A faulty starter relay is often the reason why the car refuses to start when the key is turned in the ignition. Perhaps these are not the most pleasant moments in the life of any driver. Therefore, in such cases, it is important to know how to check the starter solenoid relay, and how to start the car if it does not work.

We will tell you about the purpose of the starter solenoid relay and its structure, how you can check it and perform simple repairs yourself.

At the end of this article, watch the video that shows how to start your car if the starter solenoid relay is not working.

Also on our website you can find information about other common causes of starter malfunction with step-by-step instructions on what to do if the starter does not work.

When, when you turn the key in the ignition switch, you can clearly hear that the starter is idling, then the cause of this malfunction may be the solenoid relay. But before you start diagnosing it, you should know the purpose of this electrical unit.

Purpose of the starter retractor relay

As you know, a starter is an electric motor that is powered by a battery. When starting the engine, the starter gear must quickly engage with the flywheel ring of the engine crankshaft. At the same time, the starter electric motor is turned on, which rotates the crankshaft - this process in action is clearly visible in the animation below.

The starter solenoid relay is responsible for quickly connecting two toothed parts: the flywheel and the overrunning clutch gear (Bendix). The retractor relay is installed on the starter housing, connecting to the clutch in the front using a lever. If the relay does not push the gear forward, then the starter rotates on its own.

However, the culprit of such a malfunction may be not only the retractor relay, but also the overrunning clutch (read more about Bendix repair). If the clutch is jammed, then the force of the retractor relay is not enough to extend it.

Device

Structurally, the KamAZ starter is an electric motor with a traction relay and a mechanical drive. This mechanism is installed on the flywheel housing (located on the left side of the engine). It is secured with three bolts and studs.

The mechanism is based on a 4-pole electric motor with sequential excitation. The starter design also includes the following elements:

- Drive shaft.

- Anchor.

- Back and front cover.

- Collector.

- Brush unit.

- KamAZ starter.

- Excitation winding.

All this is combined into a metal case. Externally, the KamAZ starter looks as shown in the photo below.

The body is made of low carbon steel. It serves as a magnetic circuit where the cores are attached. The housing is closed with lids. The back one hides the brush assembly. Front – drive mechanism. The exciting winding is divided into parallel branches, which use series-connected coils. Copper wire with a rectangular cross-section is used as the winding. One end of it is connected to the positive brushes, and the other to the insulated terminal of the housing.

All coils are impregnated with a special varnish and additionally braided with cotton tape. The turns are insulated with cable paper.

Checking the starter retractor relay

To determine the reason for the lack of connection between the gear elements of the starter and the engine, you should check the functionality of the solenoid relay. For ease of diagnosis, most often it is necessary to dismantle the entire starter.

However, before you begin dismantling the starter, it is advisable to carry out several simple operations that will help identify the problem:

- Check the condition of the battery, the reliability of the terminals, remove oxides from the battery terminals;

- Make sure that the electrical wiring is securely attached to the starter with nuts. If there is corrosion, clean the contacts with fine-grained sandpaper;

- Find the starter switch relay in the car and check its condition.

Starter removal procedure

To remove the starter, you need to disconnect the wires that go to it, and then unscrew the mounting bolts (usually two or three).

Often, to perform these seemingly simple operations, the motorist has to spend a lot of time and effort.

This is explained by the fact that the starter in many car models is well hidden in the engine compartment, and in order to get to it, it is necessary to remove many interfering components and mechanisms from under the hood. And in some cars, such as the Volkswagen Golf or Passat, engine support will be required to remove it.

It is best to carry out this work in a viewing hole or on an overpass.

How to check the starter solenoid relay

When the starter has been successfully removed from the engine compartment, it should be cleaned of dirt, and the oxidized contacts should be treated with sandpaper.

- Now the starter needs to be placed next to the battery and two electrical wires of sufficient length must be prepared. It is best to use wires for “lighting” that are equipped with “crocodiles”.

- The first step is to connect the positive terminal of the battery with one electrical wire to the corresponding terminal of the solenoid relay.

- After this, the other wire is connected to the negative terminal of the battery.

- All that remains is to touch the free end of the negative electrical wire to the starter housing and find out the result:

- if upon connection there is a quick and distinct click in the area of the solenoid relay, then it is working;

- if there are no signs of “life”, then the solenoid relay needs to be repaired or replaced.

Dismantling the starter and diagnosing faults

The starter is dismantled in the following sequence:

- Disconnect the negative terminal of the battery. Before disconnecting the battery, you must check that the ignition is turned off. In some cars, if you disconnect the battery while the ignition is on, the immobilizer may become unstuck, this is a serious problem.

- Disconnect the positive terminal of the battery. Disconnect the thick and thin wire from the battery terminals.

- Unscrew the battery mounting bolts (usually there are three of them). In some cars, before this it is necessary to remove some components in the engine compartment. It is better to use the car repair manual to determine the dismantling sequence. In many vehicles, the starter is removed from the bottom.

After removing the starter, you can check its performance separately from the car. To do this, connect the negative terminal to the starter housing with a conductor with a cross-section of at least 6 sq. mm, the positive terminal to the bolt on the solenoid relay closer to the starter motor housing. The motor should rotate.

Video - how to check the starter on a battery:

Lack of rotation of the electric motor is a sign of wear on the brushes or a faulty commutator.

Next, check the functionality of the retractor relay, nickels and plug. To do this, switch the positive thick wire to the terminal of the annealing relay bolt, remote from the motor housing. Connect the conductor to the control terminal of the solenoid relay, connect it to the positive terminal of the battery.

There should be a confident response (click) of the solenoid relay. The fork must drive the bendix (clutch with gear) all the way. The starter motor should rotate stably.

It is advisable to turn the starter on and off several times, while ensuring that the bendix moves to its full length and without jamming.

If the starter fork sometimes sticks, it needs to be replaced.

Next, you should check the runout of the electric motor shaft with the conductors disconnected. To do this, you need to move the motor shaft in the transverse direction. Even small gaps in the shaft-bushing area can lead to shaft displacement and mechanical contact of the armature with the stator.

The electric motor will spin slower, slow down, and ultimately overheat. During routine maintenance of the starter, the bushings must be replaced.

To check brush wear, in most cases, complete disassembly of the starter is necessary. For many models this is not difficult. The armature restrictive ring is removed from the back of the starter, then the through bolts of the starter are unscrewed, and it is disassembled.

On the front side there are screws for removing the fork casing and the solenoid relay. As a rule, the starter brushes are made in a separate unit and are replaced at the same time.

It is somewhat difficult to place the commutator in the brush area. You can use a thin thread to artificially recess the brushes, then insert an anchor and remove the threads.

With a disassembled starter, it is easy to check the wear of the fork, bendix, and the functionality of the solenoid relay winding. If there is visible wear on the collector, it is bored out during routine repairs.

After repair work, the starter is assembled, checking the centering of the rotating parts, and then the functionality is checked without installing it on the engine.

Repair of starter retractor relay

First, we suggest watching a video instruction on how to replace the solenoid relay yourself, and then we will tell you how to repair it.

Depending on the manufacturer, starters are equipped with a collapsible or non-demountable solenoid relay. To fix a problem with a non-separable element, you just need to buy a new part. All that remains is to unscrew the two mounting bolts, remove the faulty relay and install a new one in its place (see the video above).

In the case of a detachable solenoid relay, you can try to repair it. The repair is as follows:

- Unscrew the screws securing the housing cover.

- Sometimes it is necessary to additionally solder the ends of the winding.

- Removing the cover opens up access to find a possible problem - these are power contacts that may be worn out or burnt:

- in the first case, replacing contacts will help,

- in the second case, the problem can be solved with the help of sanding paper.

- Now all that remains is to assemble the solenoid relay and check its functionality.

- The repaired starter is installed in place, after which its operation can be tested.

And lastly, we recommend watching a video that shows how you can start a motor with a non-working starter solenoid relay.

Element Role

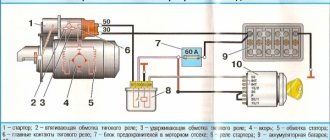

All VAZ cars, including model 2109, have a standard engine starting system, which is based on an electric starter. Here's what you need to know about him.

- A starter is a small electric motor that is connected to the flywheel of the motor via a coupling (Bendix) for a short period of time to start the rotation of the flywheel.

- Despite its small dimensions, the starter passes through itself enormous currents.

- If the starter circuit were closed directly in the ignition switch, then not a single component of the system would be able to withstand such current loads. As a result, they would burn out.

- Therefore, for these purposes, the starter is connected remotely to the battery via a relay. Its contacts are designed for high currents.

- The starter operates briefly and must be turned off after the engine starts. Otherwise, its active destruction will begin due to the influence of motor power.

- Relyushka performs these tasks perfectly. Actually, it is precisely to ensure the functioning of the system and protection against current, timely shutdown of the starter, a retractor relay is included in the design.

Element diagram

Where is the VAZ 2109 Starter Relay located?

Replacing the starter switch relay on VAZ 2108, VAZ 2109, VAZ 21099

Starter activation relay Many people will now think that we are talking about a retractor relay, in fact this is not so, in total the starter has two relays, one that turns it on and the second that extends the bendix and pushes its gear onto the crankshaft pulley (The second is the same retractor relay ), if the first one fails (happens rarely, mainly due to overloads on it or due to faulty wiring), you will not be able to start the starter and therefore the car will not start; if the second one fails, it will be a little different situation, namely the car may also not start and the clicking will occur when the key is turned, but this can be said even less, but if this relay fails completely and does not return the bendix to its reverse position, then the following will happen when turning With the key, the starter will start turning the car's engine and eventually it will start, but when you return the key after the engine has started in the reverse position, the bendix on the starter will not come back (the solenoid relay does not work) and in a very short time the starter will become unusable.

Checking status

Before changing the relay, make sure that the problem with starting the engine is related to this component.

To do this, consider two situations that indicate its malfunction.

Situation

Your actions

The relay makes clicks, but the armature does not spin

If there are clicks from the relay, check the condition of the armature. To do this, the terminals of the retractor relay are bridged with a large screwdriver or a piece of welding cable to the terminals at the ends. Taking a thin wire or a screwdriver can easily burn the terminals. When the armature is working, after closing the terminals, the armature will spin, which can be determined by the sound. Consequently, the solenoid relay itself has failed and requires repair.

Dismantling

There should be no problems with the dismantling process. The main thing here is to remove the starter, since the required relay is held on it. Therefore, dismantling is carried out as an assembly.

- Turn on the handbrake, disconnect the battery by removing the negative terminal from it.

- A wire with a large cross-section goes from the battery to the contact of the relay. It can be turned off by unscrewing it using a 13 key.

- Remove the thin winding power wire from the solenoid relay.

- Using the same 13mm wrench, unscrew the three mounting nuts holding the starter to the clutch block.

- You can remove the device through the bottom or top. If you chose the top, then you need to slightly rotate the starter around its axis and remove it.

- The lower output is more difficult, since here you need to remove the crankcase protection. But if parallel work is carried out that requires similar manipulations, problems will not arise.

Repair

Next, you have a choice to make: replace the entire relay or try to repair it.

Only a relay that has a collapsible design can be fully repaired. It is not uncommon for cars to have a relay with a non-separable body. Repairs there are also possible, but only partial.

But if you want to save money or just like to tinker with your car, you can try to bring a damaged relay back to life. To do this, we offer you detailed instructions.

Disassembled element

If this measure does not help, we will disassemble the case and repair it.

- The relay consists of a housing with a winding inside, a core with a return spring and contacts.

- The spring disconnects the starter rotor gears from the Bendix ring when the power to the relay winding is turned off.

- The back cover of the relay is fixed with screws to the body. Therefore, the first thing we do is remove this cover by unscrewing the corresponding fasteners.

- Both contact bolts have a nut, which you also unscrew.

- You will see washers under the nuts. Do not lose them so that you can return them to their place during reassembly.

- Unsolder both terminals of the winding using a soldering iron. Then remove the cover.

- If you find traces of carbon on the contacts, they can be removed with a small file.

- There is a rubber O-ring under the cover. Check it for elasticity and integrity. If the ring is damaged or worn, replace it with a new one.

- Remove the contact plate along with the rod.

- Use a flathead screwdriver to remove the return spring.

- If the spring is deformed or stretched too much, it will need to be replaced. Otherwise, a worn spring will not be able to guarantee the desired contact. As a result, the relay does not work properly.

- Disassemble the contact plate. To do this, you need to remove the retaining ring that insulates the washer. After this, the plate will fall out on its own due to the pressure created by the spring.

- Remove the contact bolts from the cover. Clean the surfaces of their contacts. Often, due to burning of the contact surfaces, the solenoid relay stops working normally.

Contact bolts

- If the carbon deposits are too strong and cannot be removed with simple sandpaper, do not rush to buy new bolts. Just rotate them 180 degrees. So they will touch on the other side, where there is no carbon deposits.

- The relay windings are located in a non-separable housing. If they are damaged, you will have no choice but to completely change the relay.

- Replace all damaged and worn elements of the switching relay, and then put everything back into the housing. Reinstall the solenoid relay and check if the ignition returns to normal.

If the relay has a non-separable housing, many recommend replacing it. But if you wish, you can even repair such a unit. To do this, you need to flare the housing with pliers, then unsolder the contacts and remove the cover. Next, follow the instructions given above.

Where is the fuel filter located?

The fuel filter (TF) on the VAZ-21099i is designed to clean gasoline from debris, dirt and various impurities; it is a monolithic structure with a rigid metal body and a filter element inside. The frequency of its replacement is every 20-30 thousand km of the distance traveled, also if the car begins to move jerkily, and diagnostics showed that the fuel pump is clogged.

It’s easy to find out where the fuel filter is located; to do this, you need to install the car on an inspection hole or a car lift. The TF is located on the bottom of the body, next to the rear beam and the gas tank, and is secured with a special clamp, which is tightened with a bolt and nut.

Before you start changing the filter, you need to relieve the fuel pressure, otherwise when you unscrew the fuel fittings, gasoline will splash under high pressure. You can relieve pressure in the line using a special nipple located at the rear of the fuel rail. Before starting such an operation, it is necessary to prepare a plastic container into which gasoline should be poured, then unscrew the safety cap.

To release the pressure, you can use a standard flat-head screwdriver; when you press the nipple valve, gasoline will come out of the system.

After removing fuel from the line, we proceed to replacing the fuel pump.

Self check

To independently check the functionality of the solenoid relay, you first need to check the starter itself. The scheme is quite simple. First of all, turn the key in the ignition and try to start the car. If the starter does not work, you will hear a specific clicking sound. This means that the fault lies in the relay.

Without disassembling or dismantling the starter, you can check the mechanism of the device yourself. To do this, bridge two contacts on the rear panel of the traction relay (they look like copper bolts). If the device starts to move (spins), then the problem is in the retractor.

Remember that when disassembling and repairing a car yourself, you should be careful and careful. Follow the instructions to avoid aggravating the damage or getting injured.

How to replace the starter switch relay on a VAZ 2108-VAZ 21099?

1. If you carefully read the above text, you will immediately guess how to remove this relay, but we will still instruct you, find this relay in your car (the location is shown in the photo above), you see a block of wires connected to it, then disconnect it, and after it is removed and set aside, take a wrench in your hands and unscrew the relay mounting nut with it and then remove it, by the way, if the work is done in the rain or in very wet weather or if you are simply afraid of a short circuit in the wiring (B In this case, all the wiring will burn out and will require replacement), then protect yourself by disconnecting the wire from the minus terminal on the battery; if you don’t know how to do this, then study “this article”, it says everything in the first paragraph.

To check whether the relay is working or not (We don’t recommend buying a new relay just like that, always check everything), you can use two different methods, the first is that you have to remove the cover from the mounting block and pull out from there a relay with exactly the same marking as you have a relay for turning on the starter, after removing these two relays, replace these two relays and try to start the car, if it doesn’t start, then it’s not the relay and you need to look for the problem either in the starter itself or in the ignition switch, the second method implies that you will find the wire bring the jumper (Indicated by a blue arrow, the wire can also be used) and its conclusions to the wire block, namely to its contacts “30” and “87” (These are the lower and upper contacts of the block, take a closer look at the relay on it, they are marked or for clarity, take a look in the photo they are indicated by a red arrow, although there is a block from a completely different car, but it is almost the same and on it you can understand where these two contacts are located), if the car starts immediately (Don’t forget to remove the jumper when it starts to start) then it’s all in relay, if not, then look further (When you do the second method, do not forget to turn the key in the ignition until all the devices light up)!

For more detailed information about checking relays using the classic example, see the videos below:

Causes and solutions to the problem

All faults can be divided into two categories:

- the breakdown lies in the starter and retractor relay;

- the starter armature rotates and the relay clicks;

The most common reason for a relay to not work is that the soldering point of the wire to the terminal has lost contact. Before disassembling the device, just try soldering these places with a soldering iron - the problem is solved. Well, if the starter still does not work, then the relay will have to be disassembled. Sometimes the coil that creates the electromagnetic field burns out. Simply replacing the old wire with a new one eliminates the problem; to do this, you just need to rewind the coil with your own hands.

In the second case, when you hear clicks, but the starter does not rotate, try bridging the terminals on the solenoid relay with a screwdriver with a rubberized handle. Having done this, the starter armature will start and begin to spin, you can easily understand this by the characteristic sound. In this case, the breakdown lies in the inability of the relay to pass electric current through itself. Be careful when working, because you are in an area of electromagnetic activity and you may get an electric shock.

When it's the starter

If after these steps the starter continues to be silent, it means it is broken. To repair it, you need to disassemble the solenoid relay. But how to do this if the mechanism itself is not intended for disassembly? In an old-style relay, you need to unscrew one or two screws and unsolder the wiring that goes inside the device.

Modern devices are non-separable, and in order to open the back panel, you will have to flare the metal body of the mechanism. Flaring can be done with a large screwdriver or pliers. After this you need to remove the cover. To repair, clean the burnt contact plate and the surfaces of the bolts from soot to a shine. The better you clean it, the longer the relay will last you.

Of course, it would be wiser and safer to go to the nearest service station, but for a number of reasons, drivers sometimes repair the car themselves. Saving money and time requires preliminary preparation and certain knowledge in machine repair.