Any internal combustion engine requires proper cooling. Without it, the motor will simply overheat, as a result of which the moving elements will instantly fail. The engines of modern cars are equipped with a liquid cooling system, which provides for constant circulation of coolant (coolant), achieved through the operation of a water pump (pump). Whatever coolant is used in the engine, prolonged heating will invariably lead to boiling. To prevent this process, a radiator is used in the cooling system. It is a system of thin tubes equipped with special lamellas that increase the area of the cooler.

When the car is in motion, the air flow hits the working surface of the radiator and passes between the lamellas, cooling the metal. Thus, the coolant temperature gradually decreases.

However, the radiator is not able to cope with overheating on its own, especially if the car is stationary or moving at low speeds. He is helped in this by an electric fan, which turns on automatically when the coolant reaches a certain temperature.

If it fails, the engine inevitably faces overheating with all the ensuing consequences. In this article, we will talk about possible reasons why the cooling fan does not turn on, as well as how to identify and resolve the related problems.

What is a radiator fan

To begin with, let us note that all the information provided is more intended for VAZ owners, although it can also be useful for drivers of foreign cars.

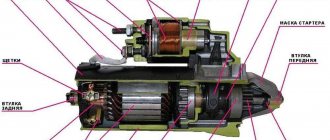

The VAZ cooling fan is an ordinary electric motor powered by 12 V from the vehicle’s on-board network. Its shaft is equipped with an impeller that generates a powerful air flow and directs it to the working surface of the radiator. The fan is mounted on a special frame (frame) to the front part. At the rear it is protected by a radiator grille.

Most VAZ cars are equipped with one fan. But there are also exceptions. For example, the NIVA cooling fan has two independent electric motors with an impeller that turn on simultaneously. This is necessary so that the engine of a domestic SUV cools faster.

How does the fan turn on?

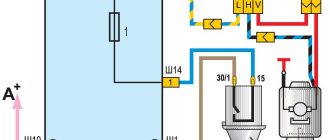

The device turns on differently in different models. In cars with carburetor engines, it starts after the coolant reaches a certain temperature (105-107 0C) and the fan switch (not to be confused with the coolant temperature sensor), which sends a signal to the relay, is triggered. It closes the electrical circuit, supplying power to the electric motor.

The cooling fan circuit for cars with an injector is slightly different. Everything here is controlled by an electronic unit. Information from the switch-on sensor is first analyzed by the controller, and only then transmitted to the relay.

Possible fan malfunctions

If the fluid temperature has reached a critical value, but the radiator cooling fan does not work, it means that there is a problem somewhere. Our task is to find it and eliminate it. Let us indicate the most common malfunctions due to which the cooling fan does not work. There aren't that many of them.

- The fan motor has failed.

- The integrity of the wiring supplying the electric motor or connecting the fan switch sensor is damaged.

- Poor contact in the motor or sensor connectors.

- The cooling fan fuse has blown.

- The fan relay is faulty.

- The sensor is faulty.

- Malfunctions in the operation of the safety valve of the expansion tank.

Fan

If the problem lies in the injector or carburetor cooling fan, then you will have to remove it. It is quite possible to repair the unit by replacing the electric motor or impeller.

To remove the valve, perform the following operations:

- Disconnect the negative terminal from the battery;

- Disconnect the wire terminals. One of them is mounted on the fan casing;

- Take a wrench and unscrew a couple of connecting bolts. They fix the vent casing on the left tank;

- Next, unscrew another lower nut holding the device casing;

- Now you will need a socket extension to unscrew the right nut on top that secures the vent housing to the radiator;

- All that remains is to unscrew the fan pressure plate. To do this, remove the pair of left nuts;

- Remove the pressure plate by hand;

- Now remove the fan along with the casing.

You have removed the unit. Now you have a choice - change the entire unit, or try to repair it by replacing the electric motor or impeller if they are damaged.

Replacing the electric motor

- Disconnect the fan motor wire that is held in place by a clamp on the casing.

- The electric motor is held on the casing by three nuts. They all need to be unscrewed.

- Remove the electric motor from the fan housing.

- Be sure to check the condition of the rubber bushings of the electric motor, which will remain on the casing. If cracks or signs of deformation are detected, they must be replaced.

- Check the electric motor for functionality. If it fails, you can purchase a new one and insert it into the old casing.

It is not uncommon that the performance of a radiator fan is impaired due to a deformed impeller. By replacing it, you can restore functionality to the device.

Replacing the impeller

To change the impeller, follow the instructions:

- Pry up the lock washer using a flathead screwdriver. It is located directly in the center of the impeller;

- Lift the washer and remove it;

- In some cases, the impeller is secured to the fan motor with a nut. Therefore, if you have one, unscrew the mount;

- Remove the impeller and assess its condition. If it is worn out or deformed, replace it with a new one;

- Many people, instead of a standard 4-blade impeller, install a more advanced 8-blade impeller.

During reassembly, make sure that the motor pin fits into the longitudinal hole on the impeller, as shown in the figure below.

Checking the electric motor

If the cooling fan does not work, the first thing you need to do is check its drive (electric motor). It's easy to do. It is enough to take two wires, connect them to the fan and power it directly from the battery. If it starts, then the problem is not with it. We need to look for it further. At the same time, you can check the contacts in the motor connector. Sometimes it happens that the problem is in them. The ingress of dirt and dust, as well as oxidation of metal surfaces can cause contact failure.

If the electric motor does not turn on after connecting to the battery, most likely it is the battery that has broken down. The reason for this may be:

- worn brushes;

- reservoir destruction;

- short circuit of the rotor or armature windings.

In the first case, it is enough to replace the brushes with new ones, and the fan motor will work like new again. In the case of destruction of the commutator or short circuit of the windings, repair may not help.

Causes of malfunctions

The fan may not turn on for the following reasons:

- the fan drive (electric motor) is faulty;

- fuse is blown;

- the relay has failed;

- broken electrical wiring;

- lack of contact in the temperature sensor connector;

- The temperature sensor is faulty.

Search for reasons

Diagnosis of a fan malfunction should begin with the fan itself. To do this, disconnect the connector on the fan and connect it, observing the polarity, directly to the battery terminals. If it turns on, it means the drive is working, the reason needs to be looked for further. If the fan does not work, this is the reason. But let's take things in order.

The fan did not turn on. We check the integrity of the wiring and the condition of the contacts on the sensor. If everything is in order, we move on to the fuse and fan relay. They are located under the hood on the left side closer to the driver, in the mounting block.

Fuse F4 is 20A, double, for the sound signal and the cooling fan (it is very easy to check; if there is no sound signal and the fan does not work, then most likely it is the culprit).

You can check the fuse with an ordinary autotester. With relays the situation is more complicated. To make sure that this is not the case, it is better to get a one hundred percent working relay somewhere and temporarily install it in the socket for testing. If the fan does not work even with it, we go to the sensor.

If the sensor is de-energized, the controller must start the fan in emergency mode for constant blowing. Disconnect the connector from it and turn on the ignition. Turning on the fan will indicate that the sensor has failed and requires replacement.

When is it necessary to change a fan?

If the cause is still in the fan itself, you can try to repair it. The problem is usually the brushes or bearings. But it also happens that the electric motor fails due to a short circuit or break in the windings. In such cases, it is better not to experiment and replace the entire drive.

We recommend: Mercedes turbine repair: features and recommendations

It is strictly forbidden to operate a vehicle with a non-working cooling fan. Overheating of the coolant will inevitably lead to the destruction of rubber pipes and hoses, as well as cylinder head gaskets and valve covers. In addition, high engine temperature can cause destruction of the piston group elements.

How much does a cooling fan cost on a VAZ 2114

You can buy a new cooling fan for a VAZ 2114 for 1500-2500 rubles. Replacing this part at a service station will cost 300-400 rubles. But you don’t have to spend money on this. Dismantling the old fan and installing a new one at home will take no more than 30 minutes.

Checking the fuse and fan relay

If everything is in order with the electrical wiring, we move on to other equipment. First, let's check the cooling fan fuse. It is usually located in the mounting block under the hood of the car and is marked F7. We check it with the same car tester. If the fuse is good, move on. We are looking for the fan switch relay. It is located under the cover of the right panel of the center console. There are three relays located there. The car owner's manual will help you determine what you need, since different models have different locations.

But how to check the relay? In field conditions, it is almost impossible to determine its performance. It’s easier to take an adjacent relay (if its parameters match) and install it in the desired slot.

Cooling fan diagnostics - trying to find the problem

There will be two temperature sensors: one, which is on the thermostat, is connected to the ECU. It is necessary to turn it off - leave the second one as it is.

DTOZH on engine 11183

We disconnect the connector, but do not remove the sensor itself. Then we turn the key to position 1, and so on.

Electrically, things look complicated: the fan relay is in one box, and the fuse is in another. We need fuse F5 (20A). By the way, both a fan and a horn are connected to it.

Mounting block 2114-3722010-60 and 2114-3722010-10

The main mounting block is installed under the hood, and the additional one is located at the left foot of the front passenger.

Additional mounting block (option 1)

In the additional block we see three relays. The "main relay" is located at the bottom. And then there are possible options:

- The fan relay is mounted in the middle;

- This relay can also be installed at the top.

We recommend: About mixing antifreeze with water: is it possible?

The second option is shown below.

Additional mounting block (option 2)

By the way, there is always a fuse located near the relay we need. It is part of the fan circuit.

Testing the fan switch sensor

The next reason why the cooling fan does not work may be a faulty sensor. Cases of failure of this element are not so rare. It is possible to accurately determine that it is the sensor that has broken down only in a car with an injection engine. If you disconnect it from the power supply, the electronic control unit will perceive this as a system malfunction and start the fan in emergency mode.

The check is carried out as follows. We warm up the car until the coolant temperature reaches 100 0C, then turn off the engine, lift the hood and disconnect the sensor by disconnecting the connector on it. After this, we start the engine. If the fan turns on, then the problem is with the sensor.

Unfortunately, such a check is not possible in cars with carburetor engines. Here, you can determine the functionality of the fan switch sensor only by replacing it with a new one and warming up the engine to operating temperature.

How to find the reason

Start checking with the electric motor. To do this, disconnect the electrical wires from it and connect it directly to the battery, observing the polarity. If the fan does not turn on, that is the problem. If it works, you need to look for another reason.

Check all contacts on the connectors, and then the relay and fuse. They are located in an additional mounting block, which is located to the right of the instrument panel near the lower heater air duct.

The fuse (50 A) can be checked with a tester; it is better to take a relay that is known to be working and install it in the appropriate socket. If the problem is not solved, move on.

Checking the temperature sensor. To do this, warm up the engine to operating temperature, turn it off and disconnect the sensor. It is located on top of the thermostat housing. When the sensor is disabled, the controller must independently start the fan to operate continuously.

Start the engine and wait for the fan to turn on. If the coolant temperature has reached a critical value and the fan does not turn on, you need to look for a break in the electrical wiring.

Do I need to change the fan?

If you have determined that the problem is in the fan itself, or rather in its electric motor, you can try to repair it. Most often, it stops working due to failure of the brushes, or due to problems with the rotor bearings. Less often the collector becomes unusable or a break occurs in the winding.

If the fan cannot be repaired, it must be replaced.

Under no circumstances should you drive a car with a non-functioning fan. Overheating of the engine will inevitably lead to the destruction of the rubber hoses of the cooling system, gaskets, and also threatens the failure of parts of the piston group.

We recommend: Replacing the cylinder head gasket in a Chevrolet Lanos with your own hands: photos and videos

Changing the safety valve

There is another malfunction that can lead to system failure. If the cooling fan does not work even after confirming the operability of all the listed elements of the chain, it is worth checking the safety valve on the expansion tank.

The role of this valve is to maintain the operating pressure in the system above atmospheric pressure. This is necessary so that the water included in the coolant does not boil when heated to 100 0C. If the safety valve fails, the pressure in the system will equalize with atmospheric pressure and the liquid will boil, reaching the boiling point of water.

The switch-on sensor, as already mentioned, can only turn on at 105-107 0C. Thus, our coolant will boil, but the fan will not work.

How to check the safety valve? This is impossible at home. It’s easier to buy a new valve, especially since it costs pennies.

Useful tips

Finally, check out these useful tips that will allow you, if not to avoid problems with turning on the cooling fan in a timely manner, then at least to correct the situation a little.

- Systematically check the operation of all elements of the cooling system. Pay attention to the coolant temperature indicators on the instrument panel, and also listen to whether the fan turns on.

- Monitor the coolant level in the system. Replace it in a timely manner.

- At least once a year, wash the expansion tank cap under running water. This solution will extend the life of the safety valve.

- If there is the slightest malfunction in the cooling system, stop driving and take corrective action.

- If the cooling fan does not work due to a sensor, fuse or relay failure, and this malfunction caught you on the road, disconnect the sensor (for an injector) or connect the electric drive directly to the on-board network (for a carburetor). This way you can drive to the nearest service station without the risk of engine overheating.