Causes of malfunctions

The main cause of the malfunction is simple mechanical wear. Any oil seal is, by its nature, a consumable - after a certain period of time it begins to deteriorate, since it is made of an elastic material.

The malfunction may manifest itself in the form of changes in shape, swelling, scarring, rupture or chipping of the material from which the consumable is made. Another manifestation of a malfunction may be the cuff being completely squeezed out of the seat.

Other causes of problems with the camshaft oil seal are incorrect selection of consumables, manufacturing defects, or incorrect installation. In these cases, the oil seal also does not perform its functions and needs to be replaced.

When do you need to change the camshaft seal?

If you start to notice oil leaks through the cap (Although this is unlikely, but still if a lot of oil leaks through the oil seal, it will drip onto the asphalt, so look under the car from time to time, but still do not remove any you won’t really see any leaks), and also if you notice a high oil consumption compared to what it was before, then you need to check the condition of all oil seals (But we don’t look at all oil seals, we only look at one) and if through this camshaft oil seal you If you see that oil is leaking and leaking out, then it needs to be replaced immediately.

Diagnostics

Diagnosis of a malfunction of the camshaft oil seal is carried out visually. Oil marks on the timing belt cover may indicate a cuff leak. For a more accurate diagnosis, remove the belt cover and inspect it. In the event of a malfunction, you can find traces of wear or even the belt jumping over one or more pulley teeth due to moisture.

Also, a seal malfunction can be detected during a scheduled replacement of the timing belt - it is during the procedure that oil leaks can be detected on the belt itself or on the camshaft gear. Another reason to replace the oil seal is deformation of the seal. Even if there are no oil leaks at the moment, they will certainly appear if the shape of the oil seal changes.

Purpose of oil seals

An oil seal (also known as a radial shaft seal) is a special device that is designed to seal rotating joints of car parts. Oil seals have been used in the automotive industry for a very long time; their design and purpose are very complex. The cuff does not touch the shaft surface during operation; the parts are sealed due to the vacuum it creates in the area of shaft rotation using special notches.

Tip: When holding the new oil seal in your hands, slightly bend its working edge: it should be elastic, even and sharp. The duration of operation of the new omental cuff depends on its sharpness

Replacement instructions

The sequence of actions when replacing the front and rear oil seals is slightly different. This is because the front oil seal can be replaced directly on the engine itself. Getting to the rear seal is usually more difficult.

Front oil seal

The sequence for replacing the front camshaft oil seal looks like this.

- The car is placed in neutral and the parking brake is applied.

- As with any work performed in the engine compartment, the battery terminals are disconnected.

- The plastic timing belt cover is removed.

- The valve cover is removed, for which you need to unscrew the fastening bolts with a screwdriver.

- A marker marks the location of the belt relative to the camshaft.

- Then you need to remove the timing belt. You don’t have to completely remove it - just remove the belt from the camshaft timing pulley. To remove it, you need to unscrew the fastening bolt with a 17 mm wrench, securing the pulley from turning. You can use a pry bar for fixation.

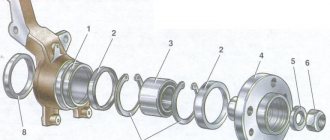

- Using a puller, the pulley is removed from the camshaft shank. If the camshaft has 2 pulleys, then both are removed, and the locations of the pulleys are also marked so that they are not confused during further installation.

- The key located behind the camshaft pulley is removed.

- Then, using a screwdriver or tweezers, remove the used oil seal. You should remove it carefully so as not to scratch the working surface of the camshaft to which the oil seal is attached.

After dismantling the old oil seal, you can proceed to installing a new one and reassembling it.

- The working edge of the new oil seal adjacent to the camshaft is lubricated with engine oil, and the outer part is treated with sealant.

- The oil seal is placed on the camshaft and then pressed using a pressing mandrel.

Further collection of the timing belt is carried out in reverse order.

- A key is placed on the camshaft.

- Then the pulley is installed. If there are two pulleys, then each is installed in the place where it was located.

- The pulleys are tightened using a torque wrench. The voltage torque can be found in the vehicle owner's manual. When tightening, it is necessary to secure the pulleys from turning using a pry bar. First you need to engage fourth gear at the gearbox.

- Then you need to put the belt on the pulleys according to the previously marked marks. You should first inspect the belt for damage, abrasions, etc. Since oil seal leaks are detected when replacing the timing belt, it is often necessary to install a new belt. In this case, it is mounted according to the factory marks.

- The tension roller mounting bolt is tightened. The tension torque can again be found in the car's owner's manual.

- Then the crankshaft is manually turned several revolutions clockwise. This checks the belt tension. If any irregularities are noticed, the tension is further adjusted.

- At the end, the valve cover is secured back and the plastic belt cover is installed.

- After replacing the oil seal, you need to add engine oil to the oil tank to the upper mark.

Rear oil seal

Rear oil seal replacement may vary from vehicle to vehicle. For some models, access to the rear oil seal is only possible when driving the car onto a lift or inspection hole and disconnecting the clutch and gearbox drive.

For other car models, access to the oil seal is limited by the camshaft position sensor, which must be removed. To do this you need:

- disconnect the electrical connector of the sensor;

- Unscrew the fastening screw and remove the sensor;

- Using a 10mm wrench, unscrew the bolt securing the gas hose holder to the sensor wire bracket;

- Unscrew the screws securing the sensor cover, remove the cover and the bundle of wires;

- remove the sensor rotor;

- Remove the sensor cover mounting plate.

After this, you can use a screwdriver to remove the rear camshaft oil seal. Replacement is carried out in the same way. After replacing the cuff, the sensor is assembled in the reverse order.

After installing the new oil seal, you must make sure that no oil leaks appear. If the oil seal is installed correctly, then even at high engine speeds the oil should not leak. Otherwise, the sensor is installed or pressed in incorrectly, or there is a manufacturing defect in the product.

Let's move on to installation

So, the old element has been removed. Now you can start installing the new one. In this case, the oil seal must be treated with engine oil. It is best to touch both edges to the worn part to ensure lubrication throughout. Next, we install the part in place and begin assembling the timing assembly. To do this, we mount the camshaft pulley and chain. Don't forget about the tensioner. Install the valve cover. An important point is that the cover is installed on a new gasket. Before installation, you need to scrape off the remains of the old one from all edges. Additionally, the gasket is treated with red silicone sealant. The bolts are tightened evenly, in several stages according to the pattern “from the center to the edges”.

Next, replacing the camshaft seals is accompanied by installing a gas ventilation pipe, a fuel hose and an air filter housing. After this, begin installing the alternator belt. How tight should I tighten it? Make sure that the deflection of the belt when pressing strongly does not exceed one centimeter.

Replacing valve seals on VAZ 2114 2115 8 and 16 valves. Correct manual

- A set of keys;

- Slotted screwdriver;

- Ratchet key;

- Valve desiccant;

- Tweezers.

The work is carried out in the following order:

- Using a Phillips screwdriver, unscrew and remove the clamp securing the crankcase ventilation hose;

- Remove the hose;

- Remove the remaining hoses in the same way;

- Using a wrench, unscrew the nuts securing the valve cover;

- Remove the cover;

- Unscrew (wrench “10”) the nuts securing the mass to the cylinder head;

- The plug is removed. To do this, you need to unscrew the screw and 2 nuts;

- Unscrew the screws securing the front timing cover and remove it;

- The crankshaft is rotated in the direction of the arrows until the marks completely coincide. We remove the plug on the clutch housing and check the marks for matches;

- The generator pulley is removed;

- The tension roller fastenings are loosened and the belt is removed;

- Remove the pulley from the camshaft;

- Using a 13 socket, we first loosen and then unscrew the 10 nuts securing the camshaft;

- We dismantle the camshaft;

- Unscrew the spark plugs;

- The crankshaft is installed according to the position of the top dead center (TDC) for cylinders 1 and 4;

- We remove the pusher along with the adjustment washer located in the socket of the block head;

- Insert a tin or lead rod (diameter 7-9 mm) into the first cylinder. We place the rod under the valve where the cap is changed;

- The desiccant is installed on the valve stem. With its help we compress the springs. Using tweezers, take out the crackers;

- The plate and spring are removed together;

- Using tongs (pliers), remove the oil seal;

- Remove the thrust washer;

- After lubricating the replacement cap (machine oil), press it into place. This is done through a special mandrel.

The rest of the procedure is performed in reverse order. We perform the same actions for the 2nd valve of this cylinder. Next we move on to cylinder 4. Having changed the caps on it, we rotate the crankshaft 180°. Using the same principle, they are replaced on the valves of cylinders 2 and 3. Replacing oil seals on a 16-valve engine differs only in the need to remove 2 camshafts. When installing the camshaft, be sure to tighten the nuts with a torque wrench. This should be done from the middle to the edge. Conclusion. The engine of any car requires attention

Therefore, it is extremely important to correct even small problems in a timely manner. Therefore, replacing valve seals on VAZ 2114 (2115) 8 and 16 valves should be done at the first sign of a problem

You don't need any additional equipment for this. When carrying out repairs, you need to do all actions as carefully as possible.

AutoFlit.ru