The brake system fault indicator is on

Most often, the reason is trivial - like a low level of brake fluid in the reservoir or excessive wear of the brake pads equipped with the corresponding sensors. Another simple reason could be... the parking brake is on (it happens that the limit switch is simply faulty). However, brake fluid leaks can also be the cause of a decrease in the level - they must be urgently identified and eliminated.

Why does the brake pedal fail after bleeding?

Often, after servicing the system, for example, replacing brake fluid, pads, discs, drums, the brake pedal fails. What is the reason for such changes?

Failures may occur for some time after replacing pads, discs or fluid and bleeding the system. Be prepared that the pedal will begin to fall, and do not immediately try to operate the car in the previous mode. Give the new brake discs and pads time to get used to it - until this happens, the car will jerk when you press the pedal, which may even vibrate, which will be transmitted to the steering wheel. The general grinding-in of new pads and discs requires 250–400 km. If the symptoms persist after this, it is recommended to check the quality of the installation, as well as the elements themselves.

Often the reason why the brake pedal fails is a damaged or misaligned brake caliper. Its vertical axis shifts relative to the axis of the brake disc, so the system is unable to function normally. Or a working caliper may be poorly secured, which is why the brake pads will definitely not be able to properly rub into the disc.

Due to problems with the caliper, the new pad cannot press against the disc with the entire area of the anti-friction lining, so the latter wear out quickly, and the performance of the brakes cannot satisfy the car owner. In this case, when pressed, the pedal slowly goes lower and lower. That is why, when replacing pads, it is important to monitor the condition of the caliper, its axial relationship to the disc. This is a mandatory rule when changing only the pads, pads and discs, or these elements and the caliper at the same time.

Parking brake ineffective

Have you tightened the lever, but the car still tries to roll downhill? In the simplest cases, the parking brake just needs to be adjusted normally. In addition, oiliness of the brake pads can affect it. It happens that the cables are jammed in the sheaths. Possible causes include oily discs or drums. Completely worn out pads may be to blame. And if the parking brake does not release the car, then most likely the pads are frozen or rusted to the brake drums.

Basic faults

The brake system itself is quite simple, but some of its elements require special attention. Main types of faults:

- The brake fluid leaks, resulting in a drop in pressure in the system. If a preliminary inspection does not find a leak, it is necessary to check the brake master cylinder. We bend the noise-insulating mat located under the brake pedal and inspect for streaks in the area of the rubber seal of the master cylinder. The presence of drips will indicate that the cause has been found and requires disassembling the cylinder and then replacing the cuff. If there is a vacuum booster, the brake master cylinder must be removed and inspected.

- When you release the brake pedal, the car drives sluggishly. Reason: the rear or front pads are jammed. Seized pads are identified by checking the heat of the corresponding wheel. We touch each disk - the hottest one will be jammed. In the case when these are the front wheels, you can, after removing the wheel, move the brake cylinder. If this fails, you will have to replace it with a new one. In the case of rear pads, the brake wheel cylinder will need to be replaced.

- When you press the pedal, braking does not occur, but it does when you press it several times in a row. This may indicate the presence of air in the system. The solution to the problem is to bleed the brakes to remove air.

- Problem with the handbrake. Most often this problem occurs in winter. It manifests itself in the fact that after a long period of parking, when the handbrake is released, the wheels remain locked. The reason is that the parking brake cable is frozen. During its operation, moisture gets there and freezes in winter. If the casing is severely damaged, it will have to be replaced.

Read, it may come in handy: How to raise or lower the suspension. Tuning and modification of the chassis

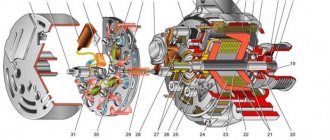

Brake master cylinder diagram

Vibration when braking

This is a fairly common malfunction that is associated solely with critical or uneven wear of the discs or drums, and the repair will consist of replacing them.

Car shifts to the side when braking

The malfunction is due to either a failure of the working (wheel) cylinder or wear of the pads. Replacing them (or repairing them) will solve the problem.

The VAZ 2107 brake pedal fails: the main reasons

The brake system must be sealed and free of air. If the pedal begins to fail, then, with a greater degree of probability, we can say that depressurization has occurred, that is, air has entered the system.

Other reasons:

- rust formation on the pedal linkage;

- failure of the vacuum booster;

- unadjusted distance between the cylinder piston and the pedal itself;

- lack of fuel fluid in the system.

It is also important to remember that brake fluid is an aggressive substance that can destroy thin pipes and even lines. That is why it is important to use only high-quality TZ. Low-quality liquid can form cracks through which it then flows out safely. But the flip side of the coin is that when you press the brake pedal, air leaks through these cracks.

Brake overheating

This type of malfunction is usually identified by the appearance of a burning smell. This is usually accompanied by an increased pedal travel, which begins to feel weak, as well as an increased braking distance. The cause of overheating can be either excessively active driving with constant braking, or simple forgetfulness, that is, the parking brake is too tight.

Additionally, possible culprits include seized cylinders and calipers.

Braking system of modern cars

The general braking scheme on modern cars suggests the presence of three main types:

- working;

- spare;

- parking

The working vehicle performs the functions of reducing the speed of the vehicle or stopping it.

The spare vehicle is intended to prevent malfunction or failure of the working system.

The parking vehicle performs the functions of holding the vehicle stationary in special conditions and in parking mode. The VAZ-2107 implements a working and parking vehicle in a “pure” form.

In a modern car, braking can be performed not only by the vehicle itself, but also by the engine, electric or hydraulic transmission brake. In addition, additional systems (or devices) are often implemented that increase the productivity of braking functions:

- anti-lock braking system (the notorious ABS);

- electric brake force distribution (or EBD);

- electrical stabilization system (ESP), etc.

The described devices and systems lead to a significant increase in the cost of the vehicle, and the VAZ-2107 brake system diagram does not provide for them.

However, domestic cars have recently begun to provide similar capabilities.

Noise when braking

High-frequency noise, squealing, and whistling can occur both during braking and, sometimes, during normal movement. The reason is the off-design mode of friction of the friction material on the working surface of the brake disc. Extreme wear on the brake pads and severe corrosion of the brake disc (often on the inside, “invisible” side) may be to blame. It happens that the brake pad lining has peeled off from the base. The list of possible causes continues with contamination of the pads, warping of the disc due to local overheating, improper fastening of the pads in the caliper, left pads or discs, etc.

Brake system on the VAZ-2107 - what every owner of the seven needs to know about it

The car is designed to move, and so that it can stop in time, brakes are used in the design. Every owner of this car should know how the brake system works on a VAZ 2107, since the life of not only the driver and passengers, but also the fate of other road users depends on the serviceability of the brakes. Let's find out in detail what is special about the brake system of the VAZ 2107 and how it works.

When the brake pedal is released, one of the wheels slows down

The following reasons are suspected: jamming of the wheel cylinder piston, swelling of the brake cups, deformation of the brake pipe, jamming of the pads due to contamination of the guide, peeling of the brake pad lining of the drum brake. It happens that the tension spring of the drum brake shoes is weakened or broken, the parking brake is overtightened, or the cable is stuck in the sheath.

- Do you know which faults you can drive with and which ones you cannot? Take the test and check your driving skill level.

- To increase the life of your car, use additives from SUPROTEC. Original SUPROTEC products can be purchased at.

Replacing front brake hoses

Replacing the front brake hoses on a VAZ 2107 is not a difficult procedure, and before performing it, you need to pump out the fluid from the expansion tank. To pump it out, it is better to use a rubber bulb or syringe. Before you start doing the work, you will need to grab a tool and get started.

- First, let's start removing the front wheel from the desired side. We remove the front wheel in order to free access to the hose.

- When access to the eyeliner opens, you must first clean the joints with a wire brush, and then treat them with WD-40 or similar lubricant.

- 5-10 minutes after treating the connections with lubricant, you can begin to unscrew the fittings. To do this, use a special 10 mm key with a slot.

- The key has a special stopper in the form of a bolt, which is screwed in after it is put on the metal tube.

- We proceed to loosen the bracket nut, for which you need to hold the fitting with a key “17”.

- As soon as the connecting coupling on the metal tube is loosened, you can remove the special key and continue unscrewing by hand.

- After disconnecting the hose, a rubber boot must be placed on the end of the tube to prevent dust or water from entering the system.

- To release the second end of the fitting from the bracket, you will need to remove the bracket with pliers.

- Using a flathead screwdriver, unscrew the screw that holds the trim bracket to the caliper. After this, you can dismantle the part.

New hose in place - Using a “14” wrench, you need to unscrew the bolt securing the second fitting.

- The copper washers must be replaced, and then proceed to install the new hose on the caliper. It is important to take into account one nuance - the tip of the fitting should be directed downward, not upward.

Read, it may come in handy: How to find what is creaking - insidious acoustics

After screwing the second fitting, you can begin to perform similar actions, but on the other front wheel. This completes the installation of the front hoses, but do not rush to install the wheels in place, as you will need to perform the procedure of removing air from the system (bleeding the brakes).

Install and screw the locking bracket