The clutch in cars is one of the main components that ensure the movement of the vehicle. Its failure threatens to completely immobilize the device. In cars with a manual transmission, the driver directly controls this unit using the leftmost pedal located under the steering column.

But in order to ensure a smoother and quieter ride, it is necessary to understand which components are activated when you press the pedal, as well as how to prevent possible malfunctions and make repairs if necessary.

The clutch mechanism includes two types of cylinders: slave and master. This material is useful if it is necessary to replace the main clutch slave cylinder. The main component of the work is the hydraulic drive, which ensures the movement of the cylinder. The operation is based on the reception of force that comes from the master cylinder, the movement of which moves the clutch release fork.

The design of the slave cylinder is almost the same in all car models with a manual gearbox, so the operating principle is the same. Typically, the following set of parts is used in manufacturing:

- retaining ring

- cap

- union

- plate

- boot and o-rings

Chevrolet Niva › Logbook › Replacing the Clutch Slave Cylinder.

Well, my patience has run out.

For 2 months it was leaking from under the car, namely from the working cylinder. Sometimes it got to the point where you would come in the morning and the pedal would already be empty. I forgot to top up the brake fluid in the evening, but it all ran away. Of course, I have a bonus that there is almost unlimited quantity of brake fluid. Top it up and let’s pump the pedal, 15-20 minutes are wasted. I endured and endured, and I went to the nearest one, Bal*K**, luckily it was nearby. It turned out that this spare part is present, 950 rubles. The manufacturer is really strange, “KAC”, let’s see how it behaves.

Having reached the garage, it turned out that we needed to sort out a little of the accumulated “junk”. Having dived into the hole, I found out that there was no dripping here, but simply flowing like from a tap,

Plus the barrel itself is cracked and needs to be replaced. It came, as they say, in one wave. To begin with, so as not to suffer later, unscrew the brake fluid supply hose to the working cylinder (17th key) and then you can safely unscrew the two bolts securing the bracket (13th key). Do not lose the plate that is under the cylinder; it presses the cylinder to the bracket and is located between the bracket and the gearbox housing, with the convex part outward. After you’ve collected everything that spilled out on you, you can safely unscrew the cylinder itself from the hose (be careful there’s a copper washer there, I don’t remember the size, but it’s better to replace it). Hurray, a stream of brake fluid started flowing at me, let it flow out, it’s not scary, but it’s realistic to get into trouble trying to fit a new cylinder. And so, nothing drips on me, I can collect it. Screwing on a new cylinder is not difficult; the difficulty arises when installing the rod. The thing is, my car doesn’t have a stabilizer (for religious reasons), which means I have nothing to rest the mounting on to pull the fork back. Fortunately, there was a bolt of the front lower silent blocks lying nearby, so I fixed it.

In your case, everything will be easier; you will have a stabilizer that you can rest against (Don’t forget to coat the rod with grease). Hurray, the rod is in place, tighten the hose, unscrew the bleeder fitting and climb out of the hole.

The turn has reached the barrel, there are no difficulties at all, 2 nuts for 10 and a clamp for 7, ready. I fill up the brake fluid and wait, since the classic pumping method alone will not work for me, so I go with my own method. The fact is that the hydraulic line is not large and is located almost vertically. Thus, you can bleed the system alone, by gravity, to squeeze out the air. We wait about one barrel for leakage, close the fitting and you're done, let's go check. Hooray! works)

P.S. For repairs using tools you need: 8 key 13 key 17 key Installation.

Source

Diaphragm spring

During operation, this disk is acted upon by a diaphragm component, which is designed to provide the required compression force. This is necessary to transmit torque. The outer diameter of this spring presses on the pressure plate with its edges. At the same time, the inner one is made in the form of metal petals. The release bearing acts on them. Together with the disc and diaphragm spring, as well as with the housing, a single unit is formed, which is called the clutch basket. It is rigidly fixed to the flywheel.

Chevrolet Niva GOLDEN_FLY › Logbook › Replacing the rcs

12/13/2020 200055 km - 16372 rubles

Got around to replacing the clutch slave cylinder

I wanted the best...it turned out better than I wanted

Knowing that the rcs was leaking and having experience in restoring the cc and cc by replacing the repair kit, I bought it

And crawled under the car on the courts

I cleaned the cylinder of dirt and started removing

I wanted to unscrew the cylinder from the hose and fix it somewhere more comfortable and warm, but nothing came of it at all.

Then I decided to do everything in a canopy

My first thought was to buy the same one (I think they are on sale) and continue what I started, but something prompted me to buy a new control center and replace it in the assembly

I don’t trust Phoenix more than Samara, so I took the lower option

Due to the missing pressure plate, I also had to take a bracket

It was already sunset and before it got dark I still couldn’t unscrew the rcs from the hose (or vice versa)

But the morning is wiser than the evening...the idea came to unscrew the hose higher up from the tube and remove it from the bracket. Not an option at all - you can’t get it in / you can’t unscrew it.

Then the idea came to unscrew the entire line from the main central station, but there was no less trouble there...

Having suffered quite a bit on the courts at minus fifteen with the hose, having pretty much licked the edges, it was decided to remove the piston from the RCS and replace it with a new one from the box, along with the rod and boot of course.

This is where things started...

While I was walking to the trunk, I returned under the car and saw a puddle of brake fluid and an almost empty barrel (cellophane was nothing).

I inserted a new piston into the RCS, installed a retaining ring, and filled the barrel with brake fluid in full (my dad had a jar in his garage)

I loaded the pusher corrugation and attached the rcs to the gearbox on a bracket.

I pumped it by gravity. The pedal is where it was. The speeds are inserted smoothly without any problems.

There is a repair kit and a new case left in the NZ, maybe I’ll buy a bracket and assemble the RCS in my spare time as a reserve.

I noticed that Gur's hoses don't have much time left.

Most likely I’ll contact the service center... I got the screws screwed up with the RCS))

Product added to bookmarks!

- Description

- Reviews

APPLICABILITY: VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107, VAZ 2121, 21213, 21214, 2131 (Niva).

The largest manufacturer of automotive security systems in the world!

The company's work is divided into 2 areas: Continental Temic - electronic components and Continental Teves - one of the world-famous manufacturers of electronic and hydraulic brake systems, chassis control systems, electronic air suspension systems, sensors.

Continental Teves works closely with Continental Temic as part of the joint operation of Continental Automotive Systems (CAS), which allows them to jointly create unique solutions.

ATE Products:

— Brake discs — Sports brake discs (Power Disc) — Motorsports brake pads (Power Pad) — Brake pad kits — Repair kits — Brake master and slave cylinders — Clutch master and slave cylinders — Brake calipers — Handbrake and clutch cables — Brake hoses

ATE supplies its products to all major car manufacturers, including VAG (VW, AUDI, SKODA), FORD, GM, BMW, TOYOTA, etc.

Niva Chevrolet and clutch slave cylinder: diagnostics, repair and replacement

The presence of a clutch in cars is not accidental, and its absence makes it impossible to travel in a vehicle. For most novice drivers, the clutch is the leftmost pedal in the car. But few people know its design, and therefore in this article we will pay attention to one of the main elements of the clutch - the working cylinder on a Chevrolet Niva. What is this product, why is it needed, where is it installed and how is it repaired and replacement parts carried out? You can learn about everything from this material.

conclusions

Knowing what can become a sign of wear and damage to the clutch, as well as how to carry out such work on your own, you will not have to contact a specialist if the need arises.

Our service has been replacing clutches on LADAs for over 10 years. During this time, we have successfully replaced clutches in more than 200 VAZ vehicles.

You don't have to look for spare parts. We will offer you the cheapest clutch for LADA in St. Petersburg. There are always more than 10 different clutch kits for VAZ in stock. You can choose a clutch kit based on your budget and operating conditions.

It takes 4-5 hours to replace a VAZ clutch. You are guaranteed to receive your car on the day you call.

After repair you will receive a full 1 year warranty

Purpose and design features of the working cylinder

There are two types of cylinders in the clutch mechanism: working and main. You can learn about the purpose of the main one from the corresponding article, and today we’ll look at the Chevrolet Niva clutch slave cylinder. The Chevrolet Niva clutch system is based on the operation of a hydraulic drive, which, in turn, is inoperative without a cylinder. The essence of its operation is to directly receive the force coming from the main cylinder and thereby move the clutch release fork.

The design of the working cylinder is absolutely identical for almost all car models, therefore the principle of operation of the device is the same. The product consists, first of all, of a base, that is, a body where the following parts are assembled in a certain order:

All parts are assembled in a certain sequence, which allows the device to function correctly.

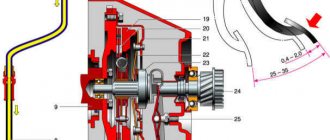

The photo below shows the working cylinder of a Niva Chevrolet.

How does the device function?

To understand the issue of purpose in more detail, let’s consider how the product’s workflow is carried out. So, when you press the main control lever (i.e. the clutch pedal), the pusher moves, which acts on the piston and it moves forward. When the piston moves under the influence of mechanical force, the pressure in the housing begins to increase. This is a process that occurs in the clutch master cylinder. After increasing the pressure, the liquid begins to be squeezed out through the discharge channel and enters the working cylinder. It contains a piston with a fork, which, under the influence of pressure, squeezes out the release bearing, thereby separating the engine and gearbox. At this moment, the corresponding gear is engaged, and then the driver releases the clutch pedal. After releasing the pedal, a return to its original position is observed: the engine engages with the transmission, which is due to the action of the pushing spring in the cylinder.

This is the essence of the functioning of the working cylinder of a Chevrolet Niva SUV. You cannot do without breakdowns and malfunctions, which are inherent in any mechanism. Thus, it is periodically necessary to repair the cylinder, since its functioning is based on friction, and, therefore, wear.

Where can I find the clutch slave cylinder in my car? On the Chevrolet Niva SUV, this product is located on the clutch housing, as on almost all cars. To do this, you need to open the hood and look at the area under the hood on the driver's side.

Fault Diagnosis

Initially, it is important to make sure that this particular element is faulty and requires replacement or repair. To do this, there are ways to identify malfunctions that will allow the car owner not to resort to the help of auto repairmen. So, if you notice the following shortcomings:

Clutch cylinder in need of repair

In this case, you should pay special attention to the working cylinder and promptly carry out repairs to avoid further troubles.

Cylinder replacement and repair

Replacement is carried out in the event of irreparable defects, which include damage to the cylinder body. In all other cases, repairs will be required. But first, let's look at how to remove the slave cylinder from a Niva Chevrolet SUV and install a new repair kit.

Common clutch malfunctions - why bleeding is needed

The reasons for wear of the mechanism are varied . If the friction linings are severely worn or burnt, it is recommended to replace the disc. If oil gets on the friction linings of the driven disc, this indicates that the sealing parts are not working properly. The disk is washed and the cause of the leak is removed.

There are malfunctions in which the clutch does not disengage completely . This is observed when:

- Warping or end runout of the driven disk. For minor damage, repairs are carried out. A serious problem requires replacing the drive.

- Loose rivets on friction linings. The driven disk is replaced along with all other parts.

- Warping and distortion of the pressure plate, which requires its replacement.

Chevrolet Niva the older the better › Logbook › Replacing RCS 2123 (clutch slave cylinder)

While driving, I pressed the clutch several times. Moreover, very sharply (the car jumped out into the meeting) - and the clutch “does not release.” The cylinder is jammed. I crawl under the car. Exactly - the working cylinder is squeezed out and does not crawl back.

I hammered it back in the direction of the red arrow. It’s good that our car is tall - you can crawl under it. The clutch worked. But a clear sign “it’s time to change” was already given.

2123-1602510 Working cylinder 900 rubles 2101-1601211 Clutch release fork cover 50 rubles 2123-1602492 Bracket VAZ-2123 clutch working cylinder 100 rubles

21230-1602494 Thrust plate aka 21230-1602157 RCS plate 30 rubles

21010-1602596 Copper washer d 12 mm 15 rubles Bolt M8x50 1.25 - 2 pcs Spring washer 8 - 2 pcs

This is how the hydraulic clutch works

Opening the tank lid

Unscrew the fluid hose from the cylinder and the cylinder itself.

(the plate was installed incorrectly - it is useless from the outside of the bracket - it should press the cylinder from the inside!)

At the same time, remove the torn cover and install a new one:

Compare old and new:

Installing a new cylinder

We put on a tube and “pump” it by gravity. (do not press the pedal!)

But the reason for the cylinder jamming is plaque and rust in the part where the cylinder rarely moves. Even with the ring removed, the piston did not come out.

Pull clutch working cylinder disassembled:

Device

The design of the unit is no different from those installed on other models of AvtoVAZ cars. The clutch slave cylinder (CLC) consists of the following parts:

- Frame.

- Connection for pumping fluid.

- Piston with plate and sealing rings.

- Pusher.

- Boot (cap).

- Washer.

- Spring.

The RCS is installed next to the plug and works as follows:

- The driver presses the pedal.

- The pusher displaces the clutch master cylinder piston, increasing the pressure in the pipeline.

- The brake fluid that fills the hydraulic drive pushes the cylinder and pusher.

- The latter moves onto the fork, which presses on the clutch basket and breaks the connection between it and the disc.

When the driver releases and stops pressing the pedal, the pressure in the system drops and the piston and pusher return to their original position under the action of a spring.

The part has article number 2123-1602510-01 and is sold at a price of 600 rubles.

Driven disk

This element is located between the flywheel and the pressure plate. The hub mechanism of this part is secured to the input shaft of the gearbox using splined joints. And this disk can move along its surface. To ensure that the clutch engages as smoothly as possible, it has special springs. They soften shocks and vibrations. The clutch disc has special friction linings on each side. They are most often made from glass fibers, brass and copper wire. These components are pressed under pressure into a mixture of rubbers and resins. This composition can withstand high temperatures.