January 15, 2015 Lada.Online 308 497 380

To start the engine, you need to ensure that a spark appears at a certain moment to ignite the air-fuel mixture in the cylinders. Problems with starting the engine occur if one or more elements of the system malfunction. The table lists possible reasons why the Priora does not start.

The spark disappeared on the 16-valve VAZ-2112 injector: causes and diagnostics

Many car enthusiasts have encountered the loss of spark on the 16-valve VAZ-2112 engine. What is this defect associated with? The first thing that suggests itself is the ignition. But, in this case, not everything is so simple, since the problem may lie deeper than it seems at first glance.

The video describes a situation when you lose a spark on the road and the car does not start:

The main reasons for the lack of spark

General view of the engine 10-12 series 16 valves

Not all motorists know the reasons for the loss of spark, much less methods for diagnosing and troubleshooting problems. So, it is worth identifying the main reasons, and then deciphering why exactly they become the cause. Finally, you need to consider ways to eliminate the defect. So, what reasons could cause the spark to disappear:

All the reasons have been found and it is worth moving on to the process of eliminating this malfunction.

Are you giving me a spark? Troubleshooting!

First of all, it’s worth noting that you don’t need to rush to check right away. As practice shows, there is a certain sequence of actions and malfunctions that could lead to loss of spark on a 16-valve engine.

Fuel pump

Fuel pump made by Bosch

Ignition is not the first reason for the ignition failure on a car. Before getting into the electrical part of the car, it’s worth delving into the mechanics, so to speak. Turn on the ignition and listen to see if the gasoline pump is working . If it is silent, then you need to check whether gasoline is entering the cylinders.

It is worth starting the diagnostic procedure by checking the fuses for serviceability. Of course, you can only view the one that is responsible for the fuel pump (in this case, when you turn on the ignition, the pump will not pump), but it is recommended to diagnose everything for integrity. If at least one fails, it must be replaced.

The fuses are located to the left of the steering wheel under the light mode switch

If the previous procedure did not help, then we turn directly to the pump itself. For diagnostics, you will have to remove the entire module, which is located under the rear sofa, and disassemble it.

The pump itself is easy to check - the contacts are closed through the tester. If there are no readings, then the part has “died” and requires replacement. If the pump is “live”, then it is necessary to clean the contact group and check the wiring for breaks.

Spark plug

Location of spark plugs on the engine

The candle becomes the second boundary, which may cause the spark to disappear. We unscrew the elements and carry out visual diagnostics. If everything is clean and beautiful outside, then you need to measure the resistance and check the gap. Of course, you can check the performance of a spark plug on a special spark plug stand, but not everyone has one in their garage. Therefore, we do everything the old fashioned way.

We connect the spark plug to a high-voltage wire, which is connected to 1 cylinder, and with the outer side to the body to obtain ground, and provide an ignition contact.

When performing this operation, you should be extremely careful, since the voltage that enters the spark can be fatal. Thus, we check all the spark plugs for the presence of a spark.

An alternative way to check spark plugs

Checking the spark plug using a piezo element from a conventional lighter

Ignition coil

Repaired ignition coil

The ignition coil can be checked using a multimeter. If it is faulty, it is recommended to replace it, but there are brave souls who repair this unit. Of course, not everything always goes smoothly and often everything ends in one thing - the installation of a new one.

High voltage wires

Checking the high-voltage wire with a multimeter

A breakdown or failure of the wire will immediately become known as the car will start to shake. But, if the explosive wires are located incorrectly in the cylinders, then you will have to place them according to the connection diagram. The missing spark problem should go away.

Gas distribution mechanism

The last place to look for a missing spark is the timing belt. Misaligned valve timing can be a problem. This could happen due to incorrect installation of the deposit disk. It is located on the crankshaft pulley and serves as a reference synchronizer for the sensor. If it is positioned correctly, when 1 cylinder is in the TTM, the sensor is placed between the 19th and 20th teeth. You can eliminate the cause by setting the disk correctly to the marks.

There is no spark, we check the functionality of the components. Algorithm for finding a spark on spark plugs and ignition coil

When the spark is lost, you will, of course, never start the car, and in such a situation, first of all, you need to check the ignition system.

The vehicle's ignition system plays a key role in its operation. If in case of many other malfunctions the car can be taken under its own power to the service station, then in case of problems with the ignition it is unlikely that it will be possible to start the engine at all.

How to check the spark

Checking the spark on a spark plug can be done in several ways:

The main reasons why there is no spark

No spark injector

You need to be very careful when checking the spark on fuel-injected cars (especially for foreign cars - you can burn the electronic unit).

It is recommended to use a spark gap to understand at what stage there is no spark on the spark plugs (no spark from the distributor, no spark from the coil, or directly from the spark plug itself). If there is no spark in all cylinders at the same time, there may be several culprits:

The entire checking procedure should begin with the integrity of the fuses, the condition of the ground contacts and contacts on high-voltage wires.

If there is no spark from the ignition coil, then the reason may be hidden in many places. First of all, you need to check the high voltage wire, which must be in perfect condition and without damage to the insulation. Otherwise, the wire needs to be replaced.

No spark, check spark plugs

If the problem is not solved, then check the spark plugs. The spark plug contacts must be clean. The fact that there is no spark may be caused by dirty spark plug contacts. It is best to replace the spark plugs, but you can also clean the contacts. But before changing the spark plugs, check whether the discharge reaches the spark plugs themselves.

To do this, remove the spark plug wire and bring it to the car body at a distance of 0.5 cm. Turn the starter several times and see if there is a spark between the wire and the body. The spark should be white with a slight blue tint.

If it is absent or present, but with a different shade, we can say that the spark plugs are fine, and the problem is in the heart of the car’s ignition system - the coil.

How to check spark on ignition coil

To see if the coil is working at all, pull the wire from the breaker distributor that comes from the coil. The same test is carried out with it as with the spark plug wires, namely, they bring the wire to a distance of 0.5 cm and turn the starter. Now, regardless of the result, we can accurately talk about the cause of the breakdown.

If there is a spark, then the problem is in the distributor-chopper; if there is no spark, then the ignition coil is faulty.

In the first case, you need to check the contacts in the distributor-breaker for oxidation, insulation damage, and also check the serviceability of the rotor. If there is no spark due to it, the rotor must be replaced.

Checking the ignition coil

Checking the ignition coil also involves inspecting the integrity of the windings for physical damage, as well as burnt spots, which indicate a short circuit in the coil. In these cases, the coil either needs to be repaired or replaced.

If, after checking, you realize that there is a spark in the car, but it does not start, then the ignition switch may need to be replaced.

to our channel in Yandex.Zen

Even more useful tips in a convenient format

Did not find an answer to your question?

conclusions

Loss of spark on a 16-valve VAZ-2112 may be a consequence of the failure of several vehicle components at once or each individually. But, if the operations indicated in the article did not help, then you should contact specialists at a car service center who will accurately identify the cause and eliminate it.

It is unlikely that several nodes will fail at once. This has not happened in my practice. Unless, of course, you hit the car properly.

The ignition coil rarely fails because it is initially reliable. But the spark plugs and fuel pump often fail.

Even if the timing phase is off, there should be a spark!

There will be a spark, but not at the right time when the air-fuel mixture arrives.

No spark on Priora 16 valve reasons

Before this I repaired the

I have a very strong feeling that the ECU has burned out.

the substitute will reveal it. but it seems to me that you still need to look where you dug (mass on the cylinder head).

Added after 6 minutes 55 seconds:

I changed the sensor, but now when the ignition is on, the fan spins constantly (even if you remove and put on the sensor chip

when cranking the starter the check does not go out

I have a very strong feeling that the ECU has burned out.

the substitute will reveal it. but it seems to me that you still need to look where you dug (mass on the cylinder head).

Added after 6 minutes 55 seconds:

I changed the sensor, but now when the ignition is on, the fan spins constantly (even if you remove and put on the sensor chip

when cranking the starter the check does not go out

The ECU bracket does not matter for January 5.1 and the like - the mass of the controller is not in the cabin, but on the distributor plug - 2 brown wires. It would be necessary to check when cranking with the starter on the MZ connector “+12V” whether it disappears, if not, then we go towards the DPKV wiring - it breaks inside the insulation in the area of the connector itself, it is replaced with a repair connector, the main thing is that if the controller is January 5.1.x, then do not confuse the polarity, If it's BOSCH, then we stick it in at random. When turning on the fan, to reduce the number of tricks, separate the mass of the fan relay from the main ECU. The DT could have been damaged during installation - using a short head, it’s easier to check with a multimeter - on one of the wires there should be +4.95..5.05V (orange), on the other there should be ground (green). It came across to me that the ground track in the controller burned out and as a result of the signals from the mass air flow sensor (ADC 4.98V), TPS, DT went off scale, but the car started!, having restored the track, everything worked as it should.

Added after 1 minute 25 seconds:

DPKV itself rings - about 500-600 Ohms, then ok.

Added after 4 minutes 12 seconds:

If the car has DC, then 1 of the wires can be connected to the mass of the DPS, DT, MAF (they are combined for some reason) - this, by the way, can be the reason for the car not starting when the SOD fan is running - these masses are combined by crimping and are then connected together with the ground of the fan relay – Apparently unnecessary leads are appearing.

The ECU bracket does not matter for January 5.1 and the like - the mass of the controller is not in the cabin, but on the distributor plug - 2 brown wires. It would be necessary to check when cranking with the starter on the MZ connector “+12V” whether it disappears, if not, then we go towards the DPKV wiring - it breaks inside the insulation in the area of the connector itself, it is replaced with a repair connector, the main thing is that if the controller is January 5.1.x, then do not confuse the polarity, If it's BOSCH, then we stick it in at random. When turning on the fan, to reduce the number of tricks, separate the mass of the fan relay from the main ECU. The DT could have been damaged during installation - using a short head, it’s easier to check with a multimeter - on one of the wires there should be +4.95..5.05V (orange), on the other there should be ground (green). It came across to me that the ground track in the controller burned out and as a result of the signals from the mass air flow sensor (ADC 4.98V), TPS, DT went off scale, but the car started!, having restored the track, everything worked as it should.

No spark prior 16 valves reasons

Welcome to ChipTuner Forum.

Theme Options

The 2nd cylinder on the Priora does not work. Prehistory. Recently I became the owner of a VAZ 2170 16v with a mileage of 90t.km. I began to notice that in the mornings the car did not start the first time, it was idling, then warmed up and after 30-50 seconds, everything was normal, it also squeezed out oil due to crankcase gases. I have made a trail. work: 1. Cleaned the ventilation system. crankcase 2. changed the O-rings on the intake receiver 3. cleaned the throttle valve (along the way for the sake of prevention) 4. changed the NGK spark plugs 5. cleaned all the injectors, measured the resistance - 12.5 ohms on each 6. voltage to the injectors - 8 V, 7 .voltage on the coils is normal 12V. 8. I pulled out the coil from the spark plugs, turned it with the starter - there was a spark. After that the car did not start, I left it overnight, it sat and started, but the problems did not go away. In the cold, the same thing happened. According to diagnostics - misfire in the 2nd cylinder.

Next I decided to flash the ECU 7.9.7. I resoldered the 6.8k Ohm resistor - it didn’t connect, soldered the eprom and 81 contacts on the computer, closed the box and calmed down - I couldn’t fix it, put it in the car, started it - now it’s constantly running both cold and hot. ((.

Maybe because of the ecu. I heard that if the key is broken, one of the cylinders may fail. but there is a spark, there is voltage on the coil and injector. It will not be possible to install a block from another car, because... My unit is somehow connected to the system via an immobilizer. At least I tried to install January 7.2 - it is not diagnosed.

There are still a couple of ideas left in my head, I need to finish them off: 1. Check the timing marks 2. Hydraulic compressors

If the Lada Priora's starter does not turn

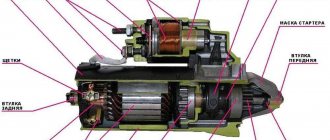

Burnt starter commutator, stuck brushes or severe wear

Open or short circuit in the starter armature winding

| Possible malfunction | Diagnostics | Remedies |

| Low battery | The voltage at the battery terminals without load is less than 12V. When trying to start the engine, a cracking noise is heard from under the hood. | Charge the battery or replace it with a new one |

| Oxidation of battery terminals or wire terminals, their fit is not tight | When you try to start the car, the voltage in the on-board network drops much more than at the battery terminals. In this case, a crash may be heard under the hood. | Clean the contacts, lubricate them with petroleum jelly and tighten the terminals |

| The engine or attachments are jammed | Check the rotation of the crankshaft, pump and generator pulley. | Repair engine, generator, pump |

| The starter is faulty, the starter drive gear or flywheel ring teeth are damaged | Remove and inspect the starter. | Repair or replace starter |

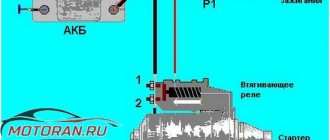

| The starter switching circuit or starter relay is faulty, the wires are damaged, or the ignition switch contacts do not close | When the key is turned to position “II”, the starter traction relay does not operate (a click is not heard under the hood). Check the +12V supply to the control contact of the traction relay. | Replace starter relay, wires, ignition switch |

| The starter traction relay is faulty, there is a short circuit or break in the retractor winding, the relay armature is stuck | When the key is turned to position “II”, the traction relay does not operate (there is no click under the hood), but + 12V is supplied to the control contact of the traction relay. Remove the relay and check its operation. | Replace the traction relay |

| Contacts or wires of the traction relay are oxidized, poor ground contact | When the starter is turned on, a clicking sound is heard under the hood, but the starter armature does not rotate. Using an ohmmeter, check the resistance of the battery-starter circuit, as well as the ground wire. If the circuit is in good condition, remove the starter and check the operation of the traction relay by applying +12V to it from the battery | Tighten the terminals, clean the contacts, replace the traction relay |

| Open or short circuit in the holding winding of the traction relay | When you try to start the engine, you hear a crashing sound under the hood. The battery voltage is within normal limits. We check the traction relay with an ohmmeter or by its excessive heating. | Replace the traction relay |

| The starter armature rotates slowly or does not rotate at all. Check the traction relay by applying voltage to the starter contact bolt directly from the battery | Replace starter or armature | |

| Freewheel slipping | When the starter is turned on, the armature rotates, the flywheel is stationary | Replace clutch or starter |

Generator testing

A properly functioning car alternator produces approximately 14 volts at idle speed with all electrical equipment turned off. At the time of the first start, the voltage should increase quickly - it will be 2 V or more. Then the current increase gradually decreases and levels off. This value will change depending on how charged the battery is, how much load is being placed on the bot network, and the temperature. The smaller it is, the higher the charge voltage. The charging current from a standard Priora generator can vary from 12.9 V to 14.8 V in frosty weather.

Priora won't start, starter turns

| Possible malfunction | Diagnostics | Remedies |

| There is no gasoline in the tank | On the instrument panel the fuel level indicator is at zero. | Pour gasoline |

| Battery is low | The voltage at the battery terminals without load is less than 12V. When trying to start the car, a crashing sound is heard from under the hood. | Charge the battery or replace it with a new one |

| Oxidation of battery terminals or wire terminals, their fit is not tight | When you try to start the engine, the voltage in the on-board network drops much more than at the battery terminals. In this case, a crash may be heard under the hood. | Clean the contacts, lubricate them with petroleum jelly and tighten the terminals |

| Unreliable connection of electrical circuits of engine control and power supply systems | Check the connections of the connectors and the reliability of the contacts in the blocks. | Fix faulty wire connections |

| Increased resistance to rotation of the crankshaft (scores on the shafts, bearing shells, cylinder-piston parts, deformation of the shafts, frozen engine oil, jammed generator, jammed coolant pump) | The crankshaft turns slowly. If the engine is started in severe frost, and the engine was working properly the day before, then most likely the engine oil has frozen. If you hear extraneous noise when starting the engine, check the free rotation of the pump and generator pulleys. | Use the recommended engine oil. Repair the engine. Replace the pump and generator. |

| Malfunction in the ignition system | Check for spark. | Check the circuits and devices of the ignition system. Replace faulty system elements. |

| The high voltage wires are connected in the wrong order or the wire is disconnected | Inspect. | Connect the wires in the correct order |

| The timing belt is broken or the belt teeth are cut off | Open the front timing cover and check. | Replace timing belt |

| Disturbed valve timing | Check the marks on the crankshaft and camshaft pulleys. | Set the correct shaft position |

| Malfunction of the computer (brains), its circuits, crankshaft position sensor or coolant temperature | Check the supply of +12V to the ECU, the sensor circuit, and the absence of damage to the sensors themselves. | Replace ECU, sensors. |

| The idle air regulator (IAC) or its circuits are faulty | Check the idle air control. When starting the engine, lightly press the gas pedal. If the engine starts and stalls when you release the gas pedal, the sensor is faulty. | Replace sensor |

| The fuse is blown or the main relay of the control system is faulty | Check fuse and relay. | Eliminate the cause of the blown fuse. Replace fuse and relay |

| Fuse blown, fuel pump relay. Circuit, relay or pump is faulty. | When the ignition is turned on, there is no sound of the pump running. Check the fuse. Apply voltage to the pump from the battery. | Clean contacts, replace faulty circuits, replace fuse, pump and relay. |

| The fuel filter is dirty, the water in the fuel line is frozen, the fuel line is damaged | Check the pressure in the fuel rail and the condition of the fuel lines. | Replace the filter, blow out or replace the fuel lines. |

| Insufficient pressure in the fuel rail | Check the pressure in the fuel rail, the pump strainer and the condition of the fuel lines. | Clean the filter. Replace pump, fuel pressure regulator |

| Faulty injectors or their power supply circuits | Check the injector windings with an ohmmeter. Check the chains for breaks. | Replace injectors, replace chains |

| Air leak into the intake tract | Inspect the joints and fittings of the hoses and clamps. During start-up, turn off the vacuum brake booster and plug the receiver fitting. | Eliminate air leaks, replace vacuum booster |

If the Priora does not start well when hot

In this case, see the second table; in addition to the reasons described, also pay attention to:

- A pressure regulator that can discharge fuel through a membrane into the receiver.

- DPKV contacts, if the sensor has been changed, check that the poles are connected correctly.

- Faulty ignition module.

Let us remind you that in some cases the Priora does not start due to a faulty immobilizer or alarm system. In some cases, reflashing the engine ECU (electronic control unit) helps solve the problem of poor starting. And regular car maintenance will help eliminate problems of poor engine starting.

Source: xn--80aal0a.xn--80asehdb

If the starter turns

It is the ignition module that becomes a stumbling block and a big problem in VAZ-2110 models. You can verify the correctness of the assumption by testing it with a working device. By installing a 100% functioning part on your car, you will be able to eliminate one possible malfunction. When you try to start everything works. The power supply stops due to the module chip. It is recommended to check the entire power supply system.

A faulty crankshaft position sensor can cause loss of spark. The main element of the entire ignition system controls the operation of the cylinders. An oscilloscope is suitable for testing. Hardware-free diagnostics in this case will not bring results. Most likely, the sensor will need to be replaced.

The electronic control unit may cause a malfunction. If operation is incorrect, the spark will disappear and not reach all cylinders. The repair does not require much effort; it will require restoring the operation of the contacts by removing the oxide from it.