This question is not often, but consistently asked by my readers and channel viewers - what is better than 8 or 16 valves in the engine block head? Many people believe that the 8-valve version is a thing of the past and spending your hard-earned money on it is, at the very least, stupid! But 16 is YES, IT IS! Others, on the contrary, insist that the 16 valve version is more expensive, more demanding to maintain, and if it breaks, “write it down”! But where is the truth, and what exactly is the difference between these two units, are they very different? I propose to weigh all the pros and cons, so there will be a video version...

You know, there are really a lot of battles on the Internet on this never-ending topic, but I think everyone here is right in their own way. After all, some expect reliability and simplicity, while others expect greater power and smooth operation. The tasks are different, and the engines are different, but let's take a closer look.

About the technical component

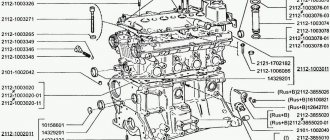

Technically, engines with 8 and 16 valves are quite different. Although all the difference is stored at the top (engine block head) where the car's camshafts (camshaft) are/are installed. In fact, this is the main design feature, but what I want to note is that almost every engine can be made into either an 8 or 16 valve version. For example, on our VAZs, the engines are very similar, and hypothetically, on the same block, you can fit a different cylinder head, with one or two camshafts.

Consumer characteristics

In addition to power and efficiency, the engine is evaluated in terms of repair and maintenance costs. The ability to improve the performance of the motor also increases its “value”. For example, to increase the engine displacement, the cylinders are bored or the piston stroke is increased.

Repair work

Any engine experiences high load during aggressive driving. Whether it's an 8 or 16 valve engine. Even with proper operation, the power unit has resource limitations. Many of the parts involved wear out and need to be replaced. Frequent problems:

- floating or high idle speed. During diagnostics, the mass air flow sensors, idle air control and throttle valve are checked;

- overheating of the engine may be due to a faulty thermostat, lack of coolant or contamination of the radiator;

- clogged injectors or old spark plugs can cause engine vibration;

- Electrical failures often occur on domestic engines;

- knocking noises under the hood indicate faulty hydraulic lifters, unadjusted pushers or a damaged connecting rod and piston group.

If the engine is equipped with push-in pistons, without grooves on the bottom, a broken timing belt causes the valve stems to bend. To avoid the problem, you need to install a high-quality belt and check its condition every 15,000 km. A safer option is to replace the pistons with non-stick ones.

A drop in compression or an increased appetite for oil is already a reason for a major overhaul, but in practice this happens after 200,000 km. The difference in the cost of major repairs of 8 and 16 valve VAZ engines is 5 - 10 thousand rubles. The average price for a complete overhaul is 8kl. — 35,000 rub.

Similar article Technical characteristics of the GAZ 52 engine

Tuning

Engines are tuned to achieve better performance, both 8 and 16 valve units. To achieve high-torque performance of the car, the engine displacement is “increased”:

- Bore the cylinders or increase their number.

- Increase piston stroke.

The most popular method is cylinder boring. However, cutting more than 3 mm from the original size may result in thinning of the walls. This reduces the service life of the part and leads to leaks.

Other tuning options:

- Increasing the number of valves.

- Installation of a sports camshaft for increased power and efficiency.

- Increasing the volume of the exhaust receiver to stabilize the engine.

- Replacing the air filter with a zero filter to increase the amount of incoming air.

- Turbocharged engine.

Main differences.

The 8-valve engine has a narrow cylinder head because it has a single camshaft. The candles are located on the block horizontally and at a certain angle. The camshaft controls the order of their opening - first it opens the intake, then the exhaust. The valve opens with the help of conical parts located on the camshaft, and closes with the help of springs located on it. In a four-cylinder engine, there are two valves for each cylinder of the engine - intake and exhaust. Actually, that’s why there are eight of them per power unit.

In a 16-valve engine, the cylinder head is wide in relation to the single-row four-cylinder block, since there are two camshafts on it. The design itself is complicated; the valves are adjusted using hydraulic compensators. Opening and closing have the same principle as in an 8-valve engine. The spark plugs in such engines are positioned strictly vertically, as if buried in the cylinder block cover. For each one engine cylinder there are already 4 valves - which means, respectively, 16 per engine. What if, instead of two small valves, we insert two larger valves... In principle, it is possible, but then the gas will fill the combustion chamber unevenly, and the engine will not operate as silently as we would like.

Advantages of an 8-valve engine:

- Initially, the design of the engine is relatively very simple and, accordingly, easy to maintain.

- The absence of hydraulic compensators undoubtedly simplifies the design of the power plant as a whole.

- Undemanding to oil.

Flaws:

- Power is less compared to a 16 valve engine. It is also impossible to achieve such high speeds - two valves per cylinder does not allow speeding up the intake and release of fuel and gases from the chamber. The process is happening slower than we would like.

- Increased fuel consumption. Due to the fact that the gas exits through one valve, which cannot let through more than it should.

- Such engines are, in essence, noisier, especially when moving at high speeds.

- The absence of hydraulic compensators requires adjustment of the valves as their precise synchronization is disrupted (even with slight deformation of the camshaft cam profile), in the worst case, a knocking sound appears.

16-valve engine and its significant advantages:

- More powerful. It accelerates better and therefore the top speed will be significantly higher than that of an 8-valve engine. More powerful. Accelerates better and therefore the top speed will be significantly higher than the 8-valve engine.

- It is also important that fuel consumption is noticeably less (should be).

- Engine noise is less.

- The valves are regulated by hydraulic compensators.

Flaws:

- The presence of hydraulic compensators requires a timely change of engine oil to avoid coking of the hydraulic compensators.

- Engine maintenance is more expensive. After all, the design of such an engine is an order of magnitude more complex than the design of an 8-valve engine.

A few words about another reason why valves should sit tightly in the seat. In addition to ensuring complete sealing of the combustion chamber, it should be taken into account that the valve discs operate under severe conditions of high heat. In addition, the plates must be in close contact with the seat, which is located on the cylinder head, which is cooled. After all, the heated plate transfers most of the heat to the saddle. This is especially true for the exhaust valve, since it is cooled only through the tight fit of the plate to the seat, and the intake valve is cooled when the incoming air-fuel mixture is in contact with the seat. If there is poor contact with the seat, no (even the most heat-resistant) valve will withstand such strong overheating. It will simply burn out and collapse, so its tight fit in the saddle is very important. Therefore, they are made from heat-resistant metal alloys. In addition, they do not have magnetic properties.

Economical

In terms of fuel consumption, a 16-valve engine differs from an 8-valve engine by being slightly more economical. Multi-valve heads fill and distribute the mixture better due to the versatile filling of the chamber. This design feature ensures economical operation. In addition, fast acceleration allows you to save fuel, which is consumed at high speeds.

In practice, consumption depends on driving style, type of fuel, tire pressure, curb weight and outside temperature.

Despite being economical in terms of fuel consumption, the 16 valve engine requires better oil and gasoline. If in an 8 valve you can get by with semi-synthetics or mineral water, in a 16 valve it is permissible to use only synthetics.

Similar article Technical characteristics of the ZMZ 402 engine

8 valve engine

This is indeed an archaic, but nevertheless reliable, simple and cheap to repair scheme. New cars with such an engine are somewhat cheaper, but are practically not inferior to 16-valve cars either in dynamic characteristics or in fuel consumption. Regular maintenance of such machines is cheaper. Most 8-valve engines have “stickless” pistons, that is, if the timing belt breaks, the piston will not meet the valve. Such engines are not demanding on the quality of motor oil and can easily run on 92-grade gasoline.

The disadvantages include low power; in comparison with a 16-valve engine, it is 10–15% lower. This happens due to the inability to spin the engine more, because the intake and exhaust are slower. 8-valve engines are quite noisy due to mechanical pushers rather than hydraulic compensators, but this is also a plus.

Price of VAZ 21124 engine on the secondary market

Due to its wide distribution, you can find such a unit at almost any disassembly center specializing in AvtoVAZ products. The cost of a good copy is often 25,000 rubles. The official dealer offers a new motor for 70,000 rubles.

| State: | New |

| Equipment: | engine assembly |

| Working volume: | 1.6 liters |

| Power: | 89 hp |

* The price for this engine is for reference only

San Sanych talks about the solution to a very common problem with such a motor.

You can contact the site administrator by email: [email protected]

All texts were written by me, are authored by Google, included in the original Yandex texts and notarized. For any borrowing, we immediately write an official letter on company letterhead in support of search networks, your hosting and domain registrar.

Next we go to court. Don’t try your luck, we have more than thirty successful Internet projects and have already won a dozen lawsuits.

16 valve engine

Such engines are more powerful, more flexible and quieter than their 8-valve counterparts. They allow you to more finely tune the operation of the timing belt, which affects the smoothness of the engine and the environment. It does not require periodic adjustment of the valves, since it is equipped with hydraulic compensators. The advantages also include a wide field for tuning, including installation of a turbine.

This engine also has a lot of disadvantages and, probably, more than the 8-valve engine: expensive repairs, because there are only two; high requirements for the quality of motor oil. It is recommended to use the more expensive 95 gasoline. If we are talking about VAZ engines, then their 16-valve engines traditionally suffer from oil leaks, since their cylinder head consists of three parts.

For the buyer of a new car, a similar choice will arise if he chooses something from AvtoVAZ or Renault. Most brands have not offered alternatives to 16-valve engines for a long time, the reason for this is high environmental requirements. When buying a used car. You can safely buy a car with an 8-valve engine; it is simple, cheap and unpretentious in operation, and also tolerates the transition from gasoline to gas well. Cars with 16-valve engines are more pleasant to drive, but more expensive to maintain.

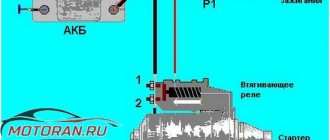

Availability of hydraulic compensators

All owners of eight-valve VAZs know very well that sooner or later they have to perform such a procedure as adjusting the valves. An increased gap leads to an unpleasant knocking sound when the engine is running, and a “clamped” valve can cause a decrease in compression, power and stable operation of the internal combustion engine, as well as other more serious consequences.

From 16th grade everything is much simpler:

here instead of standard pushers with adjusting washers, which are inherent in 8-cl. engines, hydraulic compensators are installed, which themselves “adjust” and set the required gap, respectively, without requiring any intervention from the driver.

hydraulic compensators (not from VAZ, if anything -))