quality but worn pads, are not able to cause beating in the steering wheel or car body when you press the brake pedal. This is explained by the fact that this spare part does not move on its own and is loaded from time to time, and not constantly.

Additional factors causing vibration that occur infrequently:

- problems with the steering rack or significant wear of the ball elements in the chassis;

- problems with the racks (in this case, the beating is mainly felt when performing a turning maneuver in the direction opposite to where the rack is installed);

- shock absorber supports that have failed due to damage or wear;

- significant physical impacts (curb, accidents, etc.). Note that, as a rule, before the disc deforms, there is damage to the wheel rim;

- breakage of steering tips.

Let's sum it up

Extraneous sounds and knocks must be checked on a bad road. First you need to understand where they come from, from the front or rear of the car, and only then move on to a more detailed consideration of the issue. Experienced specialists often very quickly determine the malfunction by the nature of the knock. For example, a loud, frequent knocking sound in the suspension when driving on uneven Cherry Amulet almost clearly indicates a malfunction of the stabilizer struts.

In some cases, the sound may not come from the chassis at all, but, say, from the engine. This happens, of course, rarely, but the problem is more serious. Although it is better to start troubleshooting by checking the engine airbags, the operation of the generator and the air conditioner, if any. Remember that if you have problems with the suspension, it is not at all necessary to go to a service station, where they can tell you a lot of unnecessary things. Sometimes everything can be solved on our own and almost free of charge.

Should you pay attention to the runout if it does not interfere with your ride?

In the event of steering vibration or its transmission throughout the entire body of the car, it would be safer not to bring the situation to a critical level, but to contact a specialist. As a rule, the problem does not require a solution as quickly as possible - you can drive with it for months (and sometimes years). On the other hand, it should be remembered that if the nuts are not tightened properly, the behavior of the brake disc may be unpredictable, which affects driving safety. At the same time, the beating also loads the parts of the chassis system: shock absorbers, steering, parts of the hub - and in the event of a breakdown, all these elements (as well as their replacement) will not be cheap.

In addition to the above, we note that beating at high speed is very dangerous - strong vibration can lead to loss of control of the car, and, as a result, to an accident. Driving in itself is already a source of increased danger for the driver and others. In this regard, it is better not to skimp on eliminating the causes of vibration.

By the way, many motorists don’t even realize how ridiculous they look from the outside with a vibrating steering wheel; remember this when you drive your family or just give a ride to a fellow traveler - from the outside, a shaking steering wheel looks very noticeable.

Loose bolts and nuts

“The steering wheel shakes when braking. VAZ 2110,” is a phrase that a mechanic at a service station can often hear. First of all, of course, he will check how tightly the bolts are tightened. The source of the problem is obvious and extremely simple. But at the same time one of the most dangerous. If you “forgot” to tighten the nuts while working at a tire shop, the wheel may “fall off” during one of the maneuvers, which can lead to serious injuries. Over-tightened bolts can deform the wheel rim, which can also cause it to vibrate.

Loose nuts, in addition to the wheel flying off, can cause serious repairs to wheel and brake discs, pads, and hubs. Bolts, cotter pins, and mounting holes in disks are also damaged.

Personally control the tightening of the bolts, which will help avoid many problems in the future.

Completion of work

Our experiment ended successfully, and the hubs have been time-tested - over the last year I have been driving without any beats. It’s just that the “ten-man”, asking a question about the beating of my steering wheel during high-speed braking, reminds me of a long-forgotten problem. Of course, sooner or later the brake discs will have to be changed by purchasing completely new ones, but this is a completely different story, since the whole problem will lie only in their choice.

Could the hub be faulty? Of course it can. Once, while repairing my car, I was very surprised by one circumstance. A slight runout of the hub can lead to quite noticeable runout of the brake disc. This is especially true for places that are as far away from the axle as possible, that is, for brake pads. In the case of high-speed braking, the brake pads strongly compress the disc rotating at high speed with the presence of irregularities, which leads to vibrations that are transmitted to the steering wheel through the tie rods, the steering lever and the steering mechanism itself.

Malfunction of engine mounts

Malfunctions of engine mounts are quite rare. It manifests itself in the initial stage as subtle vibration at idle and during straight-line movement at low and medium engine speeds. But with sharp acceleration and driving at high engine speeds, vibration occurs, which is transmitted through the car body. The test can be carried out with the vehicle running; an assistant will be required to perform the test. We place the car on a flat area with good lighting, secure it with the parking brake and start the engine. Warm up to operating temperature and stable idle speed. We open the hood of the car and gradually increase the engine speed to maximum, while observing the behavior of the engine relative to the rest of the compartment layout. Next, we make several throttle changes to maximum speed. If the Ford Focus 2 engine has significant deviations from the axis, then you should contact the service for further consultation with specialists and repairs. We check for wear or damage to the rear cushion securing the gearbox when reversing. When accelerating sharply, the car begins to vibrate and twitch strongly. You can replace worn out pillows on your own, but it is better to carry out this operation at a car service center. It should be borne in mind that the power unit mounting cushions should all be changed at the same time.

Steering noise when braking on a VAZ 2110

Owners of new VAZ 2110 cars quite often ask the question: “Why do noticeable and very unpleasant vibrations in the steering wheel occur when trying to brake at a speed of about 100 km/h?” Drivers of the "ten" want to know about the reasons that lead to such an unexpected reaction of the car, as well as ways to eliminate this phenomenon.

It is quite difficult to identify the cause of such abnormal behavior of a car in a garage, but experienced drivers, through trial and error, were able to find out that the reason for this phenomenon lies not in the steering, but in the braking system.

Conclusion

If the steering wheel in your car shakes when braking (2110, classic, foreign car or SUV - it doesn’t matter), the brand plays absolutely no role in this, such a problem can happen to any car. This is a reason to seriously think about your safety. Never put off diagnosis until later. Fix problems that arise immediately, and your car can last for a very long time.

Vibration of various elements of the car inevitably occurs during operation, when the moving parts of the chassis and transmission gradually wear out. But among such malfunctions, there is one dangerous malfunction - the steering wheel wobbles when braking. The more the steering wheel jerks after pressing the brake pedal sharply, the higher the likelihood of losing control and flying off the road at a decent speed. To avoid the described emergency situation, it is worth studying the nature of the problem and how to solve it.

How to detect wear on brake discs?

Before repairing, it is necessary to diagnose the breakdown.

Is it just the steering wheel that vibrates? The likely cause is wear of the front brake discs or the system as a whole. Has the brake pedal also changed its behavior? Pay attention to the rear braking system. The handbrake can be used to determine the malfunction. If the vibration stops when using it, then you should look for a problem in the front brake system. Is there any beat left? Examine the technical condition of the rear brake discs and the system as a whole. The procedure allows you to determine the location of deformed parts.

Next, you should test the wheels or study the appearance of the brake discs. Raise the car on a jack and remove it from gear. If the rear axle is suspected, then the handbrake must be lowered. Spin the wheel. Is the rotation uneven and changing intensity in the same place? The problem has been identified. If the test result is negative, move on to the next wheel.

The appearance of the brake disc says a lot about its technical condition. Noticed cracks, unevenness or chips? Replacement or grooving is required, depending on the situation. The presence of a bluish tint on the surface is a sign of overheating.

When inspecting, pay attention to the brake calipers. It's unlikely, but they can also cause vibrations in the steering wheel.

Unconventional measures

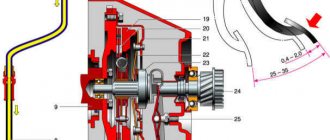

It is clear that the mood dropped to zero, however, at that moment a rather bold idea came to my head: what if at the workplace, damn it, sharpen the hub, as parts clamped in lathes are usually sharpened. Will the lathe have enough revolutions for this? The turner said that, in principle, it was possible to try, but he would not be responsible for the final result, since this was the first time in his practice that he was doing such work. He also added: “If you want to conduct experiments on your car, do it! But I’m on the edge, because I can’t give any guarantees!”

So what to do? There was nothing to lose and I agreed. In any case, this one must either be replaced or sharpened, and then the hub will have to be pressed out and pressed in again, but this work in a garage is quite difficult, in addition, you will have to purchase another bearing, and there is still no guarantee, that it will meet all quality indicators. Come on, buddy, let's experiment. As a result, you will gain invaluable experience, and I will be able to get away with minor financial expenses as a result of a favorable outcome. And in general, I’m very interested: how will all this crap end?

He quickly estimated the size of the required device and the place in which it should be secured. Here it should be noted that the devices must be rigidly fastened, and in addition, they must be located strictly perpendicular to the axis of detailed rotation. Moreover, it is necessary to accurately determine the angle at which the cutter should be fixed.

After everything was finished, good, most reliable, stops were installed under the car, the jack used to lift the body was removed, and the brake caliper was securely tied to the shock absorber using a wire. After which my partner and I started the engine and engaged first gear.

It turned out that there are enough revolutions for normal operation of the machine, the chips are removed in a thin layer and wound around the cutter, damn it. According to the results of the first pass, a completely untouched “bald patch” on the outside remained, however, we did not have time to be upset about this, since it safely disappeared after a couple of regular passes. At the end of the turning work, the hub at our disposal was ground down to zero. Next up is the next wheel.

Possible solutions

Once you have decided on the possible options for why the steering wheel shakes when braking, you need to think about the best solution to the problem.

If the cause is discs, drums or pads, these mechanisms should be replaced immediately. Operating the vehicle is not recommended until the repair is completed.

If the diagnostics revealed backlashes and gaps in the steering rod, they must be eliminated in a timely manner.

A worn ball joint requires immediate replacement. Otherwise, this may lead to her vomiting the first time she falls into a large hole, of which we have plenty on our roads. Operating the car before replacement is also highly undesirable.

If the balance is disturbed, it is worth visiting a tire workshop. Don't forget that all four wheels need to be balanced at once.

If possible, dirt should be washed off with a strong jet or cleaned mechanically. You should not be too zealous so as not to accidentally damage other units.

Loose bolts and nuts must be checked promptly and tightened as necessary. After fitting the tires, always check the tightness of the tires yourself. Remember that the nuts should also not be tightened too tightly to avoid deformation of the wheel rim.

Try to choose repair centers equipped with a torque wrench.