Note! Before starting work, we advise you to stock up on a strobe light, because without it, checking the ignition timing will not be very convenient! (What is a car strobe light?)

When should ignition timing be set? Due to incorrectly set ignition timing, the following changes will occur in the car engine:

- Firstly, the car will lose its speed qualities, that is, it will drive worse.

- The car will also respond worse to the gas pedal, and small dips will appear when you press it.

- To all this can be added unstable engine operation at idle.

- It may also be difficult to start the engine.

- Also, the car’s engine may overheat more often.

- And in conclusion, I would like to note that the engine’s fuel consumption may also increase.

How to set the ignition timing on a VAZ 2108-VAZ 21099?

Setting the ignition timing and checking it:

Note! Before you start, be sure to keep one fact in mind. The ignition is installed strictly at idle speed, while the crankshaft rotation should be in the region of “820-900” rpm!

1) First, disconnect the thin hose from the vacuum regulator fitting.

2) Next, in order to check the ignition timing, perform the following operations:

• Connect the “positive” clamp that comes from the strobe light to the “plus” terminal located on the battery.

• Then connect everything to the same battery, but only this time to the “minus” terminal, the “ground” clamp that comes from the strobe light.

- How to properly adjust the ignition on a VAZ 2109

• Next, disconnect the tip of the high-voltage wire from the terminal of the “first cylinder” distributor cover.

Note! You can see where the “first cylinder” output is located on the distributor cap by the markings on the cap itself, see the photo for more details:

• Now connect the sensor that comes from the strobe light to the terminal of the “first cylinder”, and after the sensor is connected, install a high-voltage wire on this sensor.

• Then remove the rubber plug that covers the hole in the clutch housing to prevent dirt from getting into it.

• Then insert a screwdriver into the hole in the clutch housing, and then rotate the flywheel until the mark on the flywheel is between the cutout and the division. (Where the mark is located, as well as the cutout and division, look at the photo just below, which is located above the “Note!” section)

- How to adjust the carburetor on a VAZ 2109? VAZ 2109 diagram. VAZ carburetor

• Next, start the car’s engine, and then point the flashing strobe light at the hole in the clutch boat.

• While the strobe light is flashing, the mark that is stamped on the flywheel should visually appear motionless at this time.

Note! If the ignition on your car is installed correctly, then in this case the mark indicated by the number “1” must necessarily be located between the cutout “2” and the division “3”. If your “1” mark is placed outside the cutout and division, then adjust the ignition timing!

3) After all operations, if your ignition timing is not correct, then first loosen the three nuts that secure the distributor.

4) And then turn the distributor itself until the marks align as desired.

- Ignition timing: features, rules and recommendations

Note! If you need to increase the ignition timing, then gradually turn the distributor slightly towards o. And if, on the contrary, you need to reduce the ignition timing, then in this case turn the distributor closer to o. In these “plus” and “minus” intervals, set the ignition angle that will correspond to your car!

5) When the ignition timing is set, install all previously parts in their place.

Additional information: To make it clearer for you, watch the video in which “Nail” describes everything in detail:

Probably every motorist who owns a car of the VAZ 2108-09 family has encountered problems with the ignition system. Very often, these malfunctions are caused by a trivial reason - an incorrectly set ignition. It is the question of how to set the ignition on a VAZ 2109 carburetor and injector that we will talk about below.

Consequences of incorrect ignition operation

Quite often, VAZ 2109 car owners associate problems in the operation of their car with carburetor malfunctions. In fact, some problems should be perceived solely as a consequence of incorrectly set ignition timing. Such problems can be: difficult starting of the engine and white acrid smoke from the exhaust pipe. Understanding this fact will allow you not to waste time looking for a problem where there is none, but will give you the opportunity to quickly eliminate the problem where it actually exists. It is worth understanding a simple fact: if there is no spark or the spark plugs are simply flooded, you need to look for the fault in another unit.

During long-term operation, it became clear that the VAZ-2109 model, which has a carburetor engine, needs fine adjustment of the ignition timing. Fortunately for car owners, this procedure can be done without special equipment. But it’s still better to have a strobe light on hand. This device will help you accurately set the desired ignition timing. And since this procedure will have to be carried out more than once, it is better to get such an assistant.

Yes, experienced car owners will say that the malfunctions described below may be associated with improper operation of other systems, and they will be right. We suggest checking the first and main guess about the causes of the breakdown - incorrectly set ignition angle. List of the most common engine problems:

- Excessively high level of detonation in the engine piston system. This problem can be identified by the following signs: when you press the gas pedal, a ringing sound appears in the engine. This problem is faced by inexperienced or inattentive car owners who pay insufficient attention during maintenance. The cause of premature detonation is early ignition firing, which can lead to deformation of the piston rings. But repairing this unit is very expensive.

- If black smoke comes out of the exhaust pipe when the engine starts, this may also indicate pre-ignition.

- Noticeable loss of engine power; increased fuel consumption; slow engine response to changes in operating mode, poor throttle response. All these “illnesses” in the functioning of the “heart” of your car indicate delayed ignition activation. The reason for this phenomenon is that the fuel mixture does not have time to completely burn out when the piston reaches its highest point of operation. The top point of the piston is also known as the dead point. So it turns out that with negative movement, the fuel mixture still burns in the cylinder. In addition to this, another reason is possible, namely a very high temperature of the exhaust pipes.

- If a problem in engine operation occurs directly when you press the gas, then the ignition probably fires later than necessary. With this option, the engine operates intermittently, and pressing the gas pedal causes failures in its functioning. The presence of such a problem can cause jerking when the car moves.

- The running engine does not support or poorly maintains idle speed.

The occurrence of one of the listed malfunctions in the operation of the VAZ-2109 should cause alarm in the car owner. In this case, it is worth checking the angle at which the ignition system is set. It may also be that re-setting the ignition angle will solve your problem.

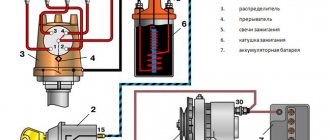

System design

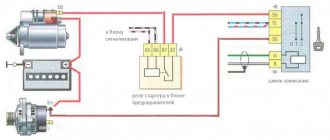

Before we begin to consider the adjustment process, we consider it necessary to understand the diagram and principle of operation of the system. Vehicles of the VAZ 2109 model range are equipped with a non-contact ignition system. The connection diagram of all elements is as follows:

The operating principle of the system is not complicated. In order for a spark to begin to be produced, the motor shaft must turn. Simultaneously with its rotation, the camshaft will also turn. As a result of this, the sensor generates a signal that will be sent to the switch. The “K” terminal of the coil will connect to the common wire (to “ground”), as a result of which a spark will occur on the main wire. At the moment when the working distributor slider connects the main wire with one or another high-voltage wire on the corresponding spark plug, a spark will appear and the car engine will start.

If the setting is made incorrectly, the candles work in the wrong time modes. Consequently, such a violation becomes the cause of unstable operation of the entire power unit.

Basic technical concepts

The ignition system is a combination of various devices and devices that ensure that an electrical discharge occurs, which in turn ignites the mixture of fuel and air in the internal combustion engine system. This system plays a huge role in the technical equipment of the car and electrical equipment.

We are not interested in the entire ignition system, but only when a spark appears, which determines the correct operation of the entire system. This moment is called ignition timing. determines the ignition time of the working mixture in compressed form. Incorrectly set ignition timing entails many problems during vehicle operation. With this article, you will learn how to identify the problem, how it threatens, and how to fix it.

VAZ-21099: under the hood

Preparatory activities and necessary tools

Installing the ignition of a VAZ 2109 carburetor begins with preparatory activities. In particular, you need:

- Warm up the car engine;

- Set the parking brake and install wheel chocks under the rear wheels.

Remember that you cannot ignore safety rules, because a car is a highly dangerous vehicle, and failure to comply with safety rules when driving, servicing and repairing it can cost you dearly.

An important point: before you start work, you should make sure that the carburetor is correctly configured on the car. It would not be superfluous to carry out a visual inspection of all elements of the system. If we are talking about a carburetor car, special attention should be paid to inspecting the condition of the distributor.

If you have a car with an injection engine, it is worth checking the ignition module for serviceability. The thing is that, as practice shows, it is this module that fails most often and is the reason for the inoperability of the entire system.

To complete the work we need:

- strobe;

- a set of keys.

How to correctly set the ignition on a VAZ 2109 carburetor - detailed instructions

The setup process is as follows:

1. Start the car engine and ensure that the engine speed is approximately 800 rpm. To set the idle speed within such limits, it is enough to use a slotted screwdriver to adjust the screw responsible for the amount of fuel mixture in the carburetor.

2. After setting the idle speed to the above value, turn off the car engine.

3. Disconnect the rubber hose from the vacuum corrector. Carefully bend the hose approximately in the middle or plug it with a screw of a suitable diameter.

4. Connect the positive terminal of the strobe to the “+” terminal of the battery;

5. Connect the negative wire of the strobe to the “-” terminal of the battery;

6. Disconnect the spark plug wire from the socket of the first cylinder as shown in the image:

Disconnect the spark plug wire

7. Install the strobe sensor into the socket and connect the high-voltage wire to it;

8. Remove the plug from the clutch housing hatch:

Removing the stub

9. Turn on the ignition and start the engine. We direct the actively changing luminous flux generated by the strobe into the clutch housing hatch:

We direct the strobe into the clutch housing hatch

10. When the light is flashing, it seems that the mark located on the flywheel is stationary. If the ignition is installed correctly, the first mark should be between the technological notch and the previous mark on the scale.

Tags

11. If after the described operations it was discovered that the ignition adjustment of the VAZ 2109 is incorrect, we continue to work.

12. Using an open-end wrench, slightly loosen the fastening nuts of the ignition system distributor:

Mounting nuts

13. After loosening the fastening nuts, turn the distributor body to the right side - if it is necessary to increase the ignition angle, and to the left side, if it is necessary to decrease the angle.

14. Connect a rubber tube to the vacuum corrector and check that the ignition is installed correctly. If the normal result is not achieved, we make repeated adjustments. How to check the correct operation of the system will be described below.

Dismantling

After dismantling the distributor, you can disassemble the device in order to repair its components, or completely replace the distributor with a new unit.

- De-energize the car by removing the negative from the battery;

- Disconnect the high-voltage components and the vacuum ignition corrector hose from the distributor;

- Remove the drive cable responsible for the throttle valves from the bracket. Next, the fastening nuts are unscrewed and the bracket is dismantled;

- Before removing the ignition distributor, apply a mark to the housing of the distributor and drive of auxiliary elements. This way you can simplify your task of setting the ignition timing for its precise setting. The mark is applied to the metal by scratching;

- Press the latch holding the block with the power wires and disconnect it from the distributor;

- Place the piston from the first cylinder to the top dead center position by moving the engine flywheel clockwise;

- Unscrew the remaining ignition distributor screws. The first fastener was removed when removing the damper cable sheath bracket;

- Remove your damaged distributor.

Disassembly and repair

Quite often, repair work with the distributor is associated with wear and the need to change the seals (coupling). To change the oil seal, as well as other failed components of the distributor, we bring to your attention the appropriate instructions, as well as video tips.

- Remove the ignition distributor cap by releasing the locking clip.

- Remove the slider. It is wiped with a clean rag and checked for mechanical damage. If there are chips or cracks, the element must be replaced.

- The runner must fit tightly on the shaft, which is achieved due to the presence of a plate spring with a pressing action. If it stretches or breaks, replace it.

- There is a resistor in the slider housing. The normal reading of its resistance is 1 kOhm. By measuring the data with an ohmmeter, you can draw conclusions regarding the performance of the component.

- Remove the low voltage wiring terminal. To do this, unscrew the mounting screw from the housing.

- Remove the plastic screen that serves as dust protection.

- A power wire comes from the Hall sensor and is held by the holder's claws. Using a screwdriver, the claws are opened and the wire is removed. Next, you need to unscrew the pair of mounting screws securing the Hall sensor support plate.

- Remove the vacuum corrector. Just be sure to disconnect it from the support plate lever before doing this. To perform this operation, carefully remove the retaining ring from the pin.

- The next step is to remove the pair of screws that hold the corrector to the distributor body.

Incandescent lamp instead of strobe light

Many car owners will ask a completely fair question: how to adjust the ignition of a VAZ 2109 in the absence of a strobe light. Of course, it is more correct to work with a strobe, especially since in this case it is possible to carry out adjustment and adjustment work as accurately as possible. However, there is another method that is useful for those who, for one reason or another, do not want to purchase a strobe.

To work, we need an ordinary incandescent lamp designed for an operating voltage of 12V. The entire algorithm of actions is as follows:

- Disconnect the wire from the distributor that goes to the ignition coil

- We connect one terminal of an incandescent light bulb to the wire. We connect the second wire from the lamp to ground.

- As in the case when setting the ignition of a VAZ 2109 using a strobe light, use a spanner to loosen the distributor fastening nuts.

- Turn on the ignition. The incandescent lamp should light up.

- Gradually turn the distributor until the lamp stops glowing. After this, turn the distributor slightly in the other direction. As soon as the lamp starts to glow again, you can tighten the fastening nuts.

Of course, the method described above cannot provide the highest possible adjustment accuracy. However, with its help it is quite possible to achieve more or less correct and stable operation of the power unit.

How to adjust the ignition on a VAZ 2109 - an alternative method

In addition to the adjustment methods described above using a strobe and a light bulb, you should remember one more method - adjustment using a standard tachometer. We emphasize that this method, like the method using a light bulb, cannot provide high accuracy of adjustment. Moreover, it is characterized by one significant drawback - it is impossible to carry out the adjustment yourself; you will need to hire an assistant. So:

- Your assistant is located behind the wheel of the car. He turns on the ignition and monitors the readings of the standard tachometer on the instrument panel.

- You loosen the nuts securing the distributor and turn it a little.

- Your assistant turns the ignition key. The tachometer needle should quickly deflect and return to zero.

- You need to ensure that the distributor remains in a position in which the tachometer needle deflects.

You may notice that this method requires patience and quite a lot of time. As practice shows, it is not possible to adjust the ignition quickly and the first time using this method . Therefore, we recommend using it only in extreme cases.

How to set the ignition on a VAZ 2109 injector

Above we described the process of adjusting carburetor engines. However, there are VAZ modifications equipped with injection power units. How to set the ignition on a VAZ 2109 with such an engine?

First of all, you should pay attention that in the case of injection engines, they do not have a distributor and a Hall sensor. At the same time, the system provides two ignition coils at once, and, accordingly, two switches. The main difference between the injection system and the classic one is that the control signals are generated by a special electronic unit. The operating principle is as follows:

Operating principle of the injection system

Thus, there is simply no need for a distributor, because it is the electronic control unit that determines in which cylinder and at what point in time there should be a spark. Signals from the control unit are supplied to the inputs of the switches, and from them to the ignition coils. One switch is responsible for sparking in the first and third cylinders, and the second - in the second and fourth.

As in the case of engines with a carburetor fuel system, adjustment is carried out according to special technological risks. The ignition marks of the VAZ 2109 injector are shown in the photo below:

Ignition marks VAZ 2109 injector

Please note that it is not possible to configure the injection engine system yourself. The thing is that this operation involves making changes to the software of the microcontroller of the electronic control unit. Of course, each specific microcontroller has its own specific firmware. Moreover, there are also non-standard firmwares, for example, with settings for a sporty driving style.

Only an experienced specialist with certain knowledge can flash an electronic control unit. Therefore, if malfunctions occur in the ignition system of an injection engine, you should seek help from a trusted car service center.

Basic concepts in ignition operation

To get to the bottom of the problem, you need to know the operating mechanisms of this node. To do this, let’s look at some basics of the theory, knowing which you can delve deeper into the issue of fixing the breakdown.

The first thing you need to understand is what the ignition system is. The ignition system is interconnected components and devices, the joint operation of which ensures the occurrence of an electrical discharge that ignites the air-enriched fuel mixture in the internal combustion chamber. Stable and uninterrupted operation of this unit plays a big role in the good technical condition of the machine in general and electrical equipment in particular.

However, to analyze the problem we do not need to know the entire system. We are more interested in the moment the spark appears, which is responsible for the correct operation of the entire system. The moment when the spark appears is called the ignition moment, since it determines the time frame in which the compressed fuel mixture is ignited. Remember once and for all: incorrectly set ignition timing causes various problems in the operation of the car. In this article we will look at several basic issues:

- how to understand that the ignition is set incorrectly;

- what consequences may there be;

- how to set the ignition correctly.