Replacing ball joints on a VAZ 2109 yourself

Many parts of any car, including the VAZ 2109, require regular replacement or repair. The ball joint also belongs to such parts. In order not to pay for the work of replacing the ball joint on a VAZ 2109, you can do it yourself in your own garage - it’s not that difficult. In this article you will find photos explaining the essence of the process, as well as a video of the process of replacing the ball on a VAZ 2109. Instructions for choosing a new ball and diagnostics are also included.

- Choosing a new ball joint

- Ball joint diagnostics

- Replacing the ball joint

- Tool

- Replacement

Choosing a new ball joint

Replacement of ball VAZ 2109

You can simply come to the store and ask for a ball for the required car model. But, after a couple of months, you will have to go to the store again and buy another one! There is no meaning to this action, and it only benefits the store owner. Let's choose the right ball joints. Please pay attention to the following points:

- Manufacturers often rivet ball joints from rubbish and regardless of the quality of the product. Noticing this pattern, car enthusiasts identified several companies with normal price and quality indicators.

- Among such manufacturers is the Trek company, which is highly praised by drivers, as well as service station workers.

- If you decide to use another company, remember that there is no such thing as cheap quality! Beware of counterfeits - the stingy pays twice. The price for balls is not that high.

- Still, when choosing a ball joint for a VAZ 2109, you should pay attention to its appearance.

- The housing must not have any damage or signs of wear. Also, the body of a good ball joint will definitely be welded from two parts.

- Pay attention to the ball pin. If it is painted black, this is a bad sign. Yes, the finger should be black, but not from paint, but from temperature hardening.

Advice! When choosing a ball, try turning the support pin. In a good ball joint it is very difficult to move without a knob.

- Don't forget about the ball joint configuration. What should be included there? The ball itself, nut, mounting bolts and boot.

- The anther must be intact and have no weak points.

- The ball joint bolts must also be hardened. Yellow bolts are usually of disgusting quality - the thread is bypassed without even tightening the nut (in some cases).

- The nut must have a Teflon insert or a cotter pin included, and there must be a through hole in the ball joint pin.

Advice! Usually lubricant is already added inside the ball, but it is often not enough. Don't forget to pay attention to this.

Purpose of the ball joint and identification of its breakdowns

The ball joint is a ball pin partially fixed in the housing. It is necessary to ensure limited movement of the suspension elements relative to each other. Two such supports are installed on the car. They are located at the lowest points just behind the front wheels. Due to their design features and the condition of most domestic roads, ball joints wear out quite quickly.

The problem can be indicated by:

- dull knocks from the side of the car when hitting a bump;

- squeaks when cornering, increased force applied to the steering wheel;

- wobbling and pulling to the side when driving on a flat road;

- rapid and uneven tire wear.

However, many of these symptoms are also common to other problems. It is possible to say with confidence that the problem arose in the ball joint only after local diagnosis. So how to check the ball joint? Usually external damage and severe deformations are visible to the naked eye. Wear on the internal surfaces can be determined by “hanging” the wheel and rocking it with your hands while pressing the brake pedal all the way - the presence of play will indicate a problem.

A more accurate result will be obtained by checking the gaps with a depth gauge through a special inspection hole located in the bottom of the housing. However, such a tool is not always at hand.

Ball joint diagnostics

It is very important to determine the time when the ball joint on the VAZ 2109 needs to be replaced and do it. Why? If on the road, at a good speed, the ball joint pin is pulled out of the ball joint itself, this does not bode well for either the car or the passengers. So:

- While driving, listen for knocking noises coming from the front of the car. A ball joint malfunction is especially evident when driving on an uneven road or when a wheel falls into a hole.

- If, when you hit a hole, you hear a dull thump from one of the front wheels, it is likely that the ball joint needs to be replaced.

- You can diagnose a ball joint in another way without special equipment. When parking the car, place your foot on the top of the front wheel.

- Next, you should make pushing movements with your foot towards the other wheel. If during this procedure you hear a dull impact sound, then you should turn to a more accurate diagnostic method and, most likely, replace the ball joint.

The following describes the most reliable way to check whether a ball joint needs to be replaced:

- For a more accurate diagnosis, you will need an inspection hole and a jack.

- The car is installed in a pit, with a parking brake and wheel chocks for greater safety.

- Using a jack, the car is raised.

Advice! You should select the jack's support point with extreme caution because the car will have to wobble from side to side.

- Once the wheel is off the ground, you can begin testing the ball joint.

- One hand is placed on the top point of the wheel, and the second on the bottom.

- Next, you should use careful and at the same time sharp movements to shake the wheels from top to bottom.

- If there is no sound of impact, move on to another wheel. If there is sound, then we do the following (a friend is needed).

- A second person should place two fingers where the ball joint pin connects to the control arm and onto the ball joint housing. If you feel the displacement of the finger in the ball body with your fingers, then it has become unusable.

Determining the malfunction of the VAZ-2109 ball joint

Structural simplicity gives the ball joint the necessary degree of reliability with a certain service life. It can range from 15 to 150,000 kilometers. This depends on your driving style and the condition of the roads on which the car is used.

The main signs that the ball needs replacement are:

- knocking in the suspension area when driving on uneven sections of the road;

- uneven tire wear;

- arbitrary displacement (wobbling) of the car from the center line of movement;

- creaking suspension and increased steering effort.

All this signals that the ball joint has reached its critical state and the need for an emergency replacement. Otherwise, when driving, the wheel may simply separate from the car. I don’t even want to mention the result of such an incident.

- a set of car keys (socket, open-end);

- mount;

- hammer;

- chisel;

- special puller for steering tips and ball joints;

- WD 40 (aerosol for cleaning, lubricating and protecting against corrosion of mechanisms and parts) or another similar preparation;

- jack;

- lubricant;

- wheel wrench;

- brush for cleaning metal.

Replacing the ball joint

When you are already convinced that the ball joint needs to be changed, you have chosen a good new ball joint and purchased it, then you can begin the repair. You need to start by preparing the necessary tool for the job. So, what does replacing ball joints on a VAZ 2109 require?

Tool

Replacing the ball joint VAZ 2109 - special puller

You will need:

- Jack

- Set of keys, heads

- Balonnik

- Wheel chocks

- Puller for ball joints VAZ 2109

- Hammer

- Mount

- Lubrication

- Metal brush

- WD-40 or equivalent

Now you can start - replacing ball joints on a VAZ 2109!

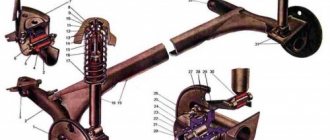

Replacement of ball joints of the front suspension of VAZ 2108, 2109, 21099 cars

The service life of the front suspension ball joints of VAZ 2108, 2109, 21099 vehicles varies between 50-60 thousand kilometers.

But due to poor manufacturing quality and difficult operating conditions, this period can be reduced to 20-30 thousand km. A failed ball joint will make itself known by a knocking sound from the suspension when driving over uneven surfaces at low speed (for example, when driving over a curb). To establish that it is the ball joint that is faulty, we carry out a small check (see “Checking ball joints for VAZ 2108, 2109, 2109 cars”). If a faulty ball joint is detected, replace it with a new one. It is recommended to replace two ball joints at once, but based on practice, you can replace only one, the one that knocks.

Necessary tools, accessories and spare parts

— Socket wrenches, ring wrenches or heads for “17” and “19”

— Ball joint remover (if you don’t have it, then use a mounting tool and a heavy hammer)

— Lubricant Litol-24 or ShRB-4

— New ball joint (or two, if the supports are replaced on both sides at once)

Preparatory work

— We jack up and hang both wheels of the car (in this case, the anti-roll bar does not tighten the suspension and it is easier to remove the ball joint)

— Remove the wheels

— We clean the front suspension parts from contamination

The procedure for replacing ball joints of the front suspension of VAZ 2108, 2109, 21099 cars

— Unscrew the nut securing the ball joint to the suspension arm

We use a key or socket on “19”. Before unscrewing, you can lightly tap the nut and fill it with WD-40.

Unscrew the nut securing the ball joint pin

— Press the ball joint pin out of the hole in the suspension arm

We use a special device - a ball joint remover.

Ball joint puller VAZ 2108, 2109, 21099

Or, by screwing the fastening nut onto the ball pin a couple of turns, we create tension between the ball and the lever using a mounting tool and hit the lever boss with a hammer until the pin is pressed out.

We disconnect the ball joint pin and the suspension arm boss using a hammer and a pry bar

— Disconnect the ball joint from the steering knuckle

Using a socket wrench or a “17” socket, unscrew the two bolts securing the ball base to the steering knuckle and remove it.

Unscrew the ball joint bolts

— Install a new ball joint

We insert the ball pin into the hole in the suspension arm. We fasten its body to the steering knuckle with two bolts. With light blows on the lever, we push its boss onto the ball pin until it stops (so that the pin does not turn when tightening the nut). Screw it onto the pin and tighten the nut securing it. The tightening torque of the pin nut is 67-82 N.m, the bolts securing the ball joint to the steering knuckle are 49-62 N.m.

If necessary, we replace the second ball joint in a similar way.

Notes and additions

— It is recommended to put a little additional lubricant (Litol-24 or ShRB-4) into its hinge before installing a new ball joint. To do this you will have to remove its boot.

Twokarburators VK - More information on the topic in our VKontakte group, on Facebook Twokarburators FS and on Odnoklassniki - Twokarburators OK

More articles on the front suspension of VAZ 2108, 2109, 21099 cars

— Replacement of front struts for VAZ 2108, 2109, 21099 cars

— Replacement of the front wheel hub bearing of VAZ 2108, 2109, 21099 cars

— Dismantling the front pillar of VAZ 2108, 2109, 21099 cars

— Replacement of the rear wheel hub bearing of VAZ 2108, 2109, 21099 cars

— Replacement of the compression stroke buffer (bump stop) of the front pillar of VAZ 2108, 2109, 21099

Comparative car repair test

— Replacement of ball joints for the suspension of a Renault Logan 1 car

Choice

When choosing a new ball joint (BJ) for replacement, focus on several basic criteria.

| Selection criterion | Peculiarities |

| Manufacturer | Today there are a lot of manufacturers of ball joints. But not all of them produce truly high-quality parts. That’s why car owners have identified certain companies for themselves. For owners of the VAZ 2109, it is worth paying attention to the manufacturing company Trek. |

| Fakes | A loud, well-known name of the ball joint manufacturer is not a guarantee of quality. There are a lot of fakes on the market now. To find the original, visit the official websites of trusted companies, learn about the features of the original packaging, the nuances of protection that allow you to distinguish fakes |

| Frame | There should be no signs of damage, wear or defects on the ball body. High-quality SHOs are always welded from two elements |

| Finger | If you notice that the ball joint pin is painted black, there is nothing good about it. A high-quality finger is also black, but it gets this color as a result of hardening the metal under high temperature. Also try rotating your finger. If you managed to do this without a knob, this is a low quality product. |

| Equipment | Responsible manufacturers, in addition to the SHO itself, complete the parts with nuts, bolts and boot |

| Anther | Make sure there is no damage, signs of wear, or other defects. |

| Bolts | The mounting bolts must be hardened. If the bolt is yellow, its quality will most likely be terrible. |

| screw | Must have a Teflon insert or cotter pin. Plus look into your finger - there should be a through hole |

| Lubrication | Often the inside of the ball joint is lubricated at the factory, but practice shows that this amount of lubricant is not enough, so when replacing you must have a little more lubricant on hand |

Brand new set

Fault diagnosis.

To determine if the ball joint is faulty, just listen to the knocking sounds of the suspension when the car moves over uneven road surfaces. Ideally, there should be no knocking, but if the ball joint is faulty, then when driving at a relatively high speed along potholes, you can hear a rather unpleasant sound, which indicates the occurrence of play between the hinge, lever and wheel hub.

To verify this fact, you can do a simple test, which is not anything complicated. To do this, install wheel chocks under the rear wheels, and lift the front wheel, where the noise is coming from, using a jack. Now grab it vertically with both hands and try to swing it in the horizontal axis. For the purity of the experiment, it is recommended to ask your partner to press the brake pedal at this moment. If the wheel wobbles accompanied by slight play, the ball joint needs to be replaced.

It is strongly recommended not to delay this process. The fact is that a worn ball joint can create trouble for the driver when cornering. As a rule, it breaks and breaks the connection between the hub and the lever. Thus, the wheel turns out together with the levers, and the car becomes uncontrollable. In the best case, you can limit yourself to repairing the suspension, in the worst case, you can get into an accident.

Before replacement

Repairing ball joints on a VAZ 2109 is impractical - people have long considered them consumables. Therefore, if a malfunction is detected, a new part will need to be selected. What should you consider when choosing a part?

Before purchasing and installing, you should pay attention to such factors.

| What aspects to check | What should be |

| Manufacturer's reputation and type of packaging. | Availability and safety of protective packaging elements. |

| Condition of the case. | It is free of scratches, chips, cavities and other defects. |

| Finger color. | It should be black, but not painted, but darkened as a result of hardening. |

| Finger mobility. | It must be impossible or very difficult to turn the element manually. |

| Equipment. | Typically, the supports are supplied with a pin nut, mounting bolts and a boot. |

Immediately after purchasing the parts, check and, if necessary, increase the amount of lubricant in the support.