Hi all! I think there is no point in reminding what consequences a faulty operation of the steering mechanism can lead to. But it’s worth talking about why the steering wheel creaks when turning, what can lead to this, and what needs to be done in such a situation.

It is worth noting that such symptoms usually occur on cars with a hydraulic type of power steering, as well as on cars without power steering at all. In the case of electric power steering, squeaks usually relate to other components. But it's still worth checking.

As part of our material, we will tell you why this happens, what can cause symptoms, and what actions the car owner should definitely take. If you have anything to add, write in the comments or ask questions on the topic.

Comments

Guests cannot leave comments on the site, please log in.

Products for LADA at the best price

A selection of accessories for LADA from AliExpress

- What to do if the electric power steering on the Lada Kalina does not work

The content of the article

Hi all! I think there is no point in reminding what consequences a faulty operation of the steering mechanism can lead to. But it’s worth talking about why the steering wheel creaks when turning, what can lead to this, and what needs to be done in such a situation.

It is worth noting that such symptoms usually occur on cars with a hydraulic type of power steering, as well as on cars without power steering at all. In the case of electric power steering, squeaks usually relate to other components. But it's still worth checking.

As part of our material, we will tell you why this happens, what can cause symptoms, and what actions the car owner should definitely take. If you have anything to add, write in the comments or ask questions on the topic.

Varieties

To facilitate the rotation of the steering wheel, a power amplifier is installed on modern cars. It comes in different types:

1) Hydraulic.

2) Electric.

3) Electrohydraulic.

The hydraulic booster operates from the force of a special fluid that is pumped by the pump.

The second mechanism is powered by an electric motor. And the third type contains elements of a hydraulic and electric amplifier. Each type has a complex design, has its own advantages and requires different maintenance and operation.

Where to begin

A car steering mechanism is a rather complicated thing. It consists of many elements and subsystems. In particular, the design and operating principle become more complicated when the steering mechanism is supplemented with an amplifier. Electric or hydraulic.

It’s worth starting with diagnostics. Moreover, you can carry it out yourself, sometimes even in the field. The essence of primary diagnosis comes down to determining the place where the extraneous sound is coming from. It would also be useful to record under what specific circumstances these creaking noises appear. It can squeak simply when rotating, while the car is moving, only on bumps on the road, or when the steering wheel rolls from the right side to the left, but in the opposite direction everything is fine.

Having determined the source of the sound using simple manipulations and experiments, you can begin further work aimed at eliminating the malfunction.

Please note that creaking noise in the steering mechanism is not normal. That is, its appearance indicates a certain problem, a developing breakdown, wear of some elements.

Continuing to ignore the squeak, at some point the steering mechanism may completely fail and fail.

You can’t even imagine what could happen if a failure occurs at high speed.

- Electric power steering for VAZ 2107 - how to install power steering, repair

Practice clearly shows that such signs appear on a variety of cars, including:

- VAZ 2107;

- Opel Astra;

- Daewoo Lanos;

- Lada Priora;

- Lada Kalina;

- Nissan Qashqai;

- VAZ 2110;

- VAZ 2114;

- Nissan X-Trail;

- Renault Logan, etc.

But the reasons are usually the same for everyone.

I propose to look at the most common provoking factors, and how to deal with them and what needs to be done in certain situations.

Definition of crunching noise from outer CV joint

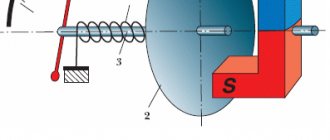

Outer CV joint design

It is necessary to choose a flat area on which you can drive a car. Turn the wheels to one side as far as they will go and drive off quickly. This will put more stress on the hinge, and if it is faulty, you will hear a familiar sound. By the way, you can listen to it yourself (with the windows open) or with an assistant so that he is near the wheel while the car is moving.

When turning the car to the left, the right outer CV joint will crunch, and when turning to the right, the left one will crunch. This is due to the fact that at this moment the corresponding hinges are the most loaded, since most of the mass of the machine is transferred to them, subject to the creation of significant torque.

How to determine the cause of squeaking and grinding noises when turning the steering wheel

It is important that extraneous noise while the car is moving can appear at any speed. The driver, turning the steering wheel in one direction or another, hears an uncharacteristic grinding sound even when driving at a speed of 30 km/h. It is noteworthy that when turning the steering wheel, a grinding noise can be heard even when the car is standing still.

Modern car models are equipped with power steering (power steering), thanks to which the steering wheel rotates as easily and silently as possible. For basic configurations, a slight hum or hissing sounds are allowed when the steering wheel is turned to extreme positions. However, there should be no grinding or squeaking noise regardless of whether power steering is installed or not.

Determining the cause of uncharacteristic noises when turning the steering wheel is not easy. The first step is to establish not only the source of uncharacteristic sounds, but also additional symptoms. Indeed, in a number of cases, the driver not only hears unusual sounds, but also feels any problems with the controls.

When diagnosing the cause of noise, several important factors must be taken into account:

- specificity of noise (humming, creaking, grinding, crunching, knocking);

- moments when noise appears (grinding noise when turning the steering wheel while moving or while the car is parked);

- frequency of noise - depending on weather conditions, engine temperature, vehicle load and other factors;

- the appearance of a grinding noise when turning the steering wheel left or right, or in both directions;

- What other symptoms appear along with the noise?

Complete answers to these questions will help a car service specialist determine the source of the problem as accurately as possible and eliminate it.

Universal diagnostic method

Diagnosis of a malfunction of the internal CV joint

We present to you an algorithm for another, universal option, how to find out which “grenade” is crunchy. You need to act in the following sequence:

- Place the car wheels level.

- Raise one of the front wheels using a jack.

- Put the car on the handbrake and neutral gear.

- Start the engine, depress the clutch, engage first gear and slowly release the clutch, that is, “move off” (as a result, the suspended wheel will begin to rotate).

- Slowly press the brake pedal, creating a natural load on the joint. If one of the internal “grenades” is faulty, then at this time you will hear familiar knocking sounds on the left or right side. If the internal CV joints are in order, then the car will simply start to stall.

- Turn the steering wheel all the way to the left. Slowly press the brake pedal. If the internal “grenade” is faulty, it will continue to knock. If the outer left CV joint is also faulty, then sound will also be added from it.

- Turn the steering wheel all the way to the right. Carry out similar procedures. If a knocking noise occurs when the steering wheel is turned to the right, it means that the right outer joint is faulty.

- Be sure to put the gear in neutral, turn off the engine, and wait until the wheel comes to a complete stop before lowering it to the ground.

When hanging wheels and diagnosing CV joints, follow safety rules, in particular, do not forget to put the car on the handbrake, or better yet, use a wheel chock.

Common causes of occurrence, noise elimination techniques

The driver of any vehicle should perceive extraneous creaking or grinding noises in the car’s mechanisms as an alarming signal. After all, we are often talking about mechanical wear of an element or its failure, which threatens loss of steering control.

A grinding noise when turning the steering wheel in place and in motion can be caused by a number of problems in the following components:

- errors when performing the wheel alignment procedure;

- steering rack;

- steering column;

- power steering;

- CV joints;

- ball joints;

- silent blocks;

- plastic elements of the interior and body.

Depending on where the sound appears, you need to analyze the problem and fix it.

In most cases of malfunctions, you will have to contact specialists, since troubleshooting the problem yourself will be difficult due to the complexity of the vehicle design and the risk of errors.

Incorrect vehicle alignment

If the source of squeaking when turning and while parking when twisting the steering wheel is the tires, then there is a high probability that the problem lies not in the steering itself, but in incorrect alignment.

Incorrect installation of the front pair of wheels will immediately affect the service life of the rubber: uneven wear will quickly cause it to fail. Therefore, when diagnosing wheel alignment errors, it is recommended to immediately contact a tire shop and repeat this procedure. It is better to use electronic equipment, since in this case errors in setting the correct position of a pair of wheels will be minimized.

Problems with the steering rack and steering column

One of the most common causes of a grinding noise when turning the steering wheel left or right is a malfunction of the steering rack. The creaking of the rack or column is accompanied by strong vibration on the steering wheel. If the noise and vibration are not strong, then further operation of the vehicle is permitted. However, as you drive, the symptoms of wear on the control elements intensify, which makes replacing the mechanism a necessary procedure.

The steering rack on cars produced in the last decade is a very complex mechanism. The car owner can only inspect the boots and determine their condition, but it is advisable to entrust a more in-depth analysis of the problem and repair work to professionals. The slightest mistake when repairing or replacing this mechanism can result in loss of control at high speed, so it is highly not recommended to fix the malfunction yourself.

Tie rod ends creaking

The steering linkage may also creak due to deformation of the anthers. If the boot is torn, sand can get into the tip through it, which causes squeaks. When inspecting the unit, it will be necessary to identify breaks.

The fault can only be eliminated by replacing a pair of tie rod ends with all components. The replacement can be done on your own if the car owner has the skills to independently maintain his vehicle.

In rare cases, the tie rod end may make unusual sounds due to friction with adjacent mechanisms. It will be necessary to adjust the position of the tips and replace the anthers. If one tip in a pair shows signs of wear, then the entire pair is replaced.

Ball and CV joint grinding

After several years of use, the ball joint wears out and begins to grind when moving. It is important to notice this sound in a timely manner and replace the support, since there is a danger of its failure when moving at high speed. It is also recommended to periodically check the condition of the boots, the tightness of which largely determines the service life of the ball joint.

If the driver hears crunching and grinding noises when turning the steering wheel left and right, then there is a high probability that the CV joint is failing. The bearing needs to be lubricated and the boot needs to be replaced. If the CV joint has mechanical defects, it must be completely replaced: such a part cannot be repaired.

Silent blocks creaking

Creaking when turning the steering wheel in place and while driving can be caused by wear of the silent blocks. As a rule, the rubber components of silent blocks begin to dry out gradually, which is especially noticeable in hot weather.

The uncharacteristic noise of silent blocks will be produced until the part breaks. It is important that creaking occurs only at high ambient temperatures and can disappear when it gets colder. If the silent block has no breaks and is not completely dry, it can continue to be used in the design of the machine. However, the first squeaks in the heat can already be considered a signal to replace these parts in the near future.

New generation cars are equipped with silent blocks made of high-strength polyurethane, which virtually eliminates the risk of them drying out in hot weather.

Bearings creaking

Unusual driving sounds coming from the steering knuckle when the steering wheel is rotated may indicate a problem with the bearings. Creaking and crackling noises accompany the operation of bearings when their lubricant runs out or sand gets inside the housing.

If the problem is not corrected in time, serious damage may occur. You will need to remove the bearings from the car and inspect them for damage. If no visible defects are observed, it is necessary to lubricate the part and install it in place. In case of damage, it is recommended to replace the bearing with a similar one.

The creaking of a plastic casing

Creaks, whistles, crackles and even howls of the plastic casing are accompanying sounds when driving any economy class car after several years of operation. Due to vibration, friction begins in all plastic elements of the interior:

- Front Panel;

- door trim;

- steering wheel cover.

This problem can be solved by additionally fixing each plastic element (with glue, rivets or self-tapping screws). In some cases, it may be necessary to replace some part of the casing.

Often car owners of old cars do not pay attention to these sounds - squeaking plastic cannot be called a problem, since it is not associated with malfunctions of the mechanical parts of the car. Such sound while driving only affects the comfortable stay of people in the cabin.

How to register a trailer for a car with the traffic police - procedure

In addition to fluid, a problem may also arise in the form of wear. If the power steering has been in service for quite a long time, be sure to check the condition of the amplifier belt and carry out comprehensive diagnostics.

Wheel alignment

If the squeak comes from the tires themselves, usually when the car is stationary, there is a high probability that the wheels were installed incorrectly.

Everything is simple here. Carry out the wheel alignment yourself or with the help of specialists, and the problem will go away.

Silent blocks

A fairly common reason, typical for hot weather.

If you start to hear a creaking noise at high air temperatures, check the silent seals. An extraneous sound indicates impending complete wear.

When it’s hot, the rubber from which the silent blocks are made gradually dries out, dries out, and decreases slightly in size. This is typical for fairly old parts.

Modern silent blocks on new cars are made of polyurethane. It does not dry out in the heat, and therefore does not usually cause squeaks.

If we miss here too, we move on.

Bearings

When a squeak is heard from the steering knuckle as the steering wheel rotates, it is probably a matter of bearings.

Creaking, squeaking and crackling noises from bearings occur when there is not enough lubrication in them or some kind of debris such as sand and dust gets inside. The problem can be solved by lubrication or complete replacement.

Rack or column

We are talking about the steering rack and steering column.

The creaking from them is quite easy to detect. In parallel with the creaking, a characteristic vibration occurs that appears when the steering wheel rotates.

Usually the source of the squeak is the column coupling. The problem is not the most serious, that is, you can operate the car with it. This can be solved by replacing the column itself.

Another creaking noise may come from the junction of the column and the rack. This is usually due to severe wear or poor adjustment. Sometimes the adjustment can be corrected.

Tips

If the boots are damaged and worn, dust and debris can penetrate directly to the tie rod end. It is they who cause that very creaking of the steering wheel at the moment of turning and when hitting bumps.

To diagnose the problem, you need to conduct a visual inspection. If you find sand or other debris there, you will have to change it.

It is strongly recommended that tie rod ends are always replaced in pairs.

This happens quite often, but mainly on old cars that have been in use for a long time.

Rubber squeak when turning the steering wheel

The creaking of rubber when turning the steering wheel can indicate a variety of problems in the design of the car. To better understand the source of these sounds, you need to drive the car onto an overpass. In this case, one person in the cabin turns the steering wheel in different directions, and another person under the car tries to determine the source of the rubber squeak.

If the problem lies in the tires on the wheels, then this will be quickly determined. You will either need to perform a wheel alignment or purchase a new set of tires to replace the worn one.

Almost every steering element is equipped with rubber or polyurethane parts. Therefore, any component in the vehicle control system can creak. As a rule, extraneous sounds occur due to a lack of lubrication or when a foreign body enters a rubber element. Therefore, to eliminate the problem, you will need to inspect the part, clean it of sand and foreign bodies, and thoroughly lubricate it. If the rubber element has cracks or tears, it must be replaced.

Quiet or loud hum when turning the steering wheel in place - solution to the problem

This noise is considered typical for all vehicles equipped with power steering. In any mode (parking in place or moving forward/backward), the power steering will emit a low hum when you turn the steering wheel. In rare cases, noise effects will become louder only when the steering wheel is turned in one direction or another.

If the power steering hum becomes louder during operation of the machine, it is necessary to check the mechanism itself. Most often, it is necessary to add power steering fluid to eliminate loud noise when driving a car.

It is important that a strong hum when the hydraulic booster is malfunctioning is always accompanied by difficulty in driving the car. Therefore, this malfunction can be identified in a timely manner when the steering wheel begins to turn more difficult.

see also

Crunching sound when turning the Prior's steering wheel- Priora carburetor

- Priora power steering

- Where is the coolant drain plug located on the Priora?

- How to drain Priora coolant

- Priora coolant volume

- Installing fog lights on a Priora

- Priora dashboard lighting

- Priora instrument panel lighting

- Installation of fog lights on Priora

- Priora throttle body

Analysis of typical complaints

The advice given at the beginning, to understand when the tapping occurs, makes it somewhat easier to find the cause. But this recommendation is effective only with a comprehensive diagnosis. For example, the mere fact of clanking in the pits is not enough; you need to listen to what is happening when the wheels are turned and whether there are any sounds in place.

If the test is done, go through common complaints.

- The noise only appears when the steering wheel is turned. If nothing is transmitted to the steering wheel, then see “ball” in more detail. Perhaps it is not tightly attached to the steering knuckle or lever. For example, bolts are often forgotten to be tightened during wheel alignment.

- The knock comes from the steering wheel. This is either a rack or a cardan on the shaft. If this only occurs on washboards and other irregularities, inspect the control shaft telescopic connection. Pay attention to the rack and pinion mechanism - the nuts securing it to the subframe or body may be loose.

- The rattle is only on the straight line, quiet in turns. Rack, cardan, ball joints.