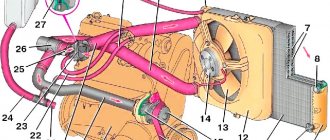

Carburetor engine power supply system: 1 – fine fuel filter; 2 – fuel supply hose to the fuel pump; 3 – fuel pump; 4 – heated air intake; 5 – check valve; b – fuel drain hose from the carburetor; 7 – cold air intake; 8 – thermostat; 9 – air filter assembly; 10 – carburetor; 11 – fuel drain pipe; 12 – fuel supply pipe from the tank; 13 – fuel tank; 14 – flange of the fuel level sensor and fuel intake tube; 15 – separator hose; 16 – filling pipe hose; 17 – filling pipe; 18 – fuel tank plug; 19 – separator; 20 – two-way valve hose; 21 - two-way valve

The fuel supply is located in the tank located under the bottom in the rear seat area. The tank is made of steel and consists of two stamped parts welded together. The tank is connected through a drain hose to a separator that captures gasoline vapors. The condensate from the separator is drained back into the tank. The separator communicates with the atmosphere through a two-way valve that prevents excessive increase or decrease in pressure in the fuel tank. The filler neck is connected to the tank with a gas-resistant rubber hose secured with clamps. The plug is sealed. Through a fuel intake with a mesh filter, gasoline is supplied from the tank through steel fuel lines and rubber gas-resistant hoses to a fine fuel filter, a fuel pump and then to the carburetor. Gasoline is sucked from the tank due to the vacuum created by the gasoline pump.

Fine filter - with a paper filter element in a plastic housing, non-separable design. There is an arrow on the filter housing that must coincide with the direction of fuel movement.

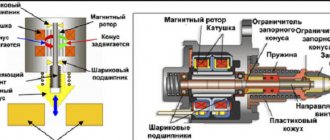

The fuel pump is a diaphragm type, mechanically driven by the camshaft eccentric, with a manual pumping lever. It consists of a lower housing with drive levers, an upper housing with valves and pipes, a diaphragm assembly and a cover. The diaphragm assembly is installed between the upper and lower housings. Two diaphragms (working) are installed on top, and one (safety) on the bottom: it prevents gasoline from entering the engine crankcase when the working diaphragms rupture. In this case, leaked gasoline is discharged through holes in the external spacer located between the safety and working diaphragms. The diaphragms, together with the internal spacer and plates (from the outside), are assembled on the rod and secured with a nut. The rod is inserted into the cavity of the balancer using a T-shaped shank. A spring is installed between the diaphragm assembly and the lower housing. The upper housing is closed with a lid secured with a bolt. Underneath there is a mesh fuel filter.

The pump is attached to the engine with two studs through a heat-insulating spacer, sealed on both sides with cardboard gaskets. Part of the gasoline supplied to the carburetor is drained back into the tank through a system of pipelines and hoses - this improves pump cooling and prevents the formation of vapor locks in the power system. The drain line has a check valve that allows fuel to flow in only one direction - from the carburetor to the tank.

The air filter housing can receive cold air through an intake near the radiator or hot air from an intake mounted on the exhaust manifold. The flow is switched by a damper controlled by a thermostat. The built-in thermal power element opens the hot air damper when the incoming air temperature is below 25 °C and completely closes it if the air is heated above 35 °C. Thus, the temperature of the incoming air is automatically maintained within 25-35 °C. The air filter is dry, with a replaceable paper filter element. The filter housing is mounted on the carburetor studs through a rubber gasket and secured with four self-locking nuts through a metal plate.

Fuel supply diagram for an engine with a fuel injection system: 1 – injectors; 2 – fitting plug for monitoring fuel pressure; 3 – injector ramp; 4 – bracket for fastening fuel pipes; 5 – fuel pressure regulator; 6 – adsorber with solenoid valve; 7 – hose for suction of gasoline vapors from the adsorber; 8 – throttle assembly; 9 – two-way valve; 10 – gravity valve; 11 – safety valve; 12 – separator; 13 – separator hose; 14 – fuel tank plug; 15 – filling pipe; 16 – filling pipe hose; 17 – fuel filter; 18 – fuel tank; 19 – electric fuel pump; 20 – fuel drain line; 21 – fuel supply line

Fuel is supplied from a tank installed under the bottom in the rear seat area. The fuel tank is made of steel and consists of two stamped halves welded together. The filler neck is connected to the tank with a gas-resistant rubber hose secured with clamps. The plug is sealed.

The fuel pump is electric, submersible, rotary, installed in the fuel tank. The developed pressure is at least 3 bar (300 kPa). The fuel pump is turned on at the command of the injection system controller (with the ignition on) through a relay. To access the electrical connector of the pump, there is a hatch under the rear seat in the bottom of the car. From the pump, fuel under pressure is supplied through a flexible hose to the fine filter and then through steel fuel lines and rubber hoses to the fuel rail. The fine fuel filter is non-separable, in a steel housing, with a paper filter element. There is an arrow on the filter housing that must coincide with the direction of fuel movement. The fuel rail serves to supply fuel to the injectors and is mounted on the intake manifold. On one side there is a fitting for monitoring the fuel pressure, on the other there is a pressure regulator. The latter changes the pressure in the fuel rail - from 2.8 to 3.2 bar (280-320 kPa) - depending on the vacuum in the receiver, maintaining a constant difference between them. This is necessary for accurate dosing of fuel by injectors.

The fuel pressure regulator is a fuel valve connected to a spring-loaded diaphragm. The valve is closed under the action of the spring. The diaphragm divides the regulator cavity into two isolated chambers - “fuel” and “air”. The “air” is connected by a vacuum hose to the receiver, and the “fuel” is connected directly to the ramp cavity. When the engine is running, the vacuum, overcoming the resistance of the spring, tends to retract the diaphragm, opening the valve. On the other hand, fuel presses on the diaphragm, also compressing the spring. As a result, the valve opens and part of the fuel is released through the drain pipe back into the tank. When you press the gas pedal, the vacuum behind the throttle valve decreases, the diaphragm, under the action of a spring, closes the valve - the fuel pressure increases. If the throttle valve is closed, the vacuum behind it is maximum, the diaphragm pulls the valve harder - the fuel pressure decreases. The pressure drop is determined by the spring stiffness and the size of the valve opening; cannot be adjusted. The pressure regulator is non-separable; if it fails, it is replaced.

VAZ-2109 injector

There are rumors on the Internet that the VAZ 2109 injector has long ceased to be popular among car owners. Anyone who wants to exchange a domestic car for a foreign car is mistaken.

For the same money they will buy a beautiful firebird, under whose plumage there will be a decrepit, senile body, like that of a courier during the Kaiser’s reign. Yes, the VAZ has its drawbacks, but it also has quite a few advantages: if you buy even a used car from one owner and with low mileage, then the engine will almost always please you, the electronics will not seem stupid, so you can close your eyes to the rest .

Just don’t wave your hands now and say that domestic g... doesn’t sink in water. The interior is not a gift, but its explosiveness is fully justified by the material from which the body is made. This is not a piece of plastic covered with foil. Perhaps tuning the interior will help you.

The car is not wasted on trifles: if the problem is in the pads, then it will remain there. It happens that the panel goes out right on the road, but the problem is quickly eliminated, the stove fails, but you can find an approach to it with skillful tuning. There is a desire to change it to a more advanced tenth model - the problem will quickly be solved. You can sell a 2109 injector quite quickly, whereas a foreign car takes months to wait for a buyer.

And no need to say that you ride on the toilet. Even a Volkswagen with 25 years of life would not allow itself to be called that. And you! Oh, I wish I could take our nine-wheeler for a ride to Moscow! After that, you can erect a monument to her and become a pedestrian, and hang a photo with your iron friend in a frame on the wall.

It’s not for nothing that they say that the VAZ is a cheap car. For citizens of Russia and post-Soviet countries there will be no problems with spare parts for a long time. Do you want to do the renovation yourself? There is a lot of information in stores and on the Internet. Try to dig up so much material for a Korean car. You would rather love the domestic auto industry than a prince from far away, rusting right under your windows.

He doesn’t want to, my dear, it starts, there are no spare parts in the workshops, you have to wait for months until they bring it. But for our cars there is always a green light. Chairs in the evening – money in the morning! The VAZ is not as bad as it might seem at first, although it requires some fine-tuning. Do you still want to try a foreign car in action? Then buy at least an unfucked version, at least ride for pleasure until breakdowns lead to a nervous breakdown.

Injector instead of carburetor

Replacing the KS with an SRV is a fairly common type of tuning, since the injector has a number of tangible advantages, and these are:

When installing distributed injection, there is no need for frequent maintenance (flushing and adjusting) of the HRSG, there is no overflow of fuel, which is why a gasoline smell often appears in the car interior, and the car may not start. But carburetor circuits also have advantages:

Despite all its disadvantages (complicated diagnostics, a large number of sensors, relatively expensive spare parts), SRVs are increasingly attracting car owners, and many are trying to install an injector instead of a carburetor on their car.

VAZ 2109 engine injector: control system diagnostics

Before touching upon general issues of diagnosing the control system, it is worth getting acquainted with the controller lamp

If a malfunction occurs while driving the car, the controller will detect it and notify the driver using “CHECK ENGINE”, while storing in its memory the necessary codes about the nature of the malfunction. With their help, the process of diagnosis and subsequent repair of the fuel injection system will be facilitated. It is the controller that is able to coordinate the operation of VAZ sensors and systems that are part of the general composition of all fuel injection units.

A few words about the DST-2M digital tester.

It is used to diagnose the engine injection control system. It is worth remembering that only a competent specialist can make the correct diagnosis. No matter how much an inexperienced mechanic strives to automate the process of diagnosing a car, having the necessary tools, he will not succeed without certain skills, which can in some cases aggravate an already difficult situation.

Diagnostics includes the following steps:

- checking the fuel supply system, the operability of all sensors, actuators and the ignition system;

- reading fault codes;

- compression measurement;

- data monitoring of the entire control system.

Once the injector has been diagnosed, the entire range of necessary services becomes clear if it is associated with a failed electronic system responsible for the performance of the engine.

General diagram of the VAZ 2109

The vehicle was equipped with engine 21083. Its displacement was 1.5 liters, power was measured at 79 hp. The motor is located across the engine compartment (pictured below). The history of the VAZ 2109 brand dates back to 1988. The car is a modernized analogue of the 2108 model and is distinguished by the presence of additional two doors in the rear.

The ability to fold the rear row seats, thereby expanding the trunk capacity, turns the Nine into a family car. There are also cars (mostly they belonged to the first releases) that were equipped with a 2108 engine, the displacement of which was 1.3 liters and the power was 64 hp.

VAZ 2109 injector controller

The controller receives the necessary information from the sensors, then makes calculations: based on them, it independently issues commands to the actuators. This device is quite reliable. One problem: it is afraid of large surges in on-board voltage. This can happen when the generator malfunctions or the starter sticks while the engine is running; sometimes the process of “lighting” another car or the use of a low-quality starting charger is to blame.

As soon as malfunctions occur, the controller immediately detects them, notifies the driver with the above-mentioned lamp, and stores the codes. Under his control, the injectors try to work smoothly, as does the ignition system.

The injectors turn on in pairs, but this depends on the type of controller itself. An interesting fact is that pairs of injectors tend to turn on alternately, approximately 180° from the crankshaft rotation. This is called double synchronous injection, but sequential operation is possible. An idle spark is provided for the system: 16-valve engines are an exception. They are already equipped with personal ignition coils for each spark plug.

This process occurs as follows: high-voltage pulses are applied to a specific pair, and the formation of a working spark occurs in the cylinder on the compression stroke and on the exhaust stroke. Otherwise, an idle spark will form. In this case, a small amount of energy is required for the cylinder during the exhaust stroke, and the rest of it is used during the compression stroke. This is how the process of ensuring normal sparking and unhindered ignition of the fuel mixture occurs. The whole process can be repeated if the cylinders decide to switch roles unexpectedly.

The controller controls not only the fuel supply, but also the energy accumulation time and ignition timing. This concerns the crankshaft rotation speed in idle mode, the uninterrupted operation of the electric fuel pump, the tachometer and the warning lamp, which is located on the VAZ instrument panel, the cooling system, and the cabin air conditioning compressor clutch. The device generates certain speed signals to the trip computer, regulates fuel consumption, and maintains the required stereochemical ratio (gasoline-air as 1:14.7).

What is the difference between an injector and a carburetor?

The fuel system in a car is designed to ensure an uninterrupted supply of the fuel mixture under any operating conditions of the car, and its engine must work equally well at idle speed, and at increased loads, also during sharp acceleration. What is the difference between an injector and a carburetor? On a carburetor car, the supply of fuel (gasoline) and its mixing with air is carried out using mechanics, while an injection vehicle is controlled electronically.

The carburetor system (CS) includes the following elements:

Due to the operation of the gas pump, fuel from the tank through the main line, passing through the filters, enters the carburetor unit (CU), where it is mixed with air in the required proportion, and then enters the cylinders and burns under pressure. Often, to prevent excess pressure, systems of this type are equipped with a check valve with an additional line for draining gasoline into the gas tank, also called “return”.

An injector or distributed injection system (MIS), unlike a CS, does not have a mechanical unit for mixing fuel with air, but more precise control and dosing is provided by an electronic control unit (ECU or controller). Depending on the modification, the SRV circuit may differ slightly, but the principle is the same for all such systems; it usually includes:

Also, the SRV is often supplemented with an absorber, an idle speed solenoid valve (EMV), and lambda probes (oxygen sensors). Over time, the injector circuit only becomes more complex, it is “overgrown” with an increasing number of sensors and control systems. Having figured out what the difference is between these two fuel systems, now let’s look at how you can install a different type of vehicle on a car.

VAZ 2109 injector does not start

Problem: the car worked fine all day and drove dozens of kilometers around the city. I stood in the garage resting for several hours. The owner decided to go out again on business, but could not start it. It seemed like something was catching, but then it died out. I had to unscrew the candles, which were thoroughly wet, and put the ones I had just bought in their place. And again a bummer! I had to check the timing belt: it turned out to be normal, I removed the battery and examined it for a failure. I checked the fuel pump: it is also ok. There is a return line, there is fuel too, but the car just doesn’t want to start.

Carburetor. Advantages and disadvantages

Let's start with the negative points. These include:

Nine carburetor

But let's not just talk about the bad. The VAZ 2109 with a carburetor also has positive qualities:

Swapping a couple of armored pipes and doing a purge is a simple option for quickly repairing a carburetor yourself. The injection engine does not understand such tricks.

Article on the topic: Engine power on the VAZ 2114 and other technical characteristics

Injector. Advantages and disadvantages

In short, all the advantages of the injector are the disadvantages of the carburetor, and all the disadvantages are the advantages of the carburetor.

Injection nine

The key features of injection engines include:

Source

VAZ 2109 stove diagram: improvement options

The design and operation of the VAZ 2109 stove does not imply any complex procedures. However, the factory heater most often cannot distribute hot air evenly to the feet and onto the windshield. The modernization carried out on the VAZ-2114, contrary to expectations, could not solve this problem. However, there are no hopeless situations, and the presented diagram of the VAZ 2109 stove will help everyone who has the desire and time to solve this problem with their own hands.

In the process we will need:

Cleaning fuel lines of VAZ 2108, 2109, 21099

If such malfunctions occur in the operation of the carburetor engine of VAZ 2108, 2109, 21099 cars, such as unstable idling, failure when pressing the gas pedal, drop in power and throttle response, difficulty starting the engine, etc., you should pay attention to the fuel supply system to the carburetor, namely on the cleanliness of fuel lines and the cleanliness of the vehicle’s fuel tank.

The presence of blockages and contaminants in them often leads to disruption of the fuel supply to the carburetor and further to the engine, followed by the occurrence of the above-mentioned malfunctions. Let's consider cleaning fuel lines on VAZ 2108, 2109, 21099 cars.

Preparatory work

— Raise the back seat in the car

Under it in the body there is a hatch for access to the fuel intake of the fuel tank. Remove the hatch by unscrewing the screws securing it.

— Remove the fuel hoses (main and return lines) from the fuel intake

To do this, loosen the clamps and move them from the fittings on the fuel intake. The fit of the tubes on the fittings is very tight, so when moving, you can help yourself with a 10 mm open-end wrench.

— Place a cloth under the fuel pipes to prevent splashing

— We disconnect, in the engine compartment, the fuel pipes from the fine fuel filter (if there is none from the inlet pipe of the fuel pump) and the non-return valve fitting. To do this, you need to loosen the clamps securing them.

Let's start cleaning.

Cleaning fuel lines of VAZ 2108, 2109, 21099

— We blow compressed air from a compressor or a conventional pump into the fuel pipes in the direction from the engine to the tank

First to the main highway, then to the return line. The duration of the purge is arbitrary.

— Check the ease of air passage through the fuel lines

To do this, we blow them through again, but this time with our mouth and evaluate them. If necessary, repeat blowing with compressed air.

We assemble everything in reverse order.

Notes and additions

— In some cases, you should not limit yourself to cleaning only the fuel lines. You should also clean the entire fuel supply system, namely the fuel tank, mesh filters in the carburetor, in the fuel pump and on the fuel intake, and replace the fine fuel filter.

— On VAZ 2108, 2109, 21099 cars a check valve is installed. When cleaning the fuel lines, it is worth removing it completely and rinsing it with gasoline. Blow with compressed air. You can check its performance by blowing it with your mouth. Air should flow freely in one direction and not at all in the other. In case of malfunction, replace the check valve.

— You can quickly clean the fuel lines on a VAZ 2108, 2109, 21099 car. To do this, we disconnect the pipes only in the engine compartment from the check valve and the fine fuel filter. Remove the cap from the gas tank. We blow with compressed air for a short time until active seething of the fuel appears in the tank. We check by blowing through the lines with our mouth.

Twokarburators VK - More information on the topic in our VKontakte group, on Facebook Twokarburators FS and on Odnoklassniki - Twokarburators OK

More articles on the site on the power supply system of VAZ 2108, 2109, 21099 cars

— Cleaning the fuel tank of VAZ 2108, 2109, 21099 cars

— Malfunctions of the fuel pump of VAZ cars

— Malfunctions of the fuel system of VAZ 2108, 2109, 21099 cars

— Fuel consumption of VAZ 2108, 2109, 21099 cars

— Gasoline used on VAZ 2108, 2109, 21099 cars

— Signs of malfunction of the check valve of the drain line VAZ 2109

What is an injector

The VAZ 21093 car has an injector, the electrical circuit in the device allows, through an electronic control system, to start and optimize engine operation. The main element of the new supply was the injection of a combustible mixture into the combustion chamber under pressure. In carburetor-type engines, the flow of the combustible mixture occurred under vacuum.

In order to ensure optimization of the operation of the VAZ 2109 injector engine, the electrical circuit is designed in such a way that through the ECU - an electronic control unit - a full range of control is carried out and the process is carried out from the supply of fuel to the emission of exhaust gases.

Car VAZ 2109 injector wiring diagram includes:

- electronic fuel injection system;

- electronic ignition system;

- system for monitoring the state of fuel supply, combustion and gas emissions.

At the same time, there are still reserve connectors in the block, allowing you to connect additional sensors for monitoring the operating status of the mechanisms. Such options include an anti-theft device, a knock sensor and others.

On a VAZ 2109 car, the injector electrical circuit is designed in such a way that the engine is controlled through the ECU. The system completely controls the fuel combustion process through it.

An injector installed on a VAZ 21093 car, the electrical circuit of which includes a block of a new type ECU type 2114-3722010-60. The unit is characterized by the use of new knife-shaped fuses. They have a large impact area, as a result of which the reliability of the unit is increased. The ECU unit has information and control connections through sensors and control of actuators. It controls the process and sends a signal to the control panel about the operating status of the following components:

- fuel tank and fuel line;

- fuel pump;

- fuel mixture pressure regulator;

- ramps and injectors;

- throttle valve;

- filters and valves on the fuel return line.

All these nodes are connected to a single unit, and if any sensor fails, the system will receive incomplete information and may refuse to start the engine. However, of course, the VAZ 2109 electric injector circuit will not start if the main DPKV device - the crankshaft position sensor - fails. Until it sends a start signal to the ECU, the unit will not give a command to receive a spark from the spark plugs.

The engine will not start

It is noted that the VAZ 21093 injector, the electrical circuit includes a lot of electronics. Due to its failure, the car may not start only if the DPKV fails. In other cases, the motor will work, but there will be various malfunctions, the causes of which should be sought. If the sensor is working properly, then you should use the classic method of troubleshooting in equipment - there is nothing to burn or nothing to set on fire.

In this case, first of all, the starting system is checked, the serviceability of the spark plugs and then the fuel supply. Details about step-by-step checking of the serviceability of vehicle components are written in the operating manual.