Is it possible to independently manufacture a short-stroke rocker?

Despite the fact that the cost of a short-stroke rocker is not so high, many people prefer to make and install it with their own hands, which, in general, is not so difficult to do. You will need very little to get the job done:

- a piece of pipe having a diameter of exactly 15 mm;

- the gear shift knob from the car for which the rocker is made;

- ball nut;

- backstage repair kit with axle and bushing;

- cardan from the steering mechanism.

The work itself on making a short-stroke link takes about two hours. The ball from the gear shift lever is cut off, its lower edge is adjusted so that a pipe can be installed, which will have to be properly welded. A nut is welded to the lower edge of the pipe and a ball nut is installed. After this, the cardan can be mounted to the gearshift lever.

Perhaps the whole process will seem somewhat difficult to some, but if it takes place under the “supervision” of an experienced mechanic/car mechanic, the success of the endeavor is guaranteed. It is possible to turn a car's standard rocker into a short-stroke one without the need to dismantle it. To do this, you will need to lift the fasteners of the “piece of iron” that extends from the gearbox to the shift lever itself. This is not to say that this procedure will make gear shifting truly sporty, but the free play of the lever will be somewhat reduced.

The process of replacing the gearbox rocker

Dismantling the old rod

First you need to loosen the clamp on the main rod and remove the hinge from it. To do this, use a 13mm wrench. Next, remove the boot and, using a 10mm wrench, unscrew the bolt on the desired cardan. Usually it is fixed almost tightly, so here you will need a hammer to loosen it a little with gentle blows. By the way, you can immediately check the condition of the oil seal and, in case of any defects, replace it with a new one.

New drawstring and cord from Kalina

Installation of a modified backstage

Having removed the old cardan, you can begin installing the new one. To do this, you must first put on the boot. Next, we place a new cardan on the gear selector rod and secure it with a fixing bolt. Be sure to make sure that the bolt fits into the special recess on the rod. Also, do not forget to apply thread locker to the bot so that it does not unscrew due to vibration.

The next step is to put the drive rod on the rod. For some models, the stem from Kalina will have to be shortened by about 1.5 cm.

Adjustment

Next, you must carefully adjust the position of the lever so that it is centered with a slight offset to the right. Here we will need an assistant who will have to monitor the placement of the lever in the cabin. After installation is complete, tighten the clamp, while an assistant must hold the lever from moving.

And, of course, you yourself should try how conveniently the lever is adjusted and, if something happens, reconfigure it.

By the way, some craftsmen cope with shortening the scenes without buying a new one. To do this, you need to disassemble the slide, as in the previous paragraph, and trim the necessary parts using a grinder. Next, weld a piece of pipe and sheet metal into the rod. If you yourself are not very knowledgeable about this, you can ask any welder. This process can be studied more clearly using a visual video.

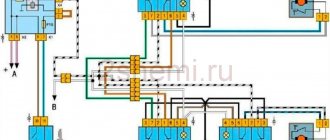

Gear shift drive rocker from Priora on VAZ 2110

| After the start of production of the Priora, the plant constantly refined the design of the car. So, starting around 2011, AvtoVAZ began equipping cars with a new type of gear shift drive. Thus, the Priora got its own gear knob (and not like on the “ten”), a rocker, a lever axis and other elements of the shift drive. Let's figure out what this modernization of the Priora gave and why this design is installed on the VAZ 2110. |

What are the scenes in a car?

| 1 | Gear shift knob cover | 21700-1703124-00 |

| 2 | Lever | 21700-1703088-00 |

| 4 | Hinge bushing | 21700-1703226-00 |

| 5 | Thrust washer | 21700-1703371-00 |

| 17 | Control drive assembly | 21700-1703010-00 |

| 18 | Lever arm | 21700-1703082-00 |

| 19 | 21700-1703219-00 | Lever axis |

- No vibrations on the gearshift knob;

- New design of the gear knob with a gray insert to match the interior style.

- Owners who have installed new parts notice a gap between parts 17 and 20. The metal disks 16 are not pressed against the spacers 16 and the lever 20 tightly enough due to the bushing 18. The problem can be solved by shortening the bushing by 1-2 mm.

- Vibrations on the gearshift knob become less, but they do not disappear completely. They say that only cable shifters have no vibrations, but even there there is a rattling of the gearshift knob.

What feedback can you give about the new design of the gear shift drive? Does it make sense to modernize the design or sufficiently modify the existing one (for example, to get rid of the rattling of the gearshift knob, you can install a backlash-free universal joint and a fluoroplastic bushing)? By the way, look at other modifications of the VAZ 2110 in Priora.

| Is it worth installing an N/O shift drive from a Priora on a VAZ 2110? |

Changing gears on a VAZ 2109

The “nine” is equipped with a five-speed manual gearbox (Gearbox). The connection between the gear selection control lever and the gearbox actuators is purely mechanical. For this purpose, a steel rod is used, the lower end of which is fixed to a ball joint in the housing of the gear selection mechanism, and the upper end is equipped with a knob that fits comfortably in the driver’s hand. This lever, not entirely justifiably, is popularly called the “slide”.

In a classic backstage, the levers are connected using a slider that can move along it. It looks especially impressive when driving the drive wheels of a mainline steam locomotive. In an automobile rocker, the elements have a certain freedom; they are connected by a hinge, but the articulation point cannot move along the rocker. Nevertheless, the name stuck.

The gear change lever of the “nine” has two degrees of freedom with three positions in each: “forward - neutral - back” and “left - neutral - right”. This gives 9 selector position options, of which two (rear left and rear right) are not used. The remaining seven correspond to five forward gears, one reverse gear and neutral.

The standard VAZ 2109 rocker is called long-stroke because the attachment point of the rod leading to the gearbox is located quite close to the ball joint. The distance to the attachment point is approximately 4 cm. With a total length of the lever with a knob of 30 cm, in order to move the gearbox rod by only 2 cm, the gearbox handle must be moved by 15 cm. Plus the play - it turns out to be a very long-stroke option, and it cannot be configured otherwise.

A fashion came from motorsport - replacing the rocker with a decrease in stroke. The repair involves moving the rod attachment point up the slide by 5–6 centimeters. It turns out to be a short-throw shifter on a VAZ 2109, the stroke of the gear shift knob is halved. Many people like it.

The Kalina wing on the VAZ 2109 also improves the situation.

Return to contents

The work on installing a short-stroke rocker on the Lada Priora takes place in several stages

Lada Kalina hatchback Sport Logbook Replacing handbrake cables on the Luca ZTD

The decorative cover from the car gearbox lever and the knob are removed. Moreover, the knob is not attached to the lever in any way; it just needs to be pulled with some force. Remove the PP gearbox lever rod from the propeller shaft, to do this, first loosen the clamp using a key set to “13”. Next, you need to release the lever, having first released the locking ball (blocks the engagement of reverse gear). To do this, remove the locking ring (when removing, under no circumstances should you pull up on the lever). Remove the retaining ring and lever with ball and spring inserted into the plastic housing. The lever and rod are removed through the vehicle interior. If you wish, you can disconnect the lever from the rod for convenience, but this is not at all necessary. In order to remove the cardan, first pull off the rubber boot, after which the fastening bolt on the left of the cardan is unscrewed with a “10” key. We replace the removed Priora driveshaft with Kalina's driveshaft. Kalina's cardan has a longer rod, which must be shortened taking into account the type of short-stroke rocker being installed. In some cases, the cardan shaft may not go in completely, which will cause the gearbox lever to shift towards the handbrake. When shortening, about 1-2 cm is sawed off. Before installing a new cardan, lubricate it from the inside with lithol

The bolt, which has a cone shape, is easy to screw in; it is important not to overtighten. Next (preferably with someone's help) install the rod. The rod is also installed through the interior: one holds it in the cabin by the elastic band, while the second one carefully pulls it through. Reassembly sequence: - Place the rod on the rod of the new cardan. Assemble the reverse gear locking mechanism, lubricate the ball with lithol. Adjust the gear lever. Tighten the clamp on the rod. Important: Please note that if you start by assembling the reverse gear locking mechanism, then you may not be able to put the rod on the rod of the new cardan. This problem can be solved by shortening the cardan. Do not forget to put the rubber boot on the cardan.

Adjust the reverse gear locking mechanism

This is due to the fact that the link is adjusted, the locking mechanism may not coincide with the plate it clings to. To do this, the plate is removed and the engagement is painstakingly adjusted. The plate mounting bracket has a cutout into which the mechanism clings. Using sandpaper or a file, it is necessary to adjust and refine the hook for free engagement. Put the cover back on the gearbox and knob.

Also read with this article:

DIY guide for replacing spark plugs on a VAZ Lada Priora

We change the steering tips of Lada Priora

Replacing the air filter Lada Priora

Changing the filter and oil in the Lada Priora engine

How to replace the oil seal

If you detect an oil leak from the gearbox, carefully inspect the crankcase.

The leak will reveal itself. Lubricant usually leaks out through the CV joint seals and rocker panels. In the latter case, to replace you will need to perform a number of actions:

- Purchase a new VAZ-2109 gearbox seal. Its price is about 100 rubles.

- Drain the oil completely from the gearbox by unscrewing the plug from the bottom using the key “17”. If necessary, you can replace the lubricant later. It is recommended to pull out the upper dipstick to facilitate oil drainage.

- Disconnect the cardan from the rocker arm.

- Remove the boot, use a 10mm wrench to unscrew the bolt securing it to the gearbox rod.

- Using an awl or a thin screwdriver, remove the old oil seal. Inspect it for damage.

- Install the new oil seal using a pipe or large washer to press in.

After replacement, install the boot. Assess the condition of the cardan: if it has too much play, it will need replacement. After carrying out all the work, be sure to check that the speeds are turned on correctly.

Do-it-yourself tuning of a VAZ 2109, manufacturing and installation of a short-distance rocker on a VAZ 2109

Lada 2101 Logbook Repair of master and slave cylinders of clutch VAZ 21011

The short-throw rocker is quite popular among car enthusiasts. This modern tuning is, first of all, good because, thanks to its size, it allows you to reduce the travel of the gearbox lever when changing gears. At the same time, gear shifting becomes much clearer.

The result of installing a short-stroke rocker gives an excellent result: clearly, quickly, pleasantly. But there are also two disadvantages: the price of a new rocker and the increased effort required when changing gears. Today, a short-throw rocker for the VAZ 2109, like for other cars, can be purchased at almost any auto store.

Moreover, the rather steep price does not stop car owners - many prefer to overpay once, but then enjoy the ride. In principle, the short-throw rocker in its design is not very different from the standard one, and after carefully studying its essence, making a short-throw rocker with your own hands will not be difficult. Moreover, this will take no more than half an hour.

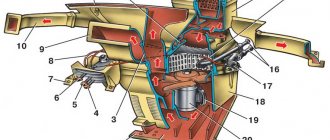

Diagram of the operating principle of the VAZ 2109 short-stroke rocker

Let's look at the diagram. The OF points indicate the gearshift lever in neutral. To engage the gear, you need to move the rod (the point of attachment of the rod to the lever - point B) to the distance AB.

In this case, the knob of the gear shift lever (point F) will travel a distance FE and move to point E. Our task is to reduce this distance of movement of the lever handle. To do this, the lever OF is increased in length to point H. This is done in the place under the hinge by the length BD.

Since the PP box remains the same, the distance by which the hinge moves remains the same: AB = CD. Judging by the diagram, distance FE is much less than distance HG, which means a decrease in the distance of movement of the lever handle.

Now you don’t need to search around the cabin, both for the gear knob and then for the gear itself. Now about manufacturing and installation. You will need:

a welding machine, a grinder with a cutting wheel (or a hacksaw for metal), two metal fragments for extending the lever, a cardan from Kalina.

The work on installing a short-throw rocker on a VAZ 2109 takes place in several stages

Prepare a “Kalinovsky” cardan.

Remove the standard rocker from the vehicle.

Use a grinder to make cuts in two places.

Next, two fragments of the required dimensions are installed and welded: a piece of pipe and a piece of sheet metal. The short-stroke link is ready. Before installing it in place in the car, the rocker must be sanded and painted. When installing, adjust the position of the gear shift lever. By installing a short-throw rocker on your VAZ 2109, you will get convenience and comfort with your own hands and at minimal cost.

Other interesting materials:

Short-throw slides for "nine"

Such designs were developed exclusively for sports models, but are widely used in production ones. Advantages of the VAZ-2109 short-stroke rocker over the standard one:

- Easier gear shifting.

- The backlash of the gearshift lever is reduced, especially when using a cardan from Kalina.

- You need to either buy it or make it yourself.

- It takes a lot of force to change gears. Despite the smaller stroke, this type of backstage is more suitable for people who are not only strong in spirit.

But you don’t have to buy a VAZ-2109 rocker in stores; you can make a short-shifter from a regular one with little welding skills.

To do this, cut the old rocker in two places and weld pieces of a metal plate to lengthen the arms. The main thing is for the new drawstring to fit into place, so first carefully study the drawing, which shows the locations of the cuts.

The VAZ 2109 is known as the most successful car of the Volga Automobile Plant after the collapse of the Soviet Union. It is still widely popular among domestic drivers. At the moment, production of the VAZ 2109 and its modifications has been suspended. In addition to 2109, its direct successor 2114 is often found on the roads of our country, as well as the successor to the “eight” 2113, and the “tens” - 2115.

Adjusting and installing a short-stroke rocker on a Priora

- VAZ 2110

- VAZ 2114

- Lada Priora

- Video publications

- VAZ tuning photo stream

- Operation and repair manuals

Tuning does not always mean installing a new body kit or shortening the Priora springs. Sometimes modernization helps improve driving comfort. An excellent example would be a short-throw rocker. VAZ owners know the “features” of the gear shift lever (GSL), which is not so easy to direct to the desired gear. The short-throw rocker on the Priora solves this problem, but we will tell you how to install it on the Priora and adjust it correctly.

The instructions in our material are also relevant for motorists who want to know how to repair and replace a conventional rocker. The instructions describe in detail the process of dismantling and adjustment, which is carried out for a factory part according to exactly the same principle.

Principle of operation

Study the diagram below to understand how the short throw rocker works. The lever is installed in the neutral position, here it is indicated by the points “O” and “F”. To start the transmission, you need to move the rod - it will connect to the control gear at point “B” - at point “A”. After this, the handle will move to point “E”. Repairs and subsequent replacements are carried out in order to reduce the distance.

This can be done if the lever extends to point “H”. This move will increase the distance. On the diagram, "A" and "B" will become points "C" and "D". Replacing the standard rocker with a short-stroke one allows you to reduce the movement of the handle. We've sorted out the theory, now we can start the repairs.

Replacing the gearbox slide

First, you should decide whether you will buy a ready-made short-stroke part or make it yourself. For Lada Priora drivers who have not upgraded components, we recommend choosing the first option. The instruction will be carried out taking into account modifications.

For work we will need:

- Two metal plates.

- Kardanchik from Kalina.

- Welding machine.

- A set of keys, including spanners.

- A grinder with a cutting wheel; alternatively, you can use a hacksaw.

Operating principle and manufacturing method

The VAZ 2109 short-throw gearbox came from professionals in motor racing; you will agree what kind of sport it is if a lot of time is spent shifting gears. What does such a scene give:

- Thanks exclusively to it, switching becomes much more pleasant for you, and the lever stroke is significantly reduced by almost half, the result obtained from the installation is simply incredible

- Therefore, smart people picked up this “theme” and launched it into the “masses”

- It turns out that today the VAZ 2109 short-stroke rocker is sold in almost every auto parts store

- Of course, the price is significantly inflated, but this is not an obstacle for most motorists

- There is nothing surprising here, because the rocker is worth it, I myself, like many car owners, was ready to buy it, I liked the short rocker of the VAZ 21093 gearbox so much.

- However, as soon as I saw its design and understood the main point of tuning, I changed my mind about paying for it, because it is possible to make one with your own hands in just half an hour of work

- What I got - see for yourself. Now I’ll tell you in a few words about how the whole mechanism works, also see the photo

The diagram I have given will allow you to understand how the short-throw rocker on the VAZ 2109 works:

- The "O" - "F" line represents the low and high points of your standard lever set to neutral.

- In order for you to engage the gear, you will need to move the rod connected to the lever (point “B” is the point of their connection) to point “A”

- The handle of the gear shift lever will move to point “E”

- You understand that our task is to reduce the “E”-“F” switching distance that the handle travels

- And for this we need to increase the length of the lever to point “H”, which will allow us to raise the rod by the same distance (the segment “C”-“D” is equal to the segment “A”-“B”)

- It turns out that the lever that changes gears will have to travel a shorter distance; in this case, you won’t have to stretch or “search throughout the cabin” for the desired gear and its lever

Reasons for replacement

There are several situations when the owner of a VAZ 2109 has or wants to get into the design of the gearbox and specifically work with the rocker:

- Oil is leaking due to a damaged rocker seal. It must be replaced;

- The old drawstring was out of order;

- I would like to exchange the long-stroke for a short-stroke in view of its advantages.

Now to the question of when replacing or repairing the backstage is a necessary measure.

- The backlash of the gearbox selector has increased significantly.

- Gears change with difficulty, and when changing speed, extraneous sounds appear.

- It is possible to change gears, but with a lot of effort.

- Speeds change incorrectly. Instead of one, a completely different one turns on.

- It is impossible to turn on all or part of the gears at all.

Even if the resulting play is still insignificant, it is advisable to immediately begin repairs or completely change the drawstring.

Replacing the oil seal

If you find that the oil in the gearbox is gradually disappearing, you can suspect the rocker seal. There is nothing else left to do but change the element.

- First, buy a new shift rod seal. It costs about 70-100 rubles.

- Drain the oil from the box, having prepared a clean container in advance. This is in case you refill the same oil. Although this is an excellent reason for you to change the transmission lubricant at the same time.

- To make sure the oil flows out better, first unscrew the filler plug or remove the speedometer gear. After draining the oil, screw the cap back on.

- We climb under the car and disconnect the fasteners of the gearbox lever driveshaft.

- Pull the boot off the cardan, unscrew the bolts securing it to the gearshift rod. Problematic fasteners that you will have to tinker with.

- After removing the cardan shaft, remove the rod boot.

- We remove the damaged oil seal using an awl or suitable available tools. The main thing here is the stock itself.

- We install a new one in place of the old oil seal and press it with a tube of the appropriate diameter.

- Put the boot back in place and rotate the driveshaft.

- Please note that the bolt securing the cardan to the rod is an adjustment bolt. Therefore, screw it in exactly the same way as before dismantling. Otherwise, some speeds may not turn on.