How to bleed the brakes on a Chevrolet Niva yourself

Experienced car owners know that the brake fluid on a Chevrolet Niva needs to be changed every fifty thousand kilometers, but at least once every 2 years. So, if the car reacts poorly to pressing the brake pedal, this indicates that there is moisture or air in the system. Consequently, it is necessary to bleed the brake system in the Chevrolet Niva, completely replacing the brake fluid. Foreign elements appear there due to the natural chemical decomposition of some components of the brake fluid and the high temperature generated during braking. The following are considered signs of air penetration into the hydraulic drive:

Note. When pumping a hydraulic drive is directly related to the repair of one of the circuits, and the serviceability of the second circuit is known, it is permissible to pump only the circuit being repaired.

The process of bleeding the hydraulic drive in a Chevrolet Niva is identical to replacing the brake fluid. The only difference is that the condition for the end of pumping of the working cylinder is the end of the release of air from the tube, and not the appearance of new brake fluid.

Thus, the car owner needs to bleed the brakes when observing any of the following signs:

When is it necessary to bleed the brakes?

The first of these is that the drive pipelines are exposed to adverse external factors.

The rear brake pipelines on VAZs are made of soft metals (copper, brass) and they pass under the bottom of the car. Oxidation processes and possible shock loads during use will be a prerequisite for the occurrence of cracks or breakdowns in the pipeline. The drive of the frontal devices is composite, one part of the pipeline is iron, and the other is rubber. Over the years, rubber “ages” and cracks appear on it. The next reason why there may be air in the system is a scheduled service of the brake system, which allows for accounting (software). The fluid used in the drive has its own resource, so it must be replaced from time to time. Specifically, during the shift, air gets inside the accounting software (software). It can also appear in the system after repairing devices, for example, when changing pads. Therefore, it is imperative to bleed the brakes after changing the pads.

But on VAZ cars it is possible to remove air bubbles using the pumping method - a process in which air is expelled from the water. For this purpose, special fittings are provided for the design of the brake devices.

It is not difficult to identify that the system requires bleeding - the failure of the pedal, the ease of pressing it and a decrease in the effectiveness of the brakes, right up to their complete absence, indicates that the accounting software (software) is too airy.

However, before starting pumping, our client should carefully examine the pipelines and components of the accounting system for leaks, and additionally the amount of water in the tank. If traces of leakage are detected, the fault should be removed by repair using repair kits (main and working brake cylinders), changing the damaged section of the accounting software complex (pipelines), and bleeding after the change. If air has entered the system due to a lack of water, then it should be replenished to the level earlier.

How to bleed the brakes on a Chevrolet Niva yourself

An assistant is required to bleed the brakes.

Meanwhile, the choice of the sequence of bleeding the brake lines is not significantly important, since each caliper has its own connection to the main cylinder.

The car must be placed on a level surface, in first or reverse gear. Then it is advisable to place wheel chocks or a device made of boards under the wheels. Next, you need to check the brake fluid level in the cylinder reservoir, which is located under the hood (between the windshield and the air filter housing). After pumping out the old fluid from the tank, add fluid to the max mark on the tank. The preparatory activities have been completed, you can proceed directly to work.

It is not so easy to determine at random when a complete replacement of the brake fluid on a Chevrolet Niva has been carried out. It’s appropriate to proceed from the following volumes: if the car has ABS, you will need 0.5 liters for each caliper; without ABS, 0.4 liters is enough. Such figures are given with a slight margin so that the replacement is carried out efficiently and the conditions for the new fluid replacement are standard.

Source

What pressure should Niva tires have?

VAZ, which produces various 4x4 SUV models, which include modifications 2121, 21213, 21214 and 2131, defines one value for all. Thus, the manufacturer recommends pumping the wheels of the front axle of an SUV to 1.9 Bar, and for the rear axle - 1.8-1.7 Bar. However, some parameters depend on the wheel size.

| Size | Front Wheel (Bar) | Rear Wheel (Bar) |

| 175/80/R16 | 2,1 | 1,9 |

| 6,95-16 | 1,8 | 1,7 |

| 175-406 | 1,8 | 1,7 |

In summer

However, the above are standard parameters. Much depends on the time of year and operating conditions of the car. In summer, these conditions are close to factory conditions, so the figure of 1.9 can be considered acceptable. But if you are planning a long trip along the highway, then you can increase the value to 2-2.2 Bar. This approach will improve the car's running speed and save 0.5-1 liter of gasoline per 100 km. However, this only applies to flat roads - if the road under the wheels is far from ideal, it is better to leave the indicator as standard.

Replacing brake fluid

If a replacement is needed, then you should study the structure of the brake system of your vehicle. Changing ABS brake fluid is very different.

Suppose without an ABC or a hydraulic accumulator, the pump and the ABC hydraulic valve block are located in one unit, then you can replace the fluid with your own hands. With integral ABC, it would be more correct to go to a service station.

Work must be carried out on each circuit of the brake system. The tools you will need are an empty bottle and a flexible hose. Additionally, you need to have a set of keys to work.

It all starts with the wheel that is furthest from the brake cylinder. First you need to drain the fluid from the brake reservoir and pour new one into it. Next, unscrew the fittings on each brake cylinder and wait until the old brake fluid drains out.

When a new one starts to leak, tighten the fitting. If the car has a diagonal system of contours, the process must begin with the right rear wheel, then the left front, then the rear left, and finally the front right.

With a parallel circuit, the sequence is:

Replacement must be carried out on removed wheels. If there is a hole, the work will be much easier. As a last resort, you can do all this with a jack, removing the wheels one by one.

At the same time, you can visually check the condition of the car, check the suspension elements and shock absorbers.

Be sure to bleed the brakes after all work. Look in the reservoir; you may need to add new fluid.

It is necessary to check the effectiveness of the brakes after replacing the brake fluid. We carry out the test on a dry road at various speeds. The car should stop smoothly and maintain directional stability. Have a good trip and no breakdowns.

Sources

Installing new calipers

Nissan BlueBird U12 calipers are best suited here. It is worth noting that the weight of the foreign car is almost identical to the Niva, which is an additional advantage for choosing this device. Among the best brake pads, it is worth noting Lucas.

To protect the device from dirt. We make a new shield. First, we prepare a cardboard blank, after which we cut out a shield from a metal sheet 1 mm thick along its contour.

It is important to make the holes correctly, according to our template

Using four bolts, we attach the shield to the adapter plate. Then the caliper bracket is attached there. If the latter begins to interfere with the movement of the brake disc, use a small backing. Next, the pads themselves are inserted into the bracket. If you do everything correctly, you will not have any difficulties with this.

The next step is to install the brake pipes. Here you need to take rubber hoses - you won’t be able to plug metal models into the caliper.

Since as a result of installation the parking brake cable will be located at the bottom, we will end up with two free brackets. To them we attach a rubber hose that comes from the caliper, as well as a metal tube that comes from the central tee

It is important that the brake hose is small, so a model from Kopeyka will do. We select the iron tube by size

The brake pipe is connected to an iron hose in the place where the handbrake cable used to be

We lay the tube in any convenient way, it is only important to secure it not at one, but at several points at once. In places where the tubes come into contact with the clamps, it is necessary to use additional protection (we simply wrap the elements in rubber or wrap them with special rubber tape)

After this we make the handbrake cable. The original version from Niva serves as the basis. Simply remove the mounting plate from it, and then shorten the spring by about 2 times. We take the boot from Moskvich. Next, we attach the cable to the handbrake drive. We attach it to a small hook located on the caliper. For lubrication we use Litol-24.

Design of the working hydraulic system

In order to increase the reliability and safety of control, the hydraulic brake system of the Chevrolet Niva is built according to a dual-circuit diagonal design. The first hydraulic drive circuit drives the front right and rear left wheels, and the second drive drives the front left and rear right wheels. Thus, controllability is maintained in the event of failure of one of the hydraulic drive circuits. The hydraulic braking system includes:

Also interesting: How to bleed the brakes on a Chevrolet Niva correctly

Features of work on the VAZ-2121 Niva

As for the VAZ-21213 Niva, this car has its own characteristics. And although the system on this car is dual-circuit, it is different from other VAZ cars.

On this SUV, one circuit combines all 4 brake mechanisms, and the second - only the front wheels. To ensure that the circuits are independent, the Niva uses a block caliper in front, to which two brake hoses fit; accordingly, there are two fittings for bleeding.

Bleeding the brakes on a Niva is done in the following sequence: first, air is expelled from the rear right mechanism, then from the rear left one. Next, the general circuit on the front brakes is pumped - first the right, then the left (the principle of the distance of the wheel from the master cylinder)

In this case, it is important not to confuse the fittings - the upper one is responsible for the general contour, and it is this that should be used

Only then is the front brake circuit pumped, for which the lower fitting is used. Here the pumping sequence does not matter; you can start with both the left and the right mechanism.

But the Chevrolet-Niva does not use such a brake design. A conventional diagonal dual-circuit system is installed there, so the pumping sequence is identical to the process on VAZ-2108 and higher cars.

Brake fluid Niva Chevrolet, choice

Let's take the following fact as an axiom - almost NONE of the leading manufacturers of pads or brake components make their own brake fluid. It is made either by chemical concerns or manufacturers of auto chemicals and oils. Example. Everything that is in jars of the TRW, BMW, ATE brands is made by manufacturers ROWE, BASF, Pentosin, ELF-TOTAL. Therefore, when I selected suppliers, I was guided by the following thought. A well-known company that deals with brake systems simply will not disgrace itself and sell a low-quality product in its own name. That's why I settled on Bosch, TRW, Brembo products. To fully pump the system of our car, 1 liter of product is enough. There is still some left for refilling.

A little theory

To transmit force, one of the properties of the fluid is used - its incompressibility. That is, when a force is created on a liquid, its volume does not change, and it acts as a transmitter.

A hydraulic brake drive is more practical than a mechanical or pneumatic one, but it has one drawback - if air gets into the fluid, the transmission of force will be significantly reduced. This is because air, like any gas, is compressible. As a result, the presence of air leads to a change in the volume of the liquid when creating force (due to gas compression). Because of this, the force is no longer transmitted to the actuators, since it is absorbed by the volume change.

https://www.youtube.com/watch?v=BRSJZkSYiVI

It turns out that effective operation of the brakes on a VAZ occurs only until air enters the drive system. And this can happen for several reasons.

Article on the topic - The design of the VAZ brake system

Purpose and operation of the pressure regulator

The pressure regulator (“sorcerer”) is designed to prevent the car from skidding during sudden braking. This is achieved due to the fact that the rear wheels begin to brake after the front ones. The time delay is provided by the regulator lever, which, when the car brakes sharply (the nose drops and the rear rises), pulls the piston in the regulator cylinder and closes the fluid supply channel to the working cylinders of the rear wheels.

In this case, the rear brakes do not work and the wheels spin until the rear of the car drops back. Thus, the “sorcerer” automatically regulates the fluid pressure in the rear cylinder path in inverse proportion to the load on the rear axle. In addition, it increases the braking efficiency of an empty vehicle when the load on the front axle is higher than on the rear.

This work must be carried out at every maintenance and after repair of the rear suspension.

Alternative way

The essence of this method is that the work is performed by two people at once. One sits in the driver’s seat and, on command, presses the brake pedal, while the other performs the necessary manipulations.

Here's how to properly bleed the brakes on a Niva:

- Start working with the rear right cylinder. Fill the expansion tank with liquid. Place a tube onto the fitting and lower the other end into a jar with a small amount of brake fluid.

- Give the command to your partner to press the brake pedal 5-7 times (of course, you also need to release it).

- When pressing the last time, it is necessary to fix the pedal in its extreme position near the floor.

- Unscrew the fitting a little and bleed air from the system. It will come out along with a small amount of liquid.

- Repeat the procedures described above until air stops flowing.

Then you need to switch to the second rear cylinder. The last to be pumped are the calipers of the right and left front wheels, respectively. The main thing is to strictly follow the sequence and add liquid to the tank in a timely manner.

This method is suitable when it is not possible to use the help of a partner. To do this, you will need to create excess pressure in the system using a simple bladder or spare tire. You'll have to be Kulibin a little to make an adapter between the chamber fittings and on the expansion tank cap (you need to use a spare cap).

The essence of the procedure is the same as in the first option. You should unscrew the bleeder fittings one by one to get rid of excess air. Experts recommend carefully monitoring the fluid level in the tank and, if necessary, adding it to the required volume.

Brake fluid selection

All brake fluids except DOT 5 use polyethylene glycol in combination with boric acid polyesters as a base, while DOT 5 uses silicone as a base. Brake fluids DOT 3, DOT 4 and DOT 5.1 have the same base and can be interchanged without any problems, at least within the same manufacturer.

Some manufacturers use polyalkylene glycol as a base for the production of DOT 3 (and possibly other grades). Information on the incompatibility of liquids based on polyethylene glycol and polyalkylene glycol could not be found anywhere, and knowledge of chemistry as a first approximation allows us to state that such a mixture will work no worse than the original components.

It should also be separately mentioned that some brake fluids are designed to work in the braking systems of cars with ABS (anti-lock braking system), most often they are marked with the addition of the designation “ABS”, for example DOT 5.1/ABS, or this is indicated separately on the packaging.

You should not mix brake fluids, even of the same class, if one of them is designed for ABS and the other is not, i.e. mix, for example, DOT 5.1 with DOT 5.1/ABS, because these fluids have slightly different chemical compositions of additives to reduce aeration (prevent the formation of bubbles) in the ABS system and there is no guarantee that as a result you will have a brake fluid that is chemically and physically stable system.

If you have a car with ABS, then you cannot use DOT not designed for ABS or even just add it to another DOT for ABS, which is understandable. If we are talking about a bicycle and hydraulic bicycle brakes, then you can use any DOT, rated for ABS or not, preferably without mixing them.

When glycol-based fluids (DOT 3, DOT 4 or DOT 5.1) are mixed with silicone-based DOT 5 fluid, a chemical reaction occurs resulting in a compound that does not meet any brake fluid requirements and is aggressive to the seal material.

Do not mix DOT 3, DOT 4 or DOT 5.1 with DOT 5 silicone fluid! A complete replacement of glycol brake fluid with silicone is possible (DOT 3, 4, 5.1 to DOT 5), but this requires first cleaning and thoroughly drying the entire brake system of old brake fluid. At the same time, there is no guarantee that the material of the brake system seals will be resistant to silicone fluid, although the chances of damage to the seals by silicone fluid are quite small, because Silicone based fluid is not as aggressive as glycol based DOT. The advantages of such a replacement in the case of a bicycle are extremely unclear.

Replacing silicone brake fluid with glycol is practically impossible (DOT 5 to DOT 3, 4 or 5.1), no matter how much you flush the entire system beforehand, because glycol DOT is very aggressive and if the brake system elements were not originally designed for it, then most likely In all, the brake system seals will be destroyed. https://www.drive2.com/l/457842415315760117/

Why the brake pedal fails: we find out the reasons and troubleshoot problems

- What is the general principle of operation of a car's braking system?

- What are the main reasons for the brake pedal to fail?

- Why does the brake pedal fail after bleeding and with the engine running?

A properly functioning braking system is an important element of safety and even a guarantee of the life of the driver and other road users. If your car's brake pedal fails, this is a danger signal. This means that you need to check the entire brake system and find out why the brake pedal is falling down.

How does the braking system work?

To understand why the brake pedal sometimes fails, you need to understand the general principle of operation, as well as the design of the braking system. It is usually hydraulic, and the problems are common for different car models. The operating principle of the system is based on the fact that a special incompressible liquid is placed in a closed volume.

Hydraulic brakes include the following elements :

- GTZ (brake master cylinder);

- RTC (brake wheel cylinders);

- hydraulic lines;

- compensatory device;

- brake discs, pads.

The working fluid here, in accordance with the name, is brake fluid, which has certain properties. The driver presses the brake, his force is transmitted to the GTZ filled with working fluid. The fact is that the device of this element contains a piston - it presses on the liquid, and through it the force is transmitted to the RTC. The latter are installed in the area where the wheels are located. Thus, the pads are pressed against the brake discs/drums. Sudden pressure on the pedal causes the pads to rigidly block the wheels.

https://www.youtube.com/watch?v=6VSweGOhCYU

Next, the driver releases his foot, and the return springs move the pads back. At the same time, the liquid is displaced into the GTZ. This short list represents the entire operation scheme of this system.

Why does the brake pedal fail?

Now let's move on to the main question of why the brake pedal fails. The system itself, recall, is closed, and the liquid inside is incompressible. Due to these properties, the force from the pedal is supplied to the pads. They press against the brake disc, causing the car to slow down and stop. In the event of a malfunction, pressing is not followed by braking: liquid under pressure leaves the system or air takes its place due to lack of tightness. Both options interfere with the normal functioning of the braking system, which means that such a car cannot be driven.

Let's take a closer look at the reasons for the failure of the brake pedal:

1. Brake fluid.

The reason why the brake pedal fails may be the quality of the brake fluid and its mixing with condensate. The latter is nothing more than water, which is compressible. It changes the characteristics of the brake fluid, so you feel your foot sink when braking.

Gradually accumulating condensation, the brake fluid (BF) changes color and becomes darker. To determine the water content in fuel fluid, you can use specialized instruments. According to the maintenance standards for most cars, this working fluid must be replaced every 40,000 km or every 4 years.

Elements of the brake system deteriorate over time due to contact with brake fluid if it does not meet all required standards. The following signs appear: fluid leakage, pedal failure, and if you release it, air leaks.

If the brake pedal fails, check how much brake fluid is currently in the system and whether there are any leaks in the system hydraulic circuit. Most often, leaks are found in the area of threaded connections of brake hoses and pipes with each other or with the caliper. Then the way out of the situation will be to pull the connection. Another cause of a leak may be damage to the tube or hose - in this case, the part needs to be replaced.

2. Air in the hydraulic system.

The ingress of air negatively affects the quality of the brake fluid and causes airing of the brake lines. The resulting plugs are compressed under pressure, and the pedal fails. The brake pads move little and the car does not slow down because there is no pressure to move the piston. Even if the driver presses the pedal to the floor, he will not achieve the desired effect. Fix this problem by pumping.

But air appears in the system not only due to mechanical defects. Often airing is a consequence of errors during bleeding after changing the brake fluid. Either way, you will feel like your leg is sinking when you try to brake.

3. Malfunction of the main brake cylinder (MBC).

In the absence of brake fluid leaks, a sign of a possible failure of the GTZ unit may be the fact that the pedal sinks and only after the second or third pumping becomes stable.

Most often, the reason for this behavior of the system is wear of the rubber seals. There are many reasons for this: from the chemically active composition of low-quality brake fluid to the natural wear and tear of rubber elements. The lack of the required density of the part contributes to the appearance of cracks in the system. Air easily leaks through them and the fuel fluid flows out.

Dealing with this problem and the fact that the pedal fails seems simple: just install new rubber seals. But this work cannot be done without skills and patience: you will have to change all the rubber bands, seals and brake fluid. Be sure to bleed the system to get rid of the air, otherwise you will again notice your foot sinking under braking.

4. Vacuum brake booster (VUT).

If there are problems with this unit, a specific sound similar to hissing appears during braking, which indicates depressurization in the vacuum booster. In this case, the pedal does not necessarily fail. This problem occurs due to malfunctions of the valve, diaphragm, and VUT seals.

In this case, as in most others, you will have to replace elements that have become unusable. We have already talked about the reasons that cause the failure of rubber seals and oil seals - these problems lead to the improper functioning of the VUT. Among other things, the pipes fail and the diaphragm of the unit cracks.

5. Violation of clearances in the brake system.

Too large gaps between the GTZ and the pedal cause the latter to fail, and the car brakes worse than before. Ideally, after pressing, the driver feels a smooth movement of the leg, then resistance increases. With an increased gap, you can feel that your foot sinks sharply when you press the pedal, and only at the end does resistance arise, although it is not always there. There is no talk of stable braking here.

6. Bleeding the brake pedal after installing new pads.

Required Tools

In order to change the brake fluid on a Chevrolet Niva, you need the tools from the table below.

Table - List of tools required to change brake fluid

| Tools | Note |

| Spanner | "at 8" |

| Transparent hose | Up to a meter long |

| Rags | To clean dirt |

| Syringe | Can be replaced with a rubber bulb |

| Tara | Can be replaced with a rubber bulb |

To carry out work, access from the bottom is required. Therefore, an inspection hole or overpass will be required. It is more convenient to replace the vehicle with a partner, but there are ways to carry out the task alone.

How to check and adjust the tension of the handbrake cable

How to bleed abs brakes yourself

In such a situation, adjustment of the Chevrolet Niva hand brake is required. This type of repair is simple, performed relatively quickly and does not require the use of special equipment. All you need for work are two keys “12”, pliers and a jack if it is not possible to put the car on the inspection hole.

To work, you need to put the Chevrolet Niva on the inspection hole

- First, check whether the handbrake really does not hold the car on the road at a slope of 25%. To do this, place the vehicle on an overpass or find a suitable section of road. If the problem occurs, then we proceed to adjustment.

- Setting the optimal parking brake cable tension is done under the car, so it is better to place it above the inspection hole. If this is not possible, use a lift or jack. In any case, the rear of the car must be raised.

- When the vehicle is ready for use, secure it and release the handbrake lever.

- Next, using a wrench, loosen the lock nut on the handbrake adjusting rod, then use a second identical wrench to tighten the adjusting nut until the cable is properly tensioned. By the way, pliers are needed to keep the rod from turning during the adjustment process.

- Now tighten the locknut and make a full stroke first to the working position, and then lower it. After this, spin each rear wheel by hand. The rotation must be uniform, jerking is not allowed. If any are felt, adjusting the Chevrolet Niva handbrake requires repeating.

And the last stage is a handbrake test in road conditions. That is, you need to carry out a standard check of the parking brake's effectiveness, as described in the first paragraph of the manual.

After assembly, the handbrake must be tested in road conditions.

- To carry out the replacement, the rear of the vehicle must be in a hanging position. Therefore, lift it using a lift or jack and remove the brake drums from the rear wheels.

- Using a “12” wrench, loosen the locknut on the adjusting rod and completely unscrew it together with the adjusting nut. You must first remove the spring from the rod, as it will not allow you to unscrew the nuts.

- After this, you can easily remove the cable equalizer and remove the cable itself from it.

- Next, by pulling the cable towards you, remove the ends of the shell from the brackets located on the left and right on the bottom of the body.

- Using manual force, remove the right and left branches of the cable from the rear axle beam brackets.

- Using a wrench, unscrew the bolts securing the holders to the brake flaps.

- Now, having disconnected the cable ends from the brake pad drive levers, pull it to remove it from the hole in the brake shield.

After dismantling, install a new Niva rear hand brake cable. To do this, also use these instructions, but perform all the steps in reverse order. And with this, the replacement of the Chevrolet Niva handbrake cable is completed, and finally, do not forget to adjust the degree of its tension

It is also important to lubricate the adjusting threads on the rod upon completion of repair work to avoid problems with unscrewing the nuts during the next adjustment or replacement

Replacing brake fluid, checking the level, topping up

| Replace the brake fluid in the hydraulic brakes every two years, regardless of the vehicle's mileage. |

| Before replacing the brake fluid, check the tightness of the hydraulic drive (see here) and eliminate any malfunctions. |

| You will need: an “8” wrench, brake fluid, a rubber or transparent hose, a transparent container. |

What brake fluid should I fill and how much?

Brake fluid type DOT-4 SAE J 1703, FMSS116. "Tom" or "Rosa" (not lower than DOT-4)

Total volume: 0.5 l .

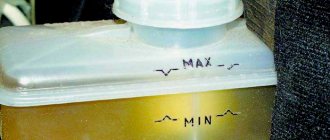

Checking the level and adding brake fluid

| When the brake fluid level in the reservoir drops below the “MIN” mark, the warning lamp in the instrument cluster lights up red. We recommend checking the level before each trip and, if necessary, adding fluid to the tank without waiting for the warning light to come on: this operation is best carried out in advance. If you have to add brake fluid to the reservoir quite often, immediately contact a specialist or fix the problem yourself. |

| You will need: brake fluid, a clean rag. |

| The reservoir is installed on the master cylinder of the brake system on the left side of the engine compartment near the bulkhead. |

Algorithm of actions

1. Remove the dust cap from the fitting (for convenience, you can first remove the wheel).

4. The assistant in the cabin slowly works the brake pedal until significant resistance appears. After that, he fixes the pedal pressed. 5. Turn the key in the unscrewing direction one turn. The liquid along with the air will escape into the vessel, but this will prevent a new portion of it from entering the system. The pedal will go down.

6. Tighten the fitting. 7. Repeat these steps until bubbles stop coming out. 8. Move to the next cylinder.

Important points

Work must be carried out only after the liquid leak has been eliminated, if this has not been preceded by repairs. After repairing the brake system, bleeding will only be necessary when depressurizing. For example, after replacing the brake pads, there will be no air in the system.

Brake pads for Chevrolet Niva

The front wheels of the Niva Chevrolet use disc brakes, and the rear wheels use drum brakes. Accordingly, the pads on them are different. Pads are the main working part of the brakes, which carry the most load and wear out the fastest. If the car is used intensively, the condition of the pads should be checked at least once every six months. Today there are many different domestic and foreign manufacturers of pads for Niva-Chevrolet cars.

They differ in price, material, service life. The so-called “Kevlar” pads from the Japanese company NIBK are considered the most effective and “cool”. They are made using modern nanotechnology from a compound that is equally effective in various operating modes. The advantages of this pad model include:

The only disadvantage of these pads is the high cost, but the price corresponds to the quality.

If you need information about replacing front pads, this is the place for you.

Malfunctions of the "vacuum"

A vacuum brake booster (VUT), or simply a “vacuum booster,” creates in the vehicle’s vehicle the pressure necessary for their proper operation.

If the amplifier is not working well, the pedal simply won't push through. Since the vacuum booster is a rather complex part consisting of many components, a malfunction of any of them can lead to this situation. And since a breakdown of an amplifier component, as a rule, requires its replacement, correct diagnostics will help save the car owner not only time, but also money.

If the filter element of the “vacuum tank” is clogged, it is enough to replace it so that the amplifier begins to function normally again. This also applies to a damaged vacuum booster diaphragm, and problems with the tip or check valve. It is enough to replace one damaged component, and the vehicle will act like new again. It is important to accurately diagnose what exactly needs to be changed.

Sometimes no major replacements are required at all. For example, in a situation where the vehicle is depressurized. The seal can be broken in two cases: either the hose between the “vacuum reservoir” and the intake manifold is damaged, or the clamps are loose. And if in the first case replacing the hose is still necessary, then in the second it is enough to tighten the clamps. This can also be done at a car service center, but the car owner is quite capable of dealing with such a problem on his own.

But it happens that the unsuitability of only one component completely renders the VUT unusable. This most likely occurs in a situation where vehicle malfunctions are ignored for a long time. As a result, a badly damaged valve moves to such a position that it disables the entire “vacuum tank”.

Brake fluid Chevrolet Niva

In accordance with the operating instructions, brake fluids that comply with the international safety class DOT-4 are used in the brake system of vehicles produced by the GM-AVTOVAZ JV. Table 13.6

Brake fluid

| Name | Manufacturer |

| "Rosa DOT-4" | OJSC "Caprolactam" |

| Spectrol Disc Brake fluid | NPF "Spektr-Auto" |

| Brake fluid DOT-4 | BP, UK |

| Brake fluid DOT-4 | STP |

Repairing auto parts yourself is a responsible task that should be taken as seriously as possible. Sometimes a faulty spare part takes the driver by surprise, forcing him to spend a lot of time and money searching for a good service station, but there is an alternative solution to the problem; this requires a small amount of knowledge and a set of tools.

When repairing Chevrolet Niva brake fluid, you need to be extremely careful and not neglect the little things. To get acquainted with the issue, car enthusiasts often use various Internet portals dedicated to auto parts. Some of them use narrowly focused forums. But, as a rule, only generalized information is provided there, which is known initially. Where can you find a reliable source that offers really useful things? Our portal is open for this 24 hours a day. Online mode allows us to help clients at any time convenient for them. Moreover, a mobile version has been developed that is available to everyone.

A detailed description of such a unit as Chevrolet Niva brake fluid has a good structure with thematic headings. In addition, there is always the opportunity to familiarize yourself with the intricacies of installation. There are often situations when a driver is confident in his abilities, but when he gets down to work, questions begin to arise. Thanks to our portal, such moments can be easily avoided. The site is a database that is updated regularly. By using it as a support during repair work, the car enthusiast receives a serious advantage. Each of the articles has reliable support, tested in practice.

In addition to the repair manual, the owner of a personal car will be able to prevent a lot of breakdowns that occur due to the human factor, thanks to the information located on the site. Users are presented with a lot of useful recommendations for proper operation, which will help significantly extend the life of the unit and avoid many negative consequences.

Online support is an excellent and most convenient way to obtain the necessary information. Another significant plus is that articles are written for people. We understand that the reader will do everything with his own hands, and we try to make it as convenient and efficient as possible. Use the resource at any time of the day and find the answer to any question you may have regarding cars.

↓ Comments ↓

1. Car structure

1.0 Car structure 1.1 General information about cars 1.2 Passport data 1.3 Car keys 1.4 Controls 1.5 Heating and ventilation 1.6 Doors 1.7 Seat belts 1.8 Adjusting the position of the front seats 1.9 Adjusting the steering wheel

2. Recommendations for use

2.0 Recommendations for operation 2.1 Safety rules and recommendations 2.2 Tools and accessories 2.3 Running in the car 2.4 Operating the car during the warranty period 2.5 Checking the car before leaving 2.6 Replacing the air filter entering the cabin 2.7 Using a jack 2.8 Towing the car

3. Problems along the way

3.0 Malfunctions along the way 3.1 The engine does not start 3.2 Malfunctions of the fuel injection system 3.3 No idle speed 3.4 Interruptions in engine operation 3.5 The car moves jerkily 3.6 The car accelerates poorly 3.7 The engine stalls while driving 3.8 The oil pressure has dropped

The Niva wheels are heating up - what to do in this case?

It often happens that the brake disc simply cannot be removed - it becomes stuck due to heat, rusts or sours due to dirt and scale. In this case, you have to use special pullers.

Experienced car mechanics remove the entire disc along with the fist and squeeze out the disc using a press.

https://www.youtube.com/watch?v=6VSweGOhCYU

If there is no puller, people often start hammering on the disc from the back side - sometimes this helps, but we do not recommend doing this. The edges of the brake disc simply break off from impacts.

If the disc cannot be removed because the pins cannot be knocked out, then you have to pick up a grinder and cut off the excess parts.

It happens that during operation the car wheels begin to heat up. This may indicate either their poor quality or breakdown.

Were you confused by the price of disc brakes and decided to buy a cheaper part? Then the heating problem can be solved very simply - replace the parts with better ones. In this case, you need to forget about saving. It is best if these are ventilated brake discs that match your “iron horse”.

Niva ventilated discs are parts with special holes and notches through which air passes and additional cooling occurs, preventing the brake disc from overheating. Such discs are very reliable, which has long been proven in practice. Most often, tire drivers choose brake discs from Brembo, Zimmerman, Delphi, Bosch and other manufacturers that have proven the quality of their products.

Having taken into account all the tips given above, you can be confident that the Niva, or rather its braking system, will never let you down and will work for your benefit for many years. This concludes the article about how to replace the front brake discs of a Chevrolet Niva. We can only hope that the new Chevrolet Niva will have fewer shortcomings and shortcomings in the braking system and that the designers will take into account the operating experience of the previous model. Good luck to everyone on the roads and safe driving.

PS: Watch the video with a review of the front brake discs and their replacement on a Chevrolet Niva from experienced car enthusiast Sergei Zykov.

It happens that everything is ready to install new disks, but the old ones do not give up and hold on tightly. There is no single solution here; you will have to think about it and tinker.

The most popular solutions are to use a pry bar or WD-40. You can also unscrew the caliper bolts and screw in the bolts without the caliper. Then you need to turn the mechanism and periodically tighten the bolts.

Since the mechanism takes on the friction of the pads, slight heating is inevitable. However, in some cases the mechanism heats up to excessive levels. In such a situation, the question arises: is this a normal option or is repair necessary?

Typically, the brakes become very hot when the pedal is pressed frequently, which occurs during an aggressive driving style. For example, brakes in sports cars get very hot. High operating temperatures not only increase wear, but also affect braking. The braking distance becomes longer, and this can lead to an accident.

There may be other reasons for extreme heat. The temperature may increase after recently replacing the pads, in which case everything will return to normal after a while. The pads may be of poor quality, or they may simply be stuck. Also, strong heating may indicate severe wear.

Not all drivers can determine the temperature. This is not difficult to do - overheating is indicated by vibrations in the steering wheel and the appearance of unusual sounds when braking. If there is strong heating, you should find the cause and eliminate it.

When operating a vehicle, it may occur that the disk becomes very hot. Of course, it will heat up during friction; this is a completely normal process. But sometimes it happens that the temperature just goes off scale. And many problems may appear - cracks, defects, severe wear. The problem of excessive heating can be solved quite simply if you take this issue seriously.

It is equipped with cast iron discs. Today you can find ventilated products on sale that have notches and holes on the working surface. It is with the help of such elements that a large amount of heat can be removed. And the brake disc will not heat up to critical temperatures.

Advantages and disadvantages of the braking system

Reviews from car enthusiasts about the brake system on the Chevrolet Niva show that it is generally quite reliable and effective, fully consistent with the class of SUV cars. The advantage is ease of control, ease of maintenance, adjustment and replacement of parts. The disadvantages are due to the use of a pressure regulator, the operation of which in some cases can manifest itself in the form of uneven braking, the appearance of vibration when braking at certain speeds, and an increase in braking distance.

Effective brakes on the Chevrolet Niva, as the main condition for the safety and controllability of the car, help maintain the high popularity of this model for many years.