How to check if the cylinder head gasket is broken

A car engine has two important parts: the cylinder block and the cylinder head (cylinder head). And their connection to each other is sealed with a cylinder head gasket. Its main task is to seal combustion chambers and channels through which antifreeze circulates. When the cylinder head gasket is punctured, problems appear in the engine, which we will discuss in this article.

Cylinder head gaskets are usually made of thin sheet metal or reinforced paronite with metal edging for the combustion chamber holes. The walls between some of the holes in the gasket are quite thin, so the slightest mistake during installation or replacement will lead to their rapid burnout.

The easiest way to check if the cylinder head gasket is blown is shown in the video at the bottom of the page.

The main guarantee of the durability of the cylinder head gasket is the ideal contact plane between the head and the cylinder block. Adjacent surfaces must be clean, free of holes and roughness.

The second important point for extending the life of the gasket will be to follow a certain order of tightening the cylinder head bolts. For this, motor manufacturers, as well as gasket manufacturers, provide a diagram for screwing in fasteners indicating the tightening torque.

Signs of a burned out cylinder head gasket

Burnout of the cylinder head gasket on passenger cars, if this happens, will cause a lot of trouble for car owners.

The main sad news is that the operation of the machine becomes unacceptable.

Be careful! Take the following signs seriously, and if they appear, then you should stop using your car and take measures for qualified repairs:

- if the temperature of the coolant rises and antifreeze (antifreeze) begins to boil;

- the engine starts to stall, traction disappears;

- The interior stops being warmed up by the heating system, as the system becomes airier and the heater motor drives cold air.

But there is still hope, albeit scanty, that the signs of a burnt-out cylinder head gasket will not be confirmed.

How to figure out how to find out the true cause of the malfunction?

Assembly Features

Before assembly, you should check the bolts securing the head to the hood; their length should not be more than 13.5 cm; if they are longer, they can no longer be used.

You should also check the flatness of the head. If it was overheated, it is possible that it was warped and will require repair in the form of trimming the plane.

During assembly, the head bolts are tightened in a certain sequence and with a strictly defined tightening torque. Next, everything is assembled in the reverse order of disassembly.

Disassembly is also carried out in the same sequence if the power plant is being modified.

Why does the cylinder head gasket break?

What does a blown cylinder head gasket look like?

Most often, the cylinder head gasket breaks due to overheating during vehicle operation. Under the influence of high temperature, the lid may “lose” its working position. Because of this, the tightness of contact with the cylinder head cover is disrupted and depressurization occurs. Changes in shape due to overheating are typical for aluminum lids. Cast iron lids do not suffer from such a “disease” because they are resistant to high temperatures. They can only crack, but this happens extremely rarely. Changes in geometry due to overheating also happen with iron-asbestos cylinder head gaskets.

We recommend: I washed the engine, why the car won’t start

Gasket failure can also be caused by improper tightening of the bolts. Moreover, both too weak and too strong a puff has a bad effect. In the first case, exhaust gases leak from the block (and they also have a destructive effect on the gasket itself, reducing its service life). By tightening the bolts too much, you can damage the gasket material.

Maximum accuracy when tightening can be achieved using a dynamometer and observing the sequence of tightening the bolts. Detailed information on these issues should be found in the user manual.

On most vehicles, you should tighten the center bolts first, then the others. In this case, it is important to follow the phased twisting process. For example, first all fasteners are pressed to 3 kgf, then (again from the central to the outer ones) - to 6 kgf, the next circle - to 9 kgf.

What is a cylinder head gasket

Inside the cylinder block (BC) there is a system of branched technological channels through which coolant circulates. Their outlet holes are located opposite similar holes in the head. Antifreeze moves under a certain pressure in the system, so no gaps in the mating of metal surfaces are allowed.

The installed gasket helps ensure sealing. It is securely clamped between flat planes using tightening bolts. The following types of gaskets are found in the automotive industry:

- paranitic, which includes asbestos material, sealing/reinforcing components, etc.;

- metal, assembled from several layers of metal, between which a heat-resistant sealant is poured.

The cylinder head gasket must not be allowed to burn out. This will lead to undesirable consequences. However, in high mileage vehicles this can happen under various circumstances. You should not drive with this problem, as it can lead to unpredictable consequences with the control and performance of the car.

Burnout of the gasket between two adjacent combustion chambers

Burnt gasket between cylinders 2 and 3. As expected, since the compression in them has dropped.

Separately, it is worth noting the case when the gasket burns out between two adjacent combustion chambers. There are no obvious visual signs of such a burnout.

But there are symptoms that indicate a burnout of this nature - a decrease in engine power, high fuel consumption, difficult starting with fully functional ignition and power systems and an adjusted gas distribution mechanism.

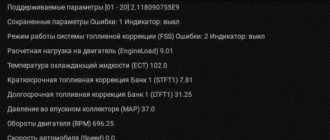

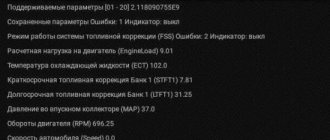

Diagnostics

We diagnose such a malfunction simply - we measure the compression level in all cylinders.

Compression measurement

In the event of a gasket breakdown, the compression in two adjacent cylinders will be an order of magnitude lower than nominal, which indicates a breakdown.

In this case, when replacing the gasket, you should carefully examine the burnout location; perhaps a hole or microcrack has appeared there, and it will continue to cause gasket burnout in this very place.

Recommended: Piston Ring Size Chart

What to do if the cylinder head gasket is blown

If, according to the results of the check, the cylinder head gasket is broken, then you have no options other than replacing it with a new one.

The cylinder head gasket is not a very expensive part. Depending on the car model, material and manufacturer, its price ranges from 300-3000 rubles. But this is just the tip of the iceberg.

- When replacing the cylinder head gasket, you will also have to change the mounting bolts. When a bolt is unscrewed, its parameters no longer meet the necessary requirements, and when tightened again with the required force, there is a high probability of the bolt body breaking. The cost of new bolts ranges from 350-1000 rubles.

- Before installing a new cylinder head gasket, it is important to check the surface of the mating planes on the cylinder block and cylinder head. If additional grinding is required, then it is necessary to purchase a gasket taking into account the thickness of the removed metal layer. Grinding the cylinder head will cost between 450-900 rubles.

- Removing the cylinder head in some engines is quite difficult. It is necessary to disconnect many parts and assemblies and drain technical fluids. Therefore, it is better to entrust this important work to qualified specialists. Replacing the gasket at a car service is estimated at 1200-4000 rubles.

After replacing the cylinder head gasket, the motorist should monitor the behavior of the engine for some time. If the engine runs stably, the exhaust gases are transparent, and the temperature does not exceed the norm, then the gasket copes well with its task and the problem is solved successfully.

Diagnostic methods

When direct or indirect signs are detected, a new task arises for the car owner. He needs to figure out how to check the cylinder head gasket for a breakdown.

There are several methods in total. Moreover, the diagnostics are quite simple and can be used in garage conditions. Experience does not play a key role here, since even novice motorists can cope with the task.

If you are interested and need to know how to check whether the cylinder head gasket on a car engine has been broken, perform the following manipulations. Any of the presented methods is suitable for obtaining an accurate answer regarding the integrity and current condition of the seal between the block and the head.

- Visual inspection. The simplest option is how you can determine for yourself that the cylinder head gasket on the engine is broken or worn out. There is no specific and strict algorithm of actions here. The malfunction is determined simply by visual observation. First you need to start the engine, open the hood and take a closer look at the area where the block and head connect. If even a small amount of smoke comes out through the cracks, there is a problem. You can also listen to the behavior of the motor, which may begin to produce uncharacteristic ringing sounds.

- Checking the radiator and coolant expansion tank. It is also necessary to check the neck, with the help of which new engine oil is filled as part of scheduled maintenance. The method is also visual. Just unscrew all the caps and look at them carefully. Don't forget to look inside the tank. If coolant has penetrated into the engine, you will see a characteristic red emulsion on the oil filler cap. If the oil is in the antifreeze, then oily spots will appear on the radiator cap or expansion tank.

- Exhaust pipe monitoring. Start the engine. You can ask an assistant to rev the throttle a little to increase the volume of smoke coming out of the exhaust pipe. If you see white smoke coming out, which is actually steam, there is probably a problem with a broken gasket. When using antifreeze, white smoke with a characteristic sweet tint usually comes out of the pipe. Additionally, look into the coolant expansion tank. If the level gradually drops, then you have probably diagnosed a gasket failure. Although the sign is considered indirect.

- Checking the presence of exhaust in the cooling system. To do this, you can use one of 2 methods. The first method involves unscrewing the cap on the radiator or expansion tank. If there is active seething inside, this is a bad sign. The second method is to use a balloon or a regular condom. The product is pulled onto the neck of the tank, having first removed the lid. Then the engine starts at a speed of about 3-5 thousand per minute. If the balloon or condom inflates (quickly or slowly), a leak has occurred. This means that the gasket will need to be replaced in the near future.

This is interesting: Replacing the main brake cylinder on a VAZ-2110: checking, repairing the GTZ

All methods have been used for decades, but continue to be effective, simple and quite accurate. Yes, you can spend extra money and go to a car service for diagnostics. But in order to save money, it is better to determine the fault yourself, and then entrust the replacement to specialists or do everything yourself.

Replacing the gasket yourself is potentially complex and difficult to do without the appropriate experience and special tools. Also, you should not trust garage service stations that do not have a license. Here it is better to spend more money, but put the car in the safe hands of specialists who will provide guarantees for the work performed.

Thermostat

The cause of overheating of the coolant may also be the thermostat - this part in the cooling system is required to maintain a stable temperature.

When the engine is still cold, all the antifreeze circulates in a small circle, bypassing the radiator, so the engine warm-up time with a closed thermostat is significantly reduced.

When the required temperature is reached, the valve of the thermostatic device is activated (opens), and the antifreeze passes in a large circle through all the pipes of the cooling system and the radiator.

This cools the engine.

If the thermostat does not open in time, boiling of the antifreeze is inevitable; the liquid will not cool to the required limit without passing through the radiator.

In any case, you need to carefully monitor the devices and prevent overheating.

How to make sure the thermostat is working properly?

First of all, you should make sure that all large radiator pipes (upper and lower) are heated evenly.

If some of them remain cold after warming up, check the functionality of the thermostat.

To check the temperature control device, it must be removed from the vehicle. Removing the thermostat is not difficult, so let’s focus on diagnostics.

To check you will need any utensils, an electric heater and a thermometer.

We pour water into the container, place the part and water in it and look at the thermometer when the thermoelement begins to open.

We recommend: How to connect a car radio to 220 correctly

The temperature range at which the valve should operate is indicated for each thermostat and depends on the specific car model.

Start of work

The very first step is to remove the air filter. Of course, on a carburetor engine it is somewhat easier to remove it. If you have an injector, you will have to tinker with its rubber fasteners. But the essence remains the same - it is necessary to disassemble the fuel system completely to get to the cylinder head. But we will look at the example of not an injection, but a carburetor seven. Still, there are many more classic cars with such a power system.

It is advisable to dismantle the carburetor, since if you remove the head along with it, you can accidentally damage it. On all classic series cars, the carburetor is removed in the same way. This procedure is quite simple, but it will take some time. Now you can unscrew the nut securing the distributor and remove the distributor along with the wires. Getting closer to the engine, all that’s left to do is drain the antifreeze from the system.

And then turn off all the pipes that you see. After this, it will be possible to dismantle the cylinder head cover. It is secured with nuts and shaped washers. Don't lose them during repairs. That's all, the preparation is complete, you can begin the most difficult part - dismantling and installing the cylinder head.

We recommend: The windshield washer does not work: we look for the cause and eliminate it

Test methods and causes of failure

The driver must take into account that operating a vehicle with a faulty gasket in the engine, even during short-term driving, is not recommended by experienced drivers. Ignoring the fact can lead to an immediate need for major repairs, which will ultimately turn out to be a more expensive undertaking than replacing a breakdown.

It is important to know that signs of a broken cylinder head gasket manifest themselves in very similar facts in both a gasoline engine and a diesel unit, regardless of the type of power plant: naturally aspirated or turbocharged.

The situation requires competent, timely and careful diagnosis. If your cylinder head gasket is blown, symptoms may include the following in the early stages:

- significantly more fuel will be spent on travel;

- starting the engine will become more difficult or take longer;

- the engine exhibits unstable operation under load and at idle;

- will become noticeable in the form of a decrease in power parameters;

- Coolant noticeably leaves the expansion tank and needs to be topped up regularly.

Also, the driver will be able to verify that the cylinder head gasket has broken if the consequences of measuring compression demonstrate its drop in the cylinders. The most common reasons why a sealing element loses its performance parameters include:

- incorrect initial installation after replacement;

- significant heating of the motor, leading to thermal deformation;

- carrying out incorrect tuning to increase the power parameters of the power unit;

- the occurrence of detonation when driving on low-quality fuel;

- The lag nuts or bolts were not tightened with proper torque or without the use of a torque wrench.

Causes of damage

Why does the head gasket burn out? For this, a small malfunction in the cooling system is enough. For example, malfunctions of the thermostat, antifreeze leaks, air entering the system, a radiator clogged with fluff, or a failed fan. This can contribute to local overheating, which can cause the gasket or the head itself to fail.

In diesel engines, the gasket can become leaky due to an increase in the combustion temperature of the air-fuel mixture, which is usually caused by a malfunction of the injectors. The same thing happens with engines running on liquefied gas. In addition, the gasket can wear out as a result of a design miscalculation, as in the Subaru 2.5 T B4.

Mechanics believe that the gasket may also be damaged due to prolonged inactivity of the car. A breakdown that occurs after repair may be caused by a violation of the technology - the order and tightening torque of the head bolts.

Irresponsible operation, leading to engine overheating, also leads to malfunction. For example, dynamic driving “in the cold” or inappropriate chip tuning.

Severe cylinder head gasket operating conditions

Of all the seals in your car's engine, the head gasket has one of the toughest jobs.

To begin with, the gasket must seal the oil and coolant ports and combustion chambers to prevent internal and external leaks. It must also withstand extreme temperatures and pressures that are constantly changing. The cylinder head must withstand temperatures that can reach 400 °F (204 °C) between the cylinder and block, and 2,000 to 4,000 °F (1,093 to 2,204 °C) in the combustion chamber.

Then, in addition to extreme temperature changes, it must withstand extreme pressures that go from negative (vacuum) to positive (typically 1,000 psi (6,895 kPa) or more) as each piston goes through its four-stroke cycle.

In addition, the head gasket must resist corrosion and chemicals and withstand the frictional force from the cylinder head (especially aluminum cylinders) that increases from cold to operating temperature. It withstands all this, eliminating minor distortions between the surface of the head and the block and vibration during engine operation.

Due to the harsh conditions in which it must operate, head gasket design has improved significantly in recent years, increasing pressure withstanding and physical resistance in variable temperature environments.

Despite this, a bad gasket can lead to extreme increases in temperature or pressure caused by engine performance problems.

This guide discusses the main reasons that can lead to its failure. Knowing the different sources of potential problems can help you diagnose the problem early and understand why it's happening.

Common faults that can lead to gasket damage

When a head gasket blows, it is important to determine the root cause of the failure before installing a new one, otherwise you risk immediately getting a blown on the new one.

One or more engine malfunctions can ruin a perfectly installed, high-quality cylinder head. Thus, knowing the operating conditions before a quality seal fails helps determine the cause of the problem and eliminate it.

The following sections discuss various engine operating conditions and the sources that can lead to these conditions. It is known that these conditions can cause breakdown if not corrected in time. If one or more of these special conditions were present before it failed, then the resources described in this section can help you diagnose the source of the problem in your vehicle and fix it before installing a new gasket.

- Engine overheating

This is interesting: Cleaning the throttle valve - detailed instructions on how to clean it yourself

Overheating is perhaps one of the most common causes of cylinder head failures. Not only can an overheated engine expose the gasket to temperatures it has not previously been exposed to, it can also cause the aluminum head to expand at a rate greater than its normal warm-up expansion, causing it to fail.

Even if this does not lead to immediate destruction, overheating can significantly weaken it and soon lead to failure.

Some reasons for engine overheating:

- Leaking cooling system

- Radiator fan failure

- Poor EGR system

- Radiator clogged

- Thermostat stuck

- Faulty water pump

- Loose timing belt

- No cooling system maintenance

- Using the wrong type of coolant

- Radiator cap leaking

- Faulty radiator hose

- Incorrect fuel combustion

Early fuel detonation in the chamber is about as common as overheating as a source of cylinder head gasket failure.

During normal combustion, the flame burning the air-fuel mixture in the combustion chamber spreads evenly. However, this process can be disrupted by a lean mixture, overheating or low octane fuel.

Abnormal combustion may manifest as detonation or pre-ignition:

- Detonation occurs when the ignition process in the cylinder develops too slowly, allowing the build-up of pressure to trigger a second ignition front at the edge of the mixture that encounters the first combustion process. Engine knocking causes internal vibration due to the shock wave generated by the explosion, which can cause physical damage to the engine, including head gasket damage.

Causes:

- Excessively lean air-fuel mixture

- Poor fuel distribution inside the cylinder

- Ignition time too long or too fast

- Faulty EGR valve

- Low octane fuel

- Pre-ignition, on the other hand, is a process that begins before the spark plug fires. This condition also results in two combustion fronts colliding, producing a ringing explosive sound. Engine knocking is considered a mild form of knocking and is heard as a light tapping noise coming from the engine.

What else causes this problem:

- Carbon deposits in the combustion chamber

- Overheated exhaust valve

- Spark plug

- Problems with the cooling system

- Poor engine lubrication

- Hot Spots

A faulty cylinder head gasket can also be caused by poor manufacturing quality from the manufacturer.

Some engine designs can cause hot spots. For example, engines with exhaust ports that are too close together can cause hot spots to develop in those areas.

This can lead to its failure if it is not reinforced in these areas.

Some gaskets are designed to properly fill minor imperfections in the surface they are protecting and can even fill minor imperfections caused by the block being manufactured at the factory.

- Installing a gasket on an uneven head

During the installation process, things can go wrong, for example:

- Reusing old bolts.

- Use of one or more bolts with damaged threads or undertightening or overtightening

- The surface of the block was not cleaned before installing a new gasket

- Using the wrong torque sequence or procedure when installing the head bolts.

- Improper use of sealant.

- Using abrasive materials to clean and polish the block surface