- Work principles

- Determining possible damage

- “We treat” the adsorber

- Replacing the adsorber

- We repair the valve

- Valve replacement

- Removing the adsorber

- Useful video

Adsorber, a term coined from English, denoting a part of a vehicle responsible for absorbing combustion products by liquid (solid) bodies in a special container. The VAZ 2114 adsorber (some call it an absorber) uses activated carbon as an absorbing element, which is what the domestic model is filled with.

The adsorber is a complex mechanical joint, sold and installed on the car, according to the kit, from the following elements:

- the adsorber itself;

- purge valve;

- gravity valve;

- vapor separator;

- tubes: steam line, valve, adsorber;

- fuel drain pipe;

- additional hoses.

Adsorber VAZ-2114: design review, features and causes of malfunction

First, you need to understand what adsorption is.

So, this is a certain process due to which the absorption of liquid and solid gaseous substances is carried out. A striking example of this can be the world’s first gas masks, where Activated Carbon acted as an adsorber. In the VAZ-2114 car, the adsorber is approximately the same device, only its design has become much more complex. A car adsorber today is a plastic case, inside of which there is a special filler that can trap gasoline vapors, thereby protecting the atmosphere from pollution. But this detail on the VAZ-2114 is not limited to this. The fact is that the adsorber also includes various valves and pipes.

If you decide to completely remove the adsorber, you will need:

- replace the gas tank cap with a leaky one;

- replace the firmware of the electrical control unit;

- plug the outlet and supply pipes.

Those car owners who convert a carburetor engine to an injection engine have an undeniable advantage. If they do not touch the tank pipes, then they will not be able to disrupt the carburetor ventilation system. In this situation, there is no need for an adsorber in such cars.

In the case of the VAZ-2114 car, which has an injection engine, everything is much more complicated. However, there is no need to remove the adsorber either. It should be noted that the only positive aspect of having an adsorber is the reduction in the amount of harmful emissions into the atmosphere of our planet. The undeniable “disadvantages” of this part include the rather high cost, as well as too much space occupied by the adsorber under the hood. It is the last two facts that, as a rule, become the reason for making a decision to remove it.

But most often, car enthusiasts remove the adsorber after it has failed. Its cost is so high that car owners come to the conclusion that they are not really concerned about the state of the Earth's atmosphere. Moreover, removing this part is quite simple. To do this, you need to put a fine filter on the separator hose.

Adsorber, a term coined from English, denoting a part of a vehicle responsible for absorbing combustion products by liquid (solid) bodies in a special container. The VAZ 2114 adsorber (some call it an absorber) uses activated carbon as an absorbing element, which is what the domestic model is filled with.

The adsorber is a complex mechanical joint, sold and installed on the car, according to the kit, from the following elements:

- the adsorber itself;

- purge valve;

- gravity valve;

- vapor separator;

- tubes: steam line, valve, adsorber;

- fuel drain pipe;

- additional hoses.

This is what this process looks like when the engine is turned off, when the engine is running, the system opens the adsorber valve (purge valve), when the valve is open, the vapors do not reach the absorber, but are directly blown into the intake pipe, where the engine successfully burns them.

- Increasing the environmental friendliness of the car due to the absorption of fumes.

- Fuel economy when driving (savings are 1%, but present).

As we figured out, gasoline vapors are absorbed by the adsorber or blown into the intake valve, which is responsible for changing operating modes and controlling the system. It switches during system startup, thanks to the engine start controller; during ignition, it turns on the receiver, the sorbent is purged and unabsorbed vapors are immediately sent to the engine, saving every milligram of evaporated fuel.

In addition to the above advantages, the system also does not allow the smell of gasoline into the lard of the car, but such a system also has disadvantages (albeit controversial), motorists complain that it:

- takes up space under the hood;

- is the culprit of unstable operation when broken;

- Expensive.

But in order to supply cars to other countries, they have to be improved and adjusted to standards, including environmental ones. And immediately you need to highlight two main points:

- An absorber is a substance that absorbs vapors. In this case we are dealing with activated carbon. It is also used in gas masks.

- An adsorber is a device in which the vapor absorption process takes place.

This, in general terms, applies specifically to cars. In fact, absorbers can be of several types, just like adsorbers. But if you need it, consult your chemistry textbooks.

Canister purge valve

What is an adsorber in a car and why is it needed: we explain in detail.

I decided to call this article exactly that, although the adsorber valve itself is not the main character here. It all started when my engine fault light came on (the check engine light came on). I waited for the next maintenance (fortunately it happened shortly before the scheduled maintenance) and informed the car service employees about it. They carried out diagnostics and said that the culprit was the canister purge valve, but they did not have this valve in stock, and for now it was possible to drive as is. I must say that at that time there were two weeks left before the end of the warranty, but they swore that they would replace the valve free of charge, even if the warranty had already expired by the time the valve arrived at the warehouse.

I was happy (despite everything, I never stop believing people)))), and in the article Three years on Priora I hastened to write that the adsorber valve was replaced under warranty. However, I was in a hurry...

As you may have guessed, no one was going to change anything for me for free. After several dozen phone calls to the car service center, I came to the disappointing conclusion that I had been duped once again. There was neither time nor desire to go to court over such a trifle. And I decided to change the canister purge valve on the Priora myself. But the experience of dealing with car services still taught me something, and I decided to check whether this ill-fated valve was really the problem.

The Priora's standard computer showed error 4. This is an error in the coolant temperature sensor. Of course, this could have been an accidental mistake. I didn't have the opportunity to use another computer or connect a laptop, so I tried to determine the source of the problem based on the symptoms. And the symptoms were:

- Sometimes (rarely) the engine was not very stable at idle

- Fuel consumption has increased quite slightly (almost imperceptibly - pure intuition)

- Sometimes a hot engine would not start the first time

- The engine began to pull worse (especially at low speeds), but also not much worse

After surfing the Internet, I came to the conclusion that the malfunction was somehow related to the air. And I read in several sources that the cause of this problem may be worn out rubber bands on the exhaust manifold fittings (see Fig. 1).

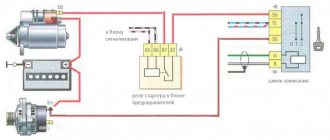

Rice. 1. Canister purge valve.

For various reasons, these rubber plugs deteriorate and lose their seal. Through the formed holes (Fig. 2), air begins to be sucked in, which leads to minor disturbances in engine operation.

Rice. 2. Damaged plug.

They write on the Internet that instead of these rubber bands you can use rubber bands from the brake cylinder bleeding fittings. You can probably install other suitable rubber bands. However, I only had tape on hand. I carefully wrapped the damaged elastic band with this tape (Fig. 3).

Rice. 3. Repair the plug using tape.

And, lo and behold, the engine malfunction light went out (of course, after resetting the errors). Of course, tape is a temporary solution to the problem. Most likely, it will not withstand temperature changes, especially in winter. But I’ve already been away for several weeks and so far everything is fine.

Conclusion

: no matter how developed the diagnostic tools are, people who work with them do not always have sufficient qualifications. And it may well be that in your case, instead of purchasing a new adsorber valve for 1500...2000 rubles (or so), you will solve the problem with the help of adhesive tape and such and such)))))

Well, if you still suspect the adsorber valve, then you can check its operation using improvised means.

We disconnect the negative terminal of the battery and remove the canister purge valve, which is held on the plastic engine cover with a latch (Fig. 1). Disconnect the power supply to the valve and the air supply/exhaust hoses. Then we try to blow the valve through the holes for the hoses. A serviceable valve is closed when the power is turned off, that is, it should not be purged.

Then carefully connect two wires to the valve power connectors and connect them to the battery (polarity does not matter). The valve should click quietly, that is, open. We try to blow out the valve again, now air should pass through the valve freely, that is, when power is applied, the valve opens. Turn off the power - the valve should close again and stop blowing.

If you succeeded in all this, then the valve itself is 99.99% likely to be working. However, there remains the possibility of malfunction of the valve control circuits. But that is another story…

Valve check on site

You will need a tester (voltmeter, multimeter) and a screwdriver. The KPA itself is installed on the radiator frame. The device can be recognized by seeing two tubes approaching it, through which the evaporation moves. Further:

- disconnect the electrical connector from the control unit by releasing the block lock;

- using a multimeter, check for the presence of voltage by touching the negative (black) probe of the device to ground, and the red probe to “A” (the letter on the block connector);

- turn on the ignition: the multimeter should show the vehicle's on-board voltage. If not, check the wiring.

Replacing the adsorber purge valve (KPA) on a Lada Granta on your own

Design and features of the oka carburetor

Today's article will be devoted to the fuel vapor recovery system, or more precisely, to the adsorber purge valve. You will learn what an adsorber purge valve is, what it is intended for, how to understand that the purge valve has failed, and also how to replace the control unit on a Lada Granta.

A little theory...

What is a canister purge valve?

In fact, the topic is quite extensive and it would take a very long time to describe the operating principle of the control unit, as well as all the intricacies of the fuel vapor ventilation system. But since the main idea of my article today is to replace the adsorber purge valve with your own hands, I will only touch on the theory superficially.

In general, as environmental standards and requirements of international associations for automakers became more stringent, cars began to be “overgrown” with various sensors, controllers and entire systems, the main task of which was to reduce the level of harmful emissions into the atmosphere. And if the catalyst burns already exhaust gases and neutralizes the level of harmful CO/CO2/CH/NO, then the adsorber fights fuel vapors.

The adsorber, which I already talked about once, is a small box or reservoir filled with fine coal, which absorbs fuel vapor, thereby performing two functions - ventilation and neutralization of harmful fumes. The work of the adsorber is extremely important when the engine is stopped; it is after you have turned off the engine that the adsorber begins to absorb and neutralize all fumes coming from the fuel tank.

When you start the engine, the adsorber purge valve turns on. It provides ventilation for fuel vapors, which are removed from the adsorber and enter the intake manifold, where they are burned during engine operation. In this way, the adsorber is “purged”, ventilated, and harmful fumes are neutralized by burning them

Read more about what an adsorber is, the principle of its operation, as well as the main malfunctions in this article, if you are interested, you can be curious, and we will move on to a more important topic

Error P0441 appears - “Incorrect air flow through the adsorber purge valve”; Fuel consumption increases; Dynamics worsen; Unstable engine operation at idle.

How to check the Lada canister purge valve?

- We remove the PDA and supply 12 V power to the terminals. The working valve should click; if the valve does not make any sounds or clicks, it is most likely out of order or, in other words, jammed.

- Second way to check. We take the CPA and try to blow it out with our mouth; if it blows through without problems, then the valve is not working. A working purge valve cannot be purged without power.

Replacing the canister purge valve on a Lada Granta with your own hands

In the store we buy a new control unit, as well as two small clamps and a hose of a suitable diameter, usually a fuel hose is suitable. We take a minimum set of tools (screwdriver, knife, pliers) and get to work, the whole process will take you no more than half an hour.

- The first thing to do is to remove the air corrugation from the air vent body; to do this, take a screwdriver and loosen the clamps. We remove the pipe and under all this equipment we find our valve.

- We disconnect the KPA mount and turn off its power; it has a block with a latch that you need to press on. Then disconnect the canister valve pipes one by one.

- One hose is the one made of “oak” plastic, put on a fitting, you can simply cut it off, don’t try to remove it, even if everything works out, it won’t stick tightly to the new valve. Moreover, we have everything provided and a new pipe has been prepared. If you really want to, you can use sealant and try to seal the connection of the old hose with it.

We remove all quick-release connections and twist them onto a new hose.

It is important not to mix up the hoses and connectors themselves, so as not to disrupt the operation of the ventilation system

We assemble everything in the reverse order and fasten the air duct pipe in place. Next, start the engine and make sure that the problem has disappeared. It is better to erase the error first.

I’ll end here, as you can see, there’s nothing complicated. Replacing the canister purge valve is not much more difficult than replacing the air filter. Try it and you will definitely succeed. If the article was useful to you, share the link to it with your loved ones by copying the link for social networks or using the special buttons below. I would also be grateful if you leave a meaningful comment. Goodbye everyone and see you again at VAZ Repair.

Photo from here: https://www.drive2.ru/l/8677844/, https://www.drive2.ru/l/7641808/

How to replace the adsorber on a VAZ 2113-VAZ 2115?

Note! A block of wires is connected to the adsorber, and you will have to work with it; dirt should not get inside the block (Watch this) as well as moisture, so in order to protect this block from a short circuit (What if water gets into it), we recommend that you first operation to remove the minus terminal from the battery, if you do not know how to do this, then in this case read the article entitled: “Replacing the battery on a VAZ”, paragraph 1 of that article says it all!

Removal: There is nothing complicated in its removal, you will only need to use a screwdriver to loosen the clamps of the hoses that go to it (There are 2 hoses in total, you can see them perfectly in the photo below, they are indicated by red arrows) and then disconnect these hoses from it when the hoses are disconnected, press the latch that holds the wire block (indicated by a blue arrow) and disconnect the block, after disconnecting it, slightly loosen the bolt that tightens the clamp, which in turn holds the adsorber in one place (you can see the clamp bolt in the small photo) , well, after which you can easily remove the adsorber and replace it with a new one.

Installation: Installing a new unit occurs in the same way as removing it, you just need to do all the operations in the reverse order of removal.

Complete removal of the adsorber from the power system

Electrical equipment of the VAZ 2107: design, operating principle and connection diagrams

Some VAZ 2114 owners decide to completely remove this part from their car for reasons of savings and to prevent future malfunctions. There are two ways to do this.

Method 1. After completely removing the adsorber from the VAZ-2114, the hose leading to the throttle valve assembly is closed using a plug. A fuel filter from any VAZ carburetor engine is inserted into the hose running from the gas tank to the adsorber.

Method 2. The adsorber is removed along with the support. The hoses previously connected to it are closed using plugs. A small hole (1-2 mm) is drilled in the standard gas tank plug to connect the cavity to the atmosphere. You can also use the cap from a carburetor “eight” or “nine” to depressurize the fuel tank.

After upgrading the power system, it may be necessary to update the firmware of the engine control unit, since it will perceive the absence of an adsorber as a malfunction in the engine and switch to emergency operation. This threatens to significantly reduce the traction qualities of the car.

The adsorber in the VAZ-2114 is an important element in the engine power system, which allows you to slightly reduce fuel consumption and eliminate the smell of gasoline in the cabin.

To perform work on replacing and checking the adsorber purge valve you will need:

- Disconnect the wiring block from the canister purge valve.

- We connect the negative probe of the multimeter to the “ground” of the car

- Turn on the ignition and check the supply voltage at terminal A of the wire block. The voltage should be 12V. If the voltage is less or absent, you need to check the battery charge, the health of the power circuit and the serviceability of the computer.

- Loosen the clamp securing the hose to the valve and remove the hose. In this case, you need to make sure that the hose does not break off.

- Using a screwdriver, remove the valve from the adsorber.

- To check the functionality of the valve, you need to apply 12V voltage to the valve terminals. The plus goes to pin A, and the minus goes to pin B. After power is applied, the valve should open with a characteristic click. If this does not happen, the valve must be replaced.

- Before installing a new valve, check the O-ring. A damaged ring must be replaced.

- We install the new valve in place in the reverse order.

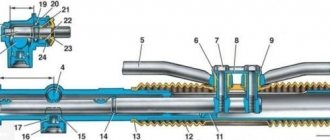

Removal and installation

Dismantling of the part is carried out according to the following algorithm:

Step 1. Disconnect the clamp from the negative terminal of the battery and block the wheels using the parking brake (“put the handbrake on”).

Step 2. Remove the wire from the adsorber valve (VAZ-2114).

Step 3. Using a Phillips screwdriver, loosen the clamps and remove the hoses from the fittings. The latter are made of plastic and break easily.

Step 4. Use a flathead screwdriver to pry the latch on the valve body and remove it.

Step 5. Loosen the clamp securing the adsorber body and pull out the latter.

Step 6. Unscrew the 3 nuts securing the front shock absorber from the side of the expansion tank and remove the plate on which the adsorber is attached. This step is only necessary if the part is completely removed from the power system.

Device and principle of operation.

The adsorbent system is an integral component of a modern vehicle. A properly functioning filter does not affect the functioning of the engine. Moreover, it allows you to save a little on gasoline, because the trapped fuel vapors are not thrown out, but burn in the engine.

Is it possible to ignore environmental standards and remove the adsorber from the car? This can be done, and it will not affect the operation of the car in any way. From a technical (but not environmental) point of view, this is even better - vapors from the tank will escape directly into the environment, and without additional cans, valves and tubes, the reliability of the car will increase.

Disabling the adsorber has other positive aspects:

- the engine compartment space is significantly freed up, because the system (especially the filter bank) takes up a lot of space;

- the known problem of unstable engine idle operation disappears;

- There is a small cost savings due to the unnecessary purchase of a new adsorber and valve in the event of their breakdown.

At the same time, we should not forget what threatens the shutdown of the adsorbing system, namely:

- There will be a smell of gasoline inside the car, because some of the vapor will go into the cabin;

- light hydrocarbons will be released into the atmosphere and pollute the environment;

- the car itself (outside) may also begin to smell of fuel.

The valves in the absorber are a technically simple device that operate differently depending on whether the engine is running or not. Like all valves, it must open and close.

When the absorber cavity is clogged or some other malfunction occurs, the valve malfunctions. With a faulty adsorber valve, serious vehicle damage can occur because pressure is not released from the fuel tank and the cavity is not purged.

Many car enthusiasts decide to remove a functional adsorber, considering it an unnecessary element in the car. At the same time, not all motorists can justify their actions.

There is also a category of car enthusiasts who remove the device if it breaks and do not return the new element to its place. The reason is the high cost of the adsorber, which was mentioned above.

The work of discarding the adsorber (if you know some aspects) takes no more than 5 minutes. All that is required is to put a fine filter on the separator tube.

In this case, fuel vapors are directed into the atmosphere. In this case, the tube from the valve is closed, and the ECU program is adjusted. If you do not perform the last action, an error appears.

POPULAR WITH READERS: Car hydroplaning, what you need to know, how to avoid

How long does the adsorber last and what are the first signs of its malfunction?

It is impossible to determine a product malfunction visually. But there are a number of signs that signal a problem almost immediately after its appearance.

Among these signs it is worth highlighting:

- Increased pressure in the tank, which manifests itself as a “hissing” sound when the lid of the fuel container is unscrewed. The reason for the phenomenon is the accumulation of vapors that have nowhere to go.

- Floating car speed at idle. The difficulty is that there are many reasons for this, and the malfunction manifests itself less often. Still, you shouldn’t ignore the problem. The issue of “floating” speed at idle should be considered separately. To check your suspicions, you need to discard the tube that leads from the manifold to the valve and install a plug (an alternative is to bend or tighten the tube). If the malfunction does not go away, then there is a high probability of contamination of the adsorber.

- Decrease in dynamics while accelerating. This problem is explained by a drop in the performance of the fuel pump due to insufficient vacuum in the fuel container.

- Valve silence. Experienced car enthusiasts know that during acceleration the operation of the valve is easily diagnosed - it begins to tap or click. If this is not the case, then the malfunction will soon manifest itself.

In the situations mentioned, the only correct solution is to replace the faulty unit and install a new adsorber. In this case, the work takes no more than 15 minutes (the sequence of actions for replacement is discussed below).

Adsorber failures

The adsorber, like any other device operating on a car, may at some point become faulty. And in the case of an adsorber, this is not surprising at all, since it is susceptible to clogging.

Determining that the adsorber has failed is quite difficult. This can be done only based on secondary symptoms, for example, increased pressure in the gas tank. If the adsorber is clogged, gasoline vapor remains locked in the tank space, and therefore the pressure on its walls increases significantly.

However, it also happens that the pressure in the tank increases so much that the cap can no longer stay in place, as a result of which it simply shoots off. This indicates that the pressure in the tank has reached its critical point as a result of a malfunction of the adsorber, which, in turn, requires urgent replacement.

By the way, many car enthusiasts firmly believe in the fact that by removing the adsorber on a VAZ-2114, nothing bad will happen. But in reality this is far from the case. Moreover, we should not forget that car manufacturers never equip cars with unnecessary parts. It's simply not profitable for them.

Therefore, simply removing the adsorber will not be enough. It needs to be repaired. The most problematic area of this unit is the purge valve, which, by the way, can be repaired by yourself. The only tool required for this action is a flathead screwdriver. But you should be extremely careful when removing it. The fact is that the mount for this valve is made of plastic, which means it breaks easily.

If this problem is not corrected, the Check Engine light on the vehicle's dashboard will constantly glow, and normal driving dynamics will be lost. Moreover, malfunctions in the adsorber or valve may cause unstable engine operation at idle.

We have figured out why the adsorber is needed, now let’s determine the signs indicating its failure. Considering the quality of fuel at gas stations in our homeland, this part often becomes dirty and fails.

Any malfunction of this mechanism can be easily determined by obvious signs:

Damage to the absorber - the fact that this mechanism of your car has problems can be determined by hearing a hissing sound when opening the tank, it indicates the accumulation of an excess amount of gasoline vapor.

Excessive pressure appears in the tank when you open the lid, there is a moment when the contact area with the external environment is small, and the pressure is quickly “relieved” through it, and the tank “hisses”, similar to a bottle of soda.

Valve failure - this will be recalled by instability of the engine at idle speed, the car will begin to randomly increase (lower) the speed itself and stall.

Before repairing, you need to make sure that the problem is here:

- Use a flat-head screwdriver to unscrew the fastener on the motor cover (be careful, the fastener is plastic, you shouldn’t break it), and then very carefully remove the clamps.

- We remove the part and blow out the valve. If air does not pass through, then the valve is operational, and the breakdown is elsewhere; if air passes through the valve, then you have found the problem.

A valve failure, in addition to unstable idle speed, will soon give you CheckEngine and significantly increased consumption.

And a less obvious sign is unstable idle speed. True, this symptom appears somewhat less frequently. The best way to solve problems is to completely replace the device, since its cost is relatively low. The price, depending on the manufacturer, ranges from 600-1200 rubles. But some motorists decide to remove the VAZ 2114 adsorber completely. What is needed for this?

And now in more detail

How can I check the functionality of this device? An important element in the absorber is the valve. To understand the function, let's look at how the adsorber works. When the car is parked, a large amount of gasoline vapor can accumulate in its tank. Some of the vapor is caught by the recuperator, and the rest settles back into the tank. The part that was caught is sent to the adsorber. When the engine is running, the absorber valve closes and interrupts the access of vapors, now they are sent into the combustion chamber. Why is this necessary? When you start the car, our device prevents vapors from entering the exhaust manifold, thereby reducing the amount of harmful substances in the gas.

What is a filter element and how does it work?

In simple terms, the absorber is a large can filled with activated carbon. In addition, the system contains:

- Separator with gravity valve. It is responsible for trapping fuel particles. The gravity valve, in turn, is used very rarely, but in an emergency (for example, if the car overturned during an accident), it will prevent fuel from overflowing from the gas tank.

- Pressure meter. It is necessary to control the level of gasoline vapor in the tank. As soon as their level is exceeded, harmful components are released.

- Filter part. In fact, this is the same can of granular activated carbon.

- Solenoid valve. Used to switch between modes for capturing emitted gasoline vapors.

If we talk about the principle of operation of the system, it is very simple:

- First, gasoline vapors rise in the gas tank and are sent to a separator, where partial condensation of the fuel occurs, which is sent back to the gas tank in liquid form.

- That part of the vapor that could not settle in the form of liquid passes through a gravity sensor and is sent to the adsorber.

- When the car engine is turned off, gasoline vapors begin to accumulate in the filter element.

- As soon as the engine starts, the canister valve comes into play, which opens and connects the canister to the intake manifold.

- Gasoline vapors are combined with oxygen (which enters the system through the throttle assembly) and pass into the intake manifold and engine cylinders, where harmful fumes burn out along with air and fuel.

As a rule, it is the adsorber valve that fails. If it begins to open and close in the wrong mode or fails completely, this can negatively affect the operation of the entire vehicle and cause breakdowns.

Operating principle

So, what does the process of purging the adsorber in a VAZ 2114 look like? When the car is parked, gasoline from the tank evaporates and first enters the separator. There, some of the vapor turns into liquid and flows back. The remaining gaseous fuel, moving along the line, enters a sealed adsorber. Activated carbon absorbs vapors and holds them until the engine starts.

When the ignition is turned on, voltage is applied to the valve from the controller that controls the engine and it opens. While the engine is running, the filler heats up and dries, releasing gasoline vapor back. Under the influence of vacuum in the intake receiver, they are sucked into the engine along with the main portion of fuel.