Hydraulic jacks are used to perform work related to lifting various objects to a certain height. They may differ in load capacity, type, purpose, but their structure and principle of operation are the same, which means that the malfunctions of the hydraulic jack will be similar.

Hydraulic jacks are used to lift heavy objects during their repair.

Possible problems

Of all the reasons why a jack (diamond-shaped, rolling or bottle) may not function, 3 key situations should be distinguished: a malfunction of the rod, a clogged system or failure of the valves. Let's look at each point in more detail.

System clogged

It can be caused by the penetration of dirt, dust or air into the oil. When air enters, the supporting rod of the jack may stop rising, begin to spring intensely, or completely sit down under the load.

Accumulated lumps of dirt can inhibit the movement of valves, which will no longer seal the channels hermetically, allowing oil to pass in both directions.

In this situation, the emphasis will not be held in one position, gradually descending to the starting point.

Ball valve malfunction

In addition to blockages, mechanical defects may occur . The ball valve at the tip of the spring, resting against the cone-shaped groove, can separate or get caught on other components of the system. Then the rod will not come out at all, since the oil circulation in the system is disrupted, and pumping does not occur. This malfunction is more complicated and requires disassembling the jack. If there are signs of wear on the ball valves, they must be replaced.

A bent rod may be a consequence of failure to comply with storage or maintenance conditions and may result from working with heavy loads and as a result of non-compliance with the rules of use. In the first episode, the piston may become covered with rust, which will weaken the tightness of its connection to the surface of the cylinder, as a result of which oil will leak. If you lift loads higher than the permitted limit, the rod may bend. The possibility of such a malfunction increases with the maximum extension of the screw and the jack installed crookedly on the ground. A bent rod is a very serious malfunction that can rarely be corrected even by specialized services.

What to do?

Doesn't hold under load

The lowering of the rod when it rests on the lifted load and sometimes without much pressure happens for 2 reasons: lack of oil or failure of the valves. Let's consider each option separately.

The lack of oil is due to normal leakage due to poor sealing; the jack bypasses oil. As a rule, this is the result of prolonged storage of the jack with the shut-off valve turned off or the wear of the gaskets. The issue can be resolved by adding oil and bleeding the device. It is advisable to use specialized oils for hydraulic systems; at worst, ordinary technical oils will do. If after filling the oil leaks even with the tap tightly closed, you need to buy a repair kit and change all the seals.

Valve failure may be due to contamination of the system or a mechanical defect. There is no need to disassemble the lifting device right away.

It would be wiser to first rinse the channels and internal surfaces that are dirty. For this purpose, drain all the oil from the device and add flushing liquid (gasoline or kerosene will do). It is pumped several times, the used liquid is drained, clean liquid is poured in, and so on 2 more times.

If washing has no effect, you will need to disassemble the jack and inspect the valves. They may not fit tightly due to loose springs or have deformed or worn out balls. The first reason is the most likely and can be corrected by rotating the spring or adding a small washer under it to increase the pressure by reducing the distance to the valve. A worn or deformed ball needs to be replaced.

Doesn't lift well

One of the most common problems is reducing the piston stroke speed to a minimum or idling too much. This malfunction is often associated with a reduction in lift height and a decrease in the maximum load. The main reason for such a problem lies in the airing of the system, which occurs as a result of a decrease in the oil level. Restoring the hydraulic jack to functionality in such a situation is quite simple. To do this, you will need 150-300 milligrams of oil and flushing liquid (if the device is older than 2 years).

First, the shut-off valve is loosened one turn from the tightened position. Then the pump rod is lowered, the stop is all the way to the end.

The plug on the fill hole is unscrewed or removed (if it is made of rubber), and the used oil is drained. When the device is many years old, it is possible that its channels and the surface inside are clogged with dirt, which can be an equally significant reason why the jack does not lift well. It needs to be washed, it wouldn't hurt to wash it several times.

Replacing damaged high pressure hoses

From all of the above, we can conclude that the repair of high pressure hoses consists of either replacing the damaged area or replacing fittings that have become unusable.

When replacing a damaged area, as well as when replacing fittings, you will need to crimp the couplings, that is, technologically these two actions are very similar.

High pressure hoses

The sequence of operations looks like this:

- The damaged sleeve is disconnected from the main mechanism.

- A new sleeve is cut to the size of the old one on a cutting machine. Moreover, for measurement, the distance between the ends of the nipples at its ends is taken. It is better to choose a hose pump designed for a higher pressure than that for which the old hose pump was designed.

- The markings on the sleeves will help you choose the right diameter.

The factory marking DN indicates the diameter of the internal channel of the hose.

If a hose designed for high pressure (heavy hose) is to be repaired, its ends are stripped inside and out to the metal braid. This operation is performed on debarking machines. Then select the necessary fittings. This can be fraught with certain difficulties, since imported fittings are manufactured to different standards. In case of difficulties, the easiest way is to take measurements on the old fitting with a caliper and a thread gauge, which will allow you to accurately set the required diameter and thread pitch and then select the necessary parameters for the new fitting using the tables. After debarking and selecting fittings, they are crimped on crimping machines. Removable crimping jaws are selected for each diameter. Next, the quality of the crimping must be checked. A control probe is used for this, but it is best to carry out testing on a special test bench.

If a non-standard connection is encountered, repairs are carried out using a repair fitting. To do this, take the head of the old fitting, to which the part to be crimped is soldered.

High-pressure hoses

This method is often used by car enthusiasts for emergency repairs of power steering hoses, as well as by owners of Kircher pumps and miniwashes.

Recommendations

To increase the service life of the jack, it is advisable to follow the following rules.

- The lifting device oil must be changed twice a year. If the hydraulic jack is used every day, then it must be replaced at least once a month and must be washed.

- Any replacement oil can be used . But for the winter season, it is advisable to fill exclusively with synthetic types of oils.

- To prevent the lubricant from thickening in winter, the jack should be kept in a dry and warm room.

- When lifting work is carried out in winter, it must be remembered that if the device is used for a long time in severe frost, it can become unusable. In this regard, it is recommended to work with it in the most extreme cases and for a short time.

The ideal “repair” of a lifting device is preventative work to prevent breakdowns, in other words, continuous maintenance and timely replacement of the working fluid with pumping. Since eliminating any malfunction will require spending personal time, and sometimes some money. In this regard, it is necessary to follow all instructions for using hydraulic lifting devices, in which case they will work for quite a long time.

For repairs to a hydraulic jack, see below.

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

A strong and simple assistant in lifting unbearable weights, it has a reliable design that serves as a guarantee of safe work. A high strength criterion is considered the main indicator of the jack’s effectiveness; however, even this level does not exclude the possibility of device failure. In this topic, we have given all the possible causes of breakdowns of hydraulic jacks of any type, disassembled them and compiled step-by-step instructions for eliminating certain malfunctions.

How to register

Use of all the benefits of a personal account is available to existing clients of the provider after concluding an agreement. To register, you need to go to the official website www.akado.ru via a PC, tablet or phone, doing the following:

1. In the upper right corner, select “Personal Account”.

2. For authorized users, login using a login or contract number and password, and for those who logged in for the first time or forgot their password, you need to follow the link “Are you logging in for the first time or have you forgotten your password?”

3. Select authorization by E-mail or phone number.

It is important to indicate exactly the data that was specified in the contract, otherwise the system will not be able to find the information and access to Akado’s personal account will be unavailable.

4. We confirm access to the mailbox through the link in the letter, and the phone number - with a special code.

Possibilities

AKADO Telecom provides a number of advantages for its clients:

- Access to the service even when the Internet is blocked or unpaid . You can make changes to the services provided or pay a bill without leaving your home and without spending mobile Internet traffic. It’s quite easy to forget to pay for the Internet, which is why there is an automatic payment function.

- Automatic payment settings - on the last day of the month or a specific day of the week, the option will save you from performing unnecessary actions and wasting time - you can view all transactions on the account in your account.

- The mobile application allows you to quickly manage services and use partner bonuses.

- The promised payment extends the use of digital services for 5 days, so as not to limit the user in case of unforeseen situations.

Required tools and materials

You can repair a hydraulic jack yourself in your own workshop if you have the required materials and tools. It is worth considering that some versions of the lifting mechanism are represented by non-separable structures, and it will be quite difficult to carry out repair work. The hydraulic jack should be disassembled taking into account its design features. To do this you may need the following tools:

- Hammer and chisel.

- Pliers.

- Screwdrivers of various diameters.

- Hacksaw.

- A set of keys and a gas wrench.

There are simply a huge number of varieties of hydraulic jacks, so it’s difficult to say exactly what tools you might need to get the job done. In some cases, it is possible to easily access the internal mechanism for maintenance or repair; in others, disassembly will take quite a lot of free time.

Data protection

The company carries out effective multi-level work to protect clients’ personal data and the security of financial transactions in the system when working from a PC or mobile device. Provides services to protect clients from hacking and information theft:

- high-quality certified protection of web services and hosting (official certification has been passed for compliance with data security conditions);

- protection against DDoS attacks for clients of different levels of use: from corporate companies to individuals (IP addresses are protected around the clock by ARBOR equipment and other security systems);

- protection of financial transactions and personal data: encryption, confirmation by SMS code, and notification of changes via SMS alerts. To use this convenient service, registration is required, but it will not take much time and will save time later. If you have any questions or problems with registration, please contact your online consultant. Make your life more comfortable by making room for what’s important, entrusting your routine to reliable specialists and proven systems!

It is worth noting that if any problems or questions arise regarding interaction with your personal account, the company’s subscribers can contact the Hotline.

The hydraulic jack has stopped lifting and does not hold under load.

Reading time: 5 minutes

There are many types of lifting mechanisms, the most common among car enthusiasts is the hydraulic type of jacks (bottle, rolling). If improperly maintained, jacks can fail, for example, they stop lifting loads. And the question immediately arises of what to do if the hydraulic jack does not lift. You don’t have to buy a new one right away; there is always a way out; often everything can be fixed by performing maintenance on the unit.

DIY jack repair

It is difficult to find a replacement hydraulic jack for the purpose of lifting and holding equipment. There are various signs that indicate equipment failure. For example, lifting a load is difficult, and the level of lifting height can be significantly reduced.

It is possible that a large number of moves must be made to install the device at the required height. If the hydraulic jack does not go down, this is a clear sign that it is broken. Knowing some breakdowns will help you decide on the choice of pumping method. This includes:

- The presence of rust inside the device, which limits the process of lowering the mechanism to the required position.

- Excessive load experienced by the device, which leads to bending of the rod.

After disassembling the unit, you will notice that the device has a cylinder containing a piston or rod that moves inside it in the presence of working oil. Pressure on the fluid is created during the operation of the cylinder valve. There is a pump that directs the liquid into the cylinder.

The device lowers the load at a speed controlled by the presence of an opening. It is necessary for the incoming liquid to flow out of the cylinder. The jack has threads on the rods, bodies and bases.

Activities for disassembling the jack

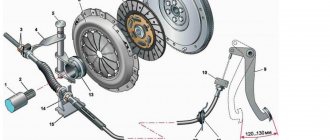

Jack repair diagram.

To open the unit, follow these basic steps:

- The unit is completely disassembled using keys.

- Unscrew the fastening elements.

- Remove the valve from the device, which bleeds the oil, as well as the primary piston.

- A detailed inspection of the unit is carried out to check the quality of the special valve ball and gaskets in order to replace them.

- Clean the device from excess elements and flush the system.

- After opening the unit, change the oil.

This must be spindle oil of a high grade or Total LHM+ type. Next, install other rubber bands and drain the used oil.

To completely drain, the lifting part of the device is moved down and then up. Open chambers allow the release of all piston fluid. The device's pressure spring must be removed. Next, close the valve by bleeding the oil using a shut-off ball. To accurately get the oil into the device, you need to lift the jack up and then lower it down. At the end of the work, fasteners are installed: pins and studs.

The device is equipped with two valves - fittings that open under pressure. Each of them has a spring-loaded “plug”, which is a nail with a head. Its tip should fit into a small hole, and the cap will rest against a special spring.

Read also: Guides for the saw table

The first valve is usually opened by pressure from the lever and is unscrewed to release. The oil is launched into the large “holding” cylinder after it has passed through the small “pumping” cylinder. When the pressure from the lever drops, the valve begins to hold oil while being closed. The second valve is necessary for etching into the reservoir from the large “holding” cylinder under overload conditions.

Before lifting the load, the jack is adjusted to a certain mass of the load so that it cannot burst during pumping, otherwise some parts may simply fly out of the mechanism body. Therefore, pumping the jack requires compliance with safety measures.

First, both valves are disassembled to check where the spring with the “nail” is located and whether they are in the correct position. Disassemble the device by laying down some material or newspaper. They make sure that not a single little thing can fly out of its place and get lost, since a replacement part will then be very difficult to find.

If malfunctions occur after pumping the jack, it is necessary to fill oil through one of the valves, possibly through the first one. The jack foot should be slowly raised by hand, and the fitting should be directed upward, so that when lowering, air can escape, but not completely. This may cause the rubber plug, which is shaped like a large rivet on the surface of the cylinder, to fly out.

By disassembling the second valve, it is adjusted again, taking into account the correct weight. There is no need to tighten it too much, since air deflation occurs under load. Carrying out gradual twisting, lift the load of the established weight. After this, pumping stops. Then they check the possibility of descent in case of excess weight.

Briefly about the main faults

- Stop. Occurs due to the lack of liquid in the chamber or the presence of contaminants in the oil.

- Insufficient lift height. Occurs due to a limited amount of working fluid.

- Slow rise, jerks. Explained by the presence of air, as well as a possible leak in the hydraulic system.

- Reduced pressure. The valve needs to be diagnosed or replaced. In this case, the jack also stops holding, lifting completely, springing, and can lower the load on its own.

Most often on forums you can find complaints that the hydraulic jack does not lift.

Types, properties and characteristics of hydraulic bottle jack

Which 2 ton rolling jack is better?

Jacks are divided into several types, the first division is based on the number of rods (half-rams):

- Single-stem bottle, the most common type Fig. 2.

- Double stem bottle Fig 3.

Fig 2. Single-rod jack

Fig 3. Double-rod jack

There is also a division based on the operating principle of the pump pumping liquid:

- Manual, activated by user pressure on the lever

- Large pumps designed to lift enormous masses are driven by a separate drive, hydraulic pump or hydraulic station.

Properties:

Load capacity is an important parameter that determines the maximum liftable weight. The parameter depends on the volume of the working chamber and strength characteristics. Bottle-type devices have a load capacity from 2 to 100 tons.

The minimum lifting height, otherwise called the minimum pick-up height. This is the height at which the load must already be in order to be able to place a jack under it.

Please pay attention to the minimum height if you are selecting a device for a car. If you have low ground clearance, then a bottle-type device due to its high design will not suit you

Maximum lift height. The height to which a load can be lifted. The bottle ones have a special feature: on the support platform there is a retractable screw that increases the minimum and maximum lifting height.

Design and principle of operation

The design of hydraulic jacks is approximately similar to both rolling and bottle jacks. Main parts of rolling devices:

- piston;

- lever arm;

- stock;

- suction valve;

- stop valve;

- oil reservoir;

- working cavity.

When the handle is lifted up, the shut-off valve is activated, and oil enters the chamber due to the operation of the suction valve. By pumping oil from the reservoir into the cavity of the working cylinder, the piston is raised. Next, to lower the piston with the rod, the bypass valve opens, then under the pressure of the load the piston will lower.

Repair and service

The jack must be disassembled for maintenance. You should not be afraid of this; there is no high pressure in it.

First you need to drain the hydraulic oil. This can be done through the filler plug, or, if it is missing, through the bypass valve. To do this, unscrew the upper hex nut and completely unscrew the lower valve.

Then the housing is removed, the tightness and condition of the lower rubber ring is checked. This element does not carry a large load; it simply prevents liquid from leaking out of the housing. We unscrew the working cylinder from the base and remove the piston.

Why won't the jack go down or up?

Reasons why the jack refuses to work:

- Cylinder failure. The working plane does not support the load; as a result, liquid flows from the cavity into the space above the piston.

- Damage to the mirror. Hydraulics lose efficiency or simply fail, this occurs due to improper transportation, it can lead to oil leakage and air entering the chamber, in which case corrosion will certainly begin over time.

- Corrosion. Leads to rapid wear of the cuffs and seals, which may result in dirt getting into the liquid and clogging the channels and valves.

- Unit fall. The greater the height from which the jack falls, the more serious the deformation of parts and main components can be.

- Too much load. Causes the rod to bend. This leads to misalignment of the main components and oil leakage.

- Use of the device for purposes other than its intended purpose, as well as failure to change the oil in a timely manner.

Hydraulic jack pumping technology

How to place a rolling jack under a car

Bleeding a hydraulic device begins with flushing the hydraulic device mechanism.

Washing the instrument ensures normal operation of the instrument. During operation, contaminants penetrate into various parts of the mechanism, which can cause serious damage, including the failure of the unit to operate.

After draining the working fluid, the container is filled with special flushing fluid. During the washing process with a special liquid, all contaminants are removed from the device. After removing contaminants, the special flushing fluid is drained and the tank is filled with working fluid. During the pumping process, the working oil passes from the filling container into the working cavity; this process is carried out quite quickly and does not take much time.

During the procedure, air is gradually displaced from the working cavity. The pumping operation should be repeated until all air bubbles are forced out of the reservoir. All operations to replace the working fluid and flush the device should be carried out in full accordance with the instructions supplied with the device by the manufacturer. The fact is that hydraulic devices of different designs have different technologies for replacing the working fluid.

After completing the work, close the bypass valve and the oil reservoir opening.

Troubleshooting Methods

Oil leakage is the main problem, due to which the rolling jack does not lift completely (if the leak is small) or at all (if the leak is significant). Because of this, air enters the cavity, and then the hydraulic jack works with little force or refuses to work at all. Leaks in the hydraulic system can be prevented by routine maintenance and checking the oil level. If the level is low, you just need to add fluid to the normal level.

Due to lack of fluid, air leaks into the hydraulics. This problem is solved by bleeding: you need to unscrew the cap of the oil tank and the bypass valve, and then simply pump the system, that is, move the lever up and down until the liquid passes into the main cylinder.

Hydraulic lift device

The main components of the system are the housing, the movable piston and the liquid medium (machine oil). The body is made of durable metal in the shape of a cylinder. It serves as both a guide for the rod and a container for technical fluid. Additional elements that bring the device into operation:

The use of valves makes it possible to increase the force applied to the lever tens of times. The plunger is necessary to move the piston by transporting the working fluid into the container below it. The valve prevents liquid from flowing back into the common container. Gradually, the plunger pumps more and more liquid under the piston, raising it. And in order for the load to drop, you only need to allow the oil to return to the common container by slightly opening the valve.

Fault Detection

The rod extends to the desired height, but then slowly (without load) lowers - in this case, the reason is most likely in the bypass valve and damaged o-rings, so the required pressure is not maintained.

If the rolling jack does not lift to the end, it means that the working stroke has decreased. At this point, the culprit is the corrosion that has formed on the rod and the surface of the cylinder. If the load being lifted is greater than the lifting capacity of the jack (indicated in the passport and on the body in tons), then there is a possibility of damage to the rod and its bending.

In order for the jack to serve for a long time and not break, you must remember the following rules:

- Hydraulic fluid replacement is necessary 2 times a year.

- If the lifting device is used every day, the hydraulic fluid should be changed monthly.

- In extreme cases, any hydraulic fluid can be used, but in winter it is recommended to use synthetic oils specified by the device manufacturer.

- To prevent the oil from thickening in winter, it is necessary to store the jack in a dry, warm place.

- It is not recommended to use the jack in the cold in winter, because it may simply stop working.

To fix a breakdown, you can lose a lot of time and money, so it’s easier to follow the operating instructions for a hydraulic jack, and then it will last a long time and will help lift the load more than once.

Rolling jack: principle of operation

A rolling jack is classified as a hydraulic jack, but has a slightly different design.

Two pairs of wheels are installed on its body, made of metal. A lifting mechanism and a hydraulic cylinder are mounted in the holes located on it, which, when extended in the horizontal direction, lifts the platform. The device itself gradually lifts the car to the desired height, while it rolls under it. The jack is set in motion by swinging the lever, and lowered by turning the valve screw. During the process of lowering the load, a tubular handle is mounted on the valve screw, and after that the partition fits into its groove. When the handle rotates around its axis, the screw itself rotates accordingly. In this case, the pressure in the working cylinder is released, and the load is lowered to the desired height.

In order for the jack to serve for a long time, it is necessary to monitor the presence of oil in it and the condition of the oil seal and valves.

There are rolling hydraulic jacks used for personal purposes for vehicles weighing up to 3000 kg. Most often, such a device, equipped with pedals necessary for preliminary lifting, is used in car services and tire stations. It can lift loads up to 4000 kg, doing the job quite quickly.

The jacks, which lift loads of up to 20 tons and are equipped with pre-lift pedals, as well as a sliding crossbar, are intended to serve heavy vehicles and special vehicles. This mechanism also has its drawbacks, which include its bulky size and heavy weight, which make it difficult to move it in a car. For its operation, a flat horizontal surface, such as asphalt or concrete, is required.

About the club

The Ost West yacht club grew out of the sailing section of the 93rd sports club of the Baltic Fleet.

In 1985, three no longer new keel sailing yachts appeared in Kaliningrad. Two “Quarter Ton” classes and one “Half Ton” class. All hulls are wooden, built by the Tallinn Experimental Shipyard for Sports Shipbuilding. Active Navy officers at that time were appointed captains of the yachts: Bagrov I.L., Zhadobko S.M., Nechastkin O.A. Later, in 1987, two more new yachts appeared: the wooden “Quarter-tonner” “Nord” and the plastic “3/4-tonner” “Askold” (Type “Teliga-104”, Polish-built). With the beginning of perestroika in the early 90s, when more or less free navigation was opened on the World Ocean, and not just in the territorial sea of the USSR, the crews literally rushed “to the West.” “Quarter-tonners” (captains Zhadobko S.M., Gorshkov V.S., Nechastkin O.A.) actively explored the Vistula and Gdansk Lagoons - the ports of Gdansk, Eldblong, Gdynia, Krynica Morska, Hel and since then the yachtsmen of our club have exclusively supported warm and friendly relations with Polish yachtsmen in this region. These relations have never, not once over the past years, been overshadowed by political squabbles between our states.

With the advent of the Askold yacht, long-distance sports trips were made every year. The ports and yacht harbors of Poland, Germany, Denmark, Sweden, Holland and Great Britain have been developed. The campaigns also had a political background: we carried the flag of a new state – Russia – to the West. At that time, the following captains served on the Askold in different years: V.S. Gorshkov, S.M. Zhadobko, I.L. Bagrov.

In the fall of 1992, officers - members of the sailing section of the Baltic Fleet Sports Club participated in the daring, in essence, and essentially unsafe, withdrawal of two yachts from the Riga Navy Yacht Club to Kaliningrad. Shutkin A.N., Korogodsky S.N., Gorshkov V.S. took part in this extreme hike. and other naval officers. Despite resistance, including from Latvian security forces, the yachts safely reached Kaliningrad. These were wooden yachts: two built by the Leningrad shipyard of the All-Russian Central Council of Trade Unions of the type “L-6”, “Arctic” and “Baltika”, as well as one “Quarter-tonner” built in Tallinn “Ushkuinik”. The yacht “Baltika” stood on the wall during the 1993 navigation until the crew was led by yacht captain S.V. Evchenko.

In 1993, a crew of Navy officers with Captain V.S. Gorshkov. on the yacht "Arctic" was invited by the heir to the English throne, Prince Charles, to the royal yacht club "Wolverstone" (Port Ipswich) to celebrate the 150th anniversary of the formation of this yacht club.