Correct removal of the VAZ 2109 engine is necessary for scheduled and routine repairs. In most cases, temporary dismantling occurs along with the gearbox. The procedure is carried out in a specialized garage with a lift. Moreover, if a person knows how to remove a VAZ engine, everything can be done with his own hands in a few hours.

It is advisable that this procedure be carried out by a car owner with some experience. Even minor errors will lead to possible damage to individual elements of the VAZ 2109 vehicle system.

Preparatory stage

Before starting work, it is strongly recommended that you familiarize yourself with the structure of the “heart” of the iron horse. This will help avoid many problems associated with incorrect connection of individual system elements, such as:

- right front support;

- generator;

- engine;

- gearbox - it is necessary to remove the gearbox only if the engine is overhauled or replaced;

- starter;

- system for turning on the lights for reversing marks VAZ 2109;

- stretching;

- left front support;

- a plug that secures the hole for draining oil from the engine;

- front wheel drives on the right side;

- rear support-fix;

- hole for draining oil from the gearbox;

- left-hand front wheel drive;

- gearbox shift drive rod.

Beginners are advised to take photographs of the listed parts in assembled form. In order to successfully dismantle the VAZ engine, it is necessary to use the tools recommended by the manufacturer. A list of these can be found in the vehicle operating instructions. Regardless of the reason that prompted the need to carry out removal and diagnostics, you must adhere to the following scheme:

A carefully removed car ignition module will help you remove the engine correctly. Due to the fragile nature of the device, do not use excessive physical force. After this, the plug located on the block is dismantled. Only after all the liquid has been drained is the next element removed.

All plugs from the drive are disconnected in random order. The same thing happens with the throttle and hose cables. Before starting this stage, it is better to use a camera to record the initial position. The photo will be useful when the installation of the VAZ engine begins.

Literally, pinpoint precision is required when it comes to removing the hose leading to the gas line. To do this, you need a key set to “17”, which will not break the rather fragile system. Here, as in the case described above, it is necessary to carry out recording using a photo.

When returning the VAZ engine to its rightful place, the photograph will help to correctly connect all the elements. There is no room for error here. Only after you have completed removing all the tubes on the “head” can you move on to those parts that are directly attached to it.

Preparation

At the preparatory stage, short but very important, it is worth completely de-energizing the car by disconnecting the battery. You also need to remove all hoses, speed and clutch sensors. Be sure to drain the oil from the engine crankcase and the liquid that cools the radiator. Removing the engine without removing the gearbox:

- first of all, you need to put a reliable support under the car, preferably wooden stumps;

- unscrew the left crab, move the stretcher to the side;

- remove the generator from the engine;

- remove the tensioner pin, pump, distributor and receiving pipe;

- do not forget to remove the head if you are planning a major overhaul;

- the motor must be removed from the box and lowered to the floor;

- in order to get the engine, you need to raise the front part higher (this is done using a jack);

- you can also just pull everything through the top.

We recommend: What kind of wheels does the KIA Sorento have?

Actions requiring increased caution

Remove the muffler and camshaft pulley last. Further actions are taken taking into account the actual situation. If the star bolts are covered with a layer of dirt and oil, then there is no need to unscrew them. Remove everything together with the camshaft. It is better to unscrew them if the motor has been used recently.

The front crankshaft pulley will help you remove the engine correctly. To do this, it is recommended to use a folding key. It is installed through the top, not through the bottom. Before using it, it is recommended to switch to speed 4-5. After this, the VAZ engine is more easily subject to normalized physical impact. If the above recommendations do not help ease the movement of the key, you must use the services of an assistant.

One of the assistants gets into the car and presses the brake pedal. In this case, it is easier to remove the front crankshaft pulley. After this, the pipe and the generator bolts located on top are dismantled.

If the transmission bolts show signs of physical wear or significant contamination, it is better to replace them.

In this case, removing the engine will reduce the likelihood of failure in the future. After all, no one knows when the next time a car owner will look under the hood.

When removing the wires from the generator, it is necessary to gradually loosen the fastening of the device itself. The more accurately your hand moves, the less likely it is to get damaged. After this, the “crab” is removed with no less care. It is secured with two bolts, which we remove using a wrench. Before unscrewing the last bolt, the device is slowly moved to the side.

Boosting methods

In most cases, achieving the required indicators is achieved by increasing the volume of the car engine. To accomplish a task of this kind, there are several options:

The first involves increasing the diameter of the cylinder block to accommodate a larger piston diameter by boring. It is called “folk” because of its low cost, because in this case all that requires expenses is the purchase of a set of pistons and wheels, as well as payment for turning services.

The second is to replace the factory crankshaft with one that has a larger crank radius and therefore a larger piston stroke and larger volume. Its cost is much higher than the first method, since you will have to spend money on a crankshaft, a set of pistons suitable for the new crankshaft (since the height of the cylinder block has certain restrictions), and special rings for the pistons. In addition, it will be necessary to pay for work related to block boring.

For many, it may be surprising that the increased displacement of the “nine” engine is not always the most advantageous method of boosting. In some situations (it all depends on what the engine should ultimately be like), it is much easier and more efficient to modify the cylinder head (cylinder head) and then install a suitable camshaft. This type of boost will also make it possible to increase the power performance of the power unit.

Of course, to maximize all the capabilities and reserves of the camshaft, a fairly serious modification of the cylinder head will be required, which may even include repressing the seats and installing valves with a large diameter. For example, engines characterized by the presence of eight valves will fit similar parts from BMW, and sixteen-valve engines will fit components from Opel and Volkswagen. At the same time, one should not lose sight of the intake/exhaust channels intended for circulating the fuel-air mixture - they also require improvement. Their improvement involves increasing the cross-sectional diameter to maximum dimensions through internal polishing.

We recommend: Tuning the VAZ 2105 carburetor

The technical characteristics of the VAZ 2109 cylinder block, like other components, leave their mark on the overall performance of the engine. You can, of course, study in more detail the influence of the types and shapes of pistons, the weight of crankshafts and much more that is somehow reflected in the operation of the engine, but this article is not about that.

The following characteristics have a particular impact on the performance of the internal combustion engine: the ratio of the length of the connecting rod to the piston stroke and the dimensions of the crankshaft crank (diameter).

The importance of the above parameters is due to the fact that the engine is essentially a pump that pumps a certain amount of mixture through itself over a specific period of time. It is these characteristics that will be discussed further.

Preparing for the reverse process

The process is completed by fixing the VAZ engine using a timing belt. It would be a good idea to use 1-2 bricks to help prevent the engine from falling. After making sure that the massive unit is fixed in space, the cushion is loosened and the engine is directly removed. Having secured the belt with your hand, you need to slowly remove the pipe.

If by this time the engine has not come off on its own, it is recommended to use a pry bar. After this, the unit is transferred to a temporary storage location for subsequent work with it. You need to remember - install everything in exactly the reverse order. If some elements have reached the end of their service life, it is better to replace them in advance.

The process of removing the “heart” of a car is complex and multi-stage. Accuracy and precision of actions is the key to successful repairs on your own. After removal, it is recommended to carry out a mandatory inspection of all engine components.

The influence of the R/S value on the VAZ 2109 engine

The ratio of connecting rod length to piston stroke is designated as R/S, and its conversion is taken with the utmost seriousness and responsibility. Many sources note that the norm for R/S is 1.75.

We recommend: Replacing Silent Blocks Toyota Corolla 110

Indicators that differ from this value have different effects on the operation of the internal combustion engine:

R/S is above normal. Its undoubted “advantages” include the ability of the piston to remain in the top dead center (TDC) position longer. This ensures excellent combustion of the fuel mixture, namely: complete combustion of the fuel, increased pressure on the piston after TDC and increased temperature in the chamber where the fuel is burned. The result is good torque at high speeds and reduced friction in the piston-cylinder pair due to the long connecting rod, which is important for the piston stroke. At the same time, a motor assembled with an R/S number exceeding the norm, due to a decrease in air flow speed, cannot ensure proper filling of the cylinders when operating at low and medium crankshaft speeds. This is a significant “minus”, but, unfortunately, not the only one. Due to the high temperature of the combustion chamber and the prolonged presence of the piston at TDC, there is a high risk of detonation;

R/S is below normal. The advantages of this position are the excellent filling speed of the cylinders at low and medium crankshaft speeds, due to the fact that the piston moves faster from TDC, as a result of which vacuum occurs quickly. An increase in the speed of movement of the mixture consisting of fuel and air has a positive effect on its quality: it becomes more homogeneous, which makes it burn better. It is much easier to achieve such indicators, since the requirements for such modification are significantly different from engines with high R/S. A low R/S value means that the connecting rod has a large angle of inclination, and accordingly, the force on the piston will be applied in a horizontal plane. As a result, this can lead to rapid wear of the cylinder walls and rings, as well as deterioration of the lubrication process.

When configuring engines, AvtoVAZ gives preference to connecting rods with a length of 121 mm, which ensure optimal performance. In contrast, tuners using a crankshaft with a larger crank radius use longer connecting rods (129.132 mm). True, their cost is significantly higher than standard products.

VAZ 2109 - how to remove the engine

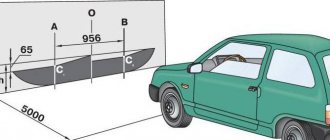

There are not so many reasons why you may need to remove the engine on a VAZ 2109 car, and in most cases the primary one is, of course, a complete overhaul of the power unit. We carry out repair work on an inspection pit, overpass or lifts. We prepare the necessary tools, as a rule, this is a standard driver’s set. The engine is removed together with the gearbox, that is, we will lower it down. The sequence of dismantling work is as follows:

- First of all, we will turn off the power to our car by disconnecting the battery.

- Next, drain the oil from the engine crankcase.

- Drain the coolant from the system.

- We disconnect the exhaust gas system, namely, having completely removed the engine crankcase protection, we remove the exhaust pipe.

- Next, remove the carburetor air filter housing, after which we disconnect all the hoses from the carburetor that supply the sensor wires and damper drive rods. The same applies to brake vacuum hoses.

- We continue to disconnect all the attachments; now we need to unscrew the nut securing the ground wire, which is mounted on a stud located on the clutch housing.

- Next, disconnect the cooling system pipes including the thermostat.

- Disconnect the central high-voltage wire from the ignition distributor, then release the clamp of the block with the supply wires and pull out the block.

- Disconnect the fuel supply hose from the fuel pump by loosening the clamp securing it.

- Remove the drive cable from the clutch lever by unscrewing the adjusting nuts.

- We disconnect the power wires from the starter - one power cable from the battery, going to the solenoid relay and the block with wires.

- We proceed in the same way with the generator.

- We de-energize the coolant temperature sensors and the oil pressure sensor by disconnecting the supply wires.

- Now we disconnect the two pipes of the interior heating radiator. Loosen the clamps securing them and remove them.

The next stage of repair work is carried out under the car. Here we need:

- Unscrew the nuts securing the drive rod from the tip of the gear shift joint. We immediately disconnect the speedometer drive rod and the reverse sensor, namely by disconnecting the supply wires.

- Disconnect the left and right guy wires. First, loosen the nut securing the brace to the suspension arm, respectively, on both. And unscrew the three bolts securing the bracket to the body. Without removing them completely, we simply move them to the side so that they do not interfere with work.

- Disconnect the steering rods. To do this, remove the cotter pin, unscrew the nut and use a special puller to press the pin out of the swing arm.

- We do the same with the ball joint, which we also disconnect from the lever. Next, using a pry bar, we pull out the inner shank of the front wheel drive and move it to the side. In place of the shank we install a technological plug, for example from an old grenade.

- Now you can start removing the engine. First of all, the power unit must be fixed; to do this, we tie it by the eyelets with a strong rope and fix the rope on a rigid support or on a winch.

- Then unscrew the nuts securing the engine to the supports.

- Now that nothing is stopping us, we slowly lower the power unit to the ground.