Home • VAZ • 2109 • Brake system

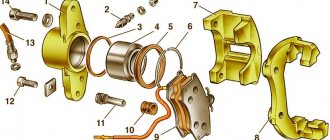

The design of the brake system of the VAZ 2109 front wheels: 1. Brake hose. 2. Bolt securing the guide pin. 3. Bleeding valve. 4. Wheel cylinder. 5. Bolt securing the cylinder to the caliper. 6. Base mounting bolts.

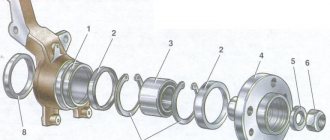

Diagram of the brake system of the VAZ 2109: 1. Wheel cylinder. 2. Piston. 3. Brake caliper base. 4. Brake disc. 5. Brake pads. 6. Caliper.

Repair of the front caliper VAZ 2110

The caliper in a car is one of the most important parts.

It is a unit necessary for attaching the brake pads of a vehicle. Only a small proportion of drivers pay due attention to the braking system, although this part of the car should be a priority. Many owners of domestic VAZ cars have managed to appreciate the importance of the caliper, or rather, the need for its full serviceability. For example, some drivers almost crashed into the vehicle in front because the braking system failed at the most inopportune moment.

The driver should definitely periodically check the serviceability of the brake caliper on the VAZ 2110 and other domestic car models. If this part is damaged, it can be restored. In cases where the possibility of restoring the caliper is excluded, the component part is completely replaced.

Brake bleeding sequence

Removing air from the hydraulic brake system of a VAZ 2108 car (the so-called bleeding) is a necessary final stage of their repair work on the hydraulic brake system. The presence of air in the hydraulic drive system is evidenced by the peculiar behavior of the brake pedal of the VAZ 2108. When pressed for the first time, the pedal behaves softly, resists pressing weakly, and sinks deeply. With several successive presses, it becomes stiffer and its stroke decreases. This behavior indicates the need to bleed the hydraulic system.

Replacing caliper guide pins and their boots on VAZ 2114-2115

The first step is to jack up the front of the car. Then remove the wheel and use a flat-blade screwdriver to bend the locking washers of the caliper bolts.

Then unscrew the two fastening bolts at the top and bottom, as shown in the photo.

Next, compress the brake cylinder using a screwdriver by inserting it between the bracket and one of the pads.

Next, you can lift the cylinder with the bracket up, as shown below, and move it to the side so that it is out of the way.

And now you can easily remove the caliper pins, both from above and from below, with minimal effort.

Then we clean the fingers from the old grease with a special product or buy a new one. Also, it is necessary to install a new boot if the old one is damaged.

Apply special caliper grease to the pin and under the boot, as shown in the photo. Then we put the finger in its place all the way so that the boot is securely fixed.

Now you can assemble the entire structure in reverse order, and do not forget to press the brake pedal several times before leaving the repair site so that the pads take their position in the guide.

Replacing caliper guide pins

If you begin to notice rattling of the calipers on your own car, then you should first pay attention to two things:

- On brake pad springs that may have weakened

- The caliper guide pins may have worn out due to lack of lubrication.

This article will examine the second option, when specific wear on the guide pins leads to similar dilemmas. First, you should pay attention to the condition of the anthers. If they are torn or even cracked, then they need to be replaced with new ones, and the fingers themselves must be re-lubricated. But more on this below.

Necessary tool for inspecting calipers on VAZ 2110, 2111 and 2112

- Flat blade screwdriver

- 13 and 17 mm wrench

- Copper grease

- Lubricant for caliper guide pins

- Brake Cleaner

Is it financially profitable?

When the owner of the car imagines how much work he has to do, willy-nilly he begins to calculate whether it makes sense to change the brake discs himself, or whether it is easier to take the car to a service station.

Depending on the manufacturer and the place where you purchase new brake discs, their price can range from 1 to 2 thousand rubles. Add to this minor expenses on consumables. Surely you have tools, a jack, and the same WD40 in your garage. That is, additional costs, in addition to the purchase of brake discs themselves, are minimal.

Now we invite you to familiarize yourself with the cost of services of professional service centers for the repair and replacement of various components of the brake system.

| Service | average price |

| Remove and install brake drum | from 300 rubles |

| Remove and install rear brake disc | from 800 rubles |

| Remove and install front brake disc | from 1000 rubles (they change more often, hence the markup) |

| Replacing drum pads | from 800 rubles |

| Replacing disc pads | from 500 rubles |

From this it becomes obvious that from a financial point of view, replacing it yourself allows you to save a decent amount of money. Plus, do not forget that not all service stations really perform their duties efficiently. Well, it’s up to you to decide for yourself.

Do-it-yourself dismantling of the caliper on a VAZ-2110

The very simple design of the product and the triviality of the process of dismantling it allow even a novice motorist to carry out repairs and maintenance. If you carefully follow the recommendations below, you are unlikely to encounter difficulties at any stage of the process. You will save a lot of money spent on a trip to a service station, and a considerable amount of time, because the service time is comparable to the time required to travel to the workshop.

Dismantling VAZ caliper

The sequence for dismantling the product is as follows:

- The first step is to jack up the car and remove the wheel. To be on the safe side, it can then be placed under the bottom of the car in case the jack fails;

- On a VAZ 2112, the caliper is attached to the bracket using two M17 bolts, which you should unscrew. Penetrating lubricant may be needed to strip the bolts;

- If you need to replace the VAZ caliper or carry out a comprehensive repair, unscrew the product from the brake hose. You seal the hose tip and you can begin further disassembling the product.

How to minimize brake fluid loss

- Open the hood and use a rag to thoroughly clean the brake master cylinder. The master cylinder is attached to the booster, a drum-like component mounted on the driver's side called the brake booster.

- Unscrew the cap of the master cylinder reservoir and place a piece of clean plastic elastic sheet over the hole, I usually just put a thick bag and tighten it well with the lid, so that there is a vacuum in the reservoir and when removing the brake hose, the fluid does not flow onto the floor.

- Then place the cap on the top of the plastic sheet and tighten the cap. This will create a vacuum and help prevent significant fluid loss when the brake line is disconnected.

Lubricating calipers: how, with what and why?

Any “extra” sound coming from the front suspension will certainly alert an experienced motorist. A worn-out bearing, a loose ball or a spinning wheel can lead to loss of controllability and even cause an accident. However, of the many knocks that chassis parts can make, the one that stands out the most is the sound made by the brake calipers - or rather, their brackets and guides. Today we will fight him.

This unpleasant and loud defect is known firsthand to many drivers, and it causes completely different reactions. Most often, the owner prefers “not to interfere with the car’s operation” - after all, this is the easiest way, and the “sound accompaniment” does not particularly affect the operation of the braking system itself. However, there are many meticulous motorists who fight sound in various ways - for example, by lubricating the guides and even modifying them.

The knocking noise occurs due to excessive clearance in the guide-bracket pair.

What to lubricate

It would seem that what could be simpler than lubricating the caliper guides? Many owners do this - during the next “overhaul” of the brake system, they take and lubricate their fingers with whatever comes to hand. As a rule, the garage assortment includes lithol and its derivatives, as well as graphite. More advanced people are puzzled by finding a specialized composition intended specifically for use in brake system components.

And now - surprise: in most cases, both of them do the wrong thing! Yes, the caliper guide pins do need to be lubricated, but not with what is usually considered a suitable lubricant, even if it is positioned as such in a car shop.

Car manufacturers produce guide lubricants under their own brands.

Here is a list of original OEM lubricants from some automakers, indicating catalog numbers:

- BMW 81 22 9 407 103, 83 23 0 305 690;

- FORD/Motorcraft D7AZ-19A331-A, XG-3-A;

- Volkswagen/Audi G 052 150 A2;

- LAND ROVER RTC7603, SYL500010;

- HONDA 08C30-B0224M, 08798-9027;

- MAZDA 0000-77-XG3A;

- NISSAN 999MP-AB002;

- SUZUKI 99000-25100;

- TOYOTA 08887-80609;

- CHRYSLER/Mopar J8993704;

- Volvo 1161325-4.

There are also lubricants produced by companies producing auto components and chemicals under their own brands:

- ACDelco 89021537 (10-4022);

- Federal Mogul F132005;

- FTE Automotive W0109;

- Stahlgruber 223 1712, 223 1729;

- TRW Automotive PFG110.

Such different lubricants

Unfortunately, in the vast majority of cases, car dealerships (both online and offline) will usually offer “the wrong thing” - that is, anti-creaking lubricant, which simply cannot be used in guides!

The fact is that copper and ceramic anti-squeak pastes are intended for application to the back side of the pads and mating elements of brake calipers, but they are not suitable for “guides” for several reasons. Firstly, after lubrication with grease, lithol, “graphite” and other lubricants based on mineral oils, the rubber boots on the fingers almost always swell, stop sticking to the fingers and, in fact, simply stop performing their function.

Secondly, only special greases based on synthetic oils and a thickener are suitable for lubricating the guides. Thanks to this, the lubricant becomes refractory and does not “drain” from the guides after heating, and also does not coke over time from exposure to water and high temperatures. High-quality specialized lubricants can easily hold up to +300C, but at the same time they are non-aggressive to seals. Moreover, such lubricants not only do not melt, but also do not dissolve in water, alkalis, dilute acids, brake fluid, as well as methanol and ethanol.

Using the wrong lubricant in practice can lead to the opposite effect - that is, the lubricated guide pins become sour in the caliper, which is why the floating bracket loses its mobility, and the pads begin to jam and overheat.

On thematic forums, hundreds of pages are devoted to choosing the “right” lubricant for guides, but the theoretical calculations and practical reviews given often contradict each other, which leads to even greater confusion.

Front brake pad guide bracket VAZ 2112 R14 (1 piece)

- We guarantee fast processing of your order during business hours (we work from 11-00 to 20-00, Saturday and Sunday are days off).

- We guarantee reliable packaging of your order (when sending it by Russian Post or transport company).

- We guarantee the fastest possible dispatch of your paid order (within 2-4 business days after receipt of payment).

- We guarantee a refund or exchange for another product (with recalculation) within 14 days from the date of receipt of the order (the product must be in good condition, without traces of installation, delivery costs are not reimbursed).

- We guarantee a free exchange of goods (transportation costs at our expense) if the purchased goods turn out to be defective.