Operating principle of power steering

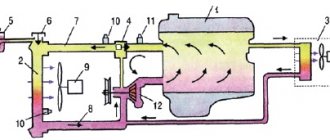

The operation of the hydraulic booster is based on the transmission of pressure by liquid. This pressure can exert forces on parts of the steering mechanism, thereby reducing steering effort. The entire design of the power steering is aimed at creating high pressure in the fluid. This pressure is created in the working line, which opens when the steering wheel is turned. The force is transmitted to the hydraulic cylinder of the steering rack or steering mechanism, and then to the steering rods. As a result of the power steering, the driver feels barely noticeable resistance on the steering wheel, which allows you to control the car in difficult road conditions.

Power steering pump

The power steering pump can be called the main unit, since it is it that pumps fluid, creating increased pressure in the line. The main element of the pump is the impeller, which is driven into rotation by a belt drive. Unfortunately, many power steering malfunctions are associated precisely with pump failure. Liquid starvation is unacceptable.

The driver must carefully monitor the fluid level, since air entering the pump leads to accelerated wear.

The presence of air can be recognized by a sudden increase in the force on the steering wheel, as well as a characteristic buzzing sound when turning the steering wheel. Bleeding the line is a standard procedure and is carried out by turning the steering wheel in one direction or the other.

The next problem is wear of the shaft bearing. The fact that the bearing has become unusable is indicated by extraneous sounds emitted from the pump when the engine is running. To verify this, just remove the drive belt and start the car. If the sounds disappeared, then the reason was in the pump. The situation can be corrected by replacing the shaft bearing.

Story

I have already said many times that I do not do tuning or modifications for the sake of the process. Only if there are problems. In this case, it all started with the “collective farmers” of AvtoVAZ. For a very long time, the plant installed German ZF power steering pumps on the assembly line, and then suddenly the Russian version came into use. As usual, the plant was not going to give any explanations, so I had to turn to another source, the manufacturer ZF. A technical seminar organized by this company was held in St. Petersburg, and I asked the German a question about this situation. Directly at the lecture (that is, the official position), the German specialist said that this is a trade secret. And during the lunch break, when I addressed him in German, he straightened up and said the following. Quote. Along with the supply of pumps, we gave a recommendation to AvtoVAZ on what SHOULD be poured into the system. At first, the plant filled it with an approximate analogue of the liquid that we recommended, and then suddenly it started pouring green Pentosin. The result was not long in coming - leaks and a humming sound when turning. But the funny thing is that all these “supposedly” warranty cases were transferred to the shoulders of ZF. The German said that we “butted heads” with the plant a little, did not get clear answers from the managers and management and simply stopped supplying this spare part. End of quote. Now we come to a simple conclusion: in order to get a working unit, as intended by the designers, we need to flush the system and fill it with what is recommended. The fluid is simple, good synthetic dextron, but along with it I recommend replacing the low pressure hoses.

Rotary valve

High pressure in the line must be controlled, otherwise the fluid will exert force in only one direction. A rotary valve is used to distribute the liquid along the line. To be more precise, there are several of them. When the steering wheel is turned, the valve opens that part of the line that corresponds to the given direction of movement of the rack rod. Usually, throughout the entire period of operation, the valve does not cause any problems, but for this it is necessary to periodically change the power steering fluid according to the established regulations, otherwise the valve may become clogged.

Steering gear

The steering mechanism performs two functions simultaneously. First, it converts steering wheel rotation force into bipod rotation force. In essence, the rotation axes rotate. Hydraulic fluid transmits force to a power cylinder connected to the bipod sector. The most common malfunction of the mechanism is associated with a leak in the high pressure line connection fitting. Typically, repairs come down to replacing the fitting along with the main hose.

The power steering can serve properly for a long time.

The main requirement is to change the fluid in a timely manner and monitor the tightness of the system.

Bleeding the power steering system of Niva Chevrolet (VAZ 2123)

Bleeding the power steering system is necessary when replacing fluid, as well as to remove air that has entered the hydraulic drive when repairing or replacing individual components of the system. To bleed the hydraulic system, open the power steering reservoir cap and add fluid to the lower mark on the reservoir cap indicator. We start the engine and at idle speed check the fluid level in the tank. If the liquid level drops, add it to the lower mark. We turn the steering wheel left and right several times until it stops, making sure that the fluid level in the tank is at the lower mark. Remove the protective rubber cap from the bleeder fitting.

The bleeder fitting is located on the steering gear cover.

We put a transparent hose on the head of the fitting, lowering its free end into the vessel. Using the “8” wrench, unscrew the fitting 1/2 turn. When a continuous stream of liquid appears in the hose, tighten the fitting. We return the steered wheels to the straight-line position of the car and let the engine run for another two to three minutes. Normal operation of the hydraulic booster should not be accompanied by noise. Turn the steering wheel all the way left and right again and, if necessary, add fluid to the tank to the bottom mark. After warming up and stabilizing the temperature of the working fluid, its level should be at the upper level, and in a cold state not fall below the minimum level.

What tools for preparation

Chevrolet Niva: VAZ 2123 filling tanks

Special tools do not require changing the oil in the power amplifier. One key number 10. Fixed screwdriver. And a container for liquid that will drain. Due to the tightness of the engine compartment, it is best to take a cut plastic bottle. Well, the process itself First, release the clamping cup clamp from the key. Wipe it gently with a cloth. It is necessary that dirt accidentally gets into the tank

Only then carefully unscrew the tank cap using the level indicator. Carefully pour the liquid into the bowl

Using a screwdriver, loosen the hose clamp from the power steering to the tank. This is a drain hose. Hole in tank, connection to remote hose, plug. The hose itself is directed into a container to drain the liquid.

see also

Characteristics of Dextron 2 and 3 - what are the differences

- 38 1 29k

Power steering malfunctions

- 22 0 33k

What kind of oil to fill in power steering

- 160 0 214k

Power steering buzzes

- 360 7 331k

15 best power steering fluids

- 122 13 371k

Bleeding the power steering and its system is carried out when replacing the working fluid, airing, which may be the result of a malfunction or repair work. Air trapped inside not only reduces the efficiency of the power steering, but can also cause serious damage, in particular, failure of the power steering pump. Therefore, pumping the hydraulic booster must be carried out in strict accordance with existing technology.

How to pump power steering

How to fill oil and bleed power steering

The procedure for replacing fluid and pumping power steering is carried out in strict accordance with the existing algorithm. Some automakers may add their own features to it. If you have a manual for your car, we recommend that you read the relevant section. In general terms, the steps must be performed in the following sequence:

- Raise the vehicle completely on a lift or with the front wheels off the ground.

- If necessary, drain the old fluid from the expansion tank. To do this, remove the return hose (going to the power steering system) from the expansion tank and put a plug on it so that liquid does not spill out of the hose. A hose leading to an empty bottle is connected to the released tap on the tank, where the old hydraulic fluid is supposed to be drained.

- It is most convenient to pump out the main volume of liquid with a syringe and pour it into a separate bottle. When there is very little liquid left, move on to the next point.

- Fill the expansion tank with working fluid to the top.

- Next, you should turn the steering wheel from side to side (from lock to lock) several times so that the old fluid remaining in the system flows out through the hose. Since the new fluid displaces the old, do not forget to monitor the oil level in the tank so that air does not get into the hose.

- If the fluid level drops, add it again.

- Start the engine for 2-3 seconds and turn it off. This is done so that the liquid begins to spread throughout the system.

Pumping out oil with a syringe

- Next, add working fluid to the tank to the MAX level and repeat the procedure by starting the engine. Repeat this cycle 3-5 times.

- The signal to stop pumping is the fact that air from the return hose stops entering the drain bottle. This means that there is no more air left in the hydraulic system and fresh, clean fluid enters the reservoir.

- After this, you need to reinstall the return hose (connect it to the expansion tank where it was originally installed).

- Refill the reservoir to the MAX level, then start the engine.

- To pump the hydraulic booster, you need to slowly turn the steering wheel 4-5 times from the left to the right stop. At the stop points, pause for 2-3 seconds. If there is any air left, it should escape into the expansion tank. During the inspection process, we make sure that the pump does not make any extraneous noise.

- An indicator that pumping has ended will be the absence of air bubbles on the surface of the liquid in the tank.

- After this, close the expansion tank tightly.

Bleeding the power steering system

can also be pumped without starting the engine , “cold”. To do this, just rotate the steering wheel from the left to the right stop . At the same time, old fluid and air leave the system. However, most automakers still recommend bleeding the system with the engine running.

Changing oil in transmission units

Before starting work, you need to stock up on a sufficient amount of transmission.

Each of the units holds the corresponding volume:

- Gearbox - 1.6 l;

- Transfer case - 0.79 l;

- The front and rear axles are 1.15 and 1.3 liters, respectively.

You can immediately buy 5 liters of 80W-90 transmission that meets the GL4/GL5 quality standard. It is suitable for all transmission units.

It is also necessary to stock up on flushing oil, which allows you to get rid of oxidation products and decomposition of lubricant components.

Changing the gearbox oil

To carry out the work you will need:

- wrench 17;

- container for collecting waste;

- hexagon 12;

- funnel;

- clean rag.

The transmission is replaced on an overpass or inspection pit. Otherwise, it will be difficult to get to the drain plug on the Chevy Niva gearbox. Order of operations:

- Warm up the engine to operating temperature. In this case, the oil will have proper fluidity and will completely drain from the crankcase.

- Place a container for collecting waste under the gearbox drain hole.

- Use a rag to clean the areas around the drain and fill plugs.

- Using a 17mm wrench, unscrew the oil filler plug. This will allow air to enter the gearbox housing.

- Use a hexagon to unscrew the drain plug.

- Wait for the entire transmission to drain from the crankcase.

- Use a rag to clean any chips from the magnetic drain plug.

- Fill in a liter of flushing oil.

- Start the engine and let it run for 3-5 minutes. At this time, you can change gears by squeezing the clutch.

- Stop the engine and drain the flushing oil.

- Tighten the drain plug.

- Using a funnel, pour new transmission oil into the drain hole.

- Screw in the filler plug.

- Start the engine and let it run for 5 minutes.

- Stop the engine and check the oil level. If necessary, top up the transmission.

Video instructions for changing the oil in the Shnivy gearbox:

Replacing the transmission in the transfer case

In addition to the keys, rag and waste container listed in the previous section, you will need a refill syringe. The oil in the transfer case is changed when the engine is warm. There is no need to change the transmission oil on a street overpass in the cold - the fluid will quickly cool down, thicken and not completely drain from the transfer case.

Replacement procedure:

- Place the machine on an inspection pit or overpass.

- Inspect and, if necessary, clean the ventilation valve.

- Clean the box around the plugs.

- Place the waste container.

- Unscrew the filler and drain plugs.

- Drain the transmission.

- Clean shavings from the magnet.

- Screw in the drain plug.

- Using a filling syringe, fill the transmission into the transfer case.

- Screw in the filler plug.

Replacement in Chevrolet Niva axles

Considering the location of the filler holes, you need to unscrew the plug with a socket head and a wrench, and not with a regular wrench. Otherwise, the set of required tools and materials is the same as that needed to change the oil in the transfer case:

- 3 liters of gear oil;

- hexagon 12;

- rag;

- refill syringe;

- container for processing.

The procedure for replacing the transmission in the front and rear axles looks like this:

- Drive the car onto an inspection hole or overpass.

- Clean the oil drain and fill plugs, as well as the axle housing near them, with a rag.

- Place a waste container under the drain hole.

- Unscrew the drain plug one by one.

- Wait until the oil stops leaking.

- Screw in the drain plug.

- Fill the transmission into the bridge using a filling syringe.

- Screw in the filler plug.

Changing transmission oil does not require special skills and abilities. Even a novice driver with no car repair experience can perform this operation. You just need to follow the instructions described above and be sure to fill the transmission with the appropriate viscosity and quality.

Typical power steering malfunctions

Malfunctions in the operation of the hydraulic booster can be easily identified by characteristic signs. Among them:

- The steering wheel turns hard . Probable causes are failure of the power steering pump, use of unsuitable working fluid, sticking of the spool mechanism channels.

- , a high-frequency sound (similar to a whistle) is heard while driving The probable cause is a loose drive belt.

- The steering wheel turns jerkily . Probable causes of the malfunction are the working fluid not meeting the specifications declared by the manufacturer, a malfunction of the fluid distributing mechanism, or a pump malfunction.

- The presence of intense foaming in the expansion tank. Probable causes are mixing of different types of fluids, failure of the power steering pump.

- When the engine is running, the steering wheel spontaneously turns in any direction . The probable cause is malfunction of the spool mechanism, most often, clogging of its working channels, incorrect assembly (for example, after installing a repair kit).

Recommendations for operation and maintenance of power steering

In order for the power steering and its system to operate normally, as well as to extend their service life, you must adhere to several simple rules:

- use working fluids recommended by the automaker , and also replace them in a timely manner (most automakers recommend replacing power steering fluid every 60.120 thousand kilometers, or once every 2 years, it depends on the driving style and intensity of use of the car);

- carry out bleeding of the power steering system in strict accordance with the algorithm described above (or observing individual requirements, if any are set by the car manufacturer);

- monitor the condition of the steering rack boot , because if it is torn, dust and dirt will enter the system, which leads to the power steering pump exiting. A sign of a problem that has already occurred is the hum of the power steering, which is not eliminated even by replacing the fluid.

Cost of replacing fluid and pumping power steering

If you plan to carry out work on replacing the fluid and pumping the power steering yourself, then you will only need to buy oil in a volume of 1 to 3 liters (including flushing, while the volume of the power steering system of a passenger car is up to 1 liter). The price of the liquid depends on the brand and store. It is within $4.15 per liter. If you do not want or cannot carry out such work yourself, contact a service station for help. Approximate prices for January 2021 are:

- fluid replacement work - 1200 rubles;

- power steering pumping - 600 rubles.

Main elements of the system

How to bleed the brakes on a Chevrolet Niva correctly

The design of the VAZ-2123 provides filling tanks that ensure smooth functioning of the mechanisms.

The main elements of the system include the following filling containers:

- fuel tank;

- transmission housing;

- power steering;

- cooling system;

- engine lubrication system;

- axle and transfer case housings;

- container for hydraulic drive of the brake system;

- tanks for washer fluid;

- containers for refilling the air conditioner.

The following is a table of fuel volumes for the Chevrolet Niva:

To improve the performance characteristics of an SUV, working fluids must be poured in quantities recommended by the developers of the Chevrolet Niva.

Fuel tank

All-wheel drive and increased cross-country ability of the Chevrolet Niva increase fuel consumption. Therefore, this AvtoVAZ model has a 58-liter fuel tank. It is located in the rear of the car. The fuel tank is made of high-strength steel and has a complex design.

Because gasoline tends to evaporate, excess pressure can build up inside the gas tank, increasing the risk of explosion. To reduce pressure, the designers of the VAZ-2123 provided an adsorber valve, with the help of which excess gasoline vapors are released.

The fuel tank housing has a stamping for the driveshaft channel, which divides the gas tank into two communicating reservoirs. Therefore, about 7 liters of fuel remains in the tank, which does not enter the fuel line. However, the design of the gas tank allows fuel to be filled under the neck, which allows you to fill up to 64 liters of fuel. This feature compensates for the unconsumable remaining gasoline.

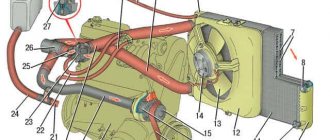

Cooling system

When the car engine is running, the temperature of the exhaust gases reaches 2000 degrees. Due to the elevated temperature, the lubricant burns out. This leads to engine malfunctions and wear of parts. To avoid engine overheating, VAZ-2123 vehicles are equipped with a closed-type liquid cooling system, which consists of the following components:

- radiator;

- expansion tank;

- fan;

- water pump.

For cooling, antifreeze is used with the addition of additives that have anti-corrosion properties. The operating principle of the cooling system is based on the forced circulation of antifreeze through the cooling jacket around the engine cylinders.

The pump ensures uniform circulation of the coolant. After starting the engine, the pump begins to pump antifreeze through the small circuit of the cooling system. When the engine heats up, the thermostat activates, after which a large circuit opens. The expansion tank is needed to relieve excess pressure that occurs when the antifreeze heats up. Passing through the radiator, the liquid is cooled by a fan.

Engine lubrication system

Friction and high temperatures reduce the service life of the engine and the service life of the vehicle. To avoid premature wear of engine parts, it is necessary to monitor the oil level. In the Chevrolet Niva, the designers have developed a combined engine lubrication system. The crankshaft and camshaft bearings, pushrod tips and rocker arm bushings are pressure lubricated. The remaining parts are lubricated using the spray method.

Using an oil pump, oil from the crankcase through the oil receiver enters the filter housing. After cleaning, the lubricant is supplied to the oil line, from where it is supplied to the parts under pressure through inclined channels. The pressure at medium speeds in a working VAZ-2123 lubrication system is from 200 to 400 kPa. A decrease or increase in pressure indicates a system malfunction.