Clutch structure and mechanism

Today, most vehicles have a single-plate friction type clutch, which has two main components: a drive and a mechanism. The first is located on static parts of the body or frame. To briefly disconnect the engine crankshaft from the gearbox shaft, you need to press the clutch pedal all the way, “disengaging it.” When pressed, the rod directs pressure from the master cylinder piston to the working cylinder. The latter moves the force to the mechanism through the release fork and the pressure bearing. At the moment the pressure decreases, the drive return springs will return the elements to their original positions.

Most often, you can find several types of drives on cars:

- Hydraulic. The design includes a tube with high pressure of the working fluid, which powers all the mechanisms.

- Mechanical. The force with which the pedal is depressed is transmitted by a cable to the release fork.

- Electric. The electric motor drives the cable, which acts similarly to a mechanical drive.

- Pneumatic. Most often used on trucks, in order to reduce the required effort to release the pedal. The design includes a pneumatic booster, which affects the piston valves.

The clutch design in the crankcase consists of several discs: driven and pressure. The first is located on the gearbox shaft splines, and the second is on the flywheel housing. Separately, there are release levers on the ball joints, and the driven disk is pivotally connected to the structure.

The driven disc is statically secured between the crankshaft and the pressure plate when the clutch is completely disengaged. The coupled structure transmits torque from the crankshaft to the gearbox shaft. When the pedal is depressed, the thrust is transferred and the fork moves the clutch. The latter, using levers, moves the pressure plate.

Design

The mechanical drive on the VAZ-2114, despite the fact that it has the least simple design, is in no way inferior in reliability to its hydraulic counterpart. Its system consists of a cable adjustable in length, sealed in a special anti-corrosion sheath, and the clutch pedal itself located in the car's interior, which, through free movement, is designed to transmit the pressing force to the clutch fork.

Despite the fact that such a scheme is simple, in general it is quite reliable.

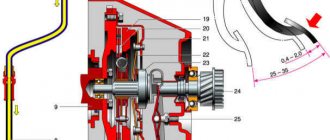

Clutch diagram

A new product in the form of a clutch cable for VAZ-2114 cars helped to avoid all the problems that all owners of classics encounter. First of all, this refers to the leakage of hydraulic fluid from the system, and as a result, loss of control over the car. It would also require work to remove air from the clutch system after repair.

At the same time, periodic checking and adjustment of the clutch pedal has remained the same.

Why is it necessary to adjust the cable travel?

This procedure is necessary so that when the pedal, and with it the clutch cable, reaches certain values, the most squat pressing of the flywheel with the basket to the driven disk is made, at the moment when its operation is necessary. At the same time, thanks to the precise adjustment of this drive, the clutch is released at the moment the clutch pedal is released.

Note! During operation of this system, when the lever is in the neutral position, or when it is turned on, no extraneous sounds or crackles should come from the gearbox housing.

You can monitor the condition of the clutch, preventing such a situation from occurring, visually by positioning the clutch pedal relative to the floor of the car, using only a ruler.

Values

The optimal values should be from 125 to 140 mm , when measuring readings first with the pedal pressed and then with the pedal released. The maximum value that is allowed when measuring such indicators is 160 mm , and if they exceed these values, then this will mean severe wear of the friction linings, and therefore, after adjusting it, the clutch itself may soon need to be replaced.

We measure the result along the bottom edge of the pedal - in the photo the result is normal.

Features of clutch in automatic and manual transmission

The clutch can be single or double disc. Depending on the principle of operation, it is divided into “wet” (in the presence of oil or lubricant) and “dry”. So, automatic transmissions most often have a multi-plate wet clutch.

Due to the absence of a pedal, the force in the automatic transmission is transmitted by a servo drive, or actuator. The entire installation is controlled using a control unit and a hydraulic distributor. In a manual transmission, two types of clutch operate alternately. Actuators differ in their operating principle:

- Electric (otherwise known as a stepper motor). The control unit constantly receives data on engine speed, and at a certain speed the servo drive receives a corresponding signal. The transmission mechanism disconnects the crankshaft and input shaft.

- Hydraulic – hydraulic cylinder. In the drive mechanism, the oil pump transmits pressure to the distributor, under certain conditions to the servo drive. After changing gears, the pump force decreases.

How to adjust the clutch on a Niva?

Conclusion

Although the adjustment work is not a difficult task, it requires some attention and patience. However, with the right approach, success will not keep you waiting. Good luck with the renovation.

A vehicle often requires adjustments to various controls and systems. For example, you may need to adjust the clutch pedal, which greatly affects the quality of driving a car with a manual transmission. This adjustment is quite easy to do without visiting service centers, and does not require any special knowledge or tools.

Reasons for adjusting the clutch pedal

It is important to understand that improper clutch operation may create virtually no problems when driving, but nevertheless it will significantly reduce the life of the clutch mechanism and gearbox. Over time, the discs wear out, which increases the clearance between the bearing and discs.

There are two main reasons why pedal adjustment is necessary:

- Replacing the clutch cable in a mechanical drive or replacing the slave cylinder. After such an intervention in the operating structure of the drive structure, adjustment is a mandatory procedure.

- Changing the pedal stroke. Excessive travel can occur as the friction linings wear out. To avoid negative consequences, it is better to regularly measure the working stroke.

In most foreign cars, adjustment is not required, since they have a self-regulating mechanism installed. The difference between the foreign-made design and the domestic one lies in some details of the ratchet mechanism.

A separate reason for adjustment is interruptions in the operation of the gearbox. If the desired gear does not engage, or is difficult to engage, the clutch is not pressed enough. Otherwise, the car may not move when the clutch is engaged. Then we can talk about a highly tensioned mechanical drive cable.

When the trip actuator needs checking

The free play of the clutch pedal must be checked and adjusted every 20 thousand km. This also needs to be done if the car starts to move at the very beginning or at the end of releasing the pedal. A correctly adjusted clutch release drive causes the car to start moving when the pedal is released approximately halfway.

This is interesting: Self-replacement and repair of the tachometer if it doesn’t work

Adjustment of the drive with hydraulics and with a cable is slightly different. To adjust the hydraulic drive, as a rule, you need a pit or overpass. Cable adjustment is usually done in the engine compartment from above, simply by opening the hood.

How to check pedal free play

Clutch free play is the period of pedal movement from the moment it is pressed to the moment it is activated. You can notice that when you press the clutch, at first there is no proper resistance, and somewhere in the middle of the stroke an increase in rigidity appears.

If the vehicle starts moving immediately when you touch the pedal, then it is better to make the adjustment urgently, since there is no free play at all. Otherwise, the pedal can be pressed to the floor, but the car does not move.

Free play is required for all manual transmissions, since it indicates clearance between the fork, bearing and disc levers and prevents constant contact of the bearing with other elements of the mechanism. It is important to monitor the size of the free play, because if it is too large, full pressure will not be enough to transmit sufficient force to squeeze the drive disk.

A separate reason for checking free play is noise and jerking when interacting with the clutch. You can measure this indicator yourself using a ruler.

It is necessary to measure the perpendicular distance from the floor to the pressure pad. Next, when you gently press the pedal, you should measure the stroke until resistance first appears. The result must be checked against the data in the vehicle's operating manual.

The general average clutch stroke for a car is 160 mm. It is recommended to carry out preventive maintenance and adjustment every 20 thousand km.

Self-replacement of the VAZ-2109 clutch cable

The clutch is an integral part of any car with a manual transmission. However, this system can also wear out and break down, so it is necessary to constantly monitor its condition and carry out scheduled repairs. The most common problem is a broken clutch cable.

Over time, it simply wears out and becomes thinner. Characteristic signs of a malfunction can be noticed immediately: when you try to press the pedal, clicks appear, and the pedal itself may simply not return to its original position.

Today we’ll talk about how the clutch cable (TC) is replaced on a carburetor and injection VAZ-2109 and what is needed for this.

Preparing for work

Initially, it is recommended to find a place where it is most convenient to inspect the car and replace the part. Since you will have to work not only under the hood, but also under the car, the best assistants will be a lift, pit or overpass. If you do not have the opportunity to use one of these options, you can simply raise the car using jacks.

Also, before starting work, you need to make sure that you have everything you need at hand. To replace the cable you will need:

- new part;

- set of wrenches;

- screwdrivers.

On average, you can replace this element on a VAZ-2109 yourself in 20 minutes.

Progress

In order to quickly and efficiently replace a frayed or broken cable, you need to take several mandatory steps. We start by working under the hood, here the following actions are performed:

- Loosening of the fastening of the vehicle mounting bracket to the box.

- Removing the lower part of the cable from the clutch release fork.

So, a start has been made, and now we need to return to the salon. The following work is performed here:

- Disconnecting the cable from the pedal. To do this, you need to remove all the floor mats from the interior.

- Removing the lock washer. To do this you will need an ordinary minus screwdriver. Next, the pin connecting the part to the bracket is removed.

- Now you can get the cable itself. There is a special rubber cushion in the engine compartment, and under the steering wheel there is a hole through which the shell will need to be removed. We press on the pillow, remove the shell and remove the old element.

Dismantling work has been completed. Now we move directly to the procedure for installing a new vehicle. Installation begins from the interior. This is done as follows:

- We insert a new cable into the hole, mount its end on the pedal, and secure it with a lock washer.

- We secure the vehicle in the box. This must be done in such a way that the bushing is located on the bracket. Then the thread will be reliably protected.

- We insert the end of the cable into the fork. Here you can lubricate the cable with oil.

Checking the gap and adjusting the clutch fork

To check the operation of the clutch fork, you need to find the threaded bushings at the end of the clutch cable and measure the difference in the gap between them at rest and in the recessed position. The ruler must be placed near the cable and the edge of the housing. After the lever is pressed all the way, the distance is measured.

The second step is to pull out the lever and repeat the measurement. The indicators are compared against the manufacturer's data and, if necessary, adjusted. To do this, loosen the lock nut (VW has a wing nut) and turn it out as necessary, reducing or increasing the gap. After all the actions, firmly fix the clutch pedal and squeeze it several times. To check the effectiveness of the actions taken, the measurements must be repeated and the results compared.

How to adjust the clutch on a Gazelle?

How to adjust the clutch on a Lada Priora?

There are two ways to measure the required position of the cable.

The first method is to orientate along the clutch pedal, the movement of which should be within 125 - 123 millimeters. But the second method is to measure the length of the cable coming out of the casing. When released, it should be 27 millimeters.

In most cases, drivers use the first option, which is explained by greater reliability. It is the procedure for the first option that we will describe in detail.

1). Using a 17mm wrench, unscrew the locknut that secures the cable casing in the box socket.

2). Next, in order to achieve the required pedal travel in the mentioned range, unscrew or tighten the second one.

3). Using a threaded plastic end cap, we correct the sag of the cable. We fasten without tightening the nuts and check for softness of gear engagement. If the clutch is adjusted correctly, the nuts can also be fixed.

How to adjust the clutch on a Lada Granta?

How to adjust the clutch on a VAZ 2114, 2115

1). Tighten the handbrake and remove the battery for safety.

How to check and adjust a hydraulic clutch

The operation of a mechanical and hydraulic drive has its own design differences. In this regard, in order to adjust the hydraulic clutch, it is necessary to check the total length from the pusher rod to the fork. According to the standards, it should be about 5 mm.

Then disconnect the spring from the working cylinder bracket. There is an adjustment nut on the rod, by unscrewing which you can change the stroke of the fork to the desired result. The general concepts of changing the working and free play may differ depending on the vehicle manufacturer. Before you begin self-adjustment, you need to read the manual for your vehicle or watch training videos:

As you can see, there are no particular difficulties in adjusting and setting the clutch. However, a beginner should carefully follow all instructions and advice from experts. To get the most effective result, it is better to first become familiar with the operating principle of the clutch mechanism.

What you need to know about clutch malfunctions

- If, during the operation of the car, the PS gradually begins to move upward, most likely the lining of the driven disk is worn out.

- When the clutch slips, the interior smells of burnt linings (ferodo). Checking the wear of the linings is quite simple: put the car in “handbrake”, start the engine, squeeze the clutch, add gas, and smoothly release the throttle. If the engine barely slows down, the disc pads are worn out. If the internal combustion engine stalls, the clutch is fine.

- Slipping can occur not only due to worn friction linings of the disc, oil can get on the basket and disc. To check your guess, you need to place the car on a lift or pit and perform an external inspection of the engine and gearbox from below. Oil enters the clutch through the gearbox input shaft oil seal, through the rear oil seal of the internal combustion engine.

- If the PS is stuck, then it could be: the fork has become sour, the piston has jammed in the working cylinder, the fork has flown off the release bearing hub (on ZMZ-402, UMZ engines of various models).

- If the PS has become “wobbly”, and in order to change gear normally, you need to depress the clutch pedal twice, it means that the master cylinder valves have begun to bypass. In this case, repair of the main circulation system or its replacement is necessary.

The clutch is one of the most important parts of a car's transmission. Thanks to it, it is possible to temporarily disconnect the connection of the engine crankshaft from the gearbox input shaft to adjust the transmission of torque. The clutch pedal is the main link between the driver and the transmission.