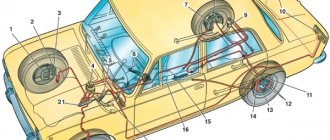

The domestic SUV VAZ-2121, also known as the legendary Niva, has been tirelessly traveling around the expanses of our vast homeland and beyond its borders since 1977. Currently, this car not only has not lost its popularity, but on the contrary - the demand of car enthusiasts for this miracle of the automotive industry is only growing every year.

Channel PROGRAMMER'S DIARY

The life of a programmer and interesting reviews of everything. Subscribe so you don't miss new videos.

Why did the Niva become such a popular car? It's simple. The car's high seating position, all-wheel drive, ease of maintenance and relatively cheap prices for spare parts - that's the whole secret. Fishing, hunting, travel, expeditions and even sports racing - all this is the nature of the Niva.

You will be interested: VAZ 2114 - replacing steering tips: which ones are better to install, how to check for malfunctions

Since 1994, serial production of the VAZ-21213 model under the name “Taiga” began.

This VAZ model is equipped with a 1.7-liter carburetor gasoline engine, a five-speed manual transmission, and a contactless ignition system. A Solex 21073 carburetor is installed on the Niva. In the modern world, when progress does not stand still, a carburetor under the hood of a car, and even an SUV, looks sad. When buying a used car, most motorists prefer to choose an injection version rather than a carburetor. And today's youth look at the carburetor in surprise, completely not understanding what it is. But if a person has at least a little understanding of technology, then understanding the essence of the Solex 21073 carburetor will not be a problem. It is enough to familiarize yourself with some information.

The design of the Solex 21073 carburetor on the Niva

You may be interested in: How to specify the path to the game on Steam? Adviсe

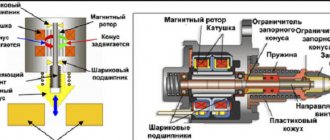

This mechanism is a device for mixing the fuel-air mixture. This mechanism is very simplified, unlike the injector. The carburetor consists of only two main parts, one of which is the body and the other is the cover. The carburetor also includes a float chamber, a pump, and an economizer, which is responsible for regulating the fuel supply in order to save it. Inside the housing there are two fuel chambers and diffusers in which a fuel-air mixture is formed. On the carburetor cover there are special fittings for supplying gasoline to the carburetor and studs for attaching the air filter. Also in the cover of the Solex 21073 carburetor there is a needle valve for the float chamber. With the help of these parts the level of fuel consumption is regulated.

You might be interested: What is paintwork in a car? Definition, thickness and features

An air damper is installed inside the carburetor, which mechanically regulates the air supply to the chambers. As you can see, the Solex 21073 carburetor on the Niva has a fairly simple design. With proper care, it will not cause problems for the car owner and will not let him down on the road.

Setting the level in the float chamber

So, we looked at the Solex device. Adjusting the carburetor will help set the optimal mode when the engine will operate as efficiently as possible and at the same time fuel consumption will not be too high. First you need to start and warm up the engine a little. Then remove the fuel hose and carburetor cover. Then disconnect the suction cable and twist the cover off the device.

It must be removed as smoothly and carefully as possible so as not to damage the float. Then use a ruler or caliper to measure the distance in each chamber. You need to measure from the mating surfaces to the edge of the gasoline. This size should be about 24 mm. If it is larger or smaller, then the parameter is adjusted by bending the float. Then the device is reassembled, the engine is started and it is warmed up.

Operating principle

As already mentioned, the Solex 21073 carburetor on the 1.7 liter Niva mixes gasoline with air and, as a result, the prepared fuel-air mixture enters the engine, where it burns. The driver starts the engine and closes the choke independently. The fuel pump pumps gasoline into the carburetor's float chamber. The amount of gasoline in this case depends on the position of the needle valve. From the float chamber, gasoline enters the nozzle, and then directly into the mixing chamber. At the same time, both cameras will start working only under heavy load on the engine. For example, if the driver sharply increases the speed by pressing the gas pedal. The engine idle mode is maintained by a solenoid valve. Thanks to this, the engine does not stall and fuel is saved at idle.

Basic Solex malfunctions and methods for eliminating them

Before looking for problems with the device, you need to make sure that the ignition system is working flawlessly and is adjusted correctly. You also need to check whether the timing belt is functioning correctly, since malfunctions in the operation of this mechanism can also cause malfunctions in the carburetor.

Table 1. Classification of possible carburetor malfunctions and methods for eliminating them.

| Malfunctions | Causes | Elimination methods |

| Difficulty starting a cold engine. | Incomplete closing of the air damper due to a broken spring or other mechanical obstacles. | Replace the spring and eliminate any problems that prevent the choke from closing. |

| Difficulty starting a hot engine. | High fuel level in the float chamber. | Adjust the fuel level. |

| Excessive fuel consumption. | Incomplete opening of the throttle valves, low fuel level in the float chamber, clogged fuel nozzle. | Adjust the damper and fuel level in the chamber. |

| Unstable engine operation. | Excessive enrichment or leanness of the mixture caused by malfunction of carburetor components, wear of the needle valve, or improper adjustment of the fuel level. | Change the needle valve, adjust the fuel level in the float chamber. |

| Interruptions in engine operation. | Malfunction of the dosing system or air leaks in the carburetor body connections. | Clean the fuel system, eliminate air leaks in the carburetor body. |

| Loss of engine power. | Malfunction of the secondary chamber throttle valve drive, decreased fuel level in the float chamber, clogged fuel nozzle. | Adjust the throttle valve drive and the fuel level in the float chamber, clean the fuel nozzle. |

| Dips during engine operation. | Damage to the diaphragm, accelerator pump, jamming of the nozzle drive lever, clogging of the idle fuel jet, incorrect installation of small diffusers. | Replace the diaphragm, eliminate the jamming of the drive lever, clean the jet, and install the diffuser correctly. |

Float mechanism

On Niva, the float chamber in the carburetor consists of two sections located on the sides of the chambers for preparing the fuel-air mixture. In general, the float mechanism consists of two floats made of hard rubber, mounted on a special lever, which looms on an axis pressed into the cover of the Solex 21073 carburetor. The essence of the float mechanism is to regulate the fuel supply.

Operating principle of the main dosing chamber

During the combustion of the fuel-air mixture in the engine cylinders, air enters the chambers through the air filter. As the air flow increases, pressure is exerted on the nozzles. As a result, fuel rises from the wells into the atomizer. At the same time, air is fed through an air jet from above into the emulsion tube. In the chamber, the fuel is mixed with air and goes into the carburetor channels, where it is directed further into the engine under high pressure. This is the operating principle of almost all Solex carburetors.

Design and principle of operation of the CXX

For the engine to idle at minimum speed, only a very small volume of mixture is required. Under such conditions, a fully closed throttle valve is observed. But the vacuum level in the diffuser is now not enough to start the GDS.

This is precisely why the DAAZ-4178-30 carburetor has an idle system in its design. Its task is to prepare a mixture that allows for stable operation of the engine with the throttle completely closed.

The system channels combine a special cavity behind the throttles and the upper part of the chambers. When the engine is idling, a fairly high vacuum is created under the damper. When exposed to it, fuel flows from the emulsion channel into the channel of the XX system. The ratio of fuel to air in the mixture depends on the capabilities of the jets.

Then the mixture enters the throttles, where it is then mixed with air. For this purpose, there is a technological gap between the damper and the walls of the chamber. This gap can be adjusted with a screw located on the damper lever. This is the quantity screw; it is used to adjust the DAAZ-4178-1107010 carburetor.

The amount of mixture that passes through the channel into the throttle space can be adjusted using a special screw with a conical nozzle. This screw is responsible for adjusting the quality of the mixture. If you twist it, this reduces the cross-section of the channel.

If the throttle valve opens more smoothly, then the amount of air increases significantly, but the volume of fuel remains the same as it was. The GDS still does not enter into this process due to lack of rarefaction. The result of this is a lean mixture and failure of the engine.

For a smoother transition from idle to medium operating mode, the DAAZ-4178-1107010-40 carburetor is equipped with a special transition system. It connects with its channels to the channels responsible for idling. There is a special hole here, which is made in such a way that after opening the damper it falls into the zone of maximum vacuum. This channel also supplies some of the mixture to the chambers. Thanks to this, there is no sharp transition between engine operating modes.

At idle, when the throttle is completely closed, air is added to the mixture. The composition is compensated by the presence of jets. If you tighten the screw responsible for the amount of mixture, then the damper will open. The gap between the damper and the chamber increases, and the amount of air decreases. At the same time, the crankshaft speed increases. If you unscrew the screw, the frequency will decrease. On a device such as the DAAZ-4178 carburetor, adjustment is carried out by rotating the adjusting screws.

Diagnostics of malfunctions of the Solex 21073 carburetor on a Niva

Any mechanism is subject to physical wear and tear during its operation. Likewise, the Solex 21073 carburetor on the Niva requires periodic inspection and maintenance. If any malfunction is detected, it is first necessary to carry out diagnostics. The causes of carburetor malfunction can be different. This includes refueling with low-quality gasoline and a dirty air filter. As a result, small particles of dirt enter the carburetor chamber. This results in problems in the system in the form of increased fuel consumption and poor operation of the mechanism as a whole. There is no need to rush to replace the carburetor with a new one. Simple cleaning and adjustment will help eliminate these symptoms.

How to restore carburetor operation?

To clean or adjust the Solex 21073 carburetor on the Niva, it must be removed. We remove the air filter housing and remove all the tubes and wires that interfere with getting the mechanism to the surface. Unscrew the nuts and remove the carburetor.

It is best to disassemble it on a table in a well-lit and ventilated area. There are many small parts in the carburetor, therefore, in order not to get confused about what and where, it is recommended to put all the parts in order. You may have to purchase a Solex 21073 carburetor repair kit for the Niva at an auto parts store. It will help you quickly fix the breakdown, and besides, it is inexpensive. Wash the carburetor with special means or regular gasoline.

Adjusting the Solex 21073 carburetor on a Niva

Adjust the carburetor on site after washing and installing it. At the bottom of the Solex 21073 carburetor there is a screw that controls the fuel supply level. Using a flat-head screwdriver, turn this screw until it stops with the engine off. Then unscrew the screw five turns back and start the engine. Next, the screw must be tightened and unscrewed until engine operation becomes uniform. After the engine speed is normalized within 900, the screw is set one turn all the way.

Idle adjustment

Many car owners, namely beginners, most often buy old cars and do not know how to adjust the carburetor correctly. The result is power loss, high fuel consumption, floating speed and other problems. After the level adjustment is successfully completed, the idle speed is adjusted. Before doing this, it is recommended to turn off the engine. To work, you will need a flat blade screwdriver and time. There is a hole on the base of the mechanism. It contains a screw responsible for the quality of the mixture. It is screwed in until it stops. However, you should not be too zealous.