The Niva car or VAZ-2121 is one of the most successful developments of domestic engineers. Having begun mass production in 1977, the car was in demand not only in the USSR, and then in Russia, but also abroad. In some countries, fan clubs of this model have even been created. The first Nivas were equipped with a three-door body and a carburetor engine with an output of 80 hp.

They rolled off the assembly line with virtually no changes in design and technical characteristics until 1993. In 1994, car enthusiasts saw a modified body and an 82.8-horsepower engine. The car was named VAZ-21213 Niva. Then the Niva VAZ-21214 appeared, on which, starting in 2002, injection power units began to be installed. In 2006, the name Niva officially ceased to exist. The car, until 2021, was called “LADA 4×4”, and now it is “Lada Niva Legend”.

From the very moment of its creation, until today, the Lada-Niva has been distinguished by the extreme degree of reliability of all components and assemblies. It is not for nothing that a huge number of these cars continue to travel on roads and off-roads, despite the fact that they came off the assembly line several decades ago. But, which is quite natural, the older the car, the more breakdowns there are. Along with the transmission, engine and body, failures of motion control systems occur, which include the speed control system.

In the article we will look at the reasons why the speedometer on the Niva does not work, using the VAZ-21213 and VAZ-21214 as an example, since these cars are the most typical and widespread representatives of the family of Tolyatti SUVs. But first, briefly about the structure of the speedometer itself and the principle of its operation.

Speedometer

The basis of the speedometer design is:

- speed sensor;

- electronic control unit;

- display.

The speed sensor receives indirect information about the speed of the vehicle, which is removed from the drive located in the transfer case. This is typical only for Niva. In other cars, the gear drive of the speedometer is installed on the output shaft of the box or on the drive of the front left wheel.

The sensor, converting the drive speed into electrical impulses (using the resulting Hall effect), transmits them to the electronic unit, which processes the signal and sends it to the display. The latter shows on its screen what the current speed of the car is. Data can be presented as numbers or a scale on digital displays, or indicated by a moving arrow pointing to the values on a graduated scale on analogue indicators.

For your information. The electronic unit, receiving and processing information, sends it not only to the speedometer display, but also to the fuel supply system. The higher the speed, the more fuel will flow into the engine. It is also interesting that the program contains an algorithm that prevents the electric power steering from operating when the speed sensor is faulty.

Speed sensor VAZ 21214 injector signs of malfunction

Every car must be equipped with a working speed sensor (DS). This device allows you to accurately determine the speed of a vehicle and display information about it on the speedometer. Operating a car with a non-working DS is not allowed, as this can lead to an emergency on the road. How to check the speed sensor and replace the device yourself - read about it below.

Description of DS

As we have already said, the main purpose of the speedometer drive sensor is to accurately determine the speed of the vehicle. Thanks to this device, the model can always know at what speed his car is moving. As for the varieties, DS can be of the contact or non-contact type. Today, most of our compatriots prefer contactless options. Contact DS, despite all the advantages, have one significant drawback - they are prone to contamination, which in turn will lead to inaccuracy of the displayed readings.

Why does the speedometer not work?

There may be several reasons why the speedometer on the Niva suddenly stopped working.

Let's list the main ones:

- The malfunction may have occurred due to a broken speed sensor.

- Secondly, the car wiring is damaged or the contact in the electrical circuit is broken.

- The third reason, sometimes, is the speedometer needle getting stuck in a certain position.

- A problem with the electronics of the control unit can also cause a speedometer malfunction.

- Incorrect installation of speed control system parts after they have been replaced or removed.

Throttle position sensor - TPS.

The function of this sensor is to provide information to the brain about the position of the gas pedal and the degree of throttle opening. The TPS contains electromechanical parts, that is, a potentiometer. This means that after some time it wears out and the sensor dies. In Russia there are about 10 companies producing this sensor. But I want to draw the reader’s attention to the so-called non-contact (inductive) TPS. It is made by one company, which used to be a “mailbox”. My experience has shown that the sensor in their “non-contact” design is virtually eternal. This is exactly what is shown in the photo.

The reason is the sensor

In principle, this is one of the few speedometer malfunctions that you can try to find and fix yourself. Not counting the jammed arrow and the torn cable. All other problems, including those with the electronic control unit and digital display, are best resolved at specialized service stations.

The first sign of a speed controller failure will be the speedometer stopping or its readings being incorrect. But the fact that the speedometer has stopped working due to the speed sensor can be determined by other signs:

- The engine constantly stalls when idling. This does not depend on whether the car is standing or rolling.

- The car cannot accelerate due to loss of power.

- Fuel consumption in all driving modes has increased sharply.

The reason that a faulty sensor affects engine performance so much is that it is included not only in the speedometer circuitry, but also in other systems.

You can check the functionality of this device using a voltmeter. It is more convenient to do this if you remove the sensor. But you can check it in its original place, without dismantling it. In any case, you need to gain access to his contacts. On a working sensor, the voltage readings will increase along with the increase in the rotation speed of its axis.

For your information. Rotation of the sensor core, which has not been removed from the vehicle, can be achieved by turning the suspended drive wheel.

Before checking and changing the sensor, which breaks quite rarely, you need to make sure the contacts are reliable. Often the problem lies in their oxidation or excessive contamination, since most Niva cars are operated in extreme conditions. Typically, the problem with a non-working speed sensor is solved after checking each contact, cleaning them and lubricating them with a protective compound.

Crankshaft position sensor - DPKV

The task of this sensor is to read the revolutions of the engine crankshaft and whether it is spinning at all. Perhaps the only sensor that I recommend keeping in your car’s first aid kit (so as not to get lost) as a spare. This is the only sensor without which the injector will not start in principle. Without the rest, the engine will sneeze like a sick person, hiccup, fart, blink the check engine... but rattle. Which means it’s bad, but go. Without DC there will not even be signs of life. Therefore, we will consider it, in medical terms, as setting the heart rhythm. I’ll tell you a little secret, if you are leaving somewhere or leaving the car in a bad place, open the hood and slightly disconnect the DC connector. It is difficult to imagine a more effective anti-theft. The main thing is not to forget about it yourself))

On-board network malfunction

Often, this is precisely the reason why the speedometer has stopped working. After all, all information in modern devices is transmitted through electrical wires. A break or short circuit may occur in the vehicle wiring. A multimeter can detect this. If you have the skills to work with this device, you can try to find and fix the problem yourself.

Before you start searching for a break, you need to carefully inspect the wires to visually detect damage. After this, the tightness of the terminals is checked. If everything seems intact, the search begins using special equipment:

- The multimeter is set to ringing mode.

- The probes are attached to the ends of the area being tested.

- If the wiring is intact, a beep will sound. Its absence will mean that the break occurred in the location being tested.

To check for a network short circuit, the multimeter is also set to ringing mode. Before starting work, the wire is disconnected from the vehicle's electrical circuit. And, if in the case of a break, the signal indicated that the cables were in good condition, then the sound of the multimeter will now show where the short circuit occurred.

As a rule, eliminating problems with the wiring and replacing the speed sensor resolves the issue with the performance of the speedometer. But, if this does not happen, you need to contact specialists as soon as possible. After all, driving a car with inoperative speed control not only harms its technical condition, but also poses a real danger to the life and health of all road users.

What is the lambda probe responsible for?

What does a lambda probe look like?

Simply put, a lambda probe, also known as an O2 sensor, is a sensor that estimates the amount of unburned fuel and oxygen in a car’s exhaust system. Although lambda probes are also used in other areas, in this article we will talk specifically about automotive oxygen sensors.

What is this oxygen sensor for? So-called catalysts, which reduce the share of harmful substances in exhaust emissions, are currently available in every more or less modern car. The lambda probe controls the amount of oxygen in the catalysts, thus extending their life. It also significantly affects the amount of fuel consumed by your car and improves engine performance.

If we mention specific facts, it is known that fuel burns efficiently only with the correct ratio of fuel and air in the fuel mixture. Otherwise (if there is less or more air), the catalysts will wear out and become unusable. Therefore, the lambda probe directly affects the vehicle's exhaust system.

Replacement.

To remove the DS, you need to place the car on a level surface. After this, it is best to disconnect the battery terminals to avoid errors in the BC.

Disconnect the wire terminals; to do this, press the plastic lock on the block. After this, use a wrench to unscrew the sensor from its seat. If you cannot unscrew it immediately, it is not recommended to use excessive force. You need to treat the threaded connection with WD-40, wait a few minutes and continue dismantling.

Installation of a new DS is carried out in the reverse order. When purchasing a new part, you need to pay attention to the external condition: the contacts must be treated with a sufficient amount of varnish, as this protects them from moisture. After completing the work, it is necessary to reset the on-board computer errors in order to remove the CHECK ENGINE error.

Niva 4x4 instrument panel diagrams

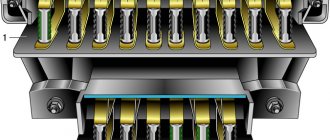

Hungarian instrument cluster before 1996 (rear view), each instrument has a separate black plate with a scale:

1 – plug connector block with conventional numbering of plugs; 2 – tachometer; 3 – voltage stabilizer; 4 – instrument cluster lighting lamp; 5 – coolant temperature indicator; 6 – fuel level indicator; 7 – resistor 470 Ohm, 0.25 W; 8 – resistor 36 Ohm, 5 W; 9 – warning lamp of the toxicity reduction system; 10 – control lamp for heated rear window; 11 – fog light indicator lamp; 12 – control lamp for high beam headlights; 13 – indicator lamp for external lighting; 14 – indicator lamp for direction indicators; 15 – voltmeter; 16 – brake fluid level warning lamp; 17 – diode IN4002; 18 – oil pressure warning lamp; 19 – differential lock warning lamp; 20 – fuel reserve warning lamp; 21 – seat belt warning lamp; 22 – parking brake warning lamp.

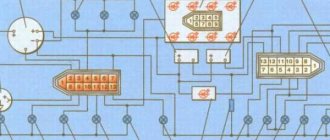

The Hungarian instrument panel was installed from 1996-1998 (rear view), each instrument has a separate black plate with a scale:

1 – tachometer; 2 – voltage stabilizer; 3 – instrument cluster lighting lamp; 4 – coolant temperature indicator; 5 – fuel level indicator; 6 – warning lamp of the toxicity reduction system; 7 – indicator lamp for heated rear window; 8 – fog light indicator lamp; 9 – control lamp for high beam headlights; 10 – indicator lamp for external lighting; 11 – indicator lamp for direction indicators; 12 – voltmeter; 13 – brake fluid level warning lamp; 14 – oil pressure warning lamp; 15 – differential lock warning lamp; 16 – fuel reserve warning lamp; 17 – seat belt warning lamp; 18 – parking brake warning lamp; D1, D2 – IN4002 diodes; R1 – resistor 470 Ohm, 0.25 W; R2 – resistor 51 Ohm, 5 W.

The Vladimir or Podolsk dashboard has been installed since 1998. The scales of all instruments are printed on one black plate:

Let us remind you that on the website you can find reports on the modification or repair of a domestic SUV.

Key words: 4x4 instrument panel