The electric motor of the heater fan (“stove”) on VAZ 2108, 2109, 21099 cars and their modifications is a commutator, DC motor with excitation from permanent magnets. Has three rotation speeds. The speed is selected by a four-position switch on the instrument panel. Below are the electrical diagrams for connecting it.

Wiring diagram for the electric motor fan (“stove”) of VAZ 2108, 2109, 21099 cars with a “low” instrument panel and mounting block 17.3722

Wiring diagram for the electric motor fan (“stove”) of VAZ 2108, 2109, 21099 cars with a “high” instrument panel and mounting block 2114

Notes and additions

— The fan electric motor can be connected to the on-board network either directly (highest speed) or through an additional resistor having two resistance spirals (0.23 Ohm and 0.82 Ohm). If both spirals are included in the chain, the speed is low, if one is 0.23, the speed is average.

More articles on electrical equipment of VAZ 2108, 2109, 21099 cars

Schematic electrical diagrams, connecting devices and pinouts of connectors

The VAZ-2109 car was produced at AvtoVAZ from 1987 to 1997. Years of production 21099: 1990-2004 - in Russia, 2004-2011 - in Ukraine. Here are colored wiring diagrams (for the injector and carburetor) with a description of all the elements for various modifications. The information is intended for self-repair of cars. Electrical circuits are divided into several blocks for ease of viewing via a computer or smartphone; there are also circuits in the form of a single picture with a description of the elements - for printing on a printer.

Like the entire car, its electrical equipment was at an average level, so owners of Nines should know the wiring diagram thoroughly for routine repairs with their own hands.

Modifications of VAZ-2109

VAZ-2109 . The basic model, which was produced from 1987 to 1997, was equipped with a 1.3-liter VAZ-2108 carburetor engine with a capacity of 64 horsepower.

VAZ-21091 . Modification of a car with a derated VAZ-21081 engine, 1.1 liter and 54 horsepower. It was mass-produced from 1987 to 1997.

VAZ-21093 . Modification of a car with a VAZ-21083 carburetor engine, 1.5 liters and 73.4 horsepower. Serially produced from 1988 to 2006.

VAZ-21093i . Modification with a VAZ-2111-80 injection engine, 1.5 liters. the first prototype appeared in 1994, mass production began in November 1998.

VAZ 21093-22 . Model made specifically for the Finnish market. It features improved interior trim, pre-installed alloy wheels and a new dashboard. The car was equipped with a 1.5 liter injection engine. Produced from 1995 to 1998.

VAZ-210934 . An all-wheel drive SUV with a VAZ-21093 body mounted on a Niva frame, on which the suspension, steering, engine, gearbox and transfer case from the same VAZ-2121 Niva model were already installed.

Wiring diagram for VAZ-2109 carburetor

- Headlight.

- Electric motor for headlight glass cleaning system. An optional part, used mainly on export vehicles.

- Limit switch for powering the engine compartment lamp.

- Klaxon.

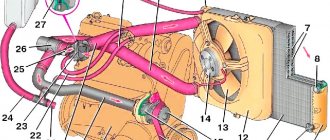

- An electric motor drives a fan installed on the radiator of the cooling system.

- Temperature indicator that provides a control signal for the electric drive of the fan impeller.

- Alternator.

- Fluid supply valve for headlight glasses. Used in conjunction with paragraph 2.

- Fluid supply valve for the glass of the fifth door.

- Fluid supply valve to the front glass.

- Spark plugs.

- Hall sensor used to distribute ignition pulses.

- Coil.

- Limit switch for reverse gear lights.

- Fluid temperature meter in the cooling system.

- Starter.

- Accumulator battery.

- A sensor that measures the fluid level in the brake booster.

- Switch that controls the ignition system.

- Sensor for determining the position of the top dead center of the piston of the first cylinder. Installed on some export VAZ 2109 with a diagnostic system. Found only on cars before 1995.

- Diagnostic block. Optional element, installed together with item 20.

- Controller for controlling the solenoid valve installed in the carburetor.

- Starter switch contact block.

- Limit switch on the carburetor.

- Economizer valve.

- Sensor signaling an emergency decrease in oil pressure.

- Washer pump drive.

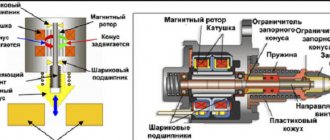

- Fan impeller motor for ventilation and heating systems.

- Resistance providing additional fan speeds.

- Speed shifter.

- Windshield wiper drive.

- Cigarette lighter.

- Illumination system for levers for adjusting heater operating parameters.

- Socket for additional equipment.

- Lamp for auxiliary lighting of the engine compartment.

- Illumination system for the glove box on the instrument panel.

- Relay and fuse link mounting block.

- Instrument panel light switch.

- Parking brake lamp limit switch.

- Brake lamp limit switch.

- Steering column switch lever block.

- Exterior lamp switch.

- Hazard switch.

- Turn on the rear fog lamp.

- Bimetallic fog lamp fuse.

- Heated glass switch on the fifth door.

- Turn signal repeaters on the front fenders.

- Central interior lighting.

- Individual lampshade.

- Switches for backlight operation on the middle pillars.

- Ignition switching unit.

- Egnition lock.

- “Low” type instrument cluster.

- Choke limit switch on the carburetor.

- Rear lights.

- Fuel level meter in the tank.

- Heated glass.

- Rear wiper drive.

- Two lamps for room illumination.

How to restore normal operation of the stove

First, let's look at the first case of defective operation of the heater of the "nine" with a high panel, when only cold air enters the side deflectors. The operation of the side nozzles is controlled by separate flaps with a polyurethane seal. In turn, the VAZ-2109 heater dampers are controlled using levers located on the control panel. Quite often there are cases when a significant gap forms between the damper and the walls of the gutter, which significantly reduces the efficiency of the stove. The problem is eliminated by forcing the damper to the optimal position.

So, get your pliers ready and remove the upper part of the dashboard. By the way, you can do without dismantling, but this way you can clearly see where the central damper of the VAZ-2109 heater is located, assess its condition and control the adjustment process. After removing the panel, find the fastening cable, which is located to the right of the accelerator pedal and, using pliers, carefully bend the wire. This creates additional tension, which reduces the free play of the spring. As a result, the damper will be able to tightly close the air duct, blocking the movement of cold air flows.

Equipment diagram for VAZ-2109 injector

The VAZ 2109 wiring for the injector has many connectors for connecting sensors to the computer.

- TPS (throttle position sensor);

- DPKV (crankshaft position sensor);

- DT (temperature sensor);

- DSA (vehicle speed sensor);

- Canister purge valve;

- MAF (mass air flow sensor);

- DD (knock sensor) and others.

The weak point of the harnesses is the power wiring on the bottom shelf of the radiator, which is constantly exposed to high temperatures and in this place it is in no way protected from water and dirt. Another problem is a harness under the carpet next to the driver's seat. Moisture constantly accumulates there, and in order to remove it, you need to dry the floor, inevitably tugging on the rope.

Since the mid-90s, VAZ 2109 began to use engines with an injection system, which greatly changed the electrical layout of the engine compartment and instrument panel. Below is an electrical diagram of a 1999 car with an ECM type GM ISFI-2S and January 4/4.1.

- 1 - nozzle system;

- 2 - candles;

- 3 — ignition control module;

- 4 — diagnostic connector;

- 5 — General Motors or January controller;

- 6 — connector for connecting the instrument cluster;

- 7 — main relay of the system;

- 8 — fuse for power supply wiring of the controller and ignition system module;

- 9 — protection of the speed sensor and air flow meter circuits;

- 10 — fuel supply pump power protection;

- 11 — fuel pump controller;

- 12 — engine temperature meter;

- 13 — idle system;

- 14 — detonation meter;

- 15 — tank purge system for collecting fuel vapors;

- 16 — crankshaft position meter;

- 17 — speed meter;

- 18 — air flow meter;

- 19 — lambda probe;

- 20 — throttle position angle meter;

- 21 — electric fuel pump complete with fuel level sensor;

- 22 — connection of the ignition system;

- 23 — control lamp;

- 24 — ignition switch;

- 25 - switching block;

- 26 — radiator cooling fan.

Since 2002, all VAZ 2109 began to be equipped only with engines with an injection system. The diagram shows the electrical wiring harness for the Bosch MP7.0 ECM (Euro 2 standards) on a 2003 car with a VAZ 2111 engine.

- 1 — four nozzles;

- 2 — spark plugs 2109;

- 3 — ignition distribution module;

- 4 - diagnostic connector, led into the car interior;

- 5 — Bosch controller connector;

- 6 — connector for the combination of lamps and instruments;

- 7 - main switching device of the system;

- 8 — fuse-link of the main device;

- 9 — controller for controlling the parameters of the fan on the cooling radiator;

- 10 — fan controller fuse;

- 11 — fuel pump control relay;

- 12 — fuel pump wiring fuse;

- 13 — intake air flow sensor;

- 14 — throttle opening angle sensor;

- 15 — engine temperature meter;

- 16 — regulator of idle speed parameters;

- 17 — sensor for measuring detonation in cylinders;

- 18 — crankshaft position sensor;

- 19 — lambda probe;

- 20 — immobilizer control unit;

- 21 — immobilizer status indicator;

- 22 — speed sensor;

- 23 - electric motor for driving the fuel pump; in the same module there is a device for measuring the remaining fuel in the tank;

- 24 — purge valve for the gasoline vapor recovery system;

- 25 — connector of the ignition system braid;

- 26 — instrument cluster with Check Engine indicator and warning lamp;

- 27 — ignition system start relay;

- 28 - lock;

- 29 — installation and switching block;

- 30 - cooling system fan.

Gluing the VAZ-2109 stove

In the case where correctly performed adjustment operations did not lead to the expected result, it is likely that the problem with insufficient sealing of the dampers is also associated with the destruction or peeling of the sealing material glued along the edge. In this case, the repair of the VAZ-2109 heater dampers consists of gluing them with a new seal. You will learn how to do this below.

Before gluing the damper of the VAZ-2109 stove, it is better to dismantle its casing - this will give access to the air ducts and make it more convenient to work. Experts recommend using bitoplast with a self-adhesive surface as a sealing material. The glue should be applied both along the edge of the air ducts and along the edge of the dampers so that they can be closed as tightly as possible. Upon completion of gluing, be sure to adjust the position of the closing elements of the stove for its most efficient operation.

As you can see, it is possible to install the VAZ-2109 high panel heater dampers in the optimal position without qualified assistance. The same applies to applying sealing material - any owner of a “nine” can cope with this task. Properly performed adjustment work in combination with gluing will ensure uniform heating of the entire vehicle interior.

Relay and fuse box diagram 2109

The fuse blocks do not depend on the fuel injection system used - carburetor or injector. BP will differ only by year of manufacture of the car. That is, the mounting blocks for the carburetor and injector are the same. The VAZ 2109-099 fuse box (carburetor, injector) is located under the hood, in the compartment in front of the windshield on the left side.

Fuse block 2114-3722010-18

K1-relay for turning on headlight cleaners; K2-relay-breaker for direction indicators and hazard warning lights; K3 - windshield wiper relay; K4-relay for monitoring the health of lamps; K5-power window relay; K6 - relay for turning on sound signals; K7-relay for turning on the electric heating of the rear window; K8-relay for high beam headlights; K9-relay for low beam headlights; F1-F16 - fuses.

Fuse block 2114-3722010-60

K1 - Headlight wiper relay, K2 - Turn signal and hazard warning relay, K3 - Windshield wiper relay, K4 - Brake light and parking light relay, K5 - Power window relay, K6 - Horn relay , K7 - Rear window heating relay, K8 - Headlight high beam relay, K9 - Headlight low beam relay, F1 - F16 - Fuses, F1 - F20 - Spare fuses.

Attention! The power terminals on the generator often become loose, heat up, spark and melt the wiring. Pay attention to this point when searching for possible faults yourself.

Electrical diagram - wiring of a VAZ 2109 car with a carburetor engine and a low instrument panel (torpedo).

A - the order of conditional numbering of plugs in the ignition switch block of VAZ 2109 electrical equipment. B - the order of conditional numbering of the plugs in the block of the electric motor of the windshield wiper of the VAZ 2109.

Picture of the VAZ 2109 electrical circuit:

Table of decoding of the VAZ 2109 electrical circuit: