Code P0133 indicates that the engine control module (ECU) has detected a slow response from the oxygen sensor (bank 1, sensor 1). Along with the Check Engine Light, this may be accompanied by increased fuel consumption, smoke from the tailpipe, or a rough idle.

Although in most cases there will be no symptoms other than the Check Engine light. Read on for information on how to diagnose and fix this problem before it causes costly repairs.

What does P0133 mean?

The Engine Control Module (ECM) uses an oxygen sensor to monitor the oxygen content of the vehicle's exhaust gases. The ECM uses the signal received from the oxygen sensor to regulate the fuel/air mixture ratio of the engine. The air-fuel ratio is controlled by the ECM to regulate fuel consumption and reduce emissions of harmful substances from the vehicle's exhaust gases. The oxygen sensor sends a voltage reading to the ECM, thereby reporting the ratio of air and fuel in the engine mixture.

When the amount of oxygen in the exhaust gas changes, the output voltage of the oxygen sensor changes. The output voltage of the oxygen sensor should change instantly, since when you press the gas pedal, the ratio of air and fuel in the mixture supplied to the engine cylinders immediately changes.

When P0133 appears, the engine control module (ECM) has detected that the oxygen sensor output voltage is not changing quickly enough to correct the air-fuel ratio, indicating that the sensor is responding too slowly.

On which cars is this problem most common?

The problem with code P0133 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Audi

- BMW

- Chevrolet (Chevrolet Aveo, Cruz, Lacetti, Silverado)

- Chrysler (Chrysler Sebring)

- Daewoo (Daewoo Matiz, Nexia)

- Dodge (Dodge Stratus)

- Ford (Ford Mondeo, Taurus, Focus, Fusion)

- Geely (Gili Emgrand)

- Honda (Honda SRV, Civic)

- Hyundai (Hyundai Accent, Getz, Matrix, Santa Fe, Solaris, Sonata, Tucson, Elantra)

- Jeep (Jeep Wrangler)

- Kia (Kia Rio, Sid, Sportage, Cerato)

- Lexus

- Lifan

- Mazda (Mazda 3, Mazda 6, Mazda cx7, Aksela)

- Mercedes

- Mitsubishi (Mitsubishi Outlander, Lancer, Pajero)

- Nissan (Nissan Beetle, Terrano, X-Trail)

- Renault (Renault Duster, Kaptur, Logan, Sandero)

- Saturn

- Skoda (Skoda Fabia)

- Ssangyong

- Subaru (Subaru Outback)

- Suzuki

- Toyota (Toyota Avensis, Corolla, Yaris)

- Volkswagen (Volkswagen Passat, Polo Sedan, Tiguan)

- Volvo (Volvo s70)

- VAZ 2112, 2114, 2115

- Gazelle Business, umz 4216

- Lada Vesta, Granta, Kalina, Largus, Priora, X-Ray

- TagAZ Accent, Sonata

- UAZ Patriot

With fault code P0133, you can sometimes encounter other errors. The most common are: P0130, P0134, P0135, P0136, P0138, P0141, P0150, P0153, P0156, P0171, P0301, P0302, P0411, P0420, P0430, P0440, P0441, P0446, P2096, P218 7.

Causes of error P0133

- Oxygen sensor malfunction

- Intake manifold leakage

- Air intake system leakage

- Short circuit or break in electrical wires related to the oxygen sensor

- Accumulation of soot or carbon deposits on the oxygen sensor, causing the hole used by the sensor to sense the oxygen content of the exhaust gas to become clogged

- Mass air flow sensor dirty

- Incorrect fuel pressure

Troubleshooting

Having figured out how the error is formed, what provokes it and on what cars it can occur, you need to answer the main question. It concerns how exactly to get rid of the error.

Experts give several recommendations in this regard.

- Using diagnostic equipment in the form of a scanner, check the ECU in deep diagnostic mode. This will open all errors that are in memory. If there are other errors than the one in question, they should be corrected by identifying the causes and then reset. After this, another diagnosis is carried out. It is possible that 0133 was the result of other malfunctions.

- If we are talking about the obvious presence of error P0133 and the reset did not give anything, then you will have to check the condition of the oxygen sensor and the associated components.

- First of all, it is recommended to check the current condition of the catalyst. Make sure there is no internal or external damage. If the integrity of the catalyst is compromised, a new one will need to be installed.

- Using diagnostic equipment, measure the voltage of the signal that comes from the oxygen sensor. This can be done with a regular multimeter set to voltage test mode. When the ignition is turned on, the reading should ideally be around 450 mV. If the ignition is turned off, wait for a reading of approximately 150 mV on the device. If they are different, the sensor needs to be replaced.

- A voltage of less than 150 mV when the engine is turned off supports the theory that the lambda probe is faulty. There is only one solution: replacing it.

- If the voltage is less than 150 mV under the same conditions, there are breaks in the wiring. You need to find them, carry out repairs, or better yet, replace the damaged wiring.

- When the car is equipped with gas equipment, to eliminate the error that appears, you will need to perform the correct settings and select the most suitable mixture. Quite often, it is because of problems with the gas rail that the error in question appears.

- Fuel injectors in the car should be cleaned and washed with special products. Their contamination negatively affects the air-fuel mixture, affects the behavior of the oxygen sensor, and the operation of the latter is ultimately disrupted. This entails the appearance of a corresponding error with code 0133.

- Be sure to check the exhaust system corrugation. Its integrity may be compromised. If the corrugation is burnt out, error P0133 will almost certainly appear until the fault is completely eliminated.

This is interesting: Causes of black spark plugs: carburetor, injector

To summarize, we can say the following. The appearance of error 0133 indicates that there are problems with the oxygen sensor. Its performance is impaired, the device reacts more slowly, which is why the ECU perceives this as an error in the engine’s operation.

The problem is quite common, but not critical. The main trouble is the change in dynamics and the increase in fuel consumption.

Diagnosing a malfunction is not difficult, nor is it difficult to fix it yourself. But sometimes the help of more qualified specialists may be required.

How does a mechanic diagnose a P0133 code?

When diagnosing this error, the mechanic will do the following:

- Visually inspect the electrical wires related to the oxygen sensor for oil contamination and damage.

- Measure the oxygen sensor output voltage using a diagnostic scanner or multimeter

- Visually inspect the oxygen sensor for clogging and excessive soot or carbon accumulation

- Check air intake and vacuum hoses for wear and damage

Carrying out diagnostics

To determine the true cause that led to the appearance of error code P0133, it is necessary to carry out diagnostic measures.

This is done by performing the following procedures:

- Using a multimeter in voltage measurement mode, the parameters of the oxygen sensor at its output are checked.

- The sensor wiring is visually checked for integrity. It is imperative to check whether there are any oil particles or other contaminants on the wires connected to it.

- Visually assess the condition of the sensor housing by removing it from its seat. There should be no traces of overheating, soot, or oil deposits on it.

- Check vacuum hoses and air intakes for leaks and quality of connections.

This is interesting: Instructions for replacing spark plugs on a car

Having detected certain malfunctions, before resetting the error, you will first need to get rid of the very cause of P0133 when reading the ECU with a diagnostic scanner.

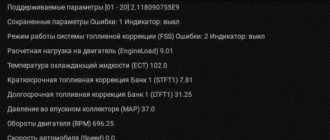

Freeze Frame Data

The first step in diagnosis should be to record the freeze frame data associated with P0133. This will show you the operating conditions present when the ECU stored the error.

Wiring Inspection

Once you have the freeze frame data, you should do a simple visual inspection of the oxygen sensor wiring. Look for any frayed, broken or melted wires.

Check the connector for moisture or corrosion. Unfortunately, the oxygen sensor wiring cannot be repaired (unless it is the heater circuit). Therefore, if you find damaged wiring, the sensor will need to be replaced.

Checking for exhaust leaks

Next, start the engine and listen for any exhaust leaks in front of the sensor. Smaller leaks around the exhaust manifold may be more obvious on a cold engine due to thermal expansion. This may also be accompanied by a visual inspection of the exhaust system.

In some rare cases, there are leaks that cannot be heard or seen, but can be detected using a smoke generator installed in the exhaust pipe.

Watch the video on how to make a smoke generator with your own hands:

This shows very small leaks in porous welds that can cause codes related to the oxygen sensor. If leaks are found, repair and clear error codes.

Oxygen sensor test

Once you have checked that the wiring is intact and there are no exhaust leaks, you will need to access the ECU data stream using an OBD2 scanner.

Here you can monitor the voltage coming from the oxygen sensor to the ECU. The voltage should constantly switch between 0 and 1 volt. If the engine is a "V" engine, you can compare bank 1 to bank 2 to see if one shifts faster than the other.

Check the voltage at 2000 rpm, close the throttle quickly, then open it. When the choke closes you should see a voltage close to 0 volts and when it opens again you should see close to 1 volt. All this must happen very quickly, in less than 100 milliseconds.

Again, if you have a dual-cylinder engine, you can compare the two sides to see if one responds more slowly than the other. If the sensor fails the test, replace it.

These tests can also be performed using a digital multimeter. To do this, you will need to find a wiring diagram to determine the purpose of the wires. Also, using the diagram, find and make sure that the sensor has a reliable ground.

Lada Vesta - data bus error codes

| Error code | Decoding |

| U0001 | CAN bus faulty |

| U0002 | CAN bus, general fault |

| U0009 | CAN bus, short circuit of line L to line H |

| U0073 | CAN bus disabled |

| U0121 | CAN bus, no data from ABS controller |

| U0122 | CAN bus, no data from ESP controller |

| U0155 | CAN bus, no data from instrument cluster |

| U0167 | CAN bus, no connection with immobilizer |

| U0415 | CAN bus, incorrect data from the ABS controller |

| U0416 | CAN bus, incorrect data from ESP controller |

| U0426 | CAN bus, incorrect data from immobilizer |

These are, in principle, all the errors that can occur when operating a Lada Vesta car. I hope you will never need this material, but if you do, then let your car be repaired very quickly.

How to diagnose a VAZ-2114

How to use the self-diagnosis function without taking into account the on-board computer?

- Press the car daily mileage reset button.

- At the same time, turn on the ignition with the key in the first position.

- Remove your finger from the key responsible for operating the odometer - the arrows should start moving.

- Press the key again and release - this simple method will fix the firmware version.

- All that remains is to press the button a third time, then release it; If there is a malfunction, an error code will appear on the screen.

Lada Vesta engine error codes

| Error code | Decoding |

| P0030 | DC heater to neutralizer, circuit faulty |

| P0031 | DC heater before the neutralizer, control circuit shorted to ground |

| P0032 | DC heater before the neutralizer, control circuit closed to the on-board network |

| P0036 | DC heater after the neutralizer, the circuit is faulty |

| P0037 | DC heater after the neutralizer, control circuit shorted to ground |

| P0038 | DC heater after the neutralizer, control circuit closed to the on-board network |

| P0106 | Intake air pressure sensor circuit, signal out of range |

| P0107 | Intake Air Pressure Sensor Circuit Low Signal |

| P0108 | Intake air pressure sensor circuit high signal |

| P0111 | Intake air temperature sensor circuit, signal out of range |

| P0112 | Intake Air Temperature Sensor Circuit Low Signal |

| P0113 | Intake Air Temperature Sensor Circuit High Signal |

| P0116 | DTOZH circuit, signal output from permissible range |

| P0117 | DTOZH circuit, low signal level |

| P0118 | DTOZH circuit, high signal level |

| P0122 | TPS circuit A, low signal level |

| P0123 | TPS circuit A, high signal level |

| P0130 | The oxygen sensor before the converter is faulty |

| P0131 | DC circuit to the neutralizer, low output signal level |

| P0132 | DC circuit to the neutralizer, high output signal level |

| P0133 | DC circuit to the neutralizer, slow response to changes in mixture composition |

| P0134 | The oxygen sensor circuit to the converter is inactive |

| P0135 | DC to the neutralizer, the heater is faulty |

| P0136 | The oxygen sensor after the neutralizer is faulty |

| P0137 | DC circuit after the neutralizer, low signal level |

| P0138 | DC circuit after the neutralizer, high signal level |

| P0140 | The oxygen sensor circuit after the converter is inactive |

| P0141 | DC after the neutralizer, the heater is faulty |

| P0171 | Fuel system too lean |

| P0172 | The fuel supply system is rich |

| P0201 | Cylinder 1 injector, circuit faulty |

| P0202 | Cylinder 2 injector, circuit faulty |

| P0203 | Cylinder 3 injector, circuit faulty |

| P0204 | Cylinder 4 injector, circuit faulty |

| P0217 | Engine temperature is higher than permissible |

| P0222 | TPS B circuit, low signal level |

| P0223 | TPS circuit B, high signal level |

| P0261 | Cylinder 1 injector control circuit short to ground |

| P0262 | Cylinder 1 injector, control circuit shorted to on-board power supply |

| P0264 | Cylinder 2 injector control circuit short to ground |

| P0265 | Cylinder 2 injector, control circuit shorted to on-board power supply |

| P0267 | Cylinder 3 injector control circuit short to ground |

| P0268 | Cylinder 3 injector, control circuit shorted to on-board power supply |

| P0270 | Cylinder 4 injector control circuit short to ground |

| P0271 | Cylinder 4 injector, control circuit shorted to on-board power supply |

| P0300 | Random multiple misfires detected |

| P0301 | Cylinder 1, misfire detected |

| P0302 | Cylinder 2, misfire detected |

| P0303 | Cylinder 3, misfire detected |

| P0304 | Cylinder 4, misfire detected |

| P0327 | Knock Sensor Circuit Low Signal |

| P0328 | Knock Sensor Circuit High Signal |

| P0335 | Crankshaft position sensor circuit is faulty |

| P0336 | DPKV circuit, signal output from permissible range |

| P0340 | Camshaft position sensor (phase sensor) is faulty |

| P0342 | Camshaft Position Sensor (Phase Sensor) Circuit Low Signal |

| P0343 | Camshaft position sensor (phase sensor) circuit, high signal level |

| P0351 | Cylinder 1 ignition coil, control circuit open |

| P0352 | Cylinder 2 ignition coil, control circuit open |

| P0353 | Ignition coil of cylinder 3, control circuit open |

| P0354 | Ignition coil of cylinder 4, control circuit open |

| P0363 | Misfires detected, fuel supply to idle cylinders turned off |

| P0422 | Neutralizer efficiency below threshold |

| P0441 | Gasoline vapor recovery system, incorrect air flow through the control unit |

| P0443 | Canister purge valve, circuit faulty |

| P0444 | Canister purge valve, control circuit open |

| P0458 | Canister purge valve, control circuit short to ground |

| P0459 | Canister purge valve, control circuit shorted to on-board network |

| P0480 | Fan relay 1 circuit faulty |

| P0481 | Fan relay 2 circuit faulty |

| P0504 | Brake pedal A/B switches, signal mismatch |

| P0513 | Incorrect immobilizer key |

| P0522 | Oil Pressure Sensor Circuit Low Signal |

| P0523 | Oil Pressure Sensor Circuit High Signal |

| P0560 | Vehicle on-board voltage |

| P0561 | On-board voltage is unstable |

| P0562 | On-board voltage, low level |

| P0563 | On-board voltage, high level |

| P0601 | CUD controller, ROM checksum error |

| P0603 | Court controller, internal RAM error |

| P0604 | Court controller, external RAM error |

| P0606 | Court controller, processor error |

| P0627 | Fuel pump relay, circuit faulty |

| P0628 | Fuel pump relay, control circuit short to ground |

| P0629 | Fuel pump relay, control circuit shorted to on-board network |

| P062F | Internal EEPROM error |

| P0641 | Sensor power supply circuit, open |

| P0642 | Sensor power circuit, low signal level |

| P0643 | Sensor power circuit, high signal level |

| P0645 | A/C compressor clutch relay, circuit faulty |

| P0646 | A/C compressor clutch relay, control circuit short to ground |

| P0647 | Air conditioning compressor clutch relay, control circuit shorted to on-board network |

| P0660 | Intake system channel length control valve, open circuit |

| P0661 | Intake system channel length control valve, control circuit short to ground |

| P0662 | Intake system channel length control valve, control circuit closed to on-board network |

| P0691 | Fan Relay 1 Control Circuit Short to Ground |

| P0692 | Fan relay 1, control circuit shorted to on-board power supply |

| P0693 | Fan Relay 2 Control Circuit Short to Ground |

| P0694 | Fan relay 2, control circuit shorted to on-board power supply |

| P1301 | Cylinder 1, misfire detected, critical for converter |

| P1302 | Cylinder 2, misfire detected, critical for converter |

| P1303 | Cylinder 3, misfire detected, critical for converter |

| P1304 | Cylinder 4, misfire detected, critical for converter |

| P1335 | Throttle Actuator Control Monitoring, Throttle Position Out of Range |

| P1336 | Monitoring the control of the throttle valve drive, mismatch of signals from sensors “A” / “B” of the throttle position |

| P1388 | Monitoring the control of the throttle valve drive, mismatch of signals from sensors “A” / “B” of the accelerator pedal position |

| P1389 | Throttle actuator control monitoring, engine speed out of range |

| P1390 | Monitoring of throttle actuator control, incorrect response to a malfunction in the system |

| P1391 | Monitoring throttle actuator control, no response to system malfunction |

| P1545 | Throttle valve actuator, throttle position out of range |

| P1558 | Throttle valve actuator, return spring faulty |

| P1559 | Throttle valve actuator, throttle position at rest is outside the permissible range |

| P1564 | Throttle valve drive control system, throttle zero position adaptation interrupted due to low on-board voltage |

| P1570 | Immobilizer, circuit faulty |

| P1578 | Throttle valve actuator control system, zero position adaptation value is out of range |

| P1579 | Throttle valve control system, throttle zero position adaptation interrupted due to external conditions |

| P1602 | Court controller, power supply loss |

| P1640 | COURT controller, EEPROM read-write error |

| P2100 | Electric throttle actuator, control circuit open |

| P2101 | Electric throttle actuator, control circuit faulty |

| P2102 | Electric throttle actuator, control circuit short to ground |

| P2103 | Electric throttle drive, control circuit shorted to on-board network |

| P2122 | Pedal Position Sensor A Circuit Low |

| P2123 | Pedal Position Sensor A Circuit High |

| P2127 | Pedal Position Sensor B Circuit Low |

| P2128 | Pedal Position Sensor B Circuit High |

| P2135 | Sensors “A” / “B” throttle position, signal mismatch |

| P2138 | Accelerator pedal position sensors “A” / “B”, signal mismatch |

| P2176 | Throttle valve control system, throttle zero position adaptation not performed |

| P2187 | Fuel system too lean at idle |

| P2188 | Fuel system too rich at idle |

| P2270 | DC after the neutralizer, no response to enriching the mixture |

| P2271 | DC after the converter, no response to lean mixture |

| P2301 | Ignition coil of cylinder 1, control circuit shorted to on-board network |

| P2304 | Ignition coil of cylinder 2, control circuit shorted to on-board network |

| P2307 | Ignition coil of cylinder 3, control circuit shorted to on-board network |

| P2310 | Ignition coil of cylinder 4, control circuit shorted to on-board network |