Vibrations in the steering wheel/brake pedal

Cause: worn or deformed brake discs.

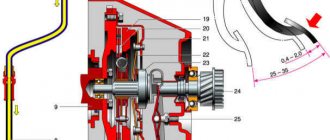

The brake rotor (disc) is part of the braking system; it rotates together with the wheel. Let us remind you that the wheel is fixed directly to the disk. By pressing the brake pedal, you force the brake pads to press against the brake disc, as a result, the rotation of the discs (and wheels) slows down and the car stops. As you understand, the brake disc is very important for the operation of the car.

Let's try to look at how brake discs work. Almost always discs are made of metal. They are made to a special width, which depends on the manufacturer and model of the machine. When you press the pedal, the pads, on which the abrasive material is applied, rub against the disc, creating serious pressure - the disc ultimately experiences a strong increase in temperature. This, in turn, leads to minor, but still changes in the metal (density changes) - the disk must be cooled over the entire area.

In practice, such cooling does not always occur (and sometimes abruptly), as a result of which a change in density leads to deformation changes only in some places, and the nature of the deformation itself is visible as a wavy surface. Next, this is what happens - if at high speed the pads are pressed against such a deformed disc, then the entire brake caliper begins to tremble, transmitting this vibration to the wheel, which, in turn, sends a beating either to the steering wheel or to the body of the entire car.

A sharp drop in brake disc temperature after pressing the brake pedal for a long time can be caused, for example, by snow or running into a puddle.

The common people often hear the phrase “disc led” - it just means the deformed surface of the brake disc. An additional sign, coupled with vibration, indicating deformation of the disk surface is a bluish tint of the metal on the disk, which is also a consequence of overheating.

It is very easy to diagnose a disk for deformation. You will need to jack up the wheel. In this case, the handbrake must be removed, the gear must be put in neutral (make sure that the car does not roll away). Then, in this state, spin the wheel - rotation should be easy and without jamming. An abnormally fast stop of the wheel or “heavy” rotation at a certain point most likely indicates damage to the brake disc.

If a car uses discs not only at the front, but also at the rear, the latter can be diagnosed by using the parking brake while braking. If you also feel a beating when you move the handle towards you, then the culprit is most likely the rear disc.

If it is the disc in front that has a deformed surface, you will feel a beating that radiates directly to the steering wheel. If the rear disc is to blame, then vibrations, in principle, may not be felt (except for severe deformation of the disc; in this case, at high speeds, shaking during braking is still felt). The vibration felt in the brake pedal does not clearly indicate whether the disc is warped at the front or rear.

If you drove down a hill for a long time using the brake pedal, and then drove into a puddle on the road, then the disc, instantly cooling, may well be the cause of the deformation. But deformation is not always caused by sudden cooling. On the contrary, excessive overheating of the disk can also cause deformation. In this case, the brake pads continuously rub against the disc, preventing it from rotating and causing a strong increase in temperature. As a result, the brake caliper jams. To eliminate this effect, you will need to remove the cause of the heating.

A deformed disk can be replaced with a new one, although its cost can cost a pretty penny: from 2 thousand to 10-15 thousand rubles. (this is affected by the make and model of the car). If this seems too expensive, the brake disc can be, as they say, bored out - this is a simple operation, performed in auto repair shops, and the disc does not even need to be removed. Its essence is to remove the surface of the damaged metal on the disk until it is even and smooth.

If the car is equipped with brake drums, then deformation on them is rare.

Vibrations sent into the steering wheel after changing the disc, hub or bearing

If you notice that vibrations reverberating through the steering wheel or body of the car were detected after work was carried out in a car repair shop, then you need to look for the cause of this misfortune there. Such shaking could be caused by a previous change of the brake disc (as well as the hub bearing or the entire hub), which from time to time causes the steering wheel to shake. Usually this happens due to low-quality replacement elements, although coupled with this is an irresponsible attitude towards the procedure for replacing parts. The disk could have been tightened with the wrong force, or the disk could have been installed crosswise without tightening. The torque that should be applied to tighten is often indicated directly on the disc.

If runout on the steering wheel or body of the car was detected after operations on the chassis of the car, try to involve the same specialist who performed these operations on the chassis.

Silent blocks in the front of the car - replacement check

A very important element of the front suspension, which can knock in the most unusual way, is a set of silent blocks. The most common knocking sounds are the rear silent blocks of the front suspension arms, as well as the support silent blocks of the stabilizer, which are attached to the body. The whole problem is solved by replacement, there is no point in diagnosing for a long time - it is better to change the part. Failure occurs for the following reasons:

the rubber simply breaks due to increased loads, it does not withstand too much pressure and is deformed under the influence of the connections of the suspension arms; The silent block stops turning freely in the right place, there is no flexibility in the suspension, and the levers knock due to the lack of the required maneuver; the rubber has worn through, worn out and decreased in size, so metallic sounds are heard from the chassis, which are difficult to diagnose; It is necessary to pay attention to the fastenings of silent blocks; often replacing them turns out to be difficult due to preliminary unskilled work with suspension parts.

You can check while driving whether the rear silent blocks of the front control arms are knocking. You need to place your foot directly on the floor and listen to whether there is a knock on your foot. The same procedure should be done on the passenger seat. The stabilizer support bushings are checked by placing your foot or hand on the part of the body behind the pedals. However, if you have suspicions, you can simply change this element. We invite you to watch a short video with self-diagnosis of the Hyundai Solaris suspension:

Vibrations in the steering wheel

Reason: destruction of the drum (disc).

Thanks for subscribing!

The most undesirable cause of beating is a cracked drum (disc). This usually occurs due to severe heat or intense physical activity. The problem is inherent in heavily worn brake discs (heavily worn down) or drums with significant corrosion.

Pads as the reason for the steering wheel beating

Although the market is saturated with counterfeit and low-quality pads, they, along with high-quality but worn pads, are not able to cause beating in the steering wheel or car body when you press the brake pedal. This is explained by the fact that this spare part does not move on its own and is loaded from time to time, and not constantly.

Additional factors causing vibration that occur infrequently:

- problems with the steering rack or significant wear of the ball elements in the chassis;

- problems with the racks (in this case, the beating is mainly felt when performing a turning maneuver in the direction opposite to where the rack is installed);

- shock absorber supports that have failed due to damage or wear;

- significant physical impacts (curb, accidents, etc.). Note that, as a rule, before the disc deforms, there is damage to the wheel rim;

- breakage of steering tips.

Identifying possible causes of knocking

Turning the steering wheel of front-wheel drive cars involves many joints, levers and rubber seals. A knocking sound in the steering wheel when turning may indicate wear of components or parts.

First of all, the assistant can turn the steering wheel, and you can listen to sounds under the car. Sometimes it is difficult to determine a breakdown by hearing, so you can touch various parts with your hand.

Wheel arch protection

One of the common causes of knocking is loosening of the wheel arch protection. In this case, it first turns under the action of the wheel, then returns to its original position, which gives rise to a characteristic “plastic” sound. Reliable fixation of the plastic protection takes a few minutes.

Hinges

Knocking when turning wheels can be generated by hinge joints: steering tips and rods, earrings and stabilizer rods. The noise occurs when a dirty or unlubricated joint jams. Sometimes it is enough to lubricate it, sometimes it is necessary to replace it.

https://youtube.com/watch?v=BH–BZCeXFc

A metallic crack that accompanies a full turn of the steering wheel may indicate a breakdown of the constant velocity joint, or in popular parlance, a “grenade”. A cracking sound when turning in both directions means that both “grenades” need to be replaced. Failure of CV joints is usually associated with a rupture of the rubber boot that protects the mechanism body. Even a small tear is enough to create the need to replace one of the most expensive components of the chassis. Therefore, it is better to check the anthers once a month for damage.

Silent blocks and ball joint

Noise can be caused by heavily worn-out rubber silent blocks and ball joints. In this case, when the wheels turn, the lever becomes skewed, which generates the sound.

Front pillar

If the steering wheel of a stationary car knocks when turning, then very often this means a breakdown of some part of the front strut. Some of these faults can be found directly, others can be found by dismantling and disassembling the rack.

Strut bearing

The stand is attached to the car body with two or three nuts. Its support is made of elastic materials that soften body vibrations. The stand rotates using a support bearing. A strong knock occurs when it jams due to deformation of the holder or lack of lubrication.

Strut spring

This spring is fixed by special rubber or plastic bumpers with cavities. When turning the wheels, the spring must remain motionless. If it is broken or comes out of its seats, a knocking noise occurs.

A knocking noise when turning occurs when the wheel bearing wears out. It is easy to diagnose such wear. You need to shorten the wheel on the sound side and check the axial play by rocking the wheel. If there is play, the bearing must be replaced, which requires appropriate equipment and knowledge. Often both bearings fail at the same time. This can be serious. The complexity of the repair here lies in the procedure of “pressing” the bearing out of its place in the hub. Such a diagnosis is fraught with long-term, expensive “treatment”, and failure to take action in a timely manner can lead to complete destruction of the front suspension.

Non-standard reasons

Often the sound is not caused by a faulty part, but by something completely different. For example, one car owner got it after a pebble flew onto the subframe of his car and got stuck there. The elements of the steering column ran over a pebble and jumped off it, generating a sound. After removing the pebble, it disappeared.

Another car owner's front arm, which was replaced after a suspension repair, began to hit the subframe when turning, which caused a knocking sound. In this case, it was enough to lift the subframe with a pry bar.

Should you pay attention to the runout if it does not interfere with your ride?

In the event of steering vibration or its transmission throughout the entire body of the car, it would be safer not to bring the situation to a critical level, but to contact a specialist. As a rule, the problem does not require a solution as quickly as possible - you can drive with it for months (and sometimes years). On the other hand, it should be remembered that if the nuts are not tightened properly, the behavior of the brake disc may be unpredictable, which affects driving safety. At the same time, the beating also loads the parts of the chassis system: shock absorbers, steering, parts of the hub - and in the event of a breakdown, all these elements (as well as their replacement) will not be cheap.

In addition to the above, we note that beating at high speed is very dangerous - strong vibration can lead to loss of control of the car, and, as a result, to an accident. Driving in itself is already a source of increased danger for the driver and others. In this regard, it is better not to skimp on eliminating the causes of vibration.

By the way, many motorists don’t even realize how ridiculous they look from the outside with a vibrating steering wheel; remember this when you drive your family or just give a ride to a fellow traveler - from the outside, a shaking steering wheel looks very noticeable.

Reasons for failure

Drivers know that rack repair kits and consumable kits are in use in stores and markets for a reason. The fact is that the steering rack is a metal product that does not bend even under high loads. To break it off you need to make incredible efforts. For this reason, mechanical racks on old cars still work properly, which, for example, thermostats cannot boast of. However, all types of racks require the integrity of the seals and bearings. They are exactly what is included in the repair kit.

Hydraulic racks have a “personal” malfunction. The hydraulic boosters fail in them, while the rest of the structure remains intact. At the service station, in the event of a breakdown, they work with the hydraulic booster, and the steering rack is cleaned, undergoes troubleshooting and replacement of the repair kit.

And finally, natural and related faults. As you know, even the best metal gradually wears away and becomes coated with oxide. In the case of the latter, the slats have protective boots, which, if tears and cracks appear, cease to protect the structure from dust, moisture and sand. The rack itself uses up its resource very quickly.

The large overloads that a car experiences when driving on broken roads affect every steering rack. The crankcase becomes covered with cracks, the integrity of the gear section is compromised. The load is transmitted through the rods, and nothing can be done about it.

Thus, the service life of the steering rack, amounting to 200-250 thousand kilometers, can be reduced several times for a number of reasons:

- Road quality and driving style;

- The owner’s attitude to the condition of the anthers;

- Timely replacement of the repair kit.

As you can see, you should never forget about the steering rack. If you monitor its condition and drive the car carefully, its operation can last a very long time. But will it point you to problems that have arisen?