The domestic car VAZ 2108 has traveled a long, difficult path with us, becoming a silent witness to numerous life, political, and social collapses and turning points. The G8 appeared back in the eighties, when the country was slowly choosing a new path, still so foggy and alluring.

Of course, like any car, the VAZ sometimes malfunctions. One of the most common car problems is a faulty steering rack. How can driving be without a steering wheel? Let's look at what features the G8 steering has, for what reasons it breaks, and how the VAZ 2108 steering rack is repaired.

Where do the problems start?

Today, like many years ago, the VAZ 2108 is quite popular even though new times have opened the way for numerous interesting import projects. The advantages that keep the model afloat include reliability, durability and low price compared to foreign cars. In such a car, it’s not scary to go to the outback, which is by no means famous for its good roads, and to the country, and it’s not a shame to appear in the city.

Most often in the "eight" the chassis fails

When the car is in good condition, and the traction is good, and the dynamics are not satisfactory, then you enjoy the ride and the speed. But the time of testing comes, and the machine begins to remind you that material things do not last forever. And this is always an unpleasant discovery.

Domestic cars break down more often than foreign cars, the reason lies in both the design technology and the quality of parts. Our people always try to save on everything, even where it is not possible. Speaking about malfunctions of the well-known G8, it is worth remembering such a mechanism as the steering rack, since it is this that breaks down quite often.

At first the problem is not too noticeable, only on difficult sections of the road the steering wheel begins to beat, as if afraid of the problems awaiting the car on the bumpy roads of endless Russia. But soon it begins to pound almost constantly, making the driver feel like an asphalt driller. After such a trip, it’s not easy to get your nerves in order and not shake yourself. In addition, knocking is often heard. These two symptoms signal one thing: the steering rack has failed.

We have two options before us: either go to the nearest auto store and look for a replacement mechanism, or repair the steering rack. The last option is considered the most optimal, economical, but requires a responsible approach.

Causes of rack malfunction

Before we begin repairing the steering rack, let's figure out what actions the car owner takes that lead to its inevitable wear. Firstly, it’s a hectic ride on bumpy roads riddled with potholes and bumps. When faced with such a problematic route, do not drive with full sail, it is better to slow down and then pick up speed. If you give up on the complexity of the road surface, then in the near future there will be absolutely nothing left of the steering rack, like the rest of the equipment.

This is the car part

The second reason lies in defects in the anthers. You should regularly check their condition, since even a small crack can lead to bad consequences: dust, dirt and even moisture will get into the steering rack, which is a disaster for any device. Contamination leads to wear of seals and leaks. As a result, the steering rack needs to be replaced or urgently repaired.

The third reason for problems with the steering wheel is the carelessness of the car owner. Sometimes car owners leave their car in the cold, even with the wheels turned out. The steering rack, like other mechanisms, does not withstand such strength tests.

Change the hydraulic fluid in the power steering mechanism in a timely manner; forgetfulness in this matter leads to irreversible consequences.

Repair

After disassembly and cleaning, it is necessary to “defect” the parts and determine the extent of replacement:

– the body is visually inspected. For chips, cracks, etc.;

– inspection of shafts for burrs, wear, scratches, etc.;

– checking bearings;

Once the defective parts are identified, assembly can begin:

– a new plastic bushing is pressed in;

– new bearings are pressed in;

– shafts are inserted and assembled;

– generously lubricated with suitable lubricant (litol, fiol, uniol)

– preliminary adjustment is made (the adjusting sleeve is tightened until it stops, then loosened until the shaft can be turned by hand);

– put on and secure the rubber boot (it is advisable to use a new one);

– install tie rods with ends without tightening them;

Repair of steering rack VAZ 2108, 2109 (Video):

Steering repair

Suspension repair in progress

Controlling a VAZ 2108 is a complex thing, but easy to understand, so it is quite possible to repair any faults that have arisen yourself. Most often, parts such as the rod, seals and slide wear out, because the entire operation of the system rests on them. If you hear a telltale knocking and grinding noise in the suspension, it means that the ball joints (rods) have most likely become unusable. You will have to go to a car store or market to buy this part.

Functionality check

From time to time it is necessary to inspect the steering. Where is the best place to start? Be sure to study the condition of the rods, their tightness, and do not forget about the protective cover. Have you noticed cracks or other damage that makes the device leaky? Change it.

You should check whether the steering wheel spoke is in a horizontal plane when the car wheels are in a straight position. If even a slight deviation is observed, it is necessary to identify the cause of the malfunction and eliminate it before it develops into a dangerous problem.

To make sure that the car's steering is working properly, you need to turn the steering wheel all the way clockwise and counterclockwise. In this case, there should be no sounds or jamming. The steering wheel must be firmly and reliably fixed; gaps in the hinges and other parts are unacceptable. Check whether the bolts and nuts of the fastenings are fully tightened.

If something goes wrong when checking the controls, knocking or other problems appear, remove the suspension control rods and check the condition of the steering mechanism again. This will make sure that knocking and malfunctions are caused by malfunctions of the steering wheel, and not by other reasons, of which there may be many.

It is also important to make adjustments. We advise you to use the following rules for proper rack setup.

- When checking the operation of the mechanism, eliminate vertical play in the rods; it should correspond to 15 degrees.

- Steering should be soft and light. Jamming occurs due to improper installation of the steering rack.

- Do not forget to make the next adjustment after 700 kilometers to avoid any serious problems with the steering.

Ball joints are a fragile, fragile part, and they often fail. But there is a very effective way to extend its service life - you sometimes need to pierce the anthers with a syringe and inject one cube of lubricant used for the transmission there. The puncture is small, so there will be no deformation of the part; the hole will immediately be covered with layers of rubber.

Greetings, friends! When I sat behind the wheel of my car for the first time, the first thought that flashed through my head was that this car was assembled from 10, and in winter it will have 4 tracks ((, because I hold the steering wheel in my hands and the car goes to the side , I taxi and lo and behold, she drives herself in the other direction, somehow reaching home, which is no less than 90 km from the place of purchase, straight to the service station, they tightened the rack and the ride became bearable. Repair of the rack/or replacement was postponed indefinitely because naturally the car broke down and it was simply necessary. So I drove away from the beginning of summer until these days... I was thinking about replacing the rack, I wanted to install a new one right away. I consulted with friends: opinions were divided - someone said that repairs were a waste of money, but someone says that even new slats are crap now... Thinking that I would always have time to buy a new slats, I decided to remove and troubleshoot the old slats (having bought a repair kit just in case). I drove the car into the garage and started disassembling it, because my work takes away from me I spent a lot of time taking the rack off slowly. During disassembly there were some surprises. I broke off both rack mounting pins on the side of the left pillar (I wouldn’t wish this on anyone). I decided to deal with the rack first and then rack my brains about the studs. So let’s get started Repair kit

Installation

When installing the steering rack, you must remember the following conditions:

- when installing the steering column, the steering wheel must be in the center and have an equal number of turns in one direction and the other (small deviations are allowed, they will be corrected at the wheel alignment stand);

- screw the rack to the body;

- insert and tighten the tie rod ends;

- put on the wheels and lower the car;

- stabilize the suspension and tighten the steering rods on the silent blocks;

Check and adjustment

After installation, the rail must be finally adjusted. There should be no vertical play in the steering rack when checking the steering rods. The play on the steering wheel should be within normal limits (approx. 15 degrees). The steering wheel should rotate easily, without biting, with an equal number of turns in both directions. When driving and turning, the steering wheel should return to its original position on its own, without driver assistance.

The next adjustment should be in the first 500 - 800 km, after repair.

Also, after repair, it is necessary to check and adjust the wheel alignment angles. PS If you were unable to repair the steering rack yourself, then contact a professional car service center for help.

Signs of breakdown

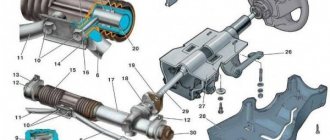

By means of steering racks, rotational movements from the steering wheel through a rack and pinion mechanism are transmitted to the rotary levers, which turn the front wheels with rods.

If you find one of the symptoms listed below on your car, be sure to conduct a full diagnosis of the condition of the unit, and then repair it.

Signs of a faulty steering rack include:

- A grinding noise is observed in the rack area when the steering wheel is rotated;

- The steering wheel periodically sticks;

- Lubricant begins to leak from the seals;

- The steering wheel has noticeable play.

These symptoms may also indicate problems in other components of the steering mechanism, but first you must check the condition of the rack, disassemble it and decide whether to replace or repair it.

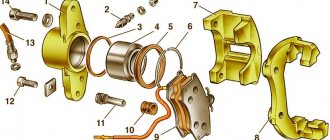

Node diagram

Why do the adjustments?

The force on the front wheels of the VAZ 2109 is transmitted through a gear, which, in turn, interacts with a rack. To eliminate any gaps that arise in the engagement, pressure springs are used.

The rack adjustment is carried out in order to eliminate the resulting backlash, as well as to improve the clarity and obedience of the steering.

If the rack is not tightened correctly, the steering wheel will turn too tightly. This phenomenon occurs due to the fact that the adjusting screw has been overtightened. The task of adjustment is to find the golden mean.

Node diagram

Dismantling

You will not be able to assess the current condition of the steering rack unless you dismantle the device.

There is no optimal way to dismantle the steering rack, since the process in any case involves quite labor-intensive, time-consuming work that involves disassembling many components.

- Suspend the front of the car with a jack to be able to remove the front wheels. Be sure to carefully consider safety measures, install wheel chocks and boots so that the machine does not move while the rack is being repaired.

- Disconnect the gas adsorber, disconnect the wires and take them to the side. This will give you full access to the steering rack.

- Unscrew the bolt from the spline connection. Before doing this, be sure to align the wheels using the steering wheel. The bolt is located near the pedals. To dismantle the fasteners, use a cardan head or a simple spanner.

- Clean the tie rod mounting nuts from accumulated dirt, then undo them using pliers. Unscrew the nuts using a spanner.

- Using a special puller, the rods are disconnected.

- Next, unscrew the rods from the steering rack housing. However, experts recommend dismantling the crankcase with the rods together, since in a vice the removal process is much easier.

- Once you have the rack free, remove it from under the car through the wheel arch. Clean, rinse and clamp in a regular vice.

Now you have a choice - completely replace the steering rack or try to repair it. The second option will take more time, but will save an impressive amount of money.

Instruction card. Repair of VAZ-2108 steering rack.

Instruction card.

Repair of VAZ-2108 steering rack

.

Tools and accessories

: hammer, chisel, socket head 22, open-end wrench 14-15, special octagonal wrench 17, special octagonal wrench 24, screwdriver, Litol-24 lubricant, plastic clamps 200\4, stationery knife, special pliers for retaining rings

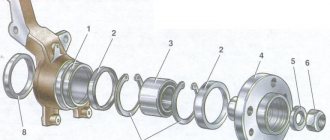

After the steering rack has been dismantled, it will be necessary to unscrew the bolts on the steering rods. To do this you will need a 22mm socket, a hammer and a chisel to bend the edges of the locking plate.

Unscrew the bolts with a 22mm head.

Remove the locking and connecting plate.

Disconnect the steering rods.

Remove the rubber support along with the spacer ring on the right side of the steering rack.

Using pliers we cut off the plastic ties that compress the edge of the corrugation.

Remove the protective cover.

On the left side of the steering rack housing, remove the protective cap and rubber support.

Using a 17 octagonal head, unscrew the rack stop nut.

After unscrewing, remove the nut.

Remove the spring from the middle.

Also remove the retaining ring.

Next, find a wooden block and secure it in a vice, and knock out the rack stop with a light tap. You can, of course, use a screwdriver to hook it into the recess that is located in the center of the stop, although it will be much harder to pull it out, since a rubber sealing ring is installed in the annular groove of the stop.

Now let's move on to the front shield and remove the rubber seal from it.

Take a flathead screwdriver and remove the rubber boot from the gear.

After removing the boot, remove the lock washer.

We take a special octagonal wrench with a 24mm head and unscrew the bearing mounting nut.

And unscrew the gear bearing mounting nut...

...after which we remove the nut from the shaft.

Now we take the 14 key, resting it on something suitable and insert it into the locking flat of the gear shaft...

... and remove the shaft gear from the crankcase.

The next step will be to dismantle the rail.

Let's move on to the next step, take a strip screwdriver and pry the support shaft in the middle...

...we pull it out of the fastening grooves.

We put damping rings on the new support plate, so that the thin side of the rings is in the center of the cutout of the plate.

Let's start installing the support sleeve, pay attention to the photo above, you can see a recess and a special hole in it, two protrusions on the support sleeve should go into this hole. After installing the support sleeve, cut off the very thin parts of the rings, as in the photo, with a stationery or any cutting tool.

Using special scissors, remove the retaining ring from the gear shaft.

And we press out the bearing with two or three fingers.

Then we press out the needle bearing. To do this, you will need a 1.5-1.2 mm drill and, accordingly, a drill. We drill a hole in such a way as to get to the end of the bearing, as in the photo...

... and knock out the needle bearing through the resulting hole.

Now you need to thoroughly rinse the steering gear housing and press in a new needle bearing from the repair kit. I usually cover the resulting hole from the drill in this way, mix super glue with metal filings and cover the hole with a match, or you can buy cold welding and cover it, it will hold fine too. We lubricate the gear mechanisms with FIOL or Litol, for example, when I installed them, I lubricated them with Litol-24, it is sold in tubes. And put everything back together in reverse order. After you assemble everything, adjust the gap between the stop and the nut, which should be 0.12 mm.

We install the rack on the car in the reverse order of removal.