The VAZ 21127 engine emerged in 2013 from the 21126 engine, completely retaining its design. Changes have been made to the design of the intake manifold - in the unit combined with the receiver, which was already used in the previous version, the developers installed dampers to regulate air flows.

ICE 21127

This, in turn, required the abandonment of the DMVR sensor; instead, DTV and DBP (air temperature and absolute pressure, respectively) are used. In other words, the designers have produced budget tuning, which is usually used by owners to independently increase engine power.

Design changes

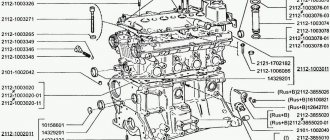

The 21127 engine was created from the previous modification 21126 of the 2112 engine, so the main design remained the same:

- cylinder head – used from the first version 21124;

- gas distribution mechanism – DOHC scheme, two camshafts, phased injection;

- cylinder block – high type from 11183, cylinder surfaces are honed;

- connecting rod and piston group - lightweight, foreign made;

- Timing drive – belt, tooth profile rounded;

- exhaust tract - catalytic collector with a large landing size of the neutralizer;

- crankshaft - with a “long” crank radius, from 11183;

- flywheel – has a chamfer for a large diameter damper;

- ignition system – there is a separate coil for each spark plug, there are no high-voltage wires;

- fuel system – ramp with imported injectors (Siemens, Bosch);

- electronic motor control system – controllers M7.9.7 or January 7.2;

- attachments - a pump with a metal impeller has a long service life.

Receiver 21127

Fuel rail 21127

“As a legacy”, the 21127 engine received ultra-low oil consumption - only 0.1% of the amount of oil used by the system. However, for the operation of the valve and hydraulic lifter cooling system, the AvtoVAZ manufacturer’s operating manual recommends purchasing exclusively high-quality lubricant, which costs 10% more.

Engine characteristics

| Manufacturer | AvtoVAZ |

| Engine brand | 21127 |

| Years of production | 2013 – … |

| Volume | 1597 cm3 (1.6 l) |

| Power | 78 kW (106 hp) |

| Torque moment | 148 Nm (at 5800 rpm) |

| Weight | 116 kg |

| Compression ratio | 11 |

| Nutrition | injector |

| Motor type | in-line |

| Injection | distributed electronically controlled |

| Ignition | coil for each spark plug |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 4 |

| Cylinder head material | aluminum alloy |

| Intake manifold | combined with receiver, polymer, built-in damper, DTV and DBP sensors |

| An exhaust manifold | catalyst |

| Camshaft | 2 pcs., marks on pulleys are offset by 2 degrees |

| Cylinder block material | cast iron |

| Cylinder diameter | 82 mm |

| Pistons | lightweight, manufacturer Federal Mogul |

| Crankshaft | from 11183 |

| Piston stroke | 75.6 mm |

| Fuel | AI-95 |

| Environmental standards | Euro 4/5 |

| Fuel consumption | highway – 5.8 l/100 km mixed cycle 7 l/100 km city – 9.6 l/100 km |

| Oil consumption | maximum 0.1 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W-30 and 10W-40 |

| Which engine oil is best by manufacturer | Liqui Moly, LukOil, Rosneft, Mannol |

| Oil for 21127 according to composition | synthetics, semi-synthetics |

| Engine oil volume | 3.5 l |

| Operating temperature | 95° |

| Motor life | declared 200,000 km actual 300,000 km |

| Adjustment of valves | hydraulic compensators |

| Cooling system | forced, antifreeze |

| Coolant quantity | 7.8 l |

| water pump | with metal impeller |

| Candles for 21127 | BCPR6ES from NGK or domestic AU17DVRM |

| Gap between spark plug electrodes | 1.1 mm |

| Timing belt | Gates, width 22 mm, service life 200,000 km |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | catalog number 90915-10001 replacement 90915-10003, with check valve |

| Flywheel | increased damper size |

| Flywheel mounting bolts | box MT – M10x1.25 mm, length 26 mm, groove 11 mm box AT – M10x1.25 mm, length 26 mm without groove |

| Valve stem seals | code 90913-02090 inlet light code 90913-02088 exhaust dark |

| Compression | from 12 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 800 – 850 min-1 |

| Tightening force of threaded connections | spark plug – 31 – 39 Nm flywheel – 62 – 87 Nm clutch bolt – 19 – 30 Nm bearing cap – 68 – 84 Nm (main) and 43 – 53 (rod) cylinder head – three stages 20 Nm, 69 – 85 Nm + 90° + 90° |

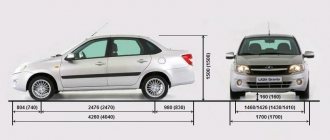

The engine is installed on:

• Lada Priora • Lada Kalina 2 • Lada Granta

Pros and cons of the VAZ-21127 engine

Pros:

- improved engine elasticity - solution to the problem of floating speed at idle

Cons:

- The cost of transport tax increases sharply, because engine more powerful than 100 hp — If the timing belt breaks, the engine still bends the valves — A car with this engine costs more

Pros and cons of the motor

The main feature of the ICE 21127 remains the insufficient safety of the valves, which can be bent by the pistons if the timing belt breaks. The second disadvantage is the expensive overhaul, even if you do it yourself:

- the timing belt complete with automatic tensioner and pulley is expensive, as it is produced by the foreign company Gates;

- The ShPG kit also has a high price, since it is manufactured by another foreign manufacturer, Federal Mogul.

Damper control valve

The advantages of the design are:

- attachments are conveniently located, which reduces labor costs for maintenance and repairs;

- increased torque and power of the internal combustion engine.

On the one hand, the manufacturer AvtoVAZ has expanded its line of engines with version 21127. On the other hand, it has provided a new spare part - an improved receiver with an inertial charging system, which is a definite plus:

- owners of Grant, Prior and Kalin of the second generation, equipped with 21126 engines, can buy this unit;

- install it yourself instead of the standard receiver of the previous configuration;

- remove the mass air flow sensor, install DBP and DTV sensors to get a power of 106 hp. With. instead of the factory 98 hp. With.

There are no other changes in the design of the internal combustion engine; there is no need to re-register the car with the traffic police. Transport tax and insurance will be cheaper, since the plant’s vehicle certificate indicates less power.

Let's move on to the cylinder block

We remove the pallet. Rotating the crankshaft as it is convenient for us, unscrew two bolts on each connecting rod cap. We use a TORX E10 head for this.

We take out the pistons along with the connecting rods. To do this, use the wooden handle of a hammer to press the connecting rod from below and lightly tap it to knock it up. We remove the old liners and buy new ones of the same size according to the markings on them. Here is another stone in AvtoVAZ’s garden, the owner has never climbed into the car from the interior or into the engine, but three pistons were of group “B” and one was “C”. It turns out that at the factory they re-sharpened one cylinder a little and simply put an enlarged piston there, no words. There are no options, we take group “C”, don’t sharpen the engine because of this. We will not touch the main liners either.

We buy a new piston group that does not bend the valves, connecting rods and connecting rod bearings.

Eliminating longitudinal play of the crankshaft

It was noticed on this motor. To eliminate it, replace the thrust half-rings. Standard and repair sizes are available. We take the first repair size, if they are too tight we sand them down a little. We unscrew the middle main bearing and gently push it with a screwdriver and move the half rings. The mark on it is in the form of three serifs, shown below.

Which cars are equipped with ICE 21127?

Immediately after development, engine 21127 is recommended to be installed on cars manufactured by AvtoVAZ:

- Lada Granta - since 2013, Lux and Norma configurations;

- Lada Kalina-2 - since 2013, only with a manual transmission, mainly on sedans and hatchbacks;

- Lada Priora - since 2013, Luxury equipment.

Lada Priora Luxe configuration

In principle, the engine’s sufficiently high performance characteristics made it possible to install it on the Lada Largus, Vesta and X-Ray. However, by the time of their serial production, the ICE 21127 had been upgraded to the next version 21129 with a control unit that complies with Euro-5 standards, so the plant management limited itself to the indicated modifications, leaving the volumes the same.

Motor 21129

Factors affecting the service life of the VAZ 2170

Toyota 3s fe engine: characteristics, malfunctions and tuning

According to the manufacturer, the ICE 21126 with sixteen valves has a stable operation duration of 200 thousand kilometers. After a certain mileage it is necessary to carry out major repairs. Taking good care of the VAZ 2170, proper maintenance (MOT) and timely replacement of damaged components and parts will lead to a long service life of the vehicle.

Reasons affecting the service life of the power unit:

- Engine overheating. Elevated temperatures of a running engine negatively affect the overall service life of the motor. Maintaining the operating temperature of the power unit elements at a constant level significantly extends its operating time.

- Fuel. The vehicle's owner's manual contains detailed information about the recommended brand of gasoline. Filling the 16-valve Priora engine with fuel must be of proven quality.

- Machine oils. Which oil is best to fill, its brand and how much lubricant is needed is indicated in the accompanying documentation for the car. The 126 sixteen valve engine accepts semi-synthetic and synthetic motor oils most well. A complete oil change should be carried out annually or after a mileage of 15 thousand kilometers.

The optimal operating engine temperature is 90 - 95 °C. The rules allow the power unit to operate at temperatures reaching up to one hundred degrees, provided that the radiator fan is running. The engine temperature is considered low if it is below 90°C. In cold weather, it takes more time to warm up the engine to the desired mark on the device.

Maintenance

In order to carry out major overhauls as rarely as possible, it is recommended to service engine 21127 according to the regulations:

- The timing belt drives the timing pulleys for 20–50 thousand km, but it needs to be inspected three times more often;

- The oxygen sensor has a slightly shorter service life - 10 thousand hours;

- The cooling system and the antifreeze itself, filters and fuel tank cap can withstand 40 thousand km of operation;

- the threshold of 25 thousand mileage cannot be overcome by spark plugs, belts and attachment belts;

- The filter along with the oil is changed every 10 thousand km.

To save budget, the internal combustion engine device allows you to perform all the specified maintenance operations in the garage without visiting service stations.

Typical breakdowns, causes, elimination

Since the 21127 motor uses a lightweight ShPG, as a result of a sudden belt break, the piston is 100% guaranteed to bend the valve. In addition, there are “diseases” characteristic of this motor:

| Power reduction | 1) burnt out valves 2) clogged air filter 3)fuel system malfunction 4) clutch slipping 5) wear of camshaft cams | 1)replacement of valves 2) cleaning or replacing consumables 3) cleaning and repair 4) clutch replacement 5) installation of a new camshaft |

| The internal combustion engine runs after the ignition is turned off | 1) carbon deposits inside the combustion chambers and on the valves 2) Problems with the ignition switch | 1)washing with a cleaning agent 2)replacing the ignition switch |

| Emergency pressure lamp comes on | 1) wear of the oil pump or main bearings 2) short circuit 3)low oil level | 1) replacement of parts 2) electrical repair 3) adding lubricant to the level |

In principle, no special complaints were noticed with the ICE 21127; this power drive is considered reliable and economical to operate.

Basic list of faults

As the domestic manufacturer assures, the resource of the power unit is 200 thousand kilometers while maintaining operational properties. Nevertheless, even such a perfect design of the 21127 engine does not exclude the occurrence of various malfunctions. Friction can often be observed, however, this is typical for most modern power units. This mainly indicates clogged injectors. Washing them gives the desired result.

Problems with electronics can also occur. Often the people who suffer the most are:

- ignition coil;

- starter;

- electronic control unit;

- fuel pressure or idle speed regulator.

Sometimes you can hear knocking noises from the engine compartment. You should not put off inspecting your car indefinitely; it is better to immediately determine the source of the extraneous noise. It is likely that the sounds are made by hydraulic compensators, and then there is nothing to worry about.

You should panic if the cause of the knocking is not in these parts. With a greater degree of probability, this may indicate wear of the connecting rod and piston group.

Engine tuning

Initially, engine 21127 had already received factory tuning, but there were still opportunities to further increase power:

- In addition to the standard receiver, a damper with a diameter of 54 mm is mounted to achieve a performance of about 110 liters. With.;

- another 10 l. With. will be added by replacing the exhaust catifold with a “spider”;

- The Stolnikov camshaft modification 8.9 will provide power in the upper speed range.

Tuning 21127

Complex tuning is possible by installing a Stolnikov 9.15 camshaft with a phase shift of 316 degrees, replacing injectors with Bosch 431 360 (more efficient compared to standard ones) and milling the valve seat stages. In this case, the internal combustion engine will receive about 150 hp. With.

Thus, motor 21127 is an industrially tuned version of the previous internal combustion engine 21126. The characteristics are improved only by modifying the intake air system (damper inside the receiver plus DBP, DTV).

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

Useful tips

Since the weak link in the cooling system is the thermostat, it is necessary to carefully monitor the antifreeze temperature, which should not exceed +95...+98 °C. Otherwise, premature wear of parts cannot be avoided.

When replacing the oil filter yourself, you need to pay attention to the valve cover seal. The presence of smudges indicates an unsatisfactory technical condition of the gasket. Because of this, motors often overheat.

Some car enthusiasts prefer to increase the power of their vehicles through chip tuning. True, as a result of flashing the control unit, no special increase in power is expected - only five horsepower.

The 21127 engine can be significantly benefited by installing Stolnikov 8.9 camshafts with a phase of 280. As a result, the car will accelerate to hundreds of kilometers per hour in less time - 9 seconds. Speed lovers will be pleased.