Reasons for failure of one of the cylinders

The engine can begin to trouble for several reasons and it is quite difficult to immediately diagnose the problem; it is recommended to start checking with the most harmless parts, following the list below.

The engine on a VAZ 2107 may triple for the following reasons:

- Worn spark plugs;

- Wear of high-voltage wires;

- Clogged filters;

- Problems with the fuel supply (clogged carburetor or injectors);

- The ignition has gone wrong (relevant for carburetor engines);

- Failure in the ignition module or DPKV (relevant for fuel-injected cars);

- Air leak in the system;

- Valve clearances are off;

- The cylinder head gasket was blown;

- CPG wear;

As you can see, this list contains problems of increasing severity. If your car shows signs of shaking, then checking and searching for the cause must be carried out using this list.

Violation of valve timing

The main parts of the gas distribution mechanism (GRM) are the intake and exhaust valves. They are “obliged” to open and close only at the right moment so that the fuel mixture enters the cylinders on time and exhaust gases are removed. This process is called phase distribution. If it is violated, you will see that the power of the engine has disappeared, which will begin to “triple” and sometimes have difficulty starting.

Causes of valve timing violations:

- wear, as well as incorrect installation, displacement of the chain or timing belt (most often this is a jump by one tooth (link));

- play or deformation of the pulley on the crankshaft;

- wear of hydraulic compensators, camshaft and (or) its bed;

- burnout or rupture of the head gasket;

- Malfunction of the camshaft position sensor (DPRV).

To restore normal operation of the timing belt, it is necessary to set the position of the timing and crankshaft shafts according to the marks. If the chain is worn, replace it. The same applies to the camshaft with a bed, hydraulic compensators, gasket and DPRV.

Solutions to the problem

To solve the problem on your own, a motorist needs to have not only a mechanic’s tool, but also a little skill in car repair. Below is a list of all possible methods for eliminating the problem of a VAZ 2107 engine stalling.

Spark plug

When tripping occurs (failure of one of the cylinders), first of all it is necessary to check the spark plugs, since they directly affect the performance of the cylinders. Quite often it happens that one of the spark plugs fails, thereby not supplying a spark to the cylinder, which leads to misfire of the fuel mixture and, accordingly, engine throttling.

If the engine on a VAZ 2107 starts to fail, the first thing you need to do is check the spark plugs, and if they have not been changed for a long time, then it is recommended to replace them with new ones; this will never be a bad idea.

High voltage wires

After spark plugs, it is necessary to check the high-voltage wires from the distributor or ignition module (depending on the type of engine - injector or carburetor). The wires are made of special silicone with high insulation resistance, inside which there is a conductor with low resistance, through which an electric current flows, having a high voltage reaching 15 kV.

When the wires wear out, abrasions appear due to friction against the engine body, their insulation is damaged and a voltage breakdown on the engine body is possible, which will lead to misfire in the cylinder to which this wire is connected and, consequently, to engine misfiring.

Filter

To ensure long engine operation, the car uses various types of filters that help purify the air and fuel that enters the cylinders. It happens that clogged filters can affect the operation of the engine; this, of course, will not cause a failure of the cylinders, but will significantly reduce the number of engine revolutions at idle, which can be confused with the failure of one of the cylinders.

If there is any suspicion of engine trouble, it is necessary to check all the filters of the car and, if necessary, replace them with new ones.

Fuel supply

Due to poor quality fuel or clogged filters, a fuel supply interruption may occur. If the engine is carburetor, then the engine will not work steadily and the speed will drop, but this will not cause the failure of any of the cylinders, since the carburetor is responsible for the operation of all 4 cylinders at once, but in the VAZ 2107 injection engine, a blockage in the fuel system can cause the engine to trip.

The 7's injection engine has injectors installed on each cylinder; it happens that debris with fuel gets into the injectors and clogs them. If one of the injectors is clogged, this can seriously affect the operation of the cylinder into which the clogged injector supplies fuel.

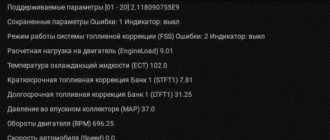

To determine whether the injectors are clogged, you need to measure the fuel pressure, then turn on each of the injectors one by one using diagnostic equipment and see how much the fuel pressure drops; on all 4 injectors, the diesel fuel pressure should drop by an equal number of divisions.

If the readings on one of the injectors vary less, this indicates that it is clogged.

Clogged injectors simply need to be washed and replaced.

Ignition problems

This problem is relevant only for carburetor engines, since in an injection engine the ignition is set automatically using special sensors.

Quite often, the ignition on the distributor goes wrong, or the distributor (runner) breaks through, which leads to engine failure. But when the ignition timing is lost and then the spark may not be supplied at the right moment, but late or, conversely, earlier than expected, this will lead to improper combustion of the fuel mixture and misfires.

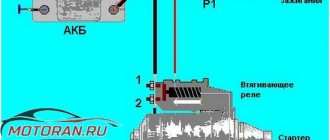

Ignition module and DPKV

This problem only occurs on injection engines, since carburetor engines do not have an ignition module (IM). A module is a part that produces a spark to operate all 4 cylinders of a car. Inside the module there are two coils responsible for the operation of a pair of cylinders (1-4), (2-3). It happens that one of the coils may fail, then two cylinders fail at once and it turns out that the engine “doubles”. If two cylinders fail at once on your car, then 80% is a breakdown in the ignition module.

Air leak

For the engine to operate properly, the proportions of fuel and air must be maintained; when these proportions are violated, the engine begins to operate unstably and incorrectly. A violation of the proportions can be caused by air leaks in the system of one of the cylinders, then this will cause the engine to trip.

The suction can be:

- Near the intake receiver at the junction with the cylinder head;

- After DMRV;

- On the sealing rings of the injectors;

- On the throttle assembly;

Valve clearances

Due to the design of the VAZ 2107 engine, there is a frequent need for valve adjustment. Many people forget about this and simply do not carry out this procedure on time, and this can lead to serious damage to the cylinder head. If you do not adjust the valves for a long time, they may become pinched and a gap will appear between the valve and the head; through this gap, hot gases will penetrate into the cylinder head, which will cause burnout of the valve, which will lead to inevitable repair of the cylinder head.

If the engine starts to stall, then one of the reasons may be a stuck valve or a burnt-out valve. In order to check this, it is necessary to measure the compression in the engine; if it is negligible or even zero, then the valve is definitely clamped.

Cylinder head gasket failure

Between the cylinder block and its head there is a special heat-resistant gasket that seals the cylinder and combustion chamber. It happens that due to overheating or old age, the gasket can be pierced between two cylinders or between the cylinder and the cooling jacket. This problem will cause a loss of compression in the cylinder, and the coolant in the tank will bubble if there is a breakdown between the cylinder and the cylinder head jacket.

CPG wear

This problem occurs in cars with fairly high mileage, when the piston fills an ellipse in the cylinder block and the piston rings wear out. All this significantly affects the compression ratio in the combustion chamber, compression drops, and the air-fuel mixture simply does not compress and ignite properly. Such consequences lead to misfires and engine tripping.

The float chamber needle valve is not sealed

If the tightness of the unit is broken, excess fuel enters the carburetor float chamber and, accordingly, further into the engine cylinders. Perhaps in this case, the needle valve has failed or a speck has gotten under its shut-off needle. In this case, it is considered that the carburetor begins to overflow. Typically, this malfunction is accompanied by difficulty starting a hot engine and popping noises in the muffler. It should be noted that the leakage of the needle valve is not always clearly noticeable. Excess fuel can seep into the float chamber without causing any obvious problems in engine operation. Only fuel consumption will increase by a liter - one and a half per hundred. Therefore, in any case, it is worth carrying out a simple check of the tightness of this device. It is described in almost any car repair and maintenance manual.

If you detect such a malfunction on your carburetor, you should replace the needle valve assembly. There is currently no point in repairing it, since a new one is inexpensive and is available for sale in almost any car store. The only thing is that you should be more careful when choosing a valve, since a low-quality product will add unnecessary problems and take time for additional diagnostics and repairs. Fuel nozzles of the main metering system or idle system are installed with a larger diameter. With this problem, the fuel mixture is significantly over-rich. To solve this problem, you need to check the markings of the jets.

Other reasons for reduced engine performance

The condition of the exhaust system also greatly influences engine power. The fact is that to protect the environment from harmful emissions during operation of the internal combustion engine, catalytic converters are installed in the exhaust.

As a rule, official services offer to replace a worn-out element, but the price of the spare part is very high. For this reason, on many cars in the CIS, the catalyst is simply knocked out, and the control unit is “deceived” by software or other available methods.

Also, when engine power decreases, it is necessary to separately check the installation of the timing belt or chain according to the marks in order to eliminate the possibility of valve timing failure. Sometimes there are situations when the belt can jump one tooth, the chain stretches, etc.

In this case, the synchronous operation of the valve mechanism in relation to the operating cycles of the internal combustion engine may be disrupted. This leads to various failures, unstable operation of the unit and reduced power.

Let us also add that engine wear and certain malfunctions also affect engine power. As a rule, worn-out internal combustion engines with mileage usually lose about 10% of their declared power.

One way or another, any leaks in the combustion chamber will lead to expanding gases breaking out of the cylinder during fuel combustion. This means that the pressure of these gases on the piston will decrease, and the internal combustion engine itself will draw poorly and operate unstably.

Finally, we note that the reason that the car has lost dynamics may not be the engine, but the transmission. In other words, the power unit develops enough power, but it is not fully transmitted to the wheels.

If, when coasting, it is noticeable that the car immediately begins to slow down, then the problem is obvious, the wheels are slightly blocked. If no problems with the brakes are identified, then automatic transmission diagnostics are necessary. It is better to entrust this procedure to experienced specialists by delivering the car to a service center.

Purpose, design features, installation location of the fuel pressure regulator of an injection engine. Signs of RTD malfunctions, checking the device.

As a result, jerks and dips appear when accelerating, and the car jerks in motion during transitional conditions. Causes and troubleshooting.

The most common reasons why an engine does not develop full power. Why do they occur? Common problems with gasoline and diesel engines.

Why the engine may not pick up speed: gasoline engine, diesel unit, car with LPG. Fault diagnosis, useful tips.

When you sharply press the gas pedal, the engine jerks, jerks and dips appear, the car does not pick up speed: the main causes of the malfunction and diagnostics.

Signs of a non-working cylinder (tribbing and vibration) of a diesel engine. Troubleshooting: compression, diesel injectors, glow plugs, injection pump and others.

Probably, any driver has encountered such a problem when the car has lost its former dynamics: it takes a long time to accelerate, and when climbing, it completely refuses to move in higher gears. In this article we will tell you in detail what to do if the VAZ engine does not pull or pulls poorly, we will look at the main causes and troubleshooting methods.

Conventionally, all types of gasoline engines can be divided into gasoline and injection. In general, their principle of operation is absolutely the same, but the factors that affect engine power become different. Let's consider the problem of carburetor and injection engines separately.

Carrying out fault diagnosis work

Remove the central wire of the distributor and secure it at a distance of 3–5 mm from ground. Unscrew the spark plugs and inspect them. Remember which particular candle has black soot.

Insert the compression gauge one by one into the spark plug hole of the cylinder. The assistant turns on the starter and cranks the engine. Keep the gas pedal pressed. This makes it easier for air to be sucked in.

After measuring compression in all cylinders, we analyze the data obtained. A boiler with a compression different from others, more than 1 atm, is the cause of engine tripping. Moreover, the pressure can be either lower than on other cylinders or higher. Measuring compression can also show that it is equal in all “boilers” of the internal combustion engine of the VAZ 2106 car. Now, one by one.

- Case one: compression in one cylinder is noticeable, more than 1 atm. , lower than others. This case is the most common. Let's pour about 15 ml of oil into this cylinder and check the compression again. There can be two results.

Compression levels have increased significantly: piston rings are stuck or broken.

Compression does not change. We carry out diagnostics to determine exactly why the engine is running unstable. We install the piston of the problem cylinder at TDC. To determine TDC, insert a clean wooden stick into the spark plug hole and slowly turn the crankshaft until the stick rises the most.

This is interesting: What to do if the fan (motor) of the Ford Focus 1 heater does not work and how to fix it

The piston at this moment will be at the highest point. Use a compressor to supply compressed air to the cylinder (2–3 atm). If you don't have a compressor, use a well-inflated car tire and a piece of rubber hose. Place the car in gear first.

Listen to where the air is coming from. If it hisses from the spark plug hole of another boiler, the gasket under the block head is damaged. Air breaks into the carburetor - the intake valve does not fit well to the seat. If air escapes from the oil filler neck (remove its cap first), the piston is damaged. You can hear air noise from the muffler - it's burnt out, the exhaust valve is not sealing tightly.

2. Case two: the compression of one of the engine boilers is much higher than the others. Did a spark plug made from it have black growths on the electrodes? This means that oil is getting into the cylinder: the oil scraper rings are broken, there is some defect in the valve-guide sleeve pair, there is a defect in the oil seals of a particular cylinder.

3. Case three: compression is almost equal everywhere, the difference is no more than 1 atm. This indicates that there is uneven wear in the CPG. Happens on an engine with a mileage of 50,000 km or more. In this case, look for the cause not in the engine, but return to the ignition, carburetor.

Malfunctioning spark plugs

The planned replacement of these elements of the ignition system is carried out after 20-30 thousand kilometers. If the spark plugs are platinum, the resource increases to 100 thousand km. However, the situation when candles (most often one of them) fail ahead of schedule is not uncommon.

You can see and hear this by a number of signs:

- the engine starts with difficulty, especially in winter;

- idling is unstable, the tachometer needle jumps, the engine may stop periodically;

- when the power unit is operating, increased vibration is observed, for example, the gearbox shift lever shakes;

- poor acceleration dynamics - the car does not develop full power, it stalls;

- when you press the accelerator, “dips” are noticeable;

- fuel consumption has increased.

When one spark plug does not work, experienced drivers say that the engine is “troubling,” that is, only 3 out of 4 cylinders are working.

To find a faulty part, you need to:

- put on dielectric rubber gloves;

- with the engine running, disconnect the high-voltage wire from each spark plug one by one;

- in this case, the nature of the engine’s operation should change, the speed should drop, but if this does not happen, it means that the cylinder is not working - the spark plug does not produce a spark.

It is worth finding out the reason for the poor performance of the part; it is quite possible that it is defective. If other spark plugs subsequently begin to fail, you will have to look for the cause elsewhere - the CPG or the fuel system.

Trouble with the engine of a VAZ-2107 car. What to do?

If this problem is not addressed in time, the engine may require major repairs. This action will entail a waste of not only time, but also significant money.

Troubles the engine of a VAZ car. What to do?

The impetus for writing this post was a real repair at the request of a client, which consisted of a simple replacement of the vacuum booster, but isn’t it true that the engine may be tripping for the wrong reasons... In this post I want to consider the main reasons for this most unpleasant phenomenon, as well as methods for diagnosing and troubleshooting repair.

Trouble VAZ engine

Let's start with the signs that the engine is running rough. “Engine trouble” - by this we mean that one or more cylinders are not working. Accordingly, the engine does not develop full power, does not have the necessary traction force, fuel consumption increases... But we all already know this, closer to the point.

We look at the spark plugs

Spark plugs are an equally important element in the ignition system and stable operation of the power unit. They need to be inspected and make sure that the spark plugs are free of carbon deposits. Unscrew them from the block head; there should be no cracks or other defects on them. Test the contacts using a multimeter.

Don't forget about high-voltage wires; they are also involved in the process of igniting the fuel-air mixture. Visually assess their condition and call them; this determines how stable the engine will operate. All these nuances directly affect the level of fuel consumption of the car.

VAZ 2106 | The car moves jerkily

In relation to a car, a jerk is a short-term spontaneous change in the engine crankshaft speed, regardless of the position of the gas pedal. In everyday use, as a rule, there are a series of jerks. The extreme case of a jerk is a failure, a noticeable delay in the engine's response to pressing the accelerator pedal.

Conventionally, three types of jerks can be distinguished:

- at the moment of starting movement;

– during acceleration;

– with steady motion, i.e. with the accelerator pedal in constant position.

To determine the causes of jerks when driving a car with an injection engine, special diagnostic equipment is required, so in this case we recommend contacting a car service center that specializes in repairing fuel injection systems. However, as practice shows, in most cases jerking is caused by insufficient fuel pressure in the engine fuel line (“rail”) or a malfunction of the throttle position sensor.

If you have some skills, you can identify the cause of jerking yourself.

Jerking when starting to move

At the moment the movement begins, the limiting case of a jerk often occurs - failure. The most unpleasant sensations are associated precisely with the delay in the engine’s response to pressing the gas pedal. Sometimes the engine even stalls. A jerk occurs at the moment the throttle valve begins to open, when, based on a signal from the throttle position sensor, the ECU determines the moment of transition from idle mode to load mode and must increase the amount of fuel supplied through the injectors. If the pressure in the fuel line is insufficient, even with increasing injection duration, there is not enough fuel for a smooth start.

| , cm2 to a special fitting on the fuel line using a piece of suitable hose . , the pressure in the fuel line must be at least 3 kgf/ cm2 . |

| NOTE The pressure test fitting has a design similar to a tire valve, with a spool. Therefore, you can use a foot tire pump hose connector to connect the pressure gauge hose. |

The reasons for the decrease in pressure may be:

| – faulty pressure regulator . In addition, failure of the regulator may be caused by a loose fitting of the hose on the fitting of the vacuum chamber of the regulator; |

| – clogged fuel filter; |

| – faulty fuel pump. |

| NOTE For methods of checking and replacing the pressure regulator, fuel filter and fuel pump, see section. 4 “Engine”, in subsection. "Supply system". |

Jerks during acceleration

The cause of jerking during acceleration may be, just as in the previous case (see “Jerking at the moment of starting movement”), insufficient fuel pressure in the fuel line. The ECU, having received a signal from the throttle position sensor about the intensive opening of the throttle at a large angle, strives to maximize the fuel supply, but due to the reduced fuel pressure it is not able to do this. For the reasons for this phenomenon and the method of checking, see “Jerk at the moment of movement starts.”

Jerks during steady motion

Such jerking is most often caused by a malfunction of the ignition system. Diagnostics and repair are necessary (see section 9 “Electrical equipment”). On the way, you can try to do it yourself:

– carefully inspect the engine compartment. Turn off the ignition and check the secure fastening and seating of all wires and connectors at the ignition module and high-voltage wires. Start the engine and listen to its operation - the crackling sound when the high voltage breaks down to ground is weak, but distinct. In complete darkness, the spark during breakdown is clearly visible;

– replace spark plugs regardless of their condition and mileage

Pay attention to the condition of the spark plugs - if they are abnormal, the engine or its systems may need to be repaired

| A specific cause of jerking during steady motion of a car with an injection engine may be damage to the throttle position sensor. Additional symptoms confirming the malfunction of this sensor are: – uneven operation of the engine at idle; – reduction in maximum engine power. |

The sensor is not dismountable and therefore cannot be repaired. If a sensor malfunction is detected (see section 9 “Electrical equipment”, “Engine control system”), it is replaced as an assembly.

automn.ru

Checking the distributor

And then we will check the VAZ 2106 distributor

. The first thing you need to pay attention to is its cover. We remove it and inspect it for damage, cracks, etc.

Through cracks, along the path of least resistance, current can flow to ground. Thus, a small voltage will already come to the spark plug or nothing at all will come, and the spark will either be weak or not exist at all.

Next we will talk about the remaining parts of the distributor. And they need to be considered in the event that you do not have a spark at all, or if you have one, but it is very weak. Those. if there is no spark in only one cylinder, then there is a 99% chance that the problem is not in the distributor.

After the lid, we immediately pay attention to the slider. The slider must also be intact and not have any damage.

Moreover, you need to inspect it both from above and from below. And the best way to do this is to unscrew it.

Next we move on to the breaker contacts. First you need to check the cleanliness of the contacts. If there is any plaque or carbon deposits, it naturally needs to be removed. It would probably be better to do this with zero sandpaper or a needle file. Next, after cleaning, you need to check the gap between the contacts. It should be 0.35-0.45mm

We take a set of probes, find a 0.35 probe and check... We also pay attention to the cams that move the contacts - they should not have significant wear and the existing wear should be the same for all cams

Next you need to pay attention to the wire that is connected to the breaker contacts. It is advisable to move it, tug it in different directions, make sure that the wire has reliable contact

It may happen that over time, due to vibration and other things, this wire breaks off and, naturally, the contact will either be very weak or disappear altogether. And this is not often paid attention to.

The next logical step is to check the capacitor. The simplest thing is to measure its capacity. It should be within 0.25 µF. But for this, of course, you will need a tester with a capacitance measurement mode. I don’t have this, so I’ll tell you about the second method. We disconnect the capacitor wire and the wire coming from the coil from the distributor breaker and connect a light bulb (12V) between them. Afterwards, turn on the ignition and look at the light bulb - if it is on, it means the capacitor is broken and needs to be replaced. If it doesn’t light up, then everything is fine with the capacitor.

In the same way you can do without a light bulb. Instead of connecting the light bulb, we simply short-circuit the wires with each other, with the ignition on, of course. If it sparks, the capacitor is broken.

Finding the cause of the tripping

We start looking for a fault, start the car, go to the exhaust pipe, listen to the sound of the exhaust. On a working engine, the sound is smooth and uniform. The fact that there is no spark on one candle is indicated by popping noises; they are repeated at certain intervals. If the popping noises are repeated at different intervals, then the reason is in the carburetor, or rather in its adjustment. Popping noises that sound at irregular intervals can be eliminated by changing the entire set of candles. Regular popping noises can be caused by poor condition of the high-voltage wires of the ignition system. High-voltage cables must under no circumstances have insulation defects, and the tips must not be oxidized. If such defects are present, then the problem may be in them. If you do not find cable defects, then you need to check the distributor cover and distributor rotor.