From this small guide you will learn how to replace the clutch on a VAZ-2112. This car has earned popularity among young people and older generations. Yes, the car is still far from being comparable to prestigious foreign cars, but it has everything you need: a very playful and powerful engine, a comfortable interior, and a rather attractive appearance. And this is all that is necessary for an unpretentious person. And the most important thing is the low cost of maintenance. Spare parts for a 12 Series car cost much less than for foreign cars. In addition, many components from older “nines” and “tens” are suitable for it.

What is clutch?

Before you go to a car service center in Moscow or another city, try to figure out how to properly replace the clutch on a two-wheeler. As you can see, there is nothing complicated in the work procedure. You can complete all repairs yourself in a few hours.

The clutch is a mechanism that allows you to disconnect the engine crankshaft and the primary gearbox. As a result, the engine can work, the gearbox lever can be in a gear position, and the car will stand still.

A clutch is needed in order to change gears while the car is moving. If it were not there, then changing gears would be problematic - the lever is very difficult to move from one position to another. And all because the engine crankshaft and the wheels of the car are rigidly connected. And it is the clutch that allows for a kind of disconnection of the power units.

When repairing a car in a car service center in Moscow or any other city, you need to carefully ensure that the technicians complete all the work to the highest possible quality.

What is a handbrake for?

According to the current Traffic Rules, the handbrake of a VAZ must hold the vehicle on a slope of up to 25%. When lifting the lever up, it should produce from 2 to 8 clicks. If the car has been in operation for more than three years, then it is necessary to check the parking brake system. You can go to a car service center, where qualified specialists will carry out high-quality diagnostics. You also need to do this process yourself. Having stopped the car on a level surface, the lever rises all the way up with a smooth movement. In this case, the clicks are counted; there should be no more than 8 of them. When leaving the cabin, you need to apply force from behind, trying to move the car. If it rolls, then you will have to adjust the handbrake. After tightening the cable, the result is the same, which means that only one thing remains - to completely check the condition of the rear brake system.

Basic clutch elements

Now let's look at what main elements are included in the design:

- VAZ-2112 clutch drive disc (usually called the “basket”). It is installed on the flywheel and secured with bolts.

- Driven disk. It stands inside the “basket” and is connected to the gearbox input shaft using a splined connection.

- The release bearing is an element that allows you to act on the petals of the basket. With its help, the slave disk is disconnected from the master disk.

- Clutch cable - allows you to transmit force from the pedal to the release bearing.

- The clutch pedal, which the driver operates with the force of his foot.

These are all the basic elements that are present in the design of a car clutch. It is worth noting that the “two-piece” uses a cable drive system, which is much cheaper than a hydraulic one. But it is much worse in terms of convenience - the pedal is tight, this is especially noticeable on older cars. And if you want the clutch on your car to be as soft as possible, change the cable in a timely manner, do not wait until it breaks.

Bottom line

Adjustment is an important step when replacing the clutch cable. Replacing the cable is a simple procedure; if all stages are performed correctly, gear shifting will occur smoothly and comfortably for the driver

Today I decided to make good use of my day off and replace the clutch cable. There are several reasons for this: 1. The rubber seal between the engine compartment and the passenger compartment broke.

2. When pressing the clutch pedal, “crunching” sounds began to appear + the pedal began to be pressed harder. Lubricating the cable mechanisms did not get rid of this.

3. Judging by the reviews, the cable “lives” until it breaks for 50-70 thousand km.

I will soon have 50 thousand and the prospect of replacing the cable on the side of the road is not very encouraging.

new cable Before changing it myself, I looked up the Internet on this topic. You can replace it in two ways: according to the official instructions, where you need to disassemble the frill to access the cable fixing bracket, or do everything from under the pedal assembly (many complain that access to the bracket is extremely inconvenient) I decided to do it according to the Murzilka. I took off the windshield wipers and frill, but access to the protective cover was blocked by the windshield wiper motor, and I really didn’t want to remove it + in Murzilka and in real life, the fastening of the protective cover is different, and even after removing the motor it was extremely difficult to get to. In the end, I put everything back together and decided to do it the second way.

Under the hood.

We loosen the fastening of the cable to the box and remove the end of the cable from the plug (I didn’t take pictures, because this is in any instructions and is not a problem).

Then we go to the salon

Here it is worth dwelling on how to make it easier for you to access the cable fastening.

We secure the clutch pedal in the upper position with a plastic clamp.

None

None Use a long flat screwdriver to remove the bracket.

the same problematic bracket. Unscrew the nut securing the cable structure to the body

We pull out the old cable from the interior side.

cable hole

old cable

The rubber seal is torn. We install a new one from the interior side. We secure the fastening of the cable structure and put the cable on the pedal.

This is where the fun begins. Putting the bracket back on is the main problem with this replacement method (judging by reviews on the internet). Yes, the position is extremely uncomfortable, but I didn’t spend much time on it, although my back still aches from the position in which I had to do it))) We secure and adjust everything under the hood according to the Murzilka. Ready!

None ps If you are of heavy build, then do better according to the Murzilka. It is really extremely inconvenient to get to the staple.

Price tag: 240 ₽ Mileage: 47000 km

The VAZ 2110 clutch pedal cable, like any other cable, breaks, usually due to wear or when the car is operated in difficult conditions. Periodically check the cable for the integrity of the metal rods that make it up. A sign that the cable is torn is when the clutch pedal sinks to the floor.

Also, the pedal fails when the clutch fork breaks, the spring of the pedal itself breaks, or, in the best case, the cable simply comes out of the fork. Replacing the clutch cable of a VAZ 2110 is not difficult.

Symptoms of a node malfunction

Before replacing the clutch on a VAZ-2112, you need to figure out whether it needs to be done at all.

Among the signs of malfunctions are the following:

- When you press the gas pedal, you can hear the engine picking up speed, but the car does not go faster. This indicates that the clutch is slipping, there is practically no connection between the driven and driving discs.

- Extraneous sounds are heard when the car moves - this may indicate the destruction of some system components. As a rule, at the same time as these sounds, the system also fails.

- A hum is heard when you lightly press the pedal - a clear sign of a faulty release bearing.

- The pedal falls through - most likely the VAZ-2112 clutch cable has broken. This is the most harmless thing that can happen.

- If the cable is intact, but the pedal falls and the clutch does not release, then the release bearing has collapsed. Unfortunately, this also happens sometimes.

Knowing all the signs of breakdowns, you can begin repairs. Replacing the clutch on a VAZ-2112 with your own hands is not difficult. You just need to know the order of the work.

Preparatory stage

Before changing the clutch on a VAZ 2110, you need to prepare a place for repairs and tools. For this process, the most suitable solutions are: a car lift or an inspection hole. If there are no such conditions, due to a hopeless situation, it is possible to replace the clutch with a 2110 in “Spartan conditions”. It is enough to find a flat surface area in a garage box, a parking space or in the yard.

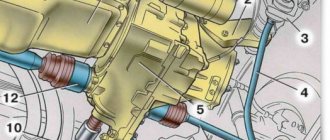

Clutch diagram for VAZ 2110: 1 - release bearing guide sleeve; 2 — gearbox input shaft; 3 — cable lead; 4 — clutch release fork; 5 — fork axle bushing; 6 — pressure disk assembly (basket); 7 — driven disk; 8 - flywheel; 9 — clutch pedal; 10 — mechanism for automatic adjustment of cable length; 13 — clutch release clutch (release bearing); 14 — lower tip of the cable sheath; 15 — bracket installed on the gearbox housing; A - the displacement distance of the leash, checked when installing the cable (27 mm).

Also, for repairs you will need:

- locksmith set with open-end wrenches and sockets up to 22 mm;

- a jack and several short boards (wooden blocks);

- container for possible draining of transmission oil from the gearbox;

centering shaft (mandrel).

As for the clutch itself, it is sold in sets (3 in one, 2 in one) and parts separately.

The system includes 3 replaceable elements:

- release bearing;

- clutch disc;

- basket.

It is more practical for a car owner to ask in advance how much new clutch parts will cost to replace a VAZ 2110. This will help prepare the necessary budget. The price of spare parts varies and depends on the manufacturer. Among manufacturers of quality parts, the leaders are: Sachs, Luk, Valeo and Krafttech. These spare parts are guaranteed to fit the vehicle and have a long service life. Poor quality parts may not fit at all or may fail in the first days after repair.

Dismantling the gearbox

The most important thing is to remove the gearbox. Therefore, it is best to carry out all work on an inspection hole or overpass - it’s really more convenient. Procedure:

- Remove the left wheel, unscrew the nuts from the ball joint and the tie rod end. You will need to move the box to the side; the drive on the left should come out without any problems.

- Loosen the nut securing the rocker and remove it from the gearbox shaft.

- Remove the starter, having first disconnected the battery and all wires from it.

- Unscrew the fastenings of the pillows holding the box. It is recommended to place a jack or reliable support under the gearbox housing before doing this.

- Disconnect the speedometer cable, disconnect the wires from the reverse sensor, as well as the ground bus.

- Unscrew the three bolts and nut that secure the gearbox housing to the engine block.

- Carefully move the box to the side; the right drive must be removed.

A little about how to properly remove the box:

- Firstly, you cannot remove both drives at once - replace one with a tube that will hold the differential.

- Secondly, it is imperative to drain the oil from the gearbox crankcase. By the way, why not replace it?

Clutch installation and assembly

Replacing the clutch on a VAZ-2112 is carried out according to the following algorithm:

- Unscrew all the bolts that secure the basket to the flywheel. If you plan to install it again, then you need to unscrew the bolts evenly, crosswise. The main thing is not to damage the basket.

- Remove the basket and disk, install new elements in their place.

- Tighten all the bolts (be sure to use new ones, since the old ones are threaded) and install the guide sleeve.

- Tighten the bolts evenly, crosswise.

- Remove the old release bearing and install a new one.

- Reassemble everything in reverse order.

This is a short tutorial, but the hardest part is lifting and lowering the box, as it is quite heavy.

Replacing the clutch cable

The price of replacing a clutch on a VAZ-2112 is quite high - you will have to pay about 3,000 rubles for more or less high-quality spare parts, and at least the same for labor. But if you do everything yourself, you can save a lot of money.

Replacing the cable is much easier. The old one needs to be dismantled, and the new one needs to be fixed on the pedal and fork. The most difficult thing is to stretch it from the engine compartment into the cabin: the hole is quite small, and there are no amenities. But everything is doable, and all the work will take you, including preparation, no more than half an hour.