Cleaning injectors is one of those types of work that needs to be done only in case of emergency, that is, according to the principle “don’t touch it while it’s quiet.” This is not surprising, given the fact that the ramp in which the injectors are located and, in principle, the injectors themselves can be called the heart of a car engine. Therefore, it is recommended to clean injectors only as a last resort, for example, when problems occur with starting the engine, increased fuel consumption, tripping or a sharp drop in power.

There are plenty of various additives on the automotive chemicals market that are added to fuel to clean the injector, but they are not always able to cope with the task assigned to them or do not perform it very well. Often, cleaning additives in fuel can cause irreparable harm to the engine, due to the fact that acidified dirt and other deposits can create a blockage that prevents the normal passage of the fuel-air mixture or completely block the access of fuel. In this article I will talk about how to wash injectors with your own hands using the example of a VAZ 2110.

Relevant: Do-it-yourself adjustment of VAZ 2101 valves

When is injector cleaning necessary?

In order to understand the condition of the injectors, you need to clearly listen to the “whispering” of your engine:

- increased fuel consumption (consumption rates),

- "triple" of the engine,

- unstable operation at idle,

- breakdowns during engine operation.

These symptoms should alert you and make you think about the stable operation of the system as a whole.

Frequency of cleaning injectors

There is no specific point in time that would indicate the frequency of their cleaning. Remember that if nothing bothers you about the operation of the engine, then there is definitely nothing that needs to be repaired. However, if symptoms appear, it is best to first carry out an analysis and determine the exact cause of the problem.

What will cleaning do?

When the injectors are cleaned, you will immediately feel changes in the operation of the engine. However, note that this depends on the amount of carbon deposits and instability before the cleaning process. Therefore, the more contaminants there are, the better the cleaning is done, the greater the chance of getting serviceable injectors.

Repair

Before removing the injectors from the dismantled rack, it is advisable to check their functionality. To check you will need:

- four identical containers,

- tester,

- wires.

Functionality check

- Connect the gasoline supply and drain hoses and the power connector to the rail with injectors.

- Place the rack over the measuring cups.

- Crank the engine with the starter.

- Evaluate the performance of the sprayers. The shape of the cloud should be approximately the same for all nozzles. The amount of fuel in the measuring containers should not differ much. Significant differences indicate contamination and changes in performance. Coked with resinous deposits and clogged, they require cleaning. A complete lack of fuel at the nozzle outlet indicates a valve malfunction and the need for replacement.

- Turn off the ignition. Disconnect the power connectors from the injectors.

- Measure the electrical resistance of the winding of each part. Its nominal value is 11–15 ohms. Deviations from the norm indicate the presence of hidden problems in the solenoid valve, which indirectly affect the shape of the torch and performance. It is advisable to replace such an injector.

- Turn on the ignition. Make sure the injector valves are tight. If a part is leaking, it should be replaced or at least try to wash it and check its functionality again.

- It is difficult to check the injector for unstable valve hanging, since this malfunction can occur quite rarely. To identify, connect the electrical connector of the injector with separate wires to the battery. Periodically turning the voltage on and off, watch the spray pattern. The shape and intensity of the torch of a working injector is the same every time; periodic changes occur when the valve does not open completely. If the background sometimes “accidentally” does not work, it must be replaced.

After the war, Germany received a ban on the development of injectors for aircraft engines

And engineers began adapting direct injection systems for passenger cars, discovering another important advantage compared to carburetors - efficiency

Cleaning engine injectors

This method is not the actual cleaning of the injectors, but it fully allows you to get rid of deposits on them without resorting to dismantling them.

First of all, this is much faster, but on the other hand, the result is not always effective. However, as VAZ-2112 car owners say, in some cases, this really helps.

Work process

- A compressor is connected to the system, similar to that described earlier, which is capable of increasing the pressure in the ramp to 3.2 atmospheres. In parallel, we connect a purifier in a container of at least 1 liter. (Most often, special injector cleaners are used in metal containers - approx.).

- Next, we start the engine and let it run for 10 minutes, after which we stop and let it rest for the same amount of time.

- Then we start it again and, by re-gassing, pass the entire liter of liquid through the injectors.

- When the engine stalls, change the spark plugs, which will become covered with soot.

The entire process of work in this way should not exceed one hour.

By the way, such work can render spark plugs unusable, so clean the injectors on the engine using old or spare spark plugs. Or guess the moment when you will change the spark plugs. We have already talked about the choice of spark plugs for 16-valve engines.

Troubleshooting

Diagnostics of injectors using a stand

After you remove the injectors, proceed to carefully inspect them. When the removal of the VAZ 2110 injectors is completed, you can see that one of them remains in the inner pipe of the engine. It will be necessary to replace its retainer and the rings responsible for the seal. In addition, injectors are also replaced when the rings lose the elasticity of their coating or when there are cracks.

Check how the injectors spray. Connect the harnesses and attach everything to the battery. Then place the nozzle in a glass container and turn on the starter to see if the gasoline is spraying correctly. Each nozzle must have at least 4 jets, in addition, the gasoline that is carried through them in containers must be at the same level. If the sprayer begins to leak, the nozzle needs to be replaced.

If it does not spray at all, you need to check whether the nozzle is receiving power. If it does not pass gasoline, disconnect the wires leading from the block and connect the battery directly with the ignition on. If it starts spraying gasoline, it means there is a problem in the electrical circuit. After the injectors have been replaced or cleaned, they will need to be reassembled, but before that, lubricate each ring with gasoline.

Cleaning injectors with ultrasound

And another method that can be easily used to clean them is ultrasound.

Pros and cons of using ultrasound

There is still debate about how useful this method is, and there is no consensus on this. Some say that this method harms the injectors due to the destruction of the mesh, and that such work should only be combined with washing and dismantling. Others say that such work has a very good effect on the condition of the injectors and does not harm them in any way; moreover, the condition of ultrasonic cleaned injectors is comparable to new parts.

In any case, it is up to you to decide whether to use this method. The cost of such work at a car service is 2,000 rubles and takes about 4 hours.

Dismantling

Before replacing or cleaning the injectors, they will need to be removed from the fuel rail. To achieve this, the following activities are carried out:

- Make sure the engine has cooled down properly. It is not safe to work on a hot engine;

- Disconnect the power wires from the fuel pump to de-energize the device;

- Try to reduce the pressure in the engine power system as much as possible. To do this, the engine starts, and then you need to wait until it stalls at idle speed;

- Repeat this procedure several times until the car simply stops responding to turns of the ignition key;

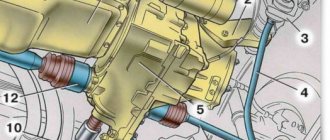

- That's it, now our goal is the fuel rail. To remove it, you must first remove the terminals from the battery, turn off the power to the ramp itself, disconnect the fuel supply hoses, and also disconnect all electrical appliances going to it. These are pressure, idle, throttle position sensors;

- If you have an 8-valve engine, then you do not need to remove the receiver. This step is relevant for engines with 16 valves;

- Experts do not recommend removing the intake manifold without dismantling the throttle valve and the hose going to it. It is better to unscrew and disconnect everything at once, which will allow you to continue working more conveniently;

- Cover the exhaust manifold openings with something to protect them from foreign objects;

- Using a hex wrench, you can unscrew a couple of bolts and remove the fuel rail along with the injectors;

- Make sure that there are no distortions when removing the ramp, otherwise problems may arise with the dismantling processes;

- We remove the injectors. To do this, remove the mounting brackets that hold the electrical connector. You also need to remove the bracket that holds the injector in its seat.

After dismantling the elements, be sure to close the seats to prevent debris and other objects from getting in, and place the nozzles themselves on a table or floor, after laying down a dry rag.

Here you can decide whether to change or clean the elements of the fuel system. If replacement is required, install new injectors in place of the old ones and follow the assembly procedure.

Cleaning

Here proceed as follows.

- Remove the rubber rings from the injectors, and when cleaning is finished, replace them with new seals.

- The cleaning process should begin with the nozzles, on which various deposits form as the car is used.

- Be sure to thoroughly clean the funnel-shaped surfaces where tar deposits accumulate.

- The next step is the fuel mixture supply channels.

- To open the solenoid valve to supply fuel, you will have to trick the device with a 5-7 V power supply.

- Some use stabilized voltage sources, phone chargers, or even a car battery. If using a battery, the voltage should be supplied through the light bulb. It will play the role of a current damper. Otherwise you risk burning the winding.

- Electricity is supplied through two wires, in the gap of one of which a button is installed. It will close and open the network. This creates an imitation of the operation of an injector in an engine due to the influence of a pulsed electric charge.

- You can supply the cleaning liquid to clean the injectors through a can of carburetor cleaner. Inexpensive and effective, even better than specialized chemicals.

- Be sure to tightly connect the cylinder and nozzle with a rubber tube, clamps and any other means.

- All is ready? You can then apply electricity to open the injector. At the same time, press the button on the cleaning agent canister.

- Soon the torch of the liquid jet, which will exit through the fuel atomizer of the injector, will change its “clumsy” direction and will begin to uniformly exit the nozzle. This indicates that you have removed all carbon deposits.

Homemade cleaning device

Before putting the cleaned nozzle back in place, check its actual condition.

Examination

To check you need:

- Measure the injector resistance using a multimeter. If the readings are within 10-15 ohms, the injector is working;

- If you deviate from these limits, cleaning is pointless. You only need to change the injectors;

- Check devices for leaks;

- To do this, when cleaning, do not turn on the electrical pulse so that the nozzle does not open;

- Under pressure, a device with a broken seal will begin to show signs of leakage. Therefore, the element must be replaced.

Injectors cannot be repaired or disassembled into parts to restore functionality. If the resistance and tightness are broken, the devices must be replaced with new ones.

Cleaning the injectors is quite easy if you properly construct the device for this procedure. If you don’t have such skills, contact a good car service center.

Prices for cleaning injectors

- In order to clean the injectors that have been removed and fixed on the ramp, you will need a total cost of about 500 rubles .

- And to clean them in the service, you will pay about 2000 rubles , and this is the same as when cleaning with ultrasound.

Since such work does not pose any difficulty, it is much easier to do everything yourself.

Injector prices

If, after the cleaning and diagnostic procedure, you come to the conclusion that it is completely faulty and needs to be replaced, then it is worth noting that you should buy a strictly analog nozzle, with the part number indicated on its body. The average price for them is in the range of 1000-1500 rubles.

Dismantling

Before replacing or cleaning the injectors, they will need to be removed from the fuel rail. To achieve this, the following activities are carried out:

- Make sure the engine has cooled down properly. It is not safe to work on a hot engine;

- Disconnect the power wires from the fuel pump to de-energize the device;

- Try to reduce the pressure in the engine power system as much as possible. To do this, the engine starts, and then you need to wait until it stalls at idle speed;

- Repeat this procedure several times until the car simply stops responding to turns of the ignition key;

- That's it, now our goal is the fuel rail. To remove it, you must first remove the terminals from the battery, turn off the power to the ramp itself, disconnect the fuel supply hoses, and also disconnect all electrical appliances going to it. These are pressure, idle, throttle position sensors;

- If you have an 8-valve engine, then you do not need to remove the receiver. This step is relevant for engines with 16 valves;

- Experts do not recommend removing the intake manifold without dismantling the throttle valve and the hose going to it. It is better to unscrew and disconnect everything at once, which will allow you to continue working more conveniently;

- Cover the exhaust manifold openings with something to protect them from foreign objects;

- Using a hex wrench, you can unscrew a couple of bolts and remove the fuel rail along with the injectors;

- Make sure that there are no distortions when removing the ramp, otherwise problems may arise with the dismantling processes;

- We remove the injectors. To do this, remove the mounting brackets that hold the electrical connector. You also need to remove the bracket that holds the injector in its seat.

After dismantling the elements, be sure to close the seats to prevent debris and other objects from getting in, and place the nozzles themselves on a table or floor, after laying down a dry rag.

Here you can decide whether to change or clean the elements of the fuel system. If replacement is required, install new injectors in place of the old ones and follow the assembly procedure.

Cleaning

Here proceed as follows.

- Remove the rubber rings from the injectors, and when cleaning is finished, replace them with new seals.

- The cleaning process should begin with the nozzles, on which various deposits form as the car is used.

- Be sure to thoroughly clean the funnel-shaped surfaces where tar deposits accumulate.

- The next step is the fuel mixture supply channels.

- To open the solenoid valve to supply fuel, you will have to trick the device with a 5-7 V power supply.

- Some use stabilized voltage sources, phone chargers, or even a car battery. If using a battery, the voltage should be supplied through the light bulb. It will play the role of a current damper. Otherwise you risk burning the winding.

- Electricity is supplied through two wires, in the gap of one of which a button is installed. It will close and open the network. This creates an imitation of the operation of an injector in an engine due to the influence of a pulsed electric charge.

- You can supply the cleaning liquid to clean the injectors through a can of carburetor cleaner. Inexpensive and effective, even better than specialized chemicals.

- Be sure to tightly connect the cylinder and nozzle with a rubber tube, clamps and any other means.

- All is ready? You can then apply electricity to open the injector. At the same time, press the button on the cleaning agent canister.

- Soon the torch of the liquid jet, which will exit through the fuel atomizer of the injector, will change its “clumsy” direction and will begin to uniformly exit the nozzle. This indicates that you have removed all carbon deposits.

Homemade cleaning device

Before putting the cleaned nozzle back in place, check its actual condition.

Examination

To check you need:

- Measure the injector resistance using a multimeter. If the readings are within 10-15 ohms, the injector is working;

- If you deviate from these limits, cleaning is pointless. You only need to change the injectors;

- Check devices for leaks;

- To do this, when cleaning, do not turn on the electrical pulse so that the nozzle does not open;

- Under pressure, a device with a broken seal will begin to show signs of leakage. Therefore, the element must be replaced.

Injectors cannot be repaired or disassembled into parts to restore functionality. If the resistance and tightness are broken, the devices must be replaced with new ones.

Repair

Before removing the injectors from the dismantled rack, it is advisable to check their functionality. To check you will need:

- four identical containers,

- tester,

- wires.

Functionality check

- Connect the gasoline supply and drain hoses and the power connector to the rail with injectors.

- Place the rack over the measuring cups.

Place the rack over the measuring cups

The shape of the cloud should be approximately the same for all nozzles

Vladimir Berestenev

bvy.su

Table: problems with injectors

| Malfunction | Remedy |

| reduced performance | flushing, replacement if flushing fails |

| leakage | flushing, replacement if flushing fails |

| increased productivity | replacement |

| valve sticking | replacement |

| unstable valve sticking | flushing, replacement if flushing fails |

| overestimated or underestimated winding resistance | replacement |

In these cases, flushing is not a panacea. This method should be used taking into account the mileage and quality of service during operation.

During operation, the injector nozzles inevitably become coked and clogged with resinous deposits. The picture is aggravated by low-quality fuel, which can introduce additional pollutants.

For some time, fuel atomizers continue to operate without any visible changes, but sooner or later contaminants accumulate, changing the shape of the spray and reducing performance.

Injector life expectancy is limited even when using the cleanest fuel. Manufacturers recommend changing them every 100–120 thousand kilometers. Due to the fact that motorists use imperfect gasoline, and the one that can be bought at gas stations, the part has to be changed after 80-100 thousand km.

There is an opinion among motorists that “there is no need to interfere if everything works fine.” This opinion is justified, but only if the owner is ready to replace the nozzles with new ones approximately every 50 thousand kilometers.

The fact is that by getting rid of minor deposits as they accumulate, the owner extends the life of the consumable, since pollutants do not have time to cause irreparable damage.

Clogged injectors begin to interfere with normal operation after 30–50 thousand km. Initially, negative processes manifest themselves only in increased fuel consumption. Owners do not always associate the increased “appetite” of the engine with injectors, since there are many reasons for this phenomenon.

In the range of 50–80 thousand km, pollution, having accumulated, can cause interruptions in engine operation, which is no longer undetectable. It becomes clear that “you have to get into the injectors,” but cleaning them at this stage may be useless. When a clogged part is used for a long time, the diameter of the nozzle often increases. Flushing will remove contaminants, but the original parameters will not be restored.

To extend the life of trouble-free operation and delay replacement, you should regularly, after approximately 3-5 thousand kilometers, fill the tank with cleaning fluid for injectors or use it in another way recommended by the manufacturer.

Motorists' opinions about the effectiveness and safety of injection chemicals are contradictory. Many people fear that flushing without removing it from the engine will clog the cylinders.

Indeed, if the car owner has not touched the injectors for a long time, it is impossible to do without removing the rack. The chemicals in the tank can cause harm instead of benefit. If you use cleaners regularly, without waiting for characteristic malfunctions to appear, there will be no harm to the engine from the chemicals.

Although injection chemistry has a beneficial effect on slightly dirty injectors, its use does not guarantee that the atomizers will comfortably “live” the entire period “allotted” to them by the manufacturer. You can unsuccessfully fill the tank with “left” gasoline at almost any gas station.

To minimize the accumulation of deposits, manufacturers recommend additional preventive flushing with special products every 30 thousand kilometers.

Fuel rail can be removed

- Removed the fuel rail:

- This is how it looked:

- I removed the injectors and wiped them of dirt:

- Soaked them in carburetor cleaner:

- While the injectors were soaking, I put together a diagram for cleaning them:

The light bulb in the circuit was 10 W, a simple halogen. I brought the button without locking and the wire from work. I didn’t use anything to supply the cleaner to the nozzle - I just put the nozzle on the can and it fits quite tightly.

ready-made cleaning scheme

- The injector is connected as follows: the left contact is positive, and the right contact is negative.

Then I cleaned each nozzle in two passes of 10-15 sprays. I didn’t take a video or photo of the spray torch - it was inconvenient to take pictures, because... he did everything alone. In principle, the nozzles were not dirty - the spray pattern did not change much, and from the very first presses it sprayed normally. Then I checked the winding resistance of all injectors. Values in the region of 11.9-12.2 Ohms are within the norm.

You can start assembling, but before that you replaced the O-rings on the injectors - replaced 4 out of 8, because half of the rings were in excellent condition (at the injector-ramp transition). I removed the ones to replace:

- Assembling the ramp with injectors:

ready to install

- And put the ramp in place:

At the same time I cleaned the cylinder head cover

- Before installing the receiver with the throttle valve, I also cleaned the valve; since the last cleaning it has become quite dirty:

before cleaning

- Also, when removing the receiver, two pillows to which it is attached fell apart - I had to go get new ones:

- We collect everything, check it and start it.

Started with half a kick. Since in general the injectors were not dirty, I didn’t expect much of an effect, but here I was pleasantly surprised. According to the first sensations, the engine began to run more softly, and responded somehow better to the gas pedal. Let's check whether this procedure helped during a cold start in the cold winter. But the most unexpected effect was a decrease in average consumption by almost a liter.

If before this my average consumption recently was consistently 9.2-9.4 liters per 100 km, then after five days of commuting to work the average consumption is already 8.6 liters per 100 km. And at XX it used to be 0.8-0.9 l/hour, but now it’s 0.7-0.8 l/hour. So it was not in vain that I climbed into the injectors and spent several hours.

Source: https://www.drive2.com/l/4788489/

conclusions

Cleaning VAZ-2110 injectors is quite simple with your own hands. If you have the necessary tools and basic knowledge of car design, any owner can easily troubleshoot problems.

Category

Interruptions in operation (malfunctions)

- Vibration

- Triple

- Extraneous sounds

- Increased consumption of fuel, oil, air

- Power reduction

- Idle faults

- Diagnostics

- Seasonal problems

- Cleaning injectors and fuel rail VAZ 21121121k

- VAZ (Lada) 2110 How many injectors are on the VAZ 2110? 03/12/2014, 00:00 | 4k2

- VAZ (Lada) 2110Injector flushing fluid 01/4/2015, 00:00 | 3k2

- VAZ (Lada) 2110 Is it possible to install a mechanical fuel pump on an injection engine? 01/30/2015, 00:00 | 2k2

- VAZ (Lada) 2110 There is a smell of gasoline in the interior of the VAZ-21102, how to find the reason? 07/18/2015, 00:00 | 1k2

- VAZ (Lada) 2110 How to identify non-working injectors on a VAZ 2110? 03/04/2017, 00:00 | 1k2

- VAZ (Lada) 2110 VAZ 2110 won’t start 12/13/2016, 00:00 | 1k2

- VAZ (Lada) 2110Washing injectors VAZ 211030.06.2016, 00:00 | 9861

- VAZ (Lada) 2110 Fuel is oozing from the fuel hose on 211007/19/2019, 00:00 | 7594

- VAZ (Lada) 2110 How to find out if the injectors are leaking on a VAZ 21124? 03/11/2019, 00:00 | 6062

Sources used:

- https://carnovato.ru/zamena-forsunok-vaz-2110-8-klapanov/

- https://masteravaza.ru/sistema-pitaniya-dvigatelya/inzhektor-sistema-pitaniya-dvigatelya/forsunki-vaz-2110-441

- https://carfrance.ru/zamena-forsunok-na-16-ti-klapannom-dvigatele-vaz-2112-svoimi-rukami/

- https://carfrance.ru/demontaj-forsunki-na-vaz-2110-svoimi-rukami/

- https://m.etlib.ru/auto/vaz-60/211021112112-2009/2110-3286/toplivnaya-sistema-33/toplivnye-forsunki-36