How to tighten the handbrake of a VAZ 2107. Adjusting the handbrake

Locking the wheels when parking a car is the task of the parking or hand brake. It is more often used on bumpy road sections.

A well-adjusted handbrake should lock the car in one place when tightened by 4-6 teeth with a surface slope of 25%. If this does not happen, the parking brake needs to be adjusted or repaired.

The breakdown of the handbrake is a common occurrence, since it is enough to just start the car without removing it from the handbrake. In this case, the pads will wear off and will no longer reach the brake drum.

Reasons for failure of the VAZ 2107 handbrake

Most likely, the cause of the breakdown lies in a stretched or unadjusted handbrake cable. A tightening should be performed if the car does not lock even after 5-7 clicks. This procedure on a VAZ 2107 can be done no more than 4 times, after which the brake pads will need to be replaced.

Another source of handbrake malfunction may be cable looping due to moisture, rust, or dirt that gets on the cable while moving. This can be eliminated by cleaning the cable and lubricating it. If after some time the breakdown occurs again, the handbrake cable 2107 needs to be replaced .

How to change a torn or stretched parking brake cable on a VAZ classic

All work must be done in the same way as during adjustment, placing the car above the inspection ditch, or lifting it using a lift. There are also some pitfalls. The brake drums, which will have to be removed, are tightly “stuck” to the axle shaft flanges. Beating the drums themselves is more expensive, they are fragile and break easily. Therefore, we will do this: – by hanging the wheels, we will reliably strengthen the car from rolling in a way suitable for your conditions; – fourth gear, release the clutch, “accelerate” and sharply “hit” the brakes; – we repeat this “procedure” until the inertia tears the drums away from the flange; – we clean off the rust from the hub flange with a file - it interferes with pulling out the drum; – rocking from side to side, using wooden drifts, remove the drum. A protrusion on its inner side, formed over years of wear, can also prevent successful removal of the drum. Now, inspect what is inside - the pads and cylinders. Severe wear on the linings is a reason to replace the pads. The cylinders should not leak brake fluid, the boots should be intact without breaks. The cable sheath is bolted to the brake shield. You need to unscrew them very carefully, generously watering them with “Vedashka”, otherwise you will twist the “head” and will have to drill it out. Have you turned away? Wonderful! All that remains is to pull out the old cable and lay a new one in its place. We put everything else back together, and then, having installed the drums and wheels in place, we adjust the parking brake, as described above. Everything is ready, we have successfully replaced the parking brake cable of a VAZ classic. Video on this topic

Read, it may come in handy: How to raise or lower the suspension.

Tuning and modification of the chassis And one more thing

Also check out

- Self-replacement of the VAZ 2110 CV joint

- Instructions for replacing the VAZ 2115 wheel bearing at home

- How to replace the rear wheel bearing and brake drum of a VAZ 2114

In addition, to correct the breakdown, it is necessary to remove the jamming defect of the handbrake lever, and perhaps also the ratchet mechanism of the ratchet.

Therefore, before repairing the handbrake, you should make sure that it is adjusted correctly and that the cause of the problem is not in the cable. At the same time, the technical condition of the rear brakes, cable, and handbrake drive must be good.

Required tools:

- 2 keys for “13”;

- pliers;

- jack.

Repair of hand brake VAZ 2107

Operating a vehicle with a faulty brake system is prohibited. This also includes cases when the handbrake does not hold the car well or does not work at all. Therefore, repairing the VAZ 2107 handbrake is a job that should be performed immediately. If lifting the lever 5-6 clicks is not enough to lock the car in place, the handbrake requires attention.

How to tighten the handbrake of a VAZ 2107 yourself

- Place the car on a viewing hole or lift.

- Jack up the rear of the car, hang the rear wheels (they should rotate freely).

- Tighten the handbrake to the locking position (5-7 clicks).

- Remove dirt from the adjusting bolt and handbrake nuts.

- Using keys “13”, tighten (or loosen) the nut that adjusts the tension of the handbrake. It is worth pulling until the free rotation of the wheels stops (at this time you can make sure that there is no play or friction).

How to tighten the handbrake of a VAZ 2107. Adjusting the handbrake

- After tightening the adjusting nut and locking the wheels, you need to tighten the adjusting nut completely. This will reduce the free play of the handbrake.

- Make sure the wheels brake, then tighten the locknut.

How to tighten the handbrake of a VAZ 2107. Adjusting the handbrake

- Lubricate the threaded holes (optionally, “Litolom” lubricant).

- Make sure that the protective sheath of the hand rope is not damaged.

This the tightening of the VAZ 2107 handbrake . All that remains is to lower the car from the jack and check the handbrake in action.

Replacing the handbrake and front cable on a VAZ 2101-VAZ 2107

Removal

Remove the guide from the tip of our cable, for more details see the article: “Replacing the rear cable”, points 3-4.

Take a wrench and remove the bolt securing the roller to the bracket (the bracket is indicated by the blue arrow). Carefully remove the roller by rolling the roller towards the tip of the front cable, as shown in the figure, and remove it from the car.

Note! Be careful: inside the roller there is a bushing (number 3 in the photo below) and a fastening bolt (number 1). Don't let the parts fall and get lost.

We recommend using Litol-24 or LSC-15 lubricant, lubricating the contacting surfaces of the bushing itself (the surface is indicated by the letter B) and the surface of the roller (the letter A). To do this, remove the bushing from the socket.

Now pull the cable to the bottom and remove the cable from the bracket and the intermediate support of the cardan drive (indicated by the blue arrow).

Get out from under the bottom of the car and move into the interior. While inside the car, remove the two screws securing the handbrake trim, remove it and set it aside.

You will see four handbrake mounting bolts. By unscrewing them, you will remove the handbrake from the car along with the attached cable (front).

Note! If necessary, disconnect the cable from the handbrake: using pliers, remove the small cotter pin (looks like a small twisted wire inserted into the hole; a washer is placed under it, holding the parts in place) that goes into the hole indicated by the red arrow. Unfortunately, the hole is hard to see in the photo, but it is present in the so-called finger, where the cable tip is installed. Remove the cotter pin securing the end of the cable and remove the washer with the cable as shown in the figure below.

Installation

New parts are installed in the reverse order of removal. ,After installation, adjust the cable; the process is described in detail in the article: “Adjusting the cable.”

Note! Is the handbrake button stuck? Most likely the spring is to blame. It can be easily removed and replaced with a new one:

- Unscrew the handbrake button completely;

- pull out the hole button together with the spring;

- replace the spring with a new one;

- Reinstall the parts in reverse order.

↑ Inspection and repair

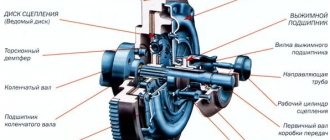

- After loosening the locknut 26 and the adjusting nut 27, remove the tension spring 11, then completely unscrew the locknut and nut.

- Disconnect the cable brackets 15 from the body floor and the rear cable end from the brake shield; remove the brackets and rear cable.

- Remove roller 8 with sleeve 7.

- Remove the lever protective cover, and then the lever assembly and front cable.

- After removing the cotter pin and thrust washer, disconnect the front cable from the handbrake lever.

- Install the parking brake in the reverse order of removal, followed by its adjustment.

Tension

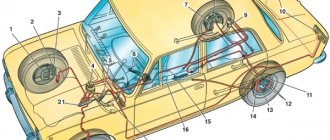

So, having understood the diagram, you can begin the procedure of tightening the handbrake cables.

The tensioning procedure is as follows.

- Place the car on an overpass or pit. If you don’t have a garage and you have the opportunity or desire to carry out the procedure at a service station, use a jack. The rear of the car is raised on a jack. The most extreme option is a curb onto which the car is driven and all you have to do is crawl under it.

- Engage the gearbox in first gear and put the car on the handbrake by pulling the lever up.

- The ideal number of handbrake clicks is from 2 to 5. If there are fewer or more clicks, it is easier to take appropriate measures to tension the cable.

- If there are less than 2 clicks, then the cable will need to be lengthened. If there are more than five clicks, then the cables are shortened.

- Lengthening the cable means relaxing it. To do this, unscrew the locknut. When tightening the cable, the locknut must be tightened in reverse.

- Before you start looking for the required nut on the bottom of the car, release the handbrake lever all the way.

- Take a 13mm wrench under the car and head down.

- Find the handbrake cable equalizer. This is the same element from which the main handbrake cable is divided into two cables.

- In some cases, it is simply not possible to gain access to the equalizer, since the muffler holders made of rubber are in the way. In such a situation, it is better to remove them. This is not difficult to do, but working with the handbrake will be much easier.

- Now there are two nuts in front of you. One is a simple nut and the other is a lock nut. Having two keys in your hands, fix the nut with the first one, and with the second one begin to unscrew or tighten the locking nut. Be careful that the nut does not start to turn.

- Taking into account the condition of the handbrake and the need to loosen or tighten the lever, turn the locknut in the appropriate direction. Remember what is the optimal number of clicks.

- Tighten or unscrew the locknut to obtain the required degree of tension.

Examination

But if you twisted the nuts there, this is not a guarantee that the handbrake now works perfectly. This needs to be clearly verified.

To do this, it is enough to go through a successive stage of verification activities.

Stage

Explanation

Spin the wheels after tensioning is completed

The wheels are lifted one by one on a jack. When the handbrake lever is turned off, they should rotate freely without obstacles. By squeezing the brake, the wheels should lock.

Drive up a slight slope, stop and engage the handbrake

The fact that the wheels do not spin when suspended is good. But you need to make sure that the handbrake holds the car even when exposed to gravity.

If the check shows that the handbrake still does not hold, even if the cable was tensioned exactly according to the instructions, the handbrake is probably simply worn out and the cable needs to be replaced.

Signs that replacement is needed

It is not uncommon for the VAZ 2114 handbrake cable to rust, as a result of which it breaks or weakens so much that no tightening can restore its previous functionality.

At the first sign of cable wear, you should consider replacing it. This problem may manifest itself as follows:

- The handbrake is not able to withstand the required traction;

- Drum brakes overheat;

- When you pull the parking brake lever, the cable does not respond to your actions;

- The cable sheath is seriously worn.