VAZ electronic throttle: design, diagnostics, flushing and repair.

In this material I want to talk about the design, diagnostics and repair of the Delphi electronic throttle valve (pipe), installed on VAZ cars together with the M74 engine management system.

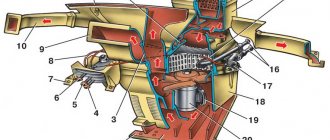

The reason for writing this article was one very typical malfunction on a VAZ 2115 car with an atypical cause, which I will talk about a little later. I would like to warn you right away that the author of this article does not bear any responsibility for unqualified intervention and repair of the electronic throttle valve in the event of its failure and emergency situations on the road, since repair of this unit is not provided, but only replacement. Design. An electrically driven throttle valve (pipe) is designed to dose the amount of air entering the intake manifold. Changing the amount of incoming air is achieved by turning the damper with an electric motor, which is controlled by a controller. Main parts of the throttle body: All photos are clickable!

1. Housing 2. Damper 3. Gearbox 4. Electric motor 5. Throttle position sensors.

The connection diagram is shown below:

Removing the throttle assembly: 1. Turn off the ignition, remove the minus terminal from the battery. 2. Unscrew the clamps and remove the intake pipe hose from the throttle body. 3. Disconnect the harness block. 4. Unscrew the 4 bolts securing the throttle assembly from the intake manifold and remove it.

Typical faults and their diagnosis. A childhood problem of the first car releases, error P2135 (Mismatch of signals from sensors A and B of the throttle position) manifests itself in the form of unstable idling, speed limit to 2000 and loss of traction. It can be successfully treated by crimping, bending and soldering the contacts of the throttle body block or by replacing the entire electrical wiring harness. On most cars it has been cured for a long time, on new ones it almost never occurs. Floating speed and unstable idle. Here we will dwell in more detail, since this phenomenon is common and appears sooner or later on almost all cars. The main reason here is the mismatch between the throttle opening angle and the amount of incoming air. On most cars it can be treated by washing. It is advisable to wash the throttle valve at least once every 20-30 thousand km. otherwise, deposits of soot and oil particles create obstacles to air movement during idle with all the ensuing consequences. Therefore, the throttle assembly must be kept clean and tidy - this is an axiom. The second reason for floating idle speed is throttle play. How does it manifest itself and how to diagnose it. Below is a screenshot of the SMS diagnostic program. The parameters were taken from a VAZ 2115 car with an M74 engine management system.

Here it is worth paying attention to the high air flow, relative filling and injection time. At the same time, the opening angle of the throttle valve is very small and the controller, trying to stabilize the idle speed, drives the ignition timing into the minus. This happens because the actual angle of the throttle valve does not correspond to the angle calculated by the control unit due to backlash. Moreover, if you initialize the throttle, then the engine may work normally for some time, but after some time or after a restart, the situation with the speed floating repeats. It is worth mentioning here that if the throttle is dirty, the parameters will also differ from the norm, with the only difference being that the valve opening angle becomes larger than usual. As an example, here is a screenshot with normal parameters:

How to eliminate throttle play. To do this, the throttle assembly must be disassembled. From the gearbox side, unscrew 4 screws (Torx 15) securing the cover.

Chevrolet Niva Status Quo › Logbook › Replacing the TPS and cleaning the throttle valve.

And so, we will continue the cycle of repairs.

Even in the summer, I periodically began to notice a freezing speed at idle or a smooth increase at idle. But it appeared rarely and was reset by sharply pressing the pedal. In the fall, this problem began to appear more and more often. I called all the stores in Yaroslavl, but nowhere was there a contactless TPS produced by the Kaluga Avtoelectronics plant. I had to order it online using code 36.3855. Of course, I was very surprised that there was no good sensor in the whole city. Today the sensor arrived and I decided to install it right away.

The sensor came without a box - in a regular package, but the markings are necessary.

I decided to change it by removing the throttle valve, at the same time I decided to wash it and look at the IAC. We remove the corrugation and remember the position of the heating hoses. For some reason, coolant did not flow from the hoses, contrary to expectations.

I can’t say that the unit required urgent washing, but since I had planned it...

The acoustic pipe was in place and intact, although I doubted it. I got him out of harm's way.

Then it's a matter of little things: remove the sensors, spray carburetor cleaner, install the sensors. Arzamas Rikor came from the factory. We unscrew it and put it aside, I decided to rearrange the foam rubber - let it be

I took out the IAC - the rod was a little covered in oil, so I sprayed it with carb cleaner.

Next, I thoroughly washed the throttle itself.

And put all the sensors in place

I'm starting it up. The idle speed floats, the rpm is about 1300. I initialize the ECU, start it again and everything is fine. I took it for a ride and everything seemed fine. It seemed that the response to the gas became clearer. Now I'll keep an eye on it - I hope the revs won't hang up anymore.

PS: on my blog you can see beautiful photographs of Uglich, for example. Come in and subscribe!

Source

Symptoms of a malfunction and how to fix them

The throttle valve mechanism has a high safety margin and is almost not subject to wear. Problems arise due to contamination of the unit. Atmospheric air, which passes through the throttle in large volumes, is cleaned by an air filter.

This is interesting: Scheduled Maintenance Schedule for the Ford Focus 3 model (Ford Focus)

However, tiny particles of dust remain in it, which settle on the parts of the mechanism. The process is aggravated by small splashes of oil that penetrate along with crankcase gases.

A coating forms on the walls and damper, which prevents the damper from closing completely or interferes with its smooth operation. Clogged channels of the unit create air resistance, as a result of which engine power decreases.

Signs of remote control contamination:

- Unstable engine operation at low speeds.

- Jerking when driving at low gas.

- Problems starting the engine.

- Power drop.

To eliminate the problem, you need to clean the throttle valve. This can be done with a special aerosol that dissolves plaque on the inner surface of the throttle assembly.

Chevrolet Niva › Logbook › Cleaning the throttle and crankcase ventilation + various little things, 68,690 km.

All the best! The car doesn't let you get bored. 1. Oil consumption is observed in the engine. Since the replacement (about 3500 km ago) I have added about 200 ml. Engine above 3-3.5 thousand rpm. I'm not twisting. Now filled with ZIC X9 FE 5W-30. I don’t see any point in sinning with this oil yet. This is not the first time it has been poured into other cars and there have never been problems with its consumption. There are no obvious leaks on the motor. I decided to start with preventive measures. I removed and washed the throttle valve (there is this one, art. 2123-1148010), the idle air valve (it costs this one, 21203-1148300-03), the receiver, the engine breather, replacing the large one (art. 2123-1014240) and the small one (art. 2123- 1014056) pipes. At the same time, replace the breather cover gasket (art. 2101-1014215), the receiver gasket (art. 2123-1008055-01), the receiver gasket on the stud (art. 2123-1008033), the throttle valve gasket (art. 2112-1148015). Actually, the main dirt was on the idle air valve. The rest of the parts are more or less clean. After assembly, starting the first time, the idle speed became even more stable (previously, judging by the BC readings, the speed stayed at 800-840, now it very rarely drops to 800, mostly staying at 840 rpm). The engine response remained at the same level. 2. The valve in the expansion tank cap is stuck again. I assembled one from three lids. I took the insides from a cover produced by “Avtopribor” (art. 2108-1311065-01). I noticed that the three holes on the Autodevice cover for air outlet from the tank have a diameter of 3.5 mm. On all other covers 1.5-2 mm. As a result, I adjusted the plug to a pressure of 0.5 kgf/sq.cm. In order to avoid problems with the plug, there are thoughts of switching to a tank from Renault Logan (analog, Meyle tank with a lid, art. 16142230000, 847 rubles, not such a big expense). 3. Regarding HBO. The system works, everything is fine, I like everything. Consumption on the highway is 11.5 liters in the city - about 13 liters. Strange, but less than with gasoline. The only thing is that the idle speed sometimes fluctuates. Moreover, when running on gasoline, there are no problems with idling. One of these days I will go to the HBO installers. I’ll update the post based on the results. For convenience, I moved the HBO button to the damper control panel.

Update dated March 16, 2021. I went to the gas equipment installers. Connected a computer with software. The HBO training period (after installing the equipment you need to drive 100 km on gasoline) went well. We slightly adjusted the map manually and the idle speed is now normal at 840, sometimes 880 rpm. Good luck on the roads!

Source

How to check TPS

The most convenient way to check the operation of the Niva Chevrolet TPS is by testing . For this you will need a multimeter. The goal is to determine the presence of power at the sensor contacts, measure the voltage and identify the causes of the breakdown. They may be a malfunction of the unit itself, poor contact between the slider and the resistor track, or problems in the vehicle's electrical network.

Availability of "ground"

The purpose of the test is to measure the “negative” power supply, the sensor:

- Disconnect the power cord from the connector.

- Inspect for the presence of dirt , oxidation or mechanical damage.

- Set the multimeter to 20V DC voltage (DCV).

- Turn the ignition key to the ON position (do not start the engine).

- Connect the red probe of the multimeter to the “plus” on the battery.

- Touch each of the three contacts on the wiring connected to the sensor with black.

On one of the contacts the device screen will show a voltage of 12V . This means that there is a ground on the sensor. If power is not displayed on any of them, the reason for the malfunction of the Niva Chevrolet throttle sensor is the absence of a “ground”.

Powered by reference voltage

The purpose of the test is to measure the power supplied to the TPS. The operation of the mechanism will be disrupted if there is insufficient or missing voltage :

- Connect the black probe of the multimeter to ground.

- Turn the ignition key to the ON position. Do not start the engine.

- Connect the red probe to each of the remaining two contacts of the sensor.

- One of them will display a power supply of about five V. The third wire will be the signal wire.

If voltage is not detected on any of the wires , the cause of the Niva Chevrolet TPS malfunction is in the electrical wiring.

Checking the output signal

The purpose of the measurement is to check the value produced by the sensor when the throttle is operating. Reconciliation is done in different positions - fully open, closed and fully closed throttle:

- Connect the red probe of the multimeter to the signal terminal, and the black one to the ground contact.

- Turn the ignition to ON position . Do not start the engine.

- Make sure the throttle valve is completely closed.

- The multimeter should show a value of 0.7 V.

- If the screen shows 0, continue : gradually open the throttle slightly. The value should also increase. When open all the way, the voltage is in the range of 4-5 V.

- If the TPS does not produce five volts when the damper is open , replace it with a new one.

Important! When performing a check, an error may enter the memory of the on-board computer, which will be displayed by the “Check Engine” warning lamp. After completing repair work, clean the OBD system manually.

Fuel Control Modes

As mentioned earlier in this chapter, the amount of fuel delivered through the injectors is controlled by the controller.

Fuel is supplied using one of two different methods: synchronous, i.e. in a certain position of the crankshaft, or asynchronous, i.e. without synchronization with the rotation of the crankshaft.

Synchronous fuel injection is the predominantly used method.

Synchronization of injector operation is ensured by using signals from the crankshaft position sensor and the phase sensor.

The controller calculates the moment when each injector is turned on, and fuel is injected once during one full operating cycle of the corresponding cylinder. This method allows you to more accurately dose fuel into the cylinders and reduce the level of toxicity of exhaust gases.

Asynchronous fuel supply is used in the starting mode and dynamic engine operating modes.

The controller processes sensor signals, determines the engine operating mode and calculates the duration of the fuel injection pulse.

The duration of the injection pulse can be monitored using a diagnostic tool.

Service

In our technical center you will receive qualified assistance and a full range of services for warranty, post-warranty maintenance and repair of KIA

and

Subaru

.

We also carry out repairs and maintenance of Mazda, Suzuki, Chevrolet, Chevrolet Niva

and other foreign brands.

All work in the service center is carried out using modern equipment by qualified personnel in accordance with the manufacturer’s recommendations.

The service area is equipped with 12 car repair stations, including the Maha instrument control line, which allows you to identify all malfunctions of the vehicle's chassis, a unique Hunter optical stand for monitoring wheel alignment angles, as well as special diagnostic equipment for cars of the brands Kia, Subaru, Mazda, Chevrolet, Chevrolet Niva, Suzuki and other foreign brands.

Removing the throttle assembly

We prepare the car and disconnect the negative terminal of the battery

Removing the decorative engine cover

Using a Phillips screwdriver, unscrew and loosen the clamp securing the rubber air supply pipe to the throttle body

Loosen the clamp and remove the pipe from the adapter pipe

We disconnect the air supply pipe from the throttle assembly and place it behind the retainer post of the decorative engine casing.

We press on the clamps of the wiring harness block of the engine management system

Removing the wiring harness block

Using a long 10mm socket, unscrew the three nuts securing the throttle assembly

Carefully remove the throttle pipe from the three studs attaching it to the receiver and remove the gasket

Install the throttle assembly in reverse order.

We replace the gasket between the receiver and the throttle assembly.

The tightening torque of the throttle assembly mounting nuts is 5-8 Nm

We attach the intake pipe hose to the throttle pipe and secure it with clamps. The tightening torque of the clamps is 1.7-2.3 Nm.

Once the throttle assembly is installed, no adjustment is required. The throttle valve is set to its original position by the controller.

Source

LET'S BE FRIENDS - 20% DISCOUNT ON SERVICE FOR NEW CLIENTS!

The official GM Avtomir service center on Irkutsk provides a 20% discount to new customers. The new client is the owner of an OPEL/CHEVROLET car, which has never previously been serviced at the GM Automir service center on Irkutskaya. Under the terms of the promotion, a 20% discount is also provided to customers who have previously undergone maintenance and repairs at the GM Automir service center on Irkutskaya, but have not come for service for more than 12 months.

Operating principle of the sensor

There are two designs of the sensor:

- Resistive is a classic potentiometer with a film track and a movable contact located on the rotation axis. As the slider moves along the track, the resistance changes. The ECU instantly receives information about the angle of rotation of the damper. Simple design, reasonable cost. The standard equipment of Niva Chevrolet engines is with exactly these sensors. The only drawback is that over time the tracks are erased, the TPS gives incorrect information or does not work at all. Requires regular replacement.

- Non-contact magnetic sensor. Inside there is a magnetic field sensor and a microcontroller that converts information about throttle rotation into a format familiar to the ECU. This device lasts a long time, since it has practically no wearing parts, and gives more accurate readings. However, the complexity of the sensor in the presence of a microcontroller makes it dependent on operating conditions. For uninterrupted operation, a stabilized supply voltage is required. With a slight deviation, the electronics fail. Of course, the cost of such a device is somewhat higher than its resistive counterpart.

Chevrolet service at Dimar Plus - at the official Chevrolet dealer in Ryazan

Sometimes worn-out car parts can be restored using special equipment. But in most cases, you cannot do without replacing Chevrolet spare parts. It is very important to install only original or manufacturer-recommended parts. This is the only way to ensure the normal functioning of the vehicle.

"Dimar Plus" is the official Chevrolet dealer in Ryazan. We cooperate directly with suppliers, so we have the opportunity to work not only with original products, but also to offer them at the most affordable prices. This is one of the key advantages why customers choose us as their Chevrolet dealer in Ryazan.

To ensure that your car lasts a long time and always remains safe, contact the official Chevrolet dealer in Ryazan - Dimar Plus. We have state-of-the-art diagnostic equipment, genuine Chevrolet parts, and top-notch service. See for yourself!

What does the bore diameter affect?

The amount of air-fuel mixture that enters the cylinders determines the power of the engine. It depends on two factors:

The first indicator depends on the position of the gas pedal, and the second on the design of the throttle assembly.

The factory equipment of the Chevrolet Niva provides for the installation of a damper with a diameter of 46 mm.

To increase the air supply and engine power, car owners install diaphragms with a large diameter - from 52 to 58 mm.

Important: engine power does not increase in proportion to the valve diameter. The amount of fuel-air mixture depends on the working volume of the cylinders. The standard size of the passage opening is sufficient to fill the combustion chamber. Increasing the valve diameter cannot radically change the characteristics of the motor.

The maximum size of the tuning damper that should be installed on a standard Chevrolet Niva engine is 54 mm. A larger diameter (56 mm) is needed only for sports versions of cars with an increased engine capacity.

Increasing the throttle flow area without modifying the engine only gives the illusion of an increase in power. The response to pressing the gas pedal becomes sharper.

For example, if you lightly press the gas, the standard throttle will open 10%, and the extended throttle will open 15-20%. At the same time, the maximum power and throttle response remain virtually unchanged. In order for the combustion chambers to be completely filled with the fuel-air mixture, you do not have to press the pedal all the way.

It happens that after installing an increased emergency protection, the standard engine actually becomes more powerful. This has a simple explanation: instead of the old clogged damper, a new clean one is installed. The same effect can be achieved by a simple and cheap method: remove and wash the throttle assembly.

Advice: it makes sense to install an enlarged throttle after boring the cylinders and installing a sports camshaft, which changes the valve timing.

Chevrolet car repair manuals and tips

Some car enthusiasts claim that when installing a throttle valve of increased diameter, the car's power increases by several percent. And if you also install a “zero” along with the “throttle”, the effect will be much better. In this article we will try to figure out whether there is any sense in a throttle valve with an increased diameter and why it is installed?

Let's first understand the theory of why an enlarged throttle valve is installed. The size of the standard throttle is 46 mm and is considered the narrowest point in the air path of the car. And if you install a throttle with a larger diameter, the passage opening will increase, and accordingly there will be a greater flow of air, which means the engine power will increase.

There are many options for oversized throttle bodies on the aftermarket tuning market, from “52” to “58” sizes. It all depends on the purpose of its installation. For example, on a standard motor without significant modifications, it makes sense to set the throttle to “52 mm” or “54 mm”. But the more productive “56” or “58” is used only for sports engines with increased engine displacement.

Conversion of gas drive 2121, 21213 to cable

Reg.: 12/06/2004 Threads / Messages: 628 / 51730

Reg.: 12/06/2004 Threads / Messages: 4029 / 23189 From: Moscow Age: 66 Car: 21214M, 2013

Reg.: 12/06/2004 Threads / Messages: 628 / 51730

Reg.: 12/06/2004 Threads / Messages: 4029 / 23189 From: Moscow Age: 66 Car: 21214M, 2013

Reg.: 12/06/2004 Threads / Messages: 628 / 51730

Reg.: 12/06/2004 Threads / Messages: 4029 / 23189 From: Moscow Age: 66 Car: 21214M, 2013

Reg.: 03/04/2005 Messages: 577 From: Moscow. South-West, Teply Stan Age: 61 Car: Belaya Niva 21213 1997 carb. WEBER DGV 32/36 MPSZ version DPKV 2_9011, detachable RPM, stud. double-row roller bearings SKF IVECO, subframe section. elevator.

Reg.: 01/12/2005 Threads / Messages: 4 / 1078 From: Voronezh Age: 67 Car: 2123 2007

Reg.: 02/03/2005 Threads / Messages: 85 / 2821 From: Adler Age: 46 Car: was. 2121 1.7carb. Born 1986 now: Toyota Lucida 2.2 TD EFI 4wd full time X-limited, 2131 1.8 carb, LPG, EUR, born 2004

Reg.: 12/08/2004 Threads / Messages: 62 / 1552 From: Moscow, Northern Tushino. Age: 65 Car: VAZ-21213, 1998, 1.7 l, “snowflake”; VAZ-21213, 1998, 1.7 l, “tea rose”, GAZ-31105 “Volga,” 2005, “nautilus”

Reg.: 01/17/2005 Messages: 22 From: Samara Age: 51 Car: 21214,2001

Reg.: 01/12/2005 Threads / Messages: 4 / 1078 From: Voronezh Age: 67 Car: 2123 2007

Reg.: 12/06/2004 Threads / Messages: 628 / 51730

I recommend a cable for a carburetor to anyone who has not yet done so.

Because it feels great when in the steppe, 50 km from the city, at 9 o’clock in the evening the gas pedal breaks. The journey home took 2 hours. If it weren’t NIVA, then it would be a tie, because along the way there were climbs that were overcome on the 1st lower level (it’s funny to see pedestrians overtaking you through the window :)).

PS1. The replacement was carried out according to the FAK (Karbofos article). There are no differences between 2121 and 21213. Pedal "Volgovskaya" (180 rubles. With "Nivskaya" it is deaf - nowhere.), the upper "stick" bends to the right by 15-20 degrees (Karbofos did not do this, IMHO in vain), cable "Moskvichevsky" (cable indexes 2108-, shells - 21412-, 50 rub.). The “Chisser” sector is attached with an M5 screw to the damper control plate, and to it is a piece of hardware with a lug for the spring. The bracket for mooring the shell at the carb is “Zubilny”. Re-bent for mounting on a “pan” (for all the change - 110 rubles)

PS2. The remains of the old drive were cut on the spot with a grinder - otherwise there is no way to pull it out. PS3. To get home, I set the carb to 3000 rpm. - and forward. PS4. The cable adjustment is now not analog, but discrete (grooves on the tube near the carb and a U-shaped clamp - similar to the one that secures the brake pipes). ZZY. And the fishing was a great success!

source

Cleaning

Using a special aerosol to clean the remote control without dismantling it is possible only when it is lightly soiled. Therefore, if problems arise, it is better to dismantle the throttle and remove dirt using a carburetor cleaner.

For this you will need:

Attention: cleaning of the diaphragm must be performed after the engine has cooled down. Otherwise, there is a risk of getting burned by the coolant or hot parts of the engine and throttle.

To clean the throttle valve, you must perform the following steps:

Attention: place a small container under the cooling system hoses to collect antifreeze.

Due to the fact that the liquid from the can is supplied under pressure, it effectively washes away plaque.

Reassembling the mechanism after cleaning is performed in the reverse order. Before installing the clamps, they should be lubricated with machine oil. This makes tightening easier and increases the reliability of the connection.

Source